BETE HR-Mini User manual

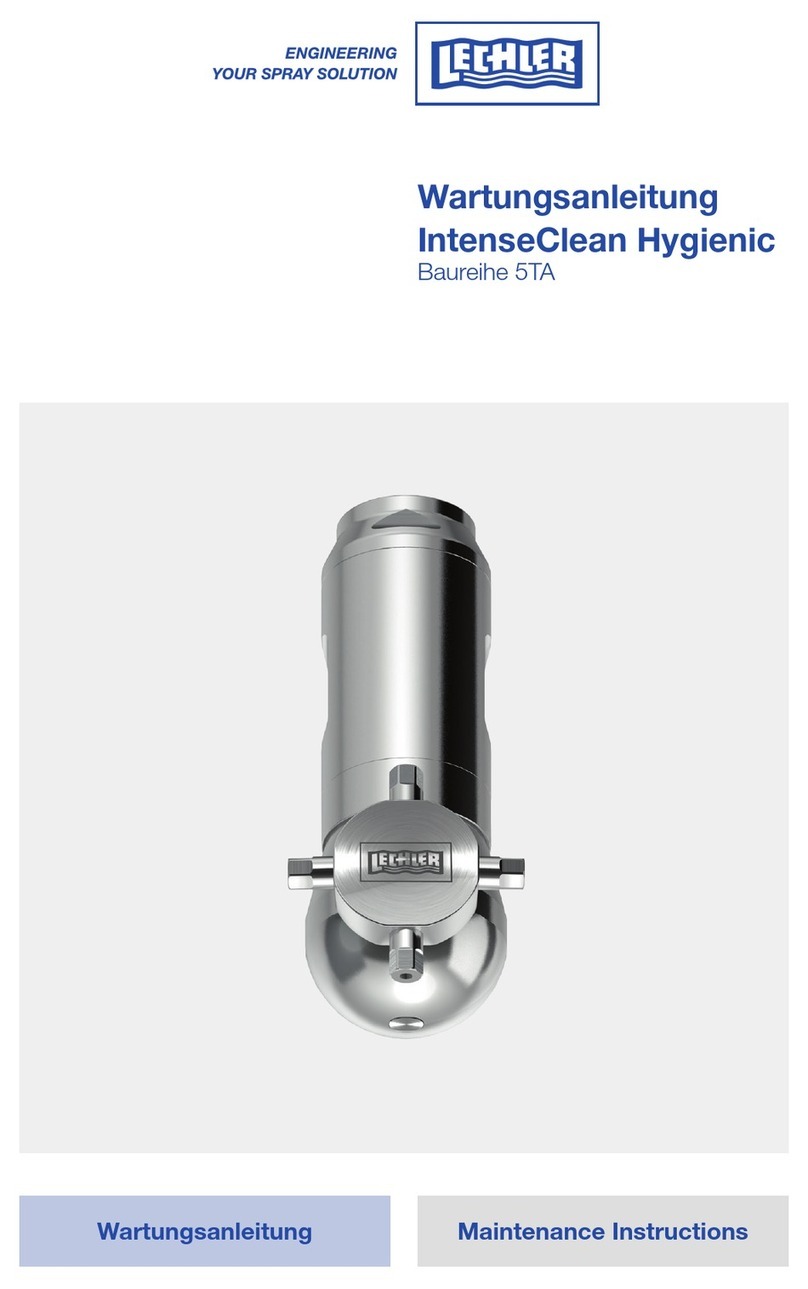

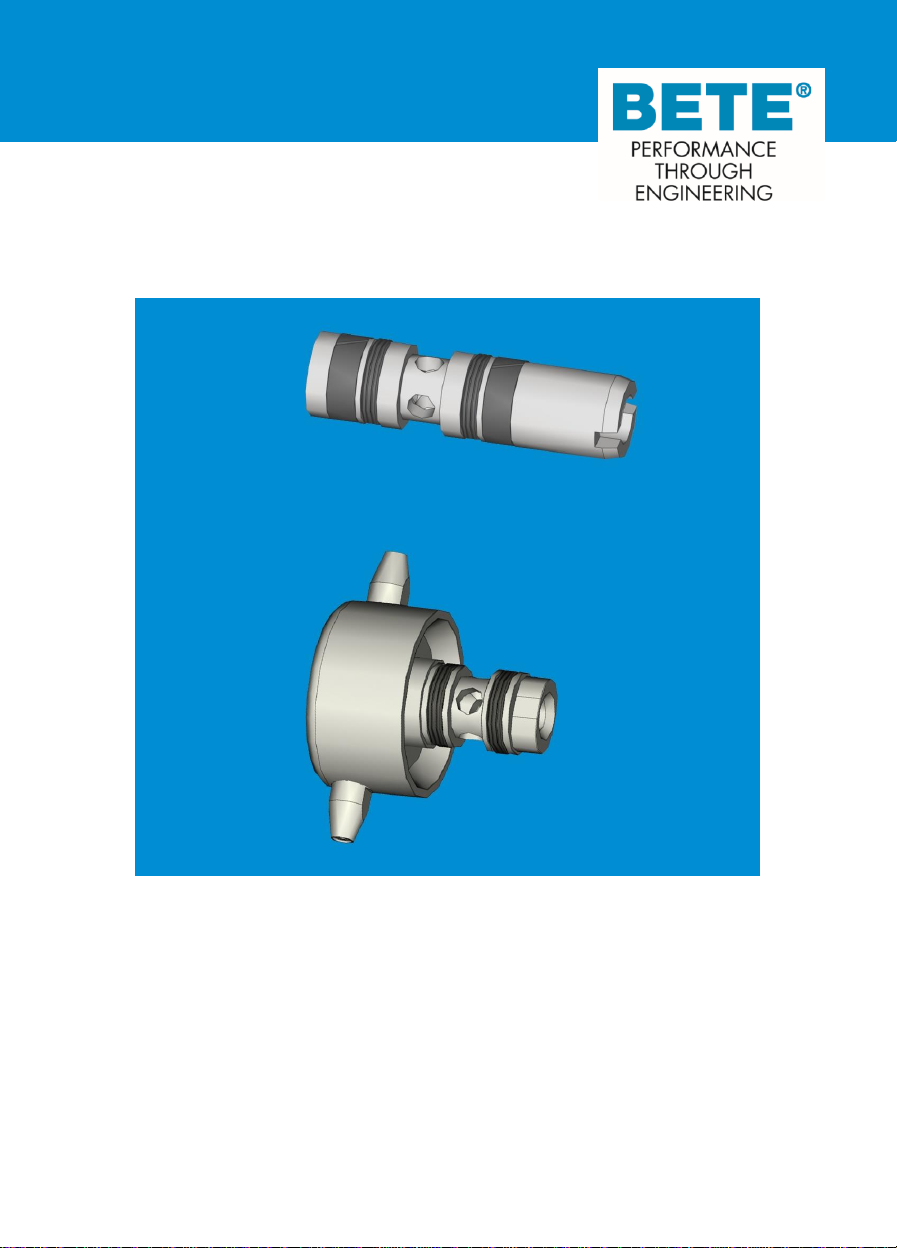

HR-Mini

Tank cleaning machine

INSTALLATION MANUAL

Replacing

Slide Seal Ring Kits and

Guide Rings

Keep for future use!

Legal notice

© BETE Deutschland GmbH

This manual and all images contained herein are copyright protected. Any use outside the

limitations of copyright law without our prior written approval is prohibited and liable to pros-

ecution. This applies especially to reproduction, translation, microfilming, saving, and edit-

ing in electronic systems.

We reserve the right to make technical alterations in the course of further development and

improvement of features.

BETE Deutschland GmbH

Dr.-C.-Otto Strasse 190

D - 44879 Bochum

Germany

+49-(0)234/936107-0

info@bete-deutschland.de

Status: 16.04.2019

HR-Mini Tank cleaning machine I

Contents

1About this installation manual.................................................................... 1

1.1 Notational conventions....................................................................................1

1.1.1 Other notational conventions .....................................................................1

1.2 Symbols used in the manual ...........................................................................2

1.2.1 Personal protective equipment ..................................................................2

2Replacing slide seal ring kits and guide rings ............................................. 3

2.1 Guide rings......................................................................................................4

2.2 Slide seal ring kits and guide rings at the shaft adapter ..................................5

2.2.1 Positions of the slide seal ring kits and guide rings on the shaft

adapter ......................................................................................................5

