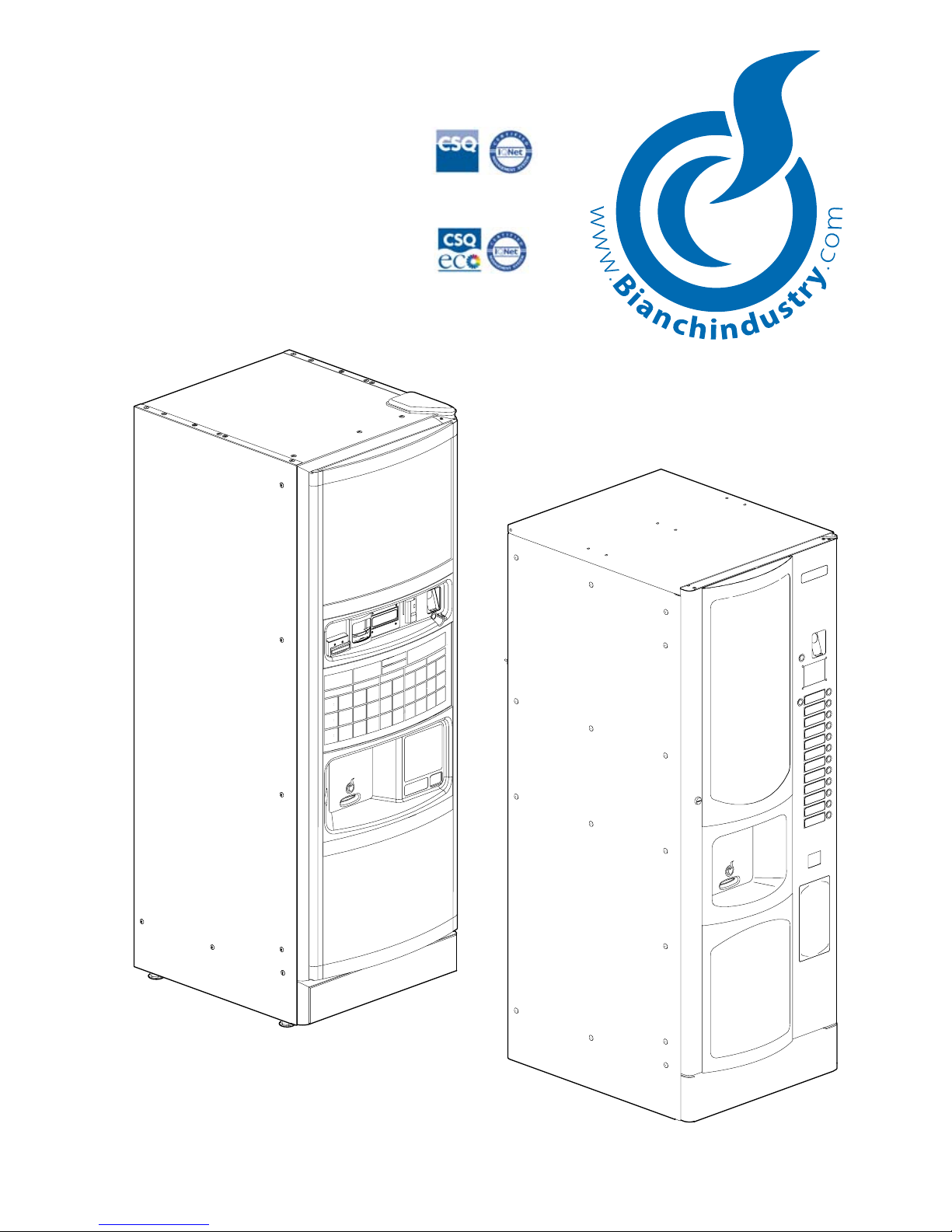

BIANCHI VENDING LEI700 User manual

LEI400

LEI700

CERT. N° 9191 BNVN

UNI EN ISO 14001:2004

CERT. N° 9105 BNVD

UNI EN ISO 9001: 2000

USE AND MAINTENANCE MANUAL

MANAGING DIRECTOR

DECLARATION OF CONFORMITY

La BIANCHI VENDING GROUP S.p.A.

Corso Africa, 9 - 24040 Zingonia di VERDELLINO (BG) Italia

declares under its own responsibility that the family of vending machines:

Brand: BIANCHI VENDING

Manufacturer: BIANCHI VENDING GROUP S.p.A.

Type/Model: LEI 700 – LEI400

is in compliance with the Basic Requirements included in the following Directives:

1) Low Voltage – 2006/95/CE (on the harmonisation of the laws of Member States relating to electrical equipment

designed for use within certain voltage limits) -LV-

2) Electromagnetic Compatibility – 2004/108/CE (on the approximation of the laws of the Member States relating to

electromagnetic compatibility) -EMC-

3) REG. (CE) 1935/2004 (on materials and articles intended to come into contact with food)

REG. (CE) 1895/2005 (on the restriction of use of certain epoxy derivatives in materials and articles intended to

come into contact with food)

DIR. 2002/72 CE (relating to plastic materials and articles intended to come into contact with foodstuffs)

The tests/checks were performed in accordance with the current European Harmonised Standards:

1)LOW VOLTAGE (Electrical Safety LV):

EN 60335-1:2002 +A1:2004 +A11:2004 +A2:2006 +A12:2006 +A13:2008 (Safety of household and similar electrical ap-

pliances – General requirements)

EN 60335-2-75:2004+ A1:2005 +A11:2006 + A2:2008 +A12:2010. (Particular requirements for commercial dispensing applian-

ces and vending machines)

EN ISO 11201:2009 + EN ISO 3744:2009 – Measurement of acoustic noise. Sound Pressure level: LpA < 70 dB(A)

2) ELECTROMAGNETIC COMPATIBILITY (EMC):

EN 55014-1:2006(Limits and methods of measurement of radio disturbance characteristics of household appliances, similar

engine or heating appliances, of tools and similar electrical apparatus)

EN 55014-2:1997 +A1:2001 +A2:2008 (Immunity requirements for household appliances, tools and similar electrical ap-

paratus)

EN 61000-3-2: 2006 (Limits for harmonic current emissions)

EN 61000-3-3:1995+ A1:2001 +A2:2005 (Limitation of voltage uctuations and icker in lowvoltage supply systems for

equipment with rated current ≤ 16 A)

EN 62233:2008 (Measurement methods for electromagnetic elds of household appliances and similar apparatus with regard

to human exposure)

3) SUITABILITY OF MATERIALS FOR CONTACT WITH FOODSTUFFS

Selected tests for the “Suitability for contact with foodstuffs” as required by Italian law: Min. Dec. 21-03-1973 and fol-

lowing amendments ⇒Decree 4th May 2006 no. 227, and by transposition of European Directives: 82/711/CEE, 85/572/

CEE, 93/8/CEE, 97/48/CE, 2002/72/CE, 2004/13/CE, 2004/19/CE, 2005/79/CE, Reg. CE no. 1935/04 and Reg. CE no.

