BETE HR-Mini Manual

HR-Mini

Tank cleaning machine

with an electric drive

OPERATING/INSTALLATION MANUAL

(Translation of the original operating/

installation manual)

Keep for future use!

Status: 16.04.2019

Legal notice

© BETE Deutschland GmbH

This manual and all images contained herein are copyright protected. Any use outside the

limitations of copyright law without our prior written approval is prohibited and liable to pros-

ecution. This applies especially to reproduction, translation, microfilming, saving, and edit-

ing in electronic systems.

We reserve the right to make technical alterations in the course of further development and

improvement of features.

BETE Deutschland GmbH

Dr.-C.-Otto Strasse 190

D - 44879 Bochum

Germany

+49-(0)234/936107-0

info@bete-deutschland.de

Status: 16.04.2019

CONTENTS

HR-Mini Tank cleaning machine I

Contentsa

1Introduction .............................................................................................1

1.1 Notational conventions....................................................................................2

1.1.1 Section-related safety information..............................................................2

1.1.2 Other notational conventions .....................................................................3

1.2 Symbols used in the manual ...........................................................................3

1.3 Warranty and liability .......................................................................................4

1.4 Service/Customer service................................................................................5

2Safety...................................................................................................... 6

2.1 General safety information ..............................................................................6

2.2 Intended use ...................................................................................................7

2.3 Duties of the plant operator.............................................................................9

2.4 Personnel requirements ................................................................................10

2.4.1 Personal protective equipment ................................................................11

2.5 Rating plate...................................................................................................11

3Structure and function ............................................................................ 12

3.1 Structure........................................................................................................12

3.2 Functioning ...................................................................................................13

3.3 Technical data...............................................................................................13

3.4 Cleaning medium..........................................................................................15

4Transport and storage ............................................................................ 16

4.1 Packaging.....................................................................................................16

4.2 Transport information ....................................................................................17

4.3 Storage .........................................................................................................18

5Installation and commissioning ............................................................... 19

5.1 Safety information .........................................................................................19

5.2 Installation position........................................................................................19

5.3 Installation .....................................................................................................19

5.3.1 Water connection.....................................................................................20

5.3.2 Electrical connection................................................................................21

5.4 Commissioning .............................................................................................21

5.4.1 Switching the HR-Mini on/off....................................................................22

6Maintenance.......................................................................................... 24

6.1 Maintenance table.........................................................................................24

6.1.1 Visual inspection......................................................................................24

CONTENTS

II HR-Mini Tank cleaning machine

6.1.2 Cleaning ..................................................................................................25

6.2 Fault table .....................................................................................................25

6.3 Stocking spare parts .....................................................................................25

6.3.1 Disassembling the HR-Mini......................................................................27

6.3.2 Installing/Removing wear parts................................................................28

6.3.3 Wear parts list..........................................................................................33

6.3.4 Optional accessories ...............................................................................34

7Decommissioning and disposal .............................................................. 35

8Annex.................................................................................................... 36

8.1 Certificates ....................................................................................................36

INTRODUCTION

Notational conventions

HR-Mini Tank cleaning machine 1

1 Introduction

This operating/installation manual (hereinafter referred to as manual) is part of the

HR-Mini tank cleaning machine (hereinafter referred to as HR-Mini) and provides

all the information required for safe and correct installation and efficient operation

of the HR-Mini.

All persons responsible for installing, operating, maintaining, checking, trouble-

shooting, dismantling, and disposing of the HR-Mini must read, understand, and

heed the manual. This applies, in particular, to any safety information.

After reading the manual, you will be able to:

−Install and operate the HR-Mini safely and correctly in accordance with in-

structions

−Clean and maintain the HR-Mini in accordance with legislation

−Take the right action in the event of a fault

In addition to this manual, it is necessary to comply with the general laws and

other regulations concerning accident prevention and environmental protection in

the country of use.

This manual is an integral part of the HR-Mini. It must be kept within easy reach

during the entire life cycle of the HR-Mini.

Additionally observe the following information in the respective current version:

−The product catalog and

−the general terms and conditions of BETE Deutschland GmbH

−and, if necessary, additional operating/installation manuals for optional ac-

cessories.