2.2.2 Installation of the slide seal ring kits (position 1/2) .....................................6

2.2.3 Installation of the guide rings (position 3/4) ...............................................7

2.3 Slide seal ring kits at the nozzle head..............................................................8

2.3.1 Positions of the slide seal ring kits at the nozzle head ...............................8

2.3.2 Installation of the slide seal ring kits (position 1/2) .....................................9

2.4 Service/Customer service..............................................................................10

ABOUT THIS INSTALLATION MANUAL

Notational conventions

HR-Mini Tank cleaning machine 1

1 About this installation manual

This manual (hereinafter referred to as manual) is a supplement to the operating/in-

stallation manual of the HR-Mini tank cleaning machine (hereinafter referred to as

HR-Mini) and provides all the information you require to install the seal rings at the

nozzle head and the shaft adapter of the HR-Mini in line with the safety regulations.

All persons responsible for installing the seal rings at the HR-Mini must read, un-

derstand, and heed the manual. This applies, in particular, to any safety infor-

mation.

In addition to this manual, it is necessary to comply with the general laws and other

regulations concerning accident prevention and environmental protection in the

country of use.

1.1 Notational conventions

Passages of this operating manual that require special attention or are a direct

hazard warning are shown as follows:

WARNING

Hazard which, unless avoided, may involve a moderate risk of death or

(serious) injury.

1.1.1 Other notational conventions

The info symbol provides useful information.

−Text following this mark represents an item in a list.

•Text following this mark represents instructions.

" " Text in double quotation marks refers to other chapters, sections or documents.

ABOUT THIS INSTALLATION MANUAL

Symbols used in the manual

2HR-Mini Tank cleaning machine

1.2 Symbols used in the manual

In this manual, particular hazards are identified by the following symbols:

Burn hazard due to hot surfaces

This symbol warns of a burn hazard resulting from coming into con-

tact with hot surfaces.

1.2.1 Personal protective equipment

When installing the seal rings at the nozzle head and the shaft adapter of the HR-

Mini, wear personal protective equipment according to the respective task to mini-

mise health hazards.

Safety gloves

Wear safety gloves to protect your hands against coming into di-

rect contact with the seal rings heated up in oil.

Face protection

Wear face protection to protect yourself against splashing hot oil.

REPLACING SLIDE SEAL RING KITS AND GUIDE RINGS

Symbols used in the manual

HR-Mini Tank cleaning machine 3

2 Replacing slide seal ring kits and

guide rings

WARNING

Damage, misuse or complete failure of the HR-Mini!

The functional safety of the HR-Mini is jeopardised when using incor-

rect of faulty spare, replacement, and accessory parts.

This may result in death or serious injury.

Component failure or malfunctioning of the HR-Mini may lead to ma-

terial and consequential damage.

•Only use original spare parts provided by the manufacturer.

NOTE

Damage on the HR-Mini

Incorrect replacement of spare or wear parts can cause damage to

components of the HR-Mini.

•In case of doubt, ensure spare or wear parts are only replaced by

BETE Deutschland GmbH or by a service center authorised by

BETE Deutschland GmbH.