1895/2005.

Zingonia di Verdellino (BG), January 2010

Dichiarazione di Conformità

Direttiva RoHS

Direttiva 2002/95/CE del Parlamento Europeo e

del Consiglio del 27 Gennaio 2003

sulla restrizione dell’uso di determinate sostanze pericolose

nelle apparecchiature elettriche ed elettroniche

Bianchi Vending Group S.p.A. dichiara che:

dal 1° luglio 2006 qualsiasi prodotto di

Bianchi Vending Group S.p.A.

immesso sul

mercato in Europa è conforme alla Direttiva RoHS, e quindi non contiene

concentrazioni che superino i limiti consentiti per le seguenti sostanze:

•Piombo (Pb)

•Mercurio (Hg)

•Cadmio (Cd)

•Cromo esavalente (Cr(VI))

•Bifenile polibromurati (PBB)

•Eteri di difenili polibromurati:

oPentaBromoDifenilEtere (PBDE)

oOttaBromoDifenilEtere (OttaBDE)

o

DecaBromoDifenilEtere (DecaBDE)

•

Pefluorooctano sulfonato (PFSO)

•PoliCloroNaftalene (PCN)

•Bis(tribromophenoxy)etano PoliCloroBifenile (PCB)

•Benzene

L’Amministratore Delegato

______________________

Zingonia di Verdellino (BG), 12 Gennaio 2009

INFORMATION TO THE USERS

Under Legislative Decree 25 September 2007, no.185 and art. 13, Legislative Decree 25 July 2005, no.151 “Implementation

of Directives 2002/95/EC, 2002/96/EC and 2003/108/EC, regarding the reduction of use of hazardous substances

in electrical and electronic equipment as well as waste disposal”.

The barred waste container symbol on the equipment means that the product, at the end of its service life, must be

disposed of separately from the other types of waste.

The user must therefore convey the equipment, at the end of its service life, to the appropriate separate collection centres for

electronic/electrotechnical waste products or return it to the dealer when purchasing a new equivalent equipment.

The appropriate separate collection and the following sending of the used equipment to recycling, treatment and eco-friendly

disposal will help avoid negative effects on the environment as well as on health along with an easier recycling of the materials

forming the equipment.

Any unauthorized disposal of the product by the user will imply the enforcement of the administrative sanctions as set out in

Legislative Decree no. 22/1997 (article 50 and following articles, Legislative Decree no. 22/1997).

Dichiarazione di Conformità

Direttiva RoHS

Direttiva 2002/95/CE del Parlamento Europeo e

del Consiglio del 27 Gennaio 2003

sulla restrizione dell’uso di determinate sostanze pericolose

nelle apparecchiature elettriche ed elettroniche

Bianchi Vending Group S.p.A. dichiara che:

dal 1° luglio 2006 qualsiasi prodotto di

Bianchi Vending Group S.p.A.

immesso sul

mercato in Europa è conforme alla Direttiva RoHS, e quindi non contiene

concentrazioni che superino i limiti consentiti per le seguenti sostanze:

•Piombo (Pb)

•Mercurio (Hg)

•Cadmio (Cd)

•Cromo esavalente (Cr(VI))

•Bifenile polibromurati (PBB)

•Eteri di difenili polibromurati:

oPentaBromoDifenilEtere (PBDE)

oOttaBromoDifenilEtere (OttaBDE)

o

DecaBromoDifenilEtere (DecaBDE)

•

Pefluorooctano sulfonato (PFSO)

•PoliCloroNaftalene (PCN)

•Bis(tribromophenoxy)etano PoliCloroBifenile (PCB)

•Benzene

L’Amministratore Delegato

______________________

Zingonia di Verdellino (BG), 12 Gennaio 2009

Declaration of Conformity

RoHS Directive

DIRECTIVE 2002/95/EC OF THE

EUROPEAN PARLIAMENT AND OF THE COUNCIL of 27 January 2003

on the restriction of the use of certain hazardous

substances in electrical and electronic equipment

Bianchi Vending Group S.p.A. declares:

Starting from July 1st 2006 any product manufactured by “Bianchi Vending Group Spa” on the

European market is Rohs Directive compliant and do not contain concentrations exceeding limits

allowed for the following substances:

•Lead (Pb)

•Mercury (Hg)

•Cadmium (Cd)

•Hexavalent Chromium (Cr(VI))

•Polybrominated Biphenyls (PBB)

•Polybrominated Diphenyl ethers:

o Polybrominated diphenyl ethers (PBDE)

o Octabromodiphenyl ether (OctaBDE)

o Decabromodiphenyl ether (DecaBDE)

• Peruorooctane sulfonate (PFOS)

•PolyChloro Naphthalenes (PCN)

•Bis(tribromophenoxy)ethane Polychlorinated biphenyl (PCB)

•Benzene

Zingonia di Verdellino (BG), 12 January 2009

Declaration of Conformity

RoHS Directive

DIRECTIVE 2002/95/EC OF THE

EUROPEAN PARLIAMENT AND OF THE COUNCIL of 27 January

2003 on the restriction of the use of certain hazardous

substances in electrical and electronic equipment.