INTRODUCTION

Notational conventions

2HR-Mini Tank cleaning machine

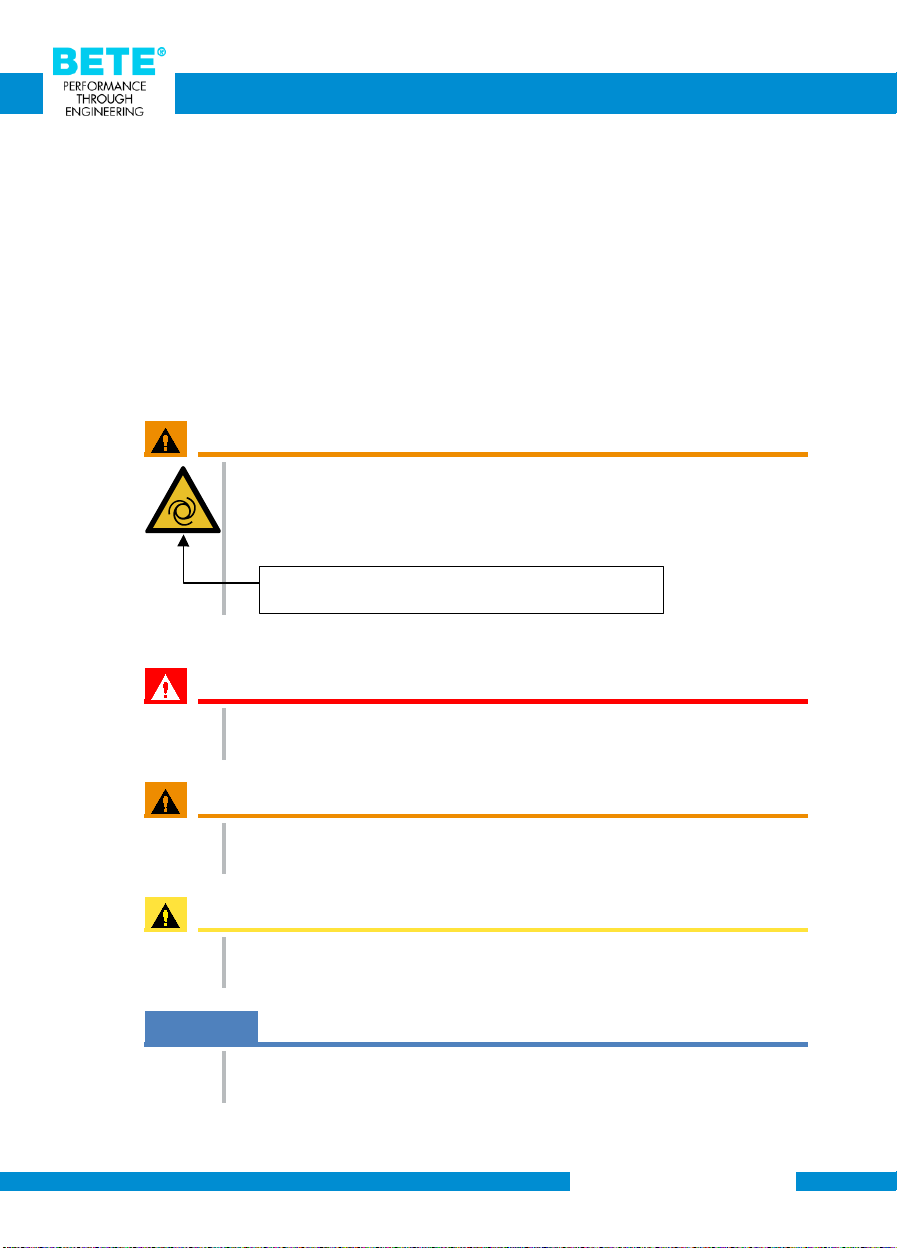

1.1 Notational conventions

Passages of this operating manual that require special attention or are a direct

hazard warning are shown as follows:

1.1.1 Section-related safety information

Section-related safety information applies not just to a specific activity but to all

activities within a certain section.

Structure

SIGNAL WORD

Type and source of danger

Possible consequence(s) of non-adherence

•Measure(s) to avoid the danger

Danger levels

DANGER

Hazard which, unless avoided, involves a high risk of death or (seri-

ous) injury.

WARNING

Hazard which, unless avoided, may involve a moderate risk of death

or (serious) injury.

CAUTION

Hazard which, unless avoided, may involve a low risk of minor or

moderate injury.

NOTE

Hazard which, unless avoided, can involve a low risk of material

damage.