REPLACING SLIDE SEAL RING KITS AND GUIDE RINGS

Guide rings

4HR-Mini Tank cleaning machine

2.1 Guide rings

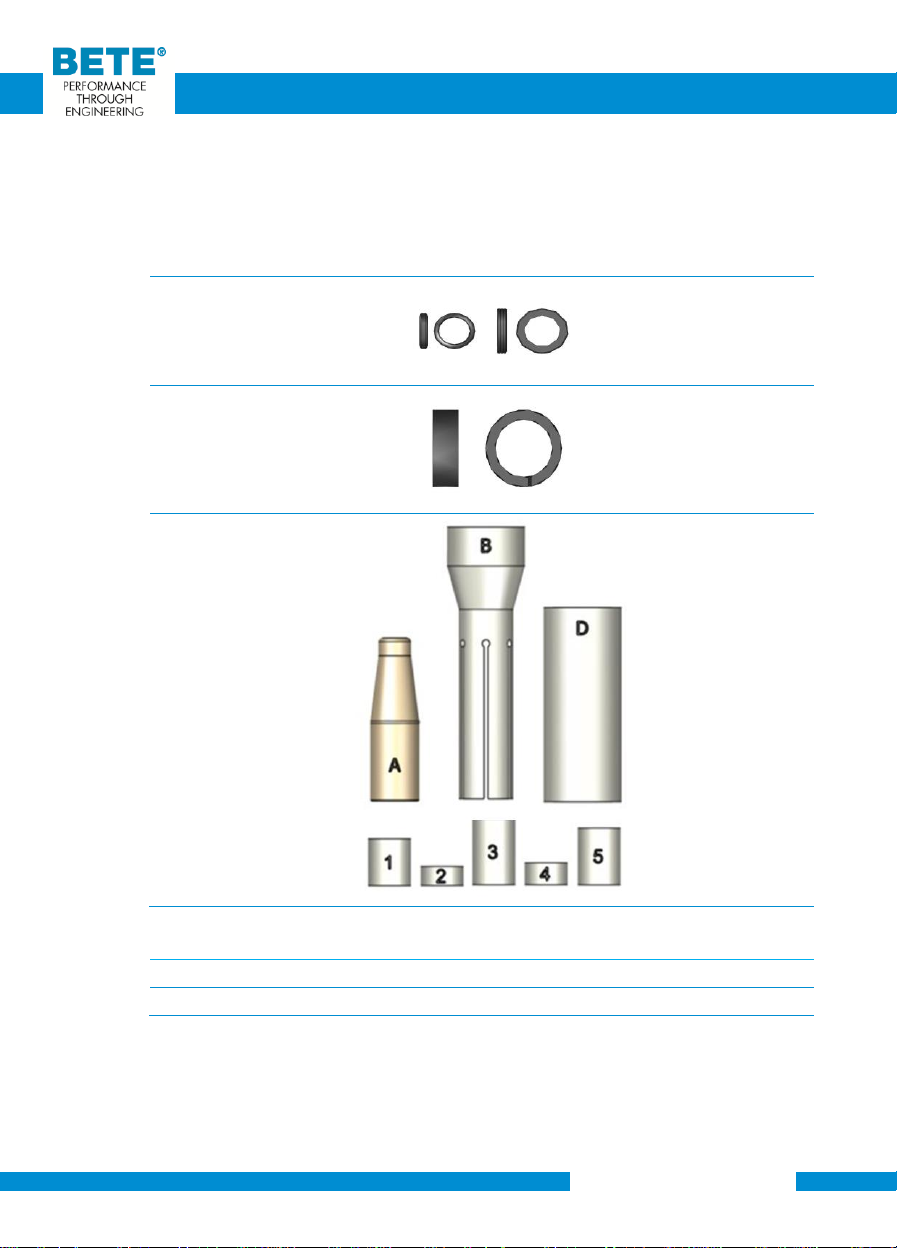

The following spare parts are required for replacing the seal rings at the nozzle

head and shaft adapter of the HR-Mini:

Spare part

Illustration

Article number

Slide seal ring kit

(consisting of O-ring

and slide ring)

HR-M-012

Guide rings

HR-M-011

(only for

the shaft

adapter)

Setup kit seal re-

placement

HR-M-016

You additionally require:

Super Lube long-term lubricant

Mineral oil HLP 46

REPLACING SLIDE SEAL RING KITS AND GUIDE RINGS

Slide seal ring kits and guide rings at the shaft adapter

HR-Mini Tank cleaning machine 5

2.2 Slide seal ring kits and guide rings at the

shaft adapter

Thoroughly clean the shaft adapter before commencing installation of the

rings!

Make sure all the required rings and the setup kit seal replacement are at

hand.

WARNING

Keep hot mineral oil (recommended: hydraulic oil of category HLP 46)

and the respective protective equipment at the ready.