Bianchi Vending Group S.p.A. declares:

Starting from July 1

st

2006 any product manufactured by “Bianchi Vending Group Spa”

on the European market is Rohs Directive compliant and do not contain concentrations

exceeding limits allowed for the following substances:

•Lead (Pb)

•Mercury (Hg)

•Cadmium (Cd)

•Hexavalent Chromium (Cr(VI))

•Polybrominated Biphenyls (PBB)

•Polybrominated Diphenyl ethers:

oPolybrominated diphenyl ethers (PBDE)

oOctabromodiphenyl ether (OctaBDE)

oDecabromodiphenyl ether (DecaBDE)

•Perfluorooctane sulfonate (PFOS)

•PolyChloro Naphthalenes (PCN)

•Bis(tribromophenoxy)ethane Polychlorinated biphenyl (PCB)

•Benzene

CHIEF EXECUTIVE OFFICER

______________________

Zingonia di Verdellino (BG), 12 Gennaio 2009

5

PE

IMPORTANT NOTICES

MAINTENANCE TECHNICIAN

The maintenance technician is dened as being the person responsible for lling up the containers with

soluble products, sugar, coffee, stirrers and cups.

The maintenance technician is also responsible for cleaning the distributor (see operations indicated in

chapter 6.0). In the event of a fault the maintenance technician must call the installation technician.

INSTALLATION TECHNICIAN

The installation technician is dened as the person responsible for the installation of the automatic distri-

butor, the starting up operations and the function settings.

Each regulation operation is the exclusive responsibility of the installation technician who also holds the

programming access password.

BEFORE USING THE MACHINE, READ THIS MANUAL CAREFULLY FOR ITS CORRECT USE IN ACCOR-

DANCE WITH THE CURRENT SAFETY STANDARDS.

ATTENTION: Important safety indications

READ the instruction manual machine carefully before using the machine

For any service or maintenance switch off the machine

ATTENTION: machine switched on

ATTENTION: hot parts in contact!

CAUTION! Parts in motion

Earthing indication

6

Here below are the STANDARD congurations of the selection labels to insert into the keyboard of the

indicated machine.

Selections keypad LEI400

Selections keypad LEI700

SUGAR

DEKA

SHORT COFFEE

LONG COFFEE

WHITE COFFEE

CAPPUCCINO

MOCCACCINO

MILK AND COFFEE

CHOCOLATE

CHOCOMILK

MILK

THE

7

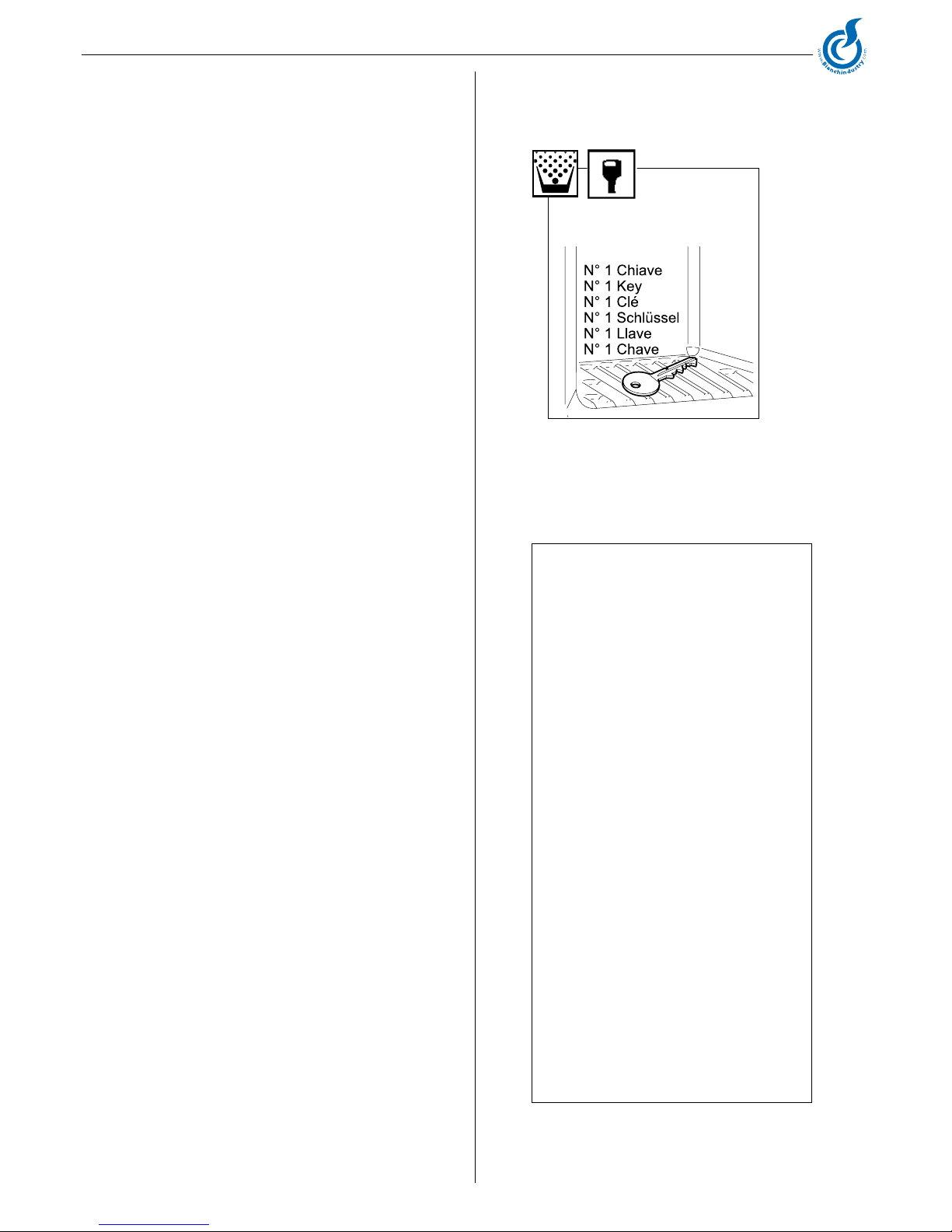

Tools necessary for undertaking interven-

tions on the automatic dispenser.