Symbol(s) for further explanation of the danger

INTRODUCTION

Symbols used in the manual

HR-Mini Tank cleaning machine 3

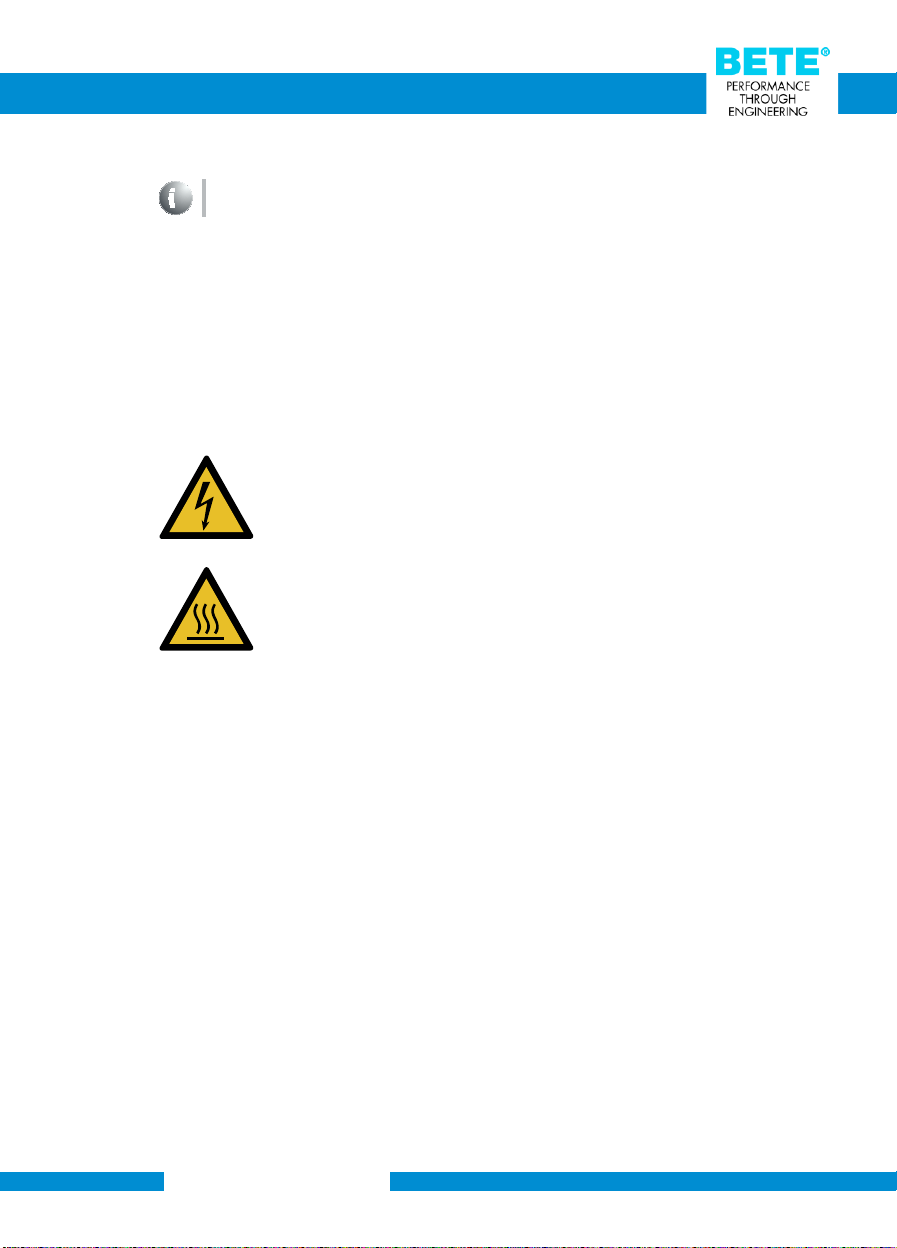

1.1.2 Other notational conventions

The info symbol provides useful information.

−Text following this mark represents an item in a list.

•Text following this mark represents instructions.

" " Text in double quotation marks refers to other chapters, sections or docu-

ments.

1.2 Symbols used in the manual

In this manual, particular hazards are identified by the following symbols:

Fatal injury hazard due to electricity

This symbol warns of a life-threatening electrical hazard.

Touching live parts poses a direct risk of death.

Burn hazard due to hot surfaces

This symbol warns of a burn hazard resulting from coming into con-

tact with hot surfaces.

INTRODUCTION

Warranty and liability

4HR-Mini Tank cleaning machine

1.3 Warranty and liability

The obligations under the supply contract, the General Terms and Conditions of

Trade, as well as the Terms and Conditions of Delivery of BETE Deutschland

GmbH, and the legal regulations in force at the time the contract was signed are

applicable.

Warranty and liability claims for personal injury and material damage are, in par-

ticular, excluded if they are attributable to one or more of the following causes:

−Unintended or inappropriate use of the HR-Mini,

−Inappropriate installation, commissioning, operation or maintenance of the

HR-Mini

−Failure to heed information in the operating manual regarding installation,

commissioning, operation, and maintenance of the HR-Mini

−Structural alterations to the HR-Mini (conversions or other alterations to the

HR-Mini are not allowed to be made without prior written permission from

BETE Deutschland GmbH. Any breach of this causes the HR-Mini to lose its

EC conformity and its authorisation to operate)

−Use of spare parts that do not satisfy the technically established requirements

−Improperly executed repairs

−Disasters, effects of extraneous elements and force majeure

We reserve the right to make technical alterations in the course of further devel-

opment and improvement of features.

INTRODUCTION

Service/Customer service

HR-Mini Tank cleaning machine 5

1.4 Service/Customer service

Our service hotline is at your disposal for any technical queries you

may have.

Phone: +49 (0) 234 93 61 07 0

E-Mail: info@bete-deutschland.de

In addition, our employees are consistently interested in new infor-

mation and experiences resulting from the application that may be of

value in improving our products.

SAFETY

General safety information

6HR-Mini Tank cleaning machine

2 Safety

2.1 General safety information

The HR-Mini has a state-of-the-art design and complies with recognised safety

rules and regulations. But using it can still endanger life and limb of users or third

parties or result in damage to the HR-Mini itself or other objects.

The following basic safety information is intended to prevent personal injury and

material damage. The plant operator must ensure that the basic safety infor-

mation is observed and complied with.

This manual contains basic information that requires special attention when in-

stalling, operating, repairing, and maintaining the HR-Mini.

Every person tasked with installing, operating, repairing, and maintaining activi-

ties must have read and understood this manual.

Always observe the safety systems and safety information described in this man-

ual.

WARNING

Failure to observe this manual, inappropriate installation, and repair

work or incorrect operation may cause faults at the HR-Mini and re-

sult in hazardous situations!

This may result in death or serious injury.

•Ensure all tasks at the HR-Mini are carried out by a specialist

taking into consideration

– the corresponding operating and installation manual(s)

– the warning and safety signs affixed to the HR-Mini

– the system-specific conditions and requirements

– the national/regional safety and accident prevention regula-

tions

•

Never install damaged devices or components.

The illustrations in this manual provide a general understanding and give

a basic representation of the current state of the HR-Mini. Deviations from

the actual version of the HR-Mini are possible depending on the version.

We recommend undertaking relevant training provided by the manufac-

turer before carrying out maintenance and repair work or having the work

completed by a person authorised and approved by the manufacturer.

SAFETY

Intended use

HR-Mini Tank cleaning machine 7

2.2 Intended use

The operational safety of the HR-Mini is only ensured if it is used as intended.