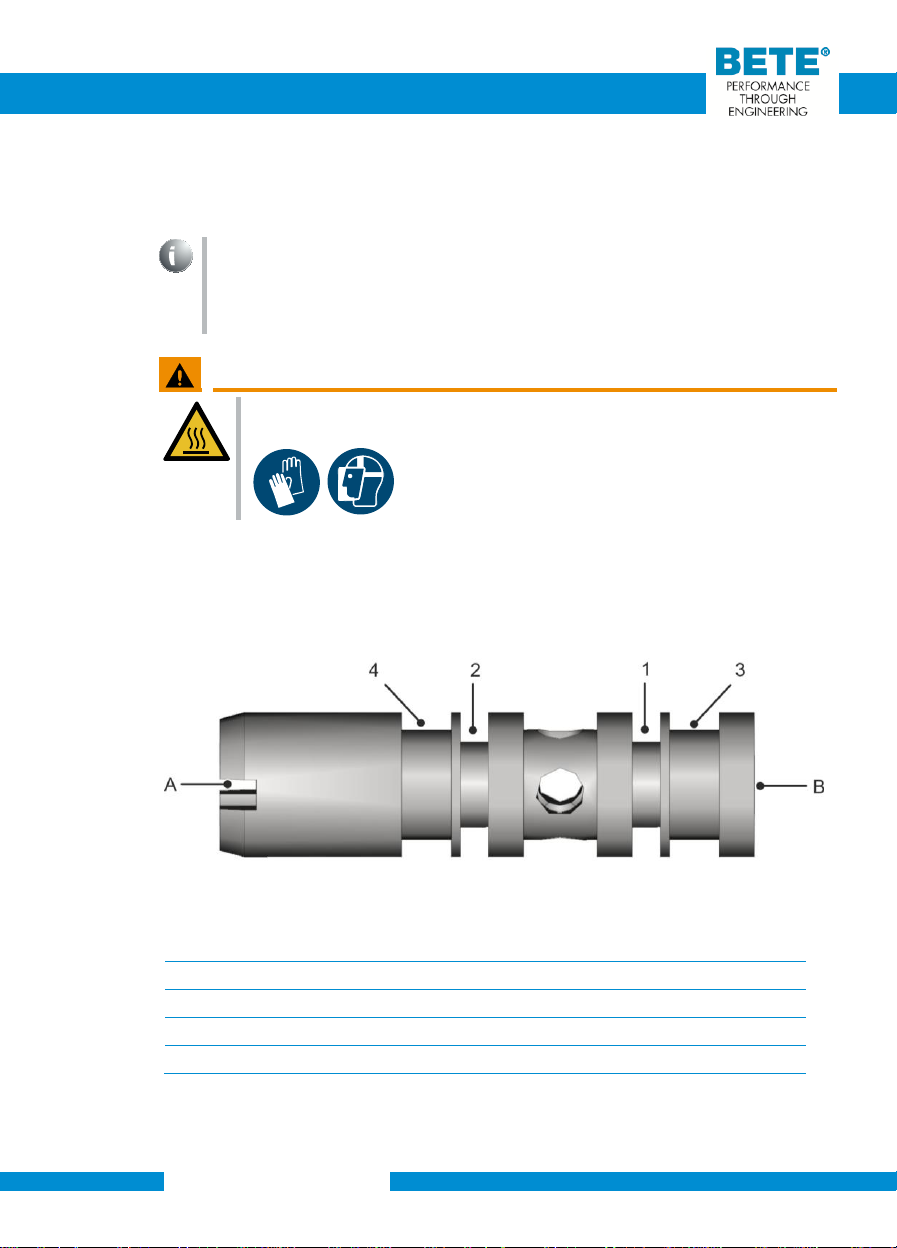

2.2.1 Positions of the slide seal ring kits and guide rings on

the shaft adapter

Pos.

Spacer expand-

ing mandrel

Installation direction

Shaft adapter

To install

1

1

Side A

Slide seal ring kit

2

–

Side B

Slide seal ring kit

3

3

Side B

Guide ring

4

2

Side A

Guide ring

Start with the position 1 and 2 at the shaft adapter (installation of the slide seal

ring kits).

REPLACING SLIDE SEAL RING KITS AND GUIDE RINGS

Slide seal ring kits and guide rings at the shaft adapter

6HR-Mini Tank cleaning machine

2.2.2 Installation of the slide seal ring kits (position 1/2)

•Insert the corresponding spacer (1 –3, see table on page 5) into the expand-

ing mandrel for the respective position at the shaft adapter.

Installing the O-ring

•Slide the expanding mandrel over

the respective end at the shaft

adapter.

•Pull the O-ring over the expanding

mandrel.

•Slide the O-ring over the expanding

mandrel to the respective position at

the shaft adapter using tool B.

•Remove tool B and the expanding

mandrel again.

Installing the slide ring

WARNING

Hot oil and hot surfaces

Risk of scalding due to hot oil and coming into contact with the

seal/guide rings heated up in the oil.

•When heating up or installing the seal/guide rings, wear thermal

gloves of category 2.