SOCKET SPANNERS

n° 5,5

n° 7

n° 8

n° 10

n° 20

n° 22

SPANNERS (fork type)

n° 7

n° 8

n° 10

n° 12

n° 14

SCREWDRIVERS

Small size

Medium size

Large size

Normal cross

Small cross

Medium cross

Large cross

Of Teon, small size for Trimmer regula-

tion.

RATCHET SPANNER no.14

TESTER

ELECTRICIAN’S SCISSORS

PROGRAMMING KIT

Keys at the disposal of the MAIN-

TENANCE and INSTALLATION

technicians

INDEX

PREMISE

IImportant notices for operator

II Important notices

III Safety rules

1.0 DESCRIPTION OF THE MACHINE’S

TECHNICAL CHARACTERISTICS

1.1 Scheduled Use

1.2 Knowing the distributor

2.0 TECHNICAL DESCRIPTION OF THE

OPERATION

2.1 Basic principle of operation

2.1.1 Cup dispensing

2.1.2 Sugar dispenser

3.0 TRANSPORTING THE AUTOMATIC

VENDING MACHINE

3.1 Moving and Transport

3.2 Stocking

3.3 Packing

3.4 Reception

3.5 Unpacking

4.0 INSTALLATION

4.1 Positioning

4.2 Water supply connection

4.3 Power supply connection

4.4 Machine starting up

4.5 Installation

4.5.1 Decalcicator resin washing where it is

installed as accessory

4.5.2 Filling of water circuit

4.5.3 Cleaning of parts in contact with food

substances

4.5.4 Payment system installation

4.6 Product loading

4.6.1 Product container loading

4.6.2 Cup loading

4.6.3 Spoon loading

4.6.4 Spent coffee grounds bag insertion

4.7 Automatic distributor layout

4.8 First self installation mode

5.0 SOFTWARE INSTRUCTIONS

5.1 Password

5.2 Machine menus

5.3 Complete programming menu

5.4 Maintenance

6.0 MAINTENANCE AND INACTIVITY

6.1 Cleaning and loading procedures

6.1.1 Recommended maintenance

6.1.2 Periodic cleaning by the maintenance technician

6.1.3 Daily cleaning procedures

6.1.4 Product Loading instructions

6.2 Ordinary and Extraordinary Maintenance

6.3 Maintenance procedures

6.3.1 Sanitization

6.4 Regulations

6.4.1 Dosage and grinding regulation

6.4.2 Instant electrovalve water ow regulation

6.4.3 Access to internal parts

6.5 BRITA decalcicator lter

6.6 Resing regeneration (optional)

6.7 Inactivity

7.0 DISMANTLEMENT

8.0 ALARMS

8.1 Alarms

8.1.1 Displayed blocking alarms

8.1.2 Alarms displayed under maintenance

8

FIG.1

+039. 035.45.02.111

fax +039. 035.883.304

PREMISE

I - Important notices for operator

This automatic distributor has been designed and constructed in

full accordance with current safety regulations and is therefore safe

for those who follow the ordinary lling and cleaning instructions

as indicated in this manual.

The user must not under any circumstances remove the

guards that require a tool for removal.

Some maintenance operations (to be done solely by specialized

technicians and indicated in this manual with a special symbol)

require that specic safety protections of the machine must be

switched off .

In accordance with the current safety regulations, certain opera-

tions are the exclusive responsibility of the installation technician,

and the ordinary maintenance technician may have access to

specic operations on with specic authorization.

The acquaintance and absolute respect, from a technical point of

view, of the safety instructions and of the danger notices contained

in this manual, are fundamental for the execution, in conditions

of minimum risk, for the installation, use and maintenance of

this machine.

II - General Instructions

Knowledge of the information and instructions

contained in the present manual is essential for

a correct use of the automatic vending machine

on the part of the user .

– Interventions by the user on the automatic vending machine

are allowed only if they are of his competence and if he has

been duly trained.

The installation technician must be fully acquainted with all

the mechanisms necessary for the correct operation of the

machine.

– It is the buyer’s responsibility to ascertain that the users have

been trained and are informed and regulations indicated in the

technical documentation supplied.

Despite the full observance of the safety regulations by the

constructor, those who operate on the automatic dispensers

must be fully aware of the potential risks involved in operations

on the machine.

– This manual is an integral part of the equipment and as such

must always remain inside of the same, so as to allow further

consultations on the part of the various operators, until the

dismantlement and/or scrapping of the machine.

– In case of loss or damage of the present manual it is possible

receive a new copy making application to the manufacturer,

with prior indication of the data registered on machines’ serial

number.

– The functional reliability and optimization of machine’s ser-

vices are guaranteed only if original parts are used.

– Modications to the machine not previously agreed on with

the construction company and undertaken by the installation

technician and/or manager, are considered to be under his

entire responsibility.

All the operations necessary to maintain the machine’s ef-

ciency, before and during it’s use are at the users charge.

– Any manipulations or modications made to the machine that

are not previously authorized by the manufacturer, relieve

the latter from any responsibility for damages deriving from,

and will automatically result in the cancellation of the machine

guarantee terms.

– This manual reects the status at the moment of the emission

of the automatic vending machine on the market; possible

modications, upgrading, adaptments that are done the ma-

chine and that are subsequently commercialized do not oblige

BIANCHI VENDING GROUP Spa neither to intervene on the

machine previously supplied, nor, neither to update the relative

technical documentation supplied together with the machine.

– It is however BIANCHI VENDING‘s Group faculty, when

deemed opportune and for valid motives, to adjourn the ma-

nuals already present on the market, sending to their customers

adjournment sheets that must be kept in the original manual.