The HR-Mini is a rotating cleaning device and is classified as a tank cleaning

machine. The HR-Mini is designed for cleaning the inside of small tanks in the

brewing, beverage, chemical, and pharmaceutical industries.

The term tank in this manual refers to sealed, empty, unpressurised tanks, hop-

pers, barrels, containers, etc. that are fitted with a drain outlet that allows the un-

obstructed discharge of the supplied cleaning medium.

The HR-Mini has been developed, designed, and manufactured solely for indus-

trial and commercial applications. Private use is strictly prohibited.

Basically, the plant operator must ensure the HR-Mini is suitable for each respec-

tive application.

When observing the stipulated limitations of use (see section “3.3 Technical da-

ta”), the HR-Mini can be used in indoor and outdoor tanks.

When doing so, the following fundamental issues must be observed:

−Only use the fully installed HR-Mini inside a sealed tank.

−Make sure the tank being cleaned is empty and is unpressurised.

−Protect the HR-Mini against freezing (e.g. residual water may freeze in cold

conditions).

−The HR-Mini is only intended for a fixed pipe installation. Installation using a

hose is FORBIDDEN.

−Insert an appropriate filter system in the supply line of the cleaning medium.

This is usually already provided in an upstream high-pressure cleaner. The

mesh size should be at least 200 mesh.

−Only operate the HR-Mini within the approved parameters (see section “3.3

Technical data”).

−Only use water as the cleaning medium.

−Only install the HR-Mini vertically with the cleaning head facing downwards.

Foreseeable misuse

The HR-Mini is NOT suitable for the following applications:

−The HR-Mini is NOT suitable for private use.

−The HR-Mini is NOT suitable for ATEX applications.

−The HR-Mini is NOT suitable for use outside tanks.

−Never aim the spray or jet of cleaning medium of the HR-Mini at people.

SAFETY

Intended use

8HR-Mini Tank cleaning machine

−It is FORBIDDEN to hold the HR-Mini in your hand during operation.

−Do NOT operate the HR-Mini with air.

The HR-Mini is only intended for the aforementioned purpose. Any other use or

modification of the HR-Mini is NOT permitted without the prior written approval of

the manufacturer.

The manufacturer shall NOT be liable for any damage or loss whatsoever caused

by misuse or unapproved modifications. Any such use shall be at the sole risk of

the plant operator.

Only operate the HR-Mini after making sure all the safety devices are in correct

working order and the system in which the HR-Mini is installed complies with the

safety requirements of all the relevant European directives (e.g. Machinery Di-

rective).

SAFETY

Duties of the plant operator

HR-Mini Tank cleaning machine 9

2.3 Duties of the plant operator

The machine is used in an industrial plant. The plant operator must therefore en-

sure that operation conforms to occupational safety regulations.

In the EEA (European Economic Area), national implementation of the European

Framework Directive on Safety and Health at Work (89/391/EEC) and of the rele-

vant individual directives, in compliance with the currently valid versions, must be

observed and duly applied.

This includes, in particular, the Use of Work Equipment Directive (2009/104/EC)

concerning the minimum health and safety requirements for the use of work

equipment by workers at work.

In Germany, the Ordinance on Industrial Health and Safety (BetrSichV) must be

observed at all times.

In other countries, relevant national directives, laws and country-specific regula-

tions on health and safety at work and accident prevention must be observed

and applied.

The following, non-exhaustive information applies in particular:

−The plant operator must ensure that the HR-Mini is only used as intended

(see section “2.2 Intended use").

−The plant operator must clearly define and arrange the responsibilities of the

personnel (e.g. for installation, operation, maintenance and cleaning).

−The plant operator must only allow suitably qualified and authorised person-

nel to work on the HR-Mini.

−The user must ensure that all staff working on or with the HR-Mini have read

and understood the manual.

−The plant operator must provide personnel with personal protective equip-

ment and also ensure that it is used (see section “2.4.1 Personal protective

equipment”).

−The plant operator agrees to only operate the HR-Mini when it is in full work-

ing order.

−Before using the HR-Mini, the operator must ensure that local regulations

were observed during installation and commissioning if this work was carried

out by the plant operator.

SAFETY

Personnel requirements

10 HR-Mini Tank cleaning machine

2.4 Personnel requirements

The HR-Mini is only allowed to be installed, maintained, and repaired by persons

who have been qualified for this. These persons must know the manual and act

in accordance with it. The respective authorisations for personnel must be de-

fined clearly.

Personnel require the following qualifications for the various activities:

Instructed personnel

Instructed personnel have been instructed by the plant operator about their tasks

and the potential risks of inappropriate behavior.

Skilled personnel

Skilled personnel are able to do their work and recognise/avoid potential hazards

on their own as a result of their training, knowledge, and experience and their fa-

miliarity with regulations.

Only people who have received adequate information, instruction, and training

are allowed to work at the HR-Mini:

−Installation/Disassembly: Industrial mechanic or comparable professional

training, practical experience in installing/disassembling devices

−Electrical work: Electrical specialist; person with suitable professional training,

knowledge, and experience who can recognise and prevent the dangers that

may be posed by electricity. The person must be familiar with carrying out

electrical installation, commissioning, troubleshooting, and repair work at the

HR-Mini and have the following qualifications:

−Professional training in the field of electrical engineering (e.g. fully quali-

fied electrician, electronics engineer or mechatronics technician)

−Several years of experience in the field of electrical engineering.