•Gently heat up the slide ring in the oil up to max. 100 degrees Celsius.

•Slide the expanding mandrel over the respective end of the shaft adapter.

•Take the slide ring out of the hot oil and pull it over the expanding mandrel.

•Slide the slide ring over the expanding mandrel to the respective position at

the shaft adapter using tool B.

REPLACING SLIDE SEAL RING KITS AND GUIDE RINGS

Slide seal ring kits and guide rings at the shaft adapter

HR-Mini Tank cleaning machine 7

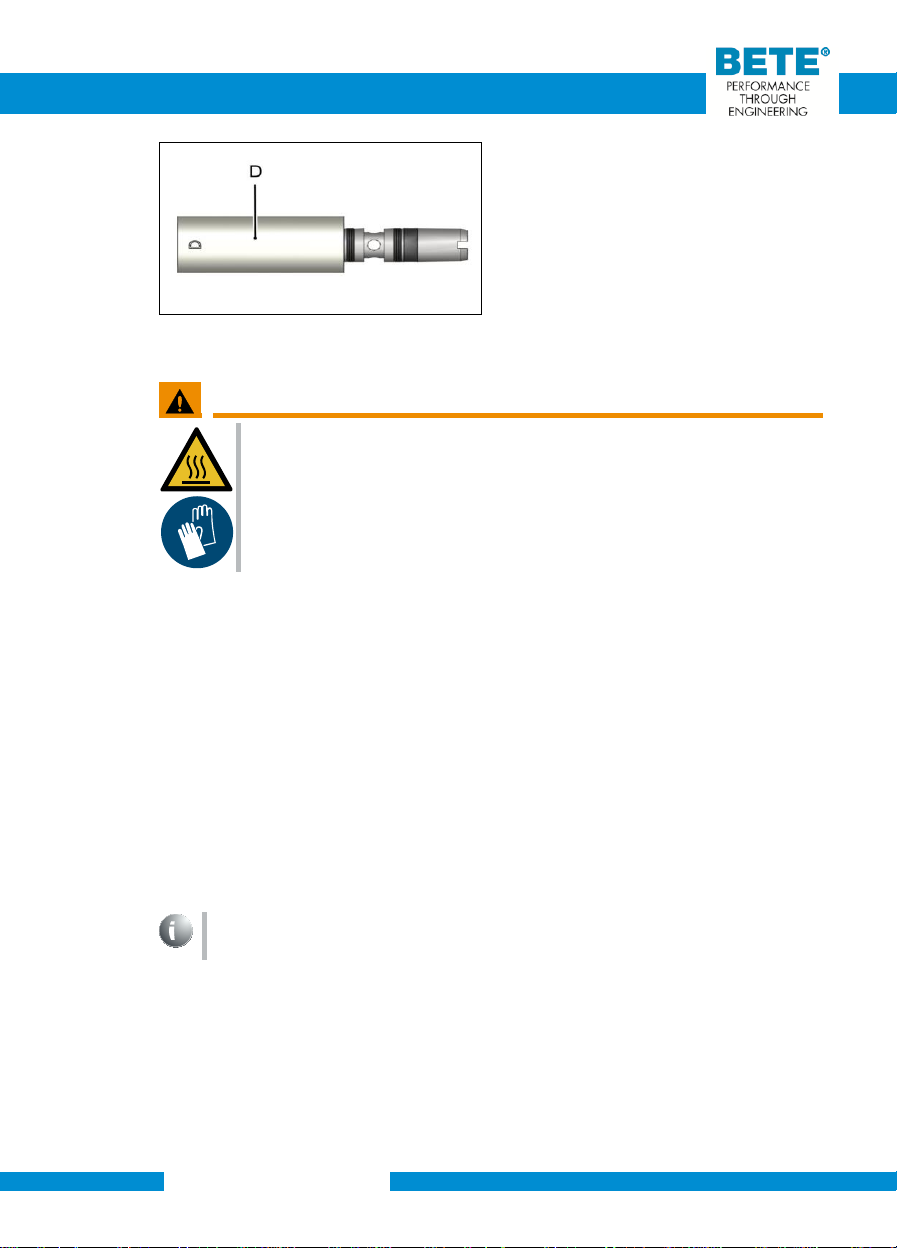

•Slide the calibration sleeve (D) over

the slide or guide ring and wait a

few minutes.