Possible technical problems that could occur are easily resolvable

consulting this manual ; For further information, contact the di-

stributor from whom the machine has been purchased, or contact

Bianchi Vending’s Technical Service at the following numbers:

When calling it is advisable to be able to give the following infor-

mation:

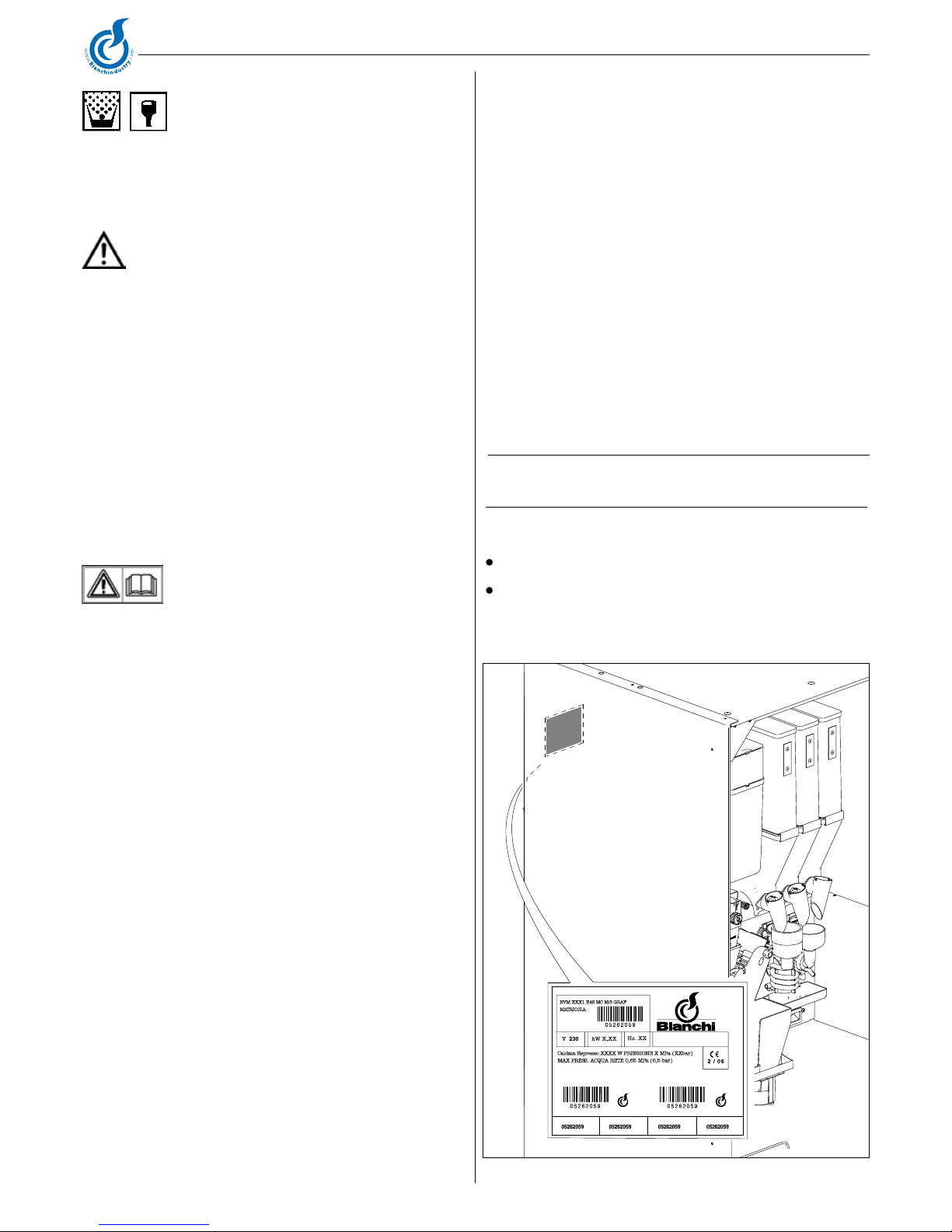

The data registered on the serial number label (Fig.1)

version of program contained in the microprocessor (Adhesive

label on the component installed on board).

9

BIANCHI VENDING GROUP Spa declines any responsibility for

damages caused to people or belongings in consequence to:

Incorrect installation

Inappropriate electrical and/or water connection.

Inadequate cleaning and maintenance

Not authorized modications

Improper use of the distributor

Not original spare parts

– Under no circumstances is Bianchi Vending Group Spa obliged

to compensate for eventual damage resulting from the forced

suspension of drink deliveries as the result of faults.

– Installation and maintenance operations , must be done exclu-

sively by qualied technical personnel with prior training for

carrying out these duties.

– For relling use only food products that are specic for auto-

matic vending machines.

– The automatic distributor is not suitable for external installation.

The machine must be installed in dry places, with temperatures

that never go below 1°C it must not be installed in places where

cleaning is done with water hoses (ex. big kitchens.).

Do not use water jets to clean the machine.

III - SAFETY NORMS

ATTENTION!

– before using the automatic distributor, read this

manual carefully.

– The installation and maintenance operations must be performed

exclusively by qualied technical personnel.

– The user must not in any circumstance be able accede to those

parts of the automatic distributor that are protected and require

a tool in order to be accessible.

– The knowledge and the absolute respect, from a technical point

of view of the safety instructions and of the danger notices con-

tained in this manual, constitute the basis for the operation ,

in conditions of minimum risk, of the installation, starting and

maintenance of the machine.

Always disconnect the POWER CABLE before main-

tenance or cleaning interventions.

ABSOLUTELY DO NOT INTERVENE ON THE MACHINE

AND DO NOT REMOVE ANY PROTECTION BEFORE THE

COOLING OF THE HOT PARTS!

– The functional reliability and optimization of machine’s ser-

vices are guaranteed only if original parts are used.

– In order to guarantee normal operation, the machine must be

installed in areas that the environmental temperature is between

a minimum of +1°C and a maximum of +50°C end humidity of

not over 85%.

– In order to guarantee a regular operation, always maintain the

automatic distributor in perfect cleaning conditions

– If at the moment of the installation, if conditions differing from

those indicated in the present manual, or should the same un-

dergo changes in time, the manufacturer must be immediately

contacted before use of the machine.

– Also check that any other eventual norms or regulations as laid

down by national or local legislation are taken into account and

applied.

This device is not intended for use by individuals (including chil-

dren) with reduced physical, sensorial or mental capacities, or by

individuals without the required knowledge and experience, unless

said individuals have been instructed on the use of the device and

are duly supervised by a person responsible for their safety.

Children must be monitored to ensure that they do not play with

the device, or use it as though it were a toy.

Access to the service area is allowed only by personnel

that have been specically trained accordingly and that

have acquired practical experience on the devices.