Work in the areas of transport, storage, cleaning, operation, and disposal should

only be carried out by people who have been given suitable instruction and train-

ing.

All the people stated above must wear appropriate protective clothing when per-

forming their duties.

SAFETY

Rating plate

HR-Mini Tank cleaning machine 11

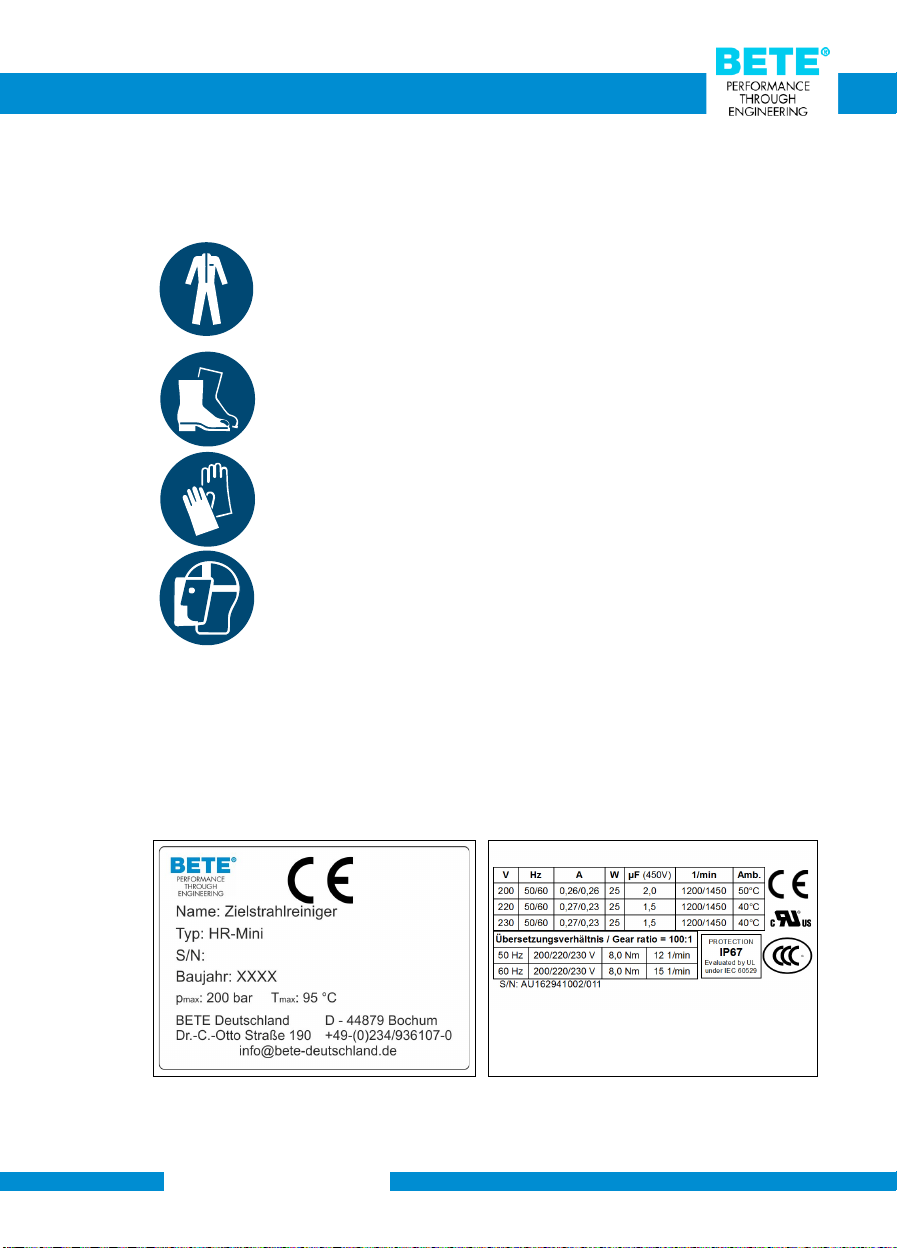

2.4.1 Personal protective equipment

When working on the HR-Mini, always wear personal protective equipment to

minimise health hazards.

Protective clothing

Protective clothing refers to tight-fitting working clothes that tear

easily and feature tight sleeves and no loose parts. They pre-

dominantly protect against becoming entangled in moving com-

ponents. Never wear rings, necklaces or other jewelry.

Safety shoes

Wear non-slip safety shoes to protect yourself against heavy

falling parts and prevent you from slipping.

Safety gloves

Wear safety gloves to protect your hands against coming into

direct contact with hot surfaces or chemical substances.

Face protection

Wear face protection to protect against media escaping under

high pressure.

The personal protective equipment must be provided by the plant operator and

must comply with the applicable requirements.

It is also necessary to obey national regulations and the plant operator's internal

instructions.