•Remove the calibration sleeve

again.

2.2.3 Installation of the guide rings (position 3/4)

WARNING

Hot oil and hot surfaces

Risk of scalding due to hot oil and coming into contact with the

seal/guide rings heated up in the oil.

•When heating up or installing the guide rings, wear thermal gloves

of category 2.

•Gently heat up the guide rings in the oil up to max. 100 degrees Celsius.

•Insert the corresponding spacer into the expanding mandrel for the respective

position at the shaft adapter.

•Slide the expanding mandrel over the respective end of the shaft adapter.

•Take the guide ring out of the hot oil and pull it over the expanding mandrel.

•Slide the guide ring over the expanding mandrel to the respective position at

the shaft adapter using tool B (also see section 2.2.2).

•Calibrate the slide ring using the calibration sleeve “D” from the respective

end of the shaft adapter (also see section 2.2.2).

Polish or roller-burnish the slide surface of the shaft adapter to ensure

smooth operation of the HR-Mini.

REPLACING SLIDE SEAL RING KITS AND GUIDE RINGS

Slide seal ring kits at the nozzle head

8HR-Mini Tank cleaning machine

2.3 Slide seal ring kits at the nozzle head

Thoroughly clean the nozzle head before commencing installation of the

rings!

Make sure all the required rings and the setup kit seal replacement are at

hand.

WARNING

Keep hot mineral oil (recommended: hydraulic oil of category HLP 46)

and the respective protective equipment at the ready.

2.3.1 Positions of the slide seal ring kits at the nozzle head

Pos.

Spacer ex-

panding

mandrel

To install

1

4

Slide seal ring kit

2

5

Slide seal ring kit

(Ill. without nozzles)

REPLACING SLIDE SEAL RING KITS AND GUIDE RINGS

Slide seal ring kits at the nozzle head

HR-Mini Tank cleaning machine 9

2.3.2 Installation of the slide seal ring kits (position 1/2)

O-ring

•Insert the corresponding spacer into the expanding mandrel for the respective

position at the nozzle head.

•Slide the expanding mandrel over the end of the nozzle head.

•Slide the O-ring over the expanding mandrel to the respective position at the

nozzle head using tool B (analog to section 2.2.2).

Slide ring

WARNING

Hot oil and hot surfaces

Risk of scalding due to hot oil and coming into contact with the

seal/guide rings heated up in the oil.

•When heating up or installing the slide rings,

wear thermal gloves of category 2.

•Gently heat up the slide rings in the oil up to max. 100 degrees Celsius.

•Slide the expanding mandrel over the end of the nozzle head.

•Take the slide ring out of the hot oil and pull it over the expanding mandrel.

•Slide the slide ring over the expanding mandrel to the respective position at

the nozzle head using tool B (analog to section 2.2.2).

•Calibrate the slide ring using the calibration sleeve “D” (analogue to sec-

tion 2.2.2).

Polish or roller-burnish the slide surface of the nozzle head to ensure

smooth operation of the HR-Mini.

REPLACING SLIDE SEAL RING KITS AND GUIDE RINGS

Service/Customer service

10 HR-Mini Tank cleaning machine

2.4 Service/Customer service

Our service hotline is at your disposal for any technical queries you

may have.

Phone: +49 (0) 234 93 61 07 0

E-Mail: info@bete-deutschland.de

In addition, our employees are consistently interested in new infor-

mation and experiences resulting from the application that may be

of value in improving our products.

REPLACING SLIDE SEAL RING KITS AND GUIDE RINGS

Notes

HR-Mini Tank cleaning machine 11

Notes

BETE Deutschland GmbH

Dr.-C.-Otto Strasse 190

D - 44879 Bochum

Germany

+49-(0)234/936107-0

info@bete-deutschland.de

Other manuals for HR-Mini

1

Table of contents

Other BETE Cleaning Equipment manuals

Popular Cleaning Equipment manuals by other brands

Mako

Mako StyliCleaner Getting started

Clean Logix

Clean Logix BLX-1000-GEN2 user manual

Ro.Bia.Plast

Ro.Bia.Plast pulizia & stiro MultiEnergy Vap Instruction book

Avantco

Avantco 600 Series Operator's manual for Attachment

Good Way

Good Way GDS-15-PH Operating and maintenance instructions

Alfalaval

Alfalaval Emmie instruction manual