10

Fig. 1.1

Lei700

Lei400

1.0 TECHNICAL CHARACTERISTICS

1.1 Foreseen use

The automatic distributor is exclusively for the dispensing of drinks,

prepared mixing food substances with water (by infusion as far

as concerns espresso coffee).

For this purpose use products declared as suitable by the manu-

facturer for automatic distribution in open containers. The drinks

are made in specic plastic cups automatically dispensed by the

machine. Where foreseen, also the spoon for mixing the sugar is

dispensed.

The drinks must be consumed immediately and in no case are to

be kept for subsequent consumption.

Lei700 Lei400

Height (A) mm 1830 1630

Width (B) mm 666 650

Depth (C) mm 776 770

Weight 140 kg÷190 kg (3) 128

Power Supply V230 - 50Hz / V120 - 60Hz

Installed power (1) 1,8 kW ÷ 3,2 kW 1,8 kW ÷ 3,2 kW

Nominal current (Max) 8 A - 15 A 8 A - 15 A

Water supply 0,5 ÷ 6,5 bar 0,5 ÷ 6,5 bar

AVERAGE CONSUMPTIONS:

IDLE STATE MODE

according to EVA-EMP 110-220 Wh/h 110-220 Wh/h

ENERGY CONSUMPTION

PER LITRE according to EVA-EMP 150-230 Wh/L 150-230 Wh/L

Water supply connection 3/8” gas 3/4” gas

Electrical supply connec. Schuko plug Schuko plug

DISTRIBUTORE BICCHIERI

Diametro bicchieri 70÷74mm 70÷74mm

RESISTENZA CALDAIA

of armoured type: coffee boiler:

1500W

coffee boiler:

1500W

of armoured type: instant boiler:

2000W

instant boiler:

2000W

PRODUCT CONTAINER CAPACITY

Coffee in beans

Double grinder

da 3,8 a 4,5 Kg

Kg 3,5 cad. (x2) Kg 2,5*

Instant coffee Kg 1,4 Kg 1,0

Barley Kg 1,4 Kg 1,25

Powder milk Kg 2,2 Kg 1,70

Creamer Kg 4,0 Kg 3,20

Chocolate Kg 4,8 Kg 3,6

Tea Kg 5,2 Kg 3,30

Frozen-dry tea Kg 2,4 Kg 1,70

Broth Kg 3,8 Kg 3,6

Sugar Kg 5,2 Kg 4,0

Caps N° 700 400

Spoons N° 540 400

Type of light LED LED

A-weighted sound pressure level

A-weighted sound power level

*With assembly of the 3.8 kg extension kit.

(1) Check the rated output indicated on the data plate applied by

the distributor.

(2) According to the requested version and the applicable standards

in the place of use.

(3) According to the version.

11

Fig. 1.2

1.2 KNOWING THE DISTRIBUTOR

Mod. Lei700 (Fig.1.2)

1Coffee group and grinder

2Drink dispensing group

3 Sugar dispenser group

4Payment system

5Cup column

6Electronics board CPU

7Power card

8Spoons column

9 Water softener lter

10 Water bin

11 Dispensing chamber

12 Service button

13 Washing button

12

Fig. 1.3

Mod. Lei400 (Fig.1.3)

1Coffee group and grinder

2Drink dispensing group

3 Sugar dispenser group

4Payment system

5Cup column

6Electronics board CPU

7Power card

8Spoons column

9 Water softener lter

10 Water bin

11 Dispensing chamber

12 Service button

13 Washing button

14 Upper case

13

Fig. 2.1

Fig. 2.2

2.0 TECHNICAL DESCRIPTION OF THE OPERA-

TION

During the normal functioning the distributor is set in standby

status.

Introducing the necessary amount, according to the set price,

and after pressing the key relative to the desired drink, the drink

dispensing cycle is activated and can be divided in to different

processes:

2.1 BASIC PRINCIPLE OF OPERATION

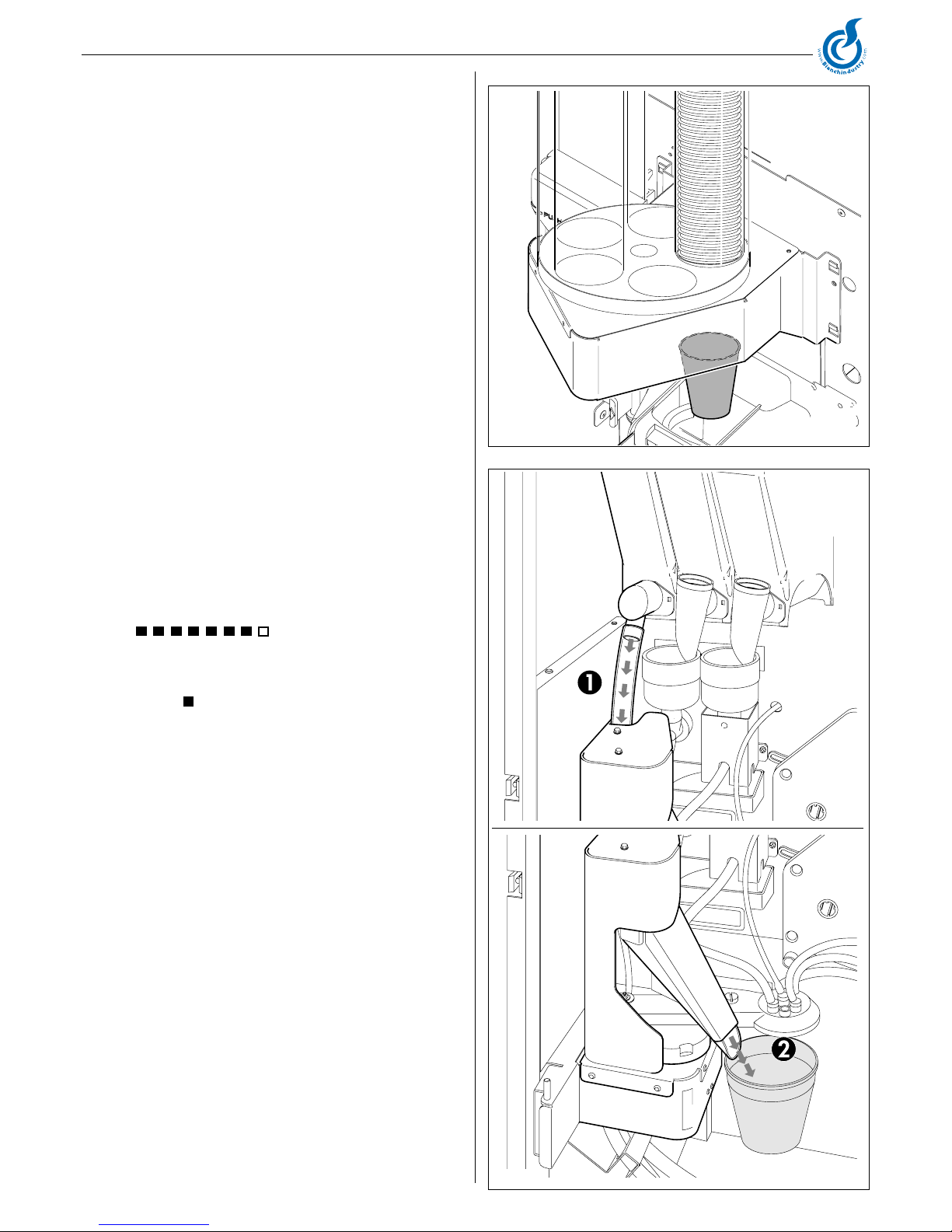

2.1.1 CUP DISPENSING

– It is the rst operation that the distributor starts (except for

the selections with pre-selection “without CUP”).

– the motor inside of the cup dispenser moves the plastic gear

to separate and make the cup fall into the cup ring inside the

cup dispenser (Fig.2.1).

2.1.2 SUGAR DISPENSER

The sugar is dispensed directly in the cup in the E versions whereas

for the I versions it is pre-mixed with the instant drinks.

The display management of the presentation INC+ / DEC- Sugar,

is represented this way:

Line 1: Sugar

Line 2:

Each square is equivalent to x sec of sugar according to the fol-

lowing equation

= (A+B)/8

A = Quantity in seconds of sugar in the standard drink

B = Quantity in seconds of sugar in the preselection +

8 = Maximum number of squares

The dispensing procedure occurs according to the following pha-

ses:

- the geared motor activates the helicoidal screw conveyor of the

sugar product container, dispensing the desired quantity into

the product chutes (Fig.2.2)

14

Fig. 2.4

Fig. 2.3

Fig. 2.5

Fig. 2.6

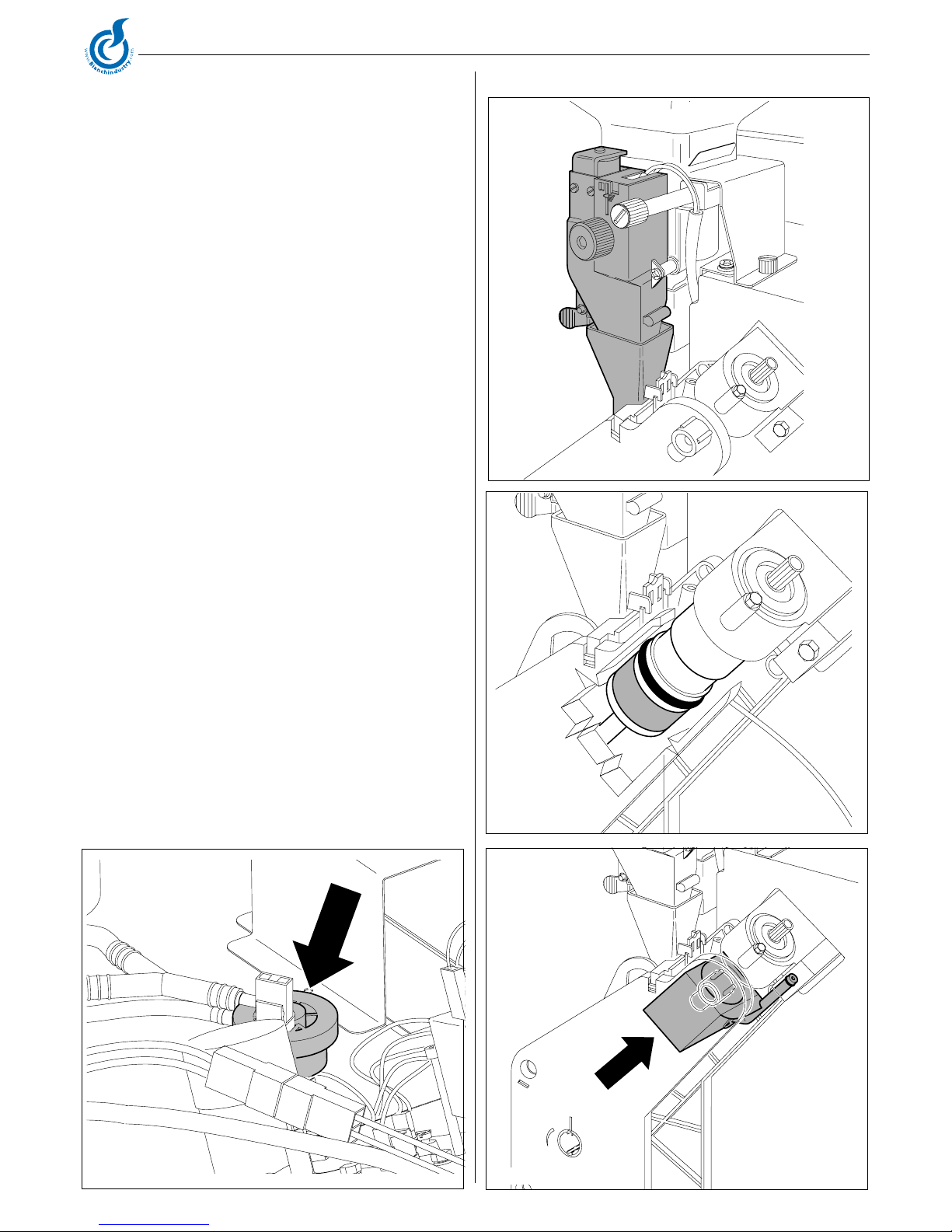

ESPRESSO COFFEE

This process functions only the models equipped with the coffee

espresso group (brass or plastic), after the cup and sugar dispen-

sing processes have been effected.