2.5 Rating plate

Figure 2.1: HR-Mini and motor rating plate

STRUCTURE AND FUNCTION

Structure

12 HR-Mini Tank cleaning machine

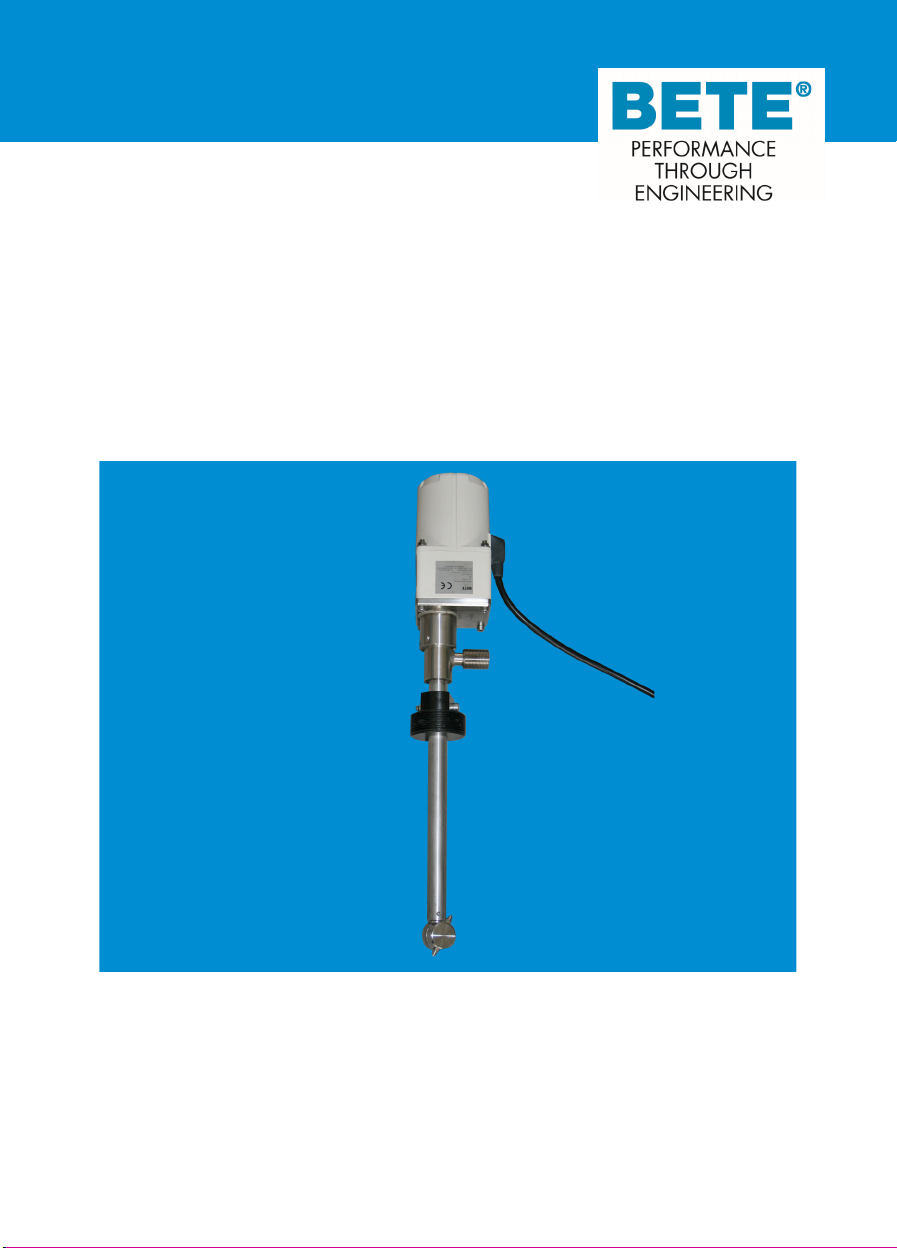

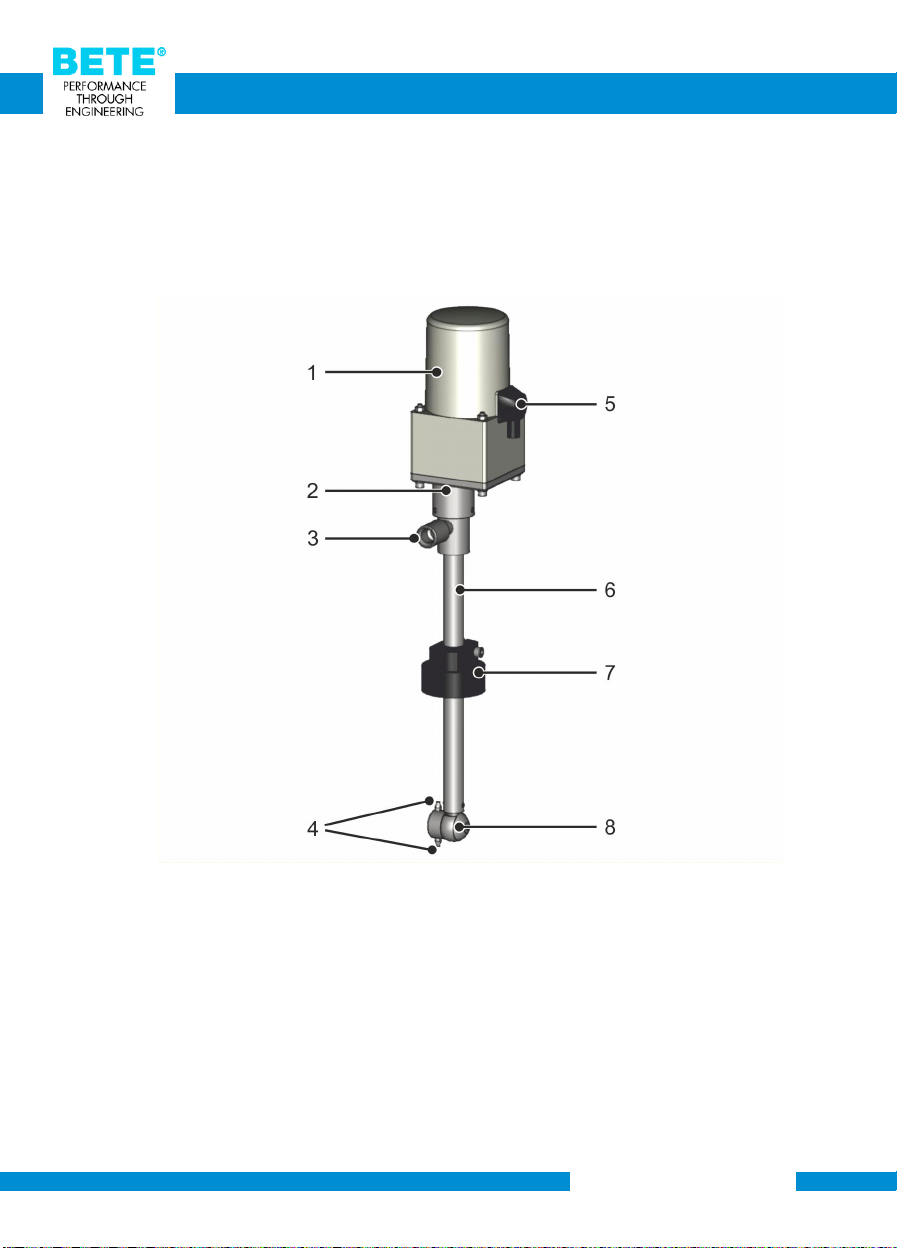

3 Structure and function

3.1 Structure

Figure 3.1: Overview of HR-Mini

1

Drive motor

5

Power cord

2

Flange

6

Exterior pipe

3

Water connection

7

2” collar

4

Solid stream nozzles

8

Nozzle head

STRUCTURE AND FUNCTION

Functioning

HR-Mini Tank cleaning machine 13

3.2 Functioning

The HR-Mini is a motor-driven, versatile tank cleaning machine designed for

cleaning small, difficult-to-clean tanks in the brewing, beverage, chemical, and

pharmaceutical industries.

It is fixed in the tank opening using a 2” collar (included in the scope of delivery).

The HR-Mini is made of stainless steel and plastic. The induction motor uses the

shaft and bevel gears to drive the nozzle head and enable 360 degree cleaning

of the tank in precisely defined cleaning cycles.

The solid stream nozzles employ the jet principle to concentrate the cleaning

medium, resulting in a high-energy jet. The mechanical cleaning efficiency de-

pends on the velocity, quantity, and impact angle of the cleaning medium.

The intensive cleaning jets help to remove stubborn deposits from the side of the

tank which are blasted off and flushed out at high speed.

Various nozzle sizes are available depending on the requirements and tank size.

3.3 Technical data

Electric drive for Europe

Electric drive for USA

230 V / 50 Hz, IP 67 standard

110 V / 60 Hz, IP 67 standard

Water pressure connection 80 - 160 bar

Working pressure HR-Mini max. 200 bar,

recommended 80 – 160 bar

Water temperature during operation 1 - 95 °C

Water connection with external thread M22x1,5 fine thread DIN 13-2

Speed 15 min-1

Hole diameter in nozzle head

1.2 mm (standard)

0.8 mm / 0.9 mm / 1.0 mm / 1.3 mm

(optional)

Length

510 mm

Width

80 mm

Weight 2.2 kg

Max. tank diameter

2 m

STRUCTURE AND FUNCTION

Technical data

14 HR-Mini Tank cleaning machine

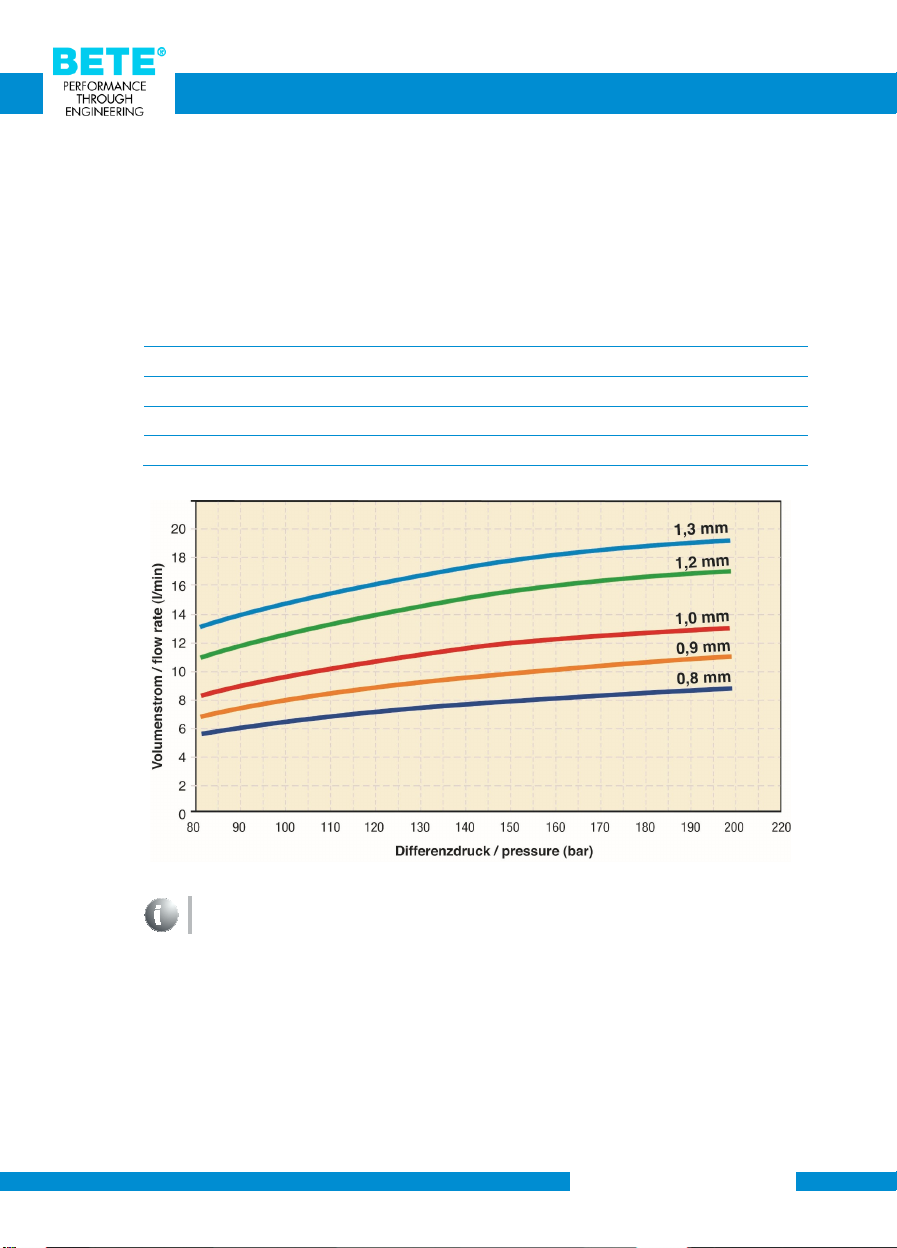

Consumption data volume flow

Consumption of the HR-Mini cleaning liquid depends on several factors, e.g. on

the pressure of the cleaning liquid and the size of the holes in the nozzle heads.

Consumption (throughput) rises, for instance, when increasing the pressure. Al-

ways observe the permissible range for the working pressure of the cleaning me-

dium.

Ø 0.8 mm

Ø 0.9 mm

Ø 1.0 mm

Ø 1.2 mm

Ø 1.3 mm

80

bar

5.53 l/min

6.96 l/min

8.18 l/min

11.15 l/min

13.06 l/min

120

bar

6.47 l/min

8.63 l/min

10.03 l/min

13.63 l/min

15.97 l/min

160

bar

7.57 l/min

9.99 l/min

11.51 l/min

15.52 l/min

18.17 l/min

200

bar

8.82 l/min

11.13 l/min

12.95 l/min

16.92 l/min

--

The volume flow may vary +/– 10 %.

STRUCTURE AND FUNCTION

Cleaning medium

HR-Mini Tank cleaning machine 15

3.4 Cleaning medium

NOTE

Risk of damage to the HR-Mini caused by the cleaning medium!

Dirt or foreign objects in the cleaning medium may disrupt correct

functioning of the HR-Mini.

This may lead to material and consequential damage.

•Insert a suitable filter system in the supply line of the cleaning

medium. You are recommended to use a fine 200 mesh screen fil-

ter.

The HR-Mini should only be operated with clean water. Other cleaning media are

strictly prohibited.

TRANSPORT AND STORAGE

Packaging

16 HR-Mini Tank cleaning machine

4 Transport and storage

BETE Deutschland GmbH products are checked carefully prior to delivery and

packaged suitable for transport and storage. Nonetheless, damage during

transport CANNOT be excluded.

If damage occurs (including spare and wear parts), please contact

BETE Deutschland GmbH immediately to report the damage.

Scope of supply

−HR-Mini

−2” collar

−Operating and installation manual

Goods inwards inspection:

−Use the delivery note and the order confirmation to inspect goods immediate-

ly upon delivery for any short-comings.

−Inspect (visual inspection) the delivery for possible transport damage.

Complaints:

−If goods are in a damaged or incomplete condition, please file a complaint to

the transporting company immediately.

−Remember to keep the packaging until the transport company has possibly

checked the goods or for returning the goods.

Returning goods:

When returning goods, pack the parts in a manner that prevents any damage

during transport. If possible, use the original packaging and the original packag-

ing material. In case both are no longer available, contact a professional packag-

ing company for help.

−If you have any questions about packaging and securing products during

transport, feel free to contact BETE Deutschland GmbH.

4.1 Packaging

The HR-Mini is supplied fully assembled. The packaging is adapted to the rele-

vant transport conditions. Any required accessories, spare parts, the operating

and installation manual, and technical documents are packed separately and en-

closed with the delivery.

Other manuals for HR-Mini

1

Table of contents

Other BETE Cleaning Equipment manuals

Popular Cleaning Equipment manuals by other brands

Suevia

Suevia 130.5011 EASYCLEANER Mounting instructions

i-MO

i-MO Öko 2000 user guide

unGer

unGer Hydro Power Ultra UNP01 operating instructions

Black & Decker

Black & Decker BHPC130 Original instructions

Uni-ram

Uni-ram UG5000E operating manual

Axi

Axi MTC HC-300 Installation, operating and maintenance manual