– the grinder is activated until it reaches the dose of ground coffee

set by the doser (Fig.2.3)

– the doser electromagnet is activated , causing the opening of the

door and consequent fall of the coffee into the brew chamber

– the rotation group geared motor brings it into the dispensing

position and simultaneously compresses the ground coffee

(Fig.2.4 - Fig.2.5).

– the pump that dispenses the quantity of programmed water

and that is controlled by a specic electronic device, (volume

meter), extracting the water from the coffee boiler(Fig.2.6).

– the coffee group geared motor is activated again so as to bring

again into standby position ; during this movement the used

coffee grounds are expelled

The sequence of these operations (grinding and coffee dispensing)

could occur in inverse order according to the type of programme

used.

15

Fig. 2.7

Fig. 2.10

Fig. 2.8 Fig. 2.9

Fig. 2.11

SPOON DISPENSING

This process is activated only in the versions where the spoon

dispenser is foreseen; In these versions it is possible to select

the spoon in the selections without sugar and/ or in the instant

selections.

- the geared motor that operates the spoon release device is

activated making the spoon fall into the cup. (Fig.2.7).

INSTANT DRINKS

This process is activated when the cup and spoon dispensing

processes have been completed.

According to the type drink requested and to the distributor mo-

del, several of the various processes described here below can

be activated.

– If present, the whipper motor is activated (Fig.2.8)

- The electro valve xed on the soup boiler (Fig.2.9) or on the

coffee boiler (Fig.2.10). it is activated to introduce into the

mixer the programmed water quantity.

- The instant product geared motor activates the helicoidal screw conveyor so as to dispense the quantity of product programmed into

the mixer (in some versions several products can be processed in the same mixer such as milk and chocolate) (Fig.2.11)

- Once the preset water and powder quantity has been preset has been supplied, the mixer is disabled after a time (T) set during the

programming.

16

Fig. 3.1

Fig. 3.2 Fig. 3.3

Fig. 3.4

190 kg

3.0 MOVING AN AUTOMATIC VENDING

MACHINE

3.1 Moving and transport (Fig.3.1)

The transport of the distributor must be effected by competent

personnel.

The distributor is delivered on a pallet; for the shifting use a trol-

ley and move it slowly in order to avoid capsizing or dangerous

movements.

Avoid :

– lifting the distributor with ropes or presses

– dragging the distributor

– upset or lay down the distributor during transport

– give jolts to the distributor

Avoid as the distributor:

– bumping it

– overloading it with other packages

– exposing it to rain, to cold or sources of heat

– keeping it in damp places

The construction company is not liable for any damage which

may be caused for the partial or complete non-observance of the

warning notices indicated above.

3.2 Stocking

For eventual stocking, avoid laying several machines over each

other, maintain it in vertical position, in dry places with tempera-

tures not inferior to 1°C (Fig.3.2).

3.3 Packing

The distributor is protected with polystyrene angles and by a

transparent lm in polypropylene (Fig.3.2).

The automatic distributor will be delivered packed, assuring both

a mechanical protection and protection against damages from

the external environment.

On the package labels are applied indicating:

maneouver with care

don’t turn upside-down

protect from the rain

don’t superimpose

protect from sources of heat

not resistant against bumps

type of distributor and serial number.

3.4 Reception

Upon reception of the automatic distributor you need to check that

the same has not suffered damages during the transport.

If damages of any nature are noticed place a claim with the

forwarder immediately.

At the end of the transport the packing must result without

damages which means it must not :

– present dents, signs of bumps, deformations or damages of the

external packaging

– present wet zones or signs that could lead to suppose that the

packing has been exposed to rain, cold or heat.

– present signs of tampering

3.5 Unpacking

- Free the distributor from the packaging , cutting the protective

lm in which it is wrapped, along one of the protection angles

(Fig.3.3).

- Remove the distributor from transport pallet, unscrewing the

screws (A) that block the xing cross staff heads to the pallet

(Fig.3.4).

17

Fig. 3.6

Fig. 3.7 Fig. 3.8

Fig. 3.5

– Release the pallet and insert the 4 feet into the threaded slots

(g. 3.5) freed of the screws (A)

– remove the key from the drink dispensing chamber (Fig.3.6)

Open the door of the distributor and remove the adhesive tape

from the components listed here below:

cup turret (example in Fig.3.7)

coin box

sugar container

weight on the spoon dispenser column

coin mechanism cover / Master board

product containers

water bin oat mechanism

bottom skirting-board

water bin

remove the polystyrene that that blocks the product containers

(Fig.3.8)

The packing material must not be left accessible to others,

as it is a potential environmental pollution sources. For the

disposal contact qualied companies authorized.

18

Fig. 4.3

Fig. 4.1

Fig. 4.2

4.0 INSTALLATION

4.1 Positioning

– If positioned near to a wall, there must be a minimum distance

from the wall of at least 5 cm. (Fig.4.1) so as to allow a regu-

lar ventilation. In no case cover the distributor with cloths or

similar.

- For safety reasons we recommend use of the lock-on brackets

(Fig. 4.2)

– Position the distributor, checking the leveling by means of the

adjustable feet already assembled on the machines (Fig.4.3).

make sure that the distributor doesn’t have an inclination of

more than 2 degrees.

WARNING! Do not position the device near inammable

objects, keep a minimum safety distance of 30 cm.

Bianchi Vending Group spa declines all responsibility for in-

conveniences due to the non observance of the above mentioned

installation norms.

If the installation is made in safety evacuation corridors make

sure that with the distributor door open there is anyhow sufcient

space to pass by (Fig.4.1).

So as to avoid that the oor gets dirty, due to accidental spilling of

the products, use, if necessary, under the distributor, a protection

sufciently wide to cover the distributors’ operating space.

19

Fig. 4.8

Fig. 4.9

Fig. 4.6 Fig. 4.7

Fig. 4.4 Fig. 4.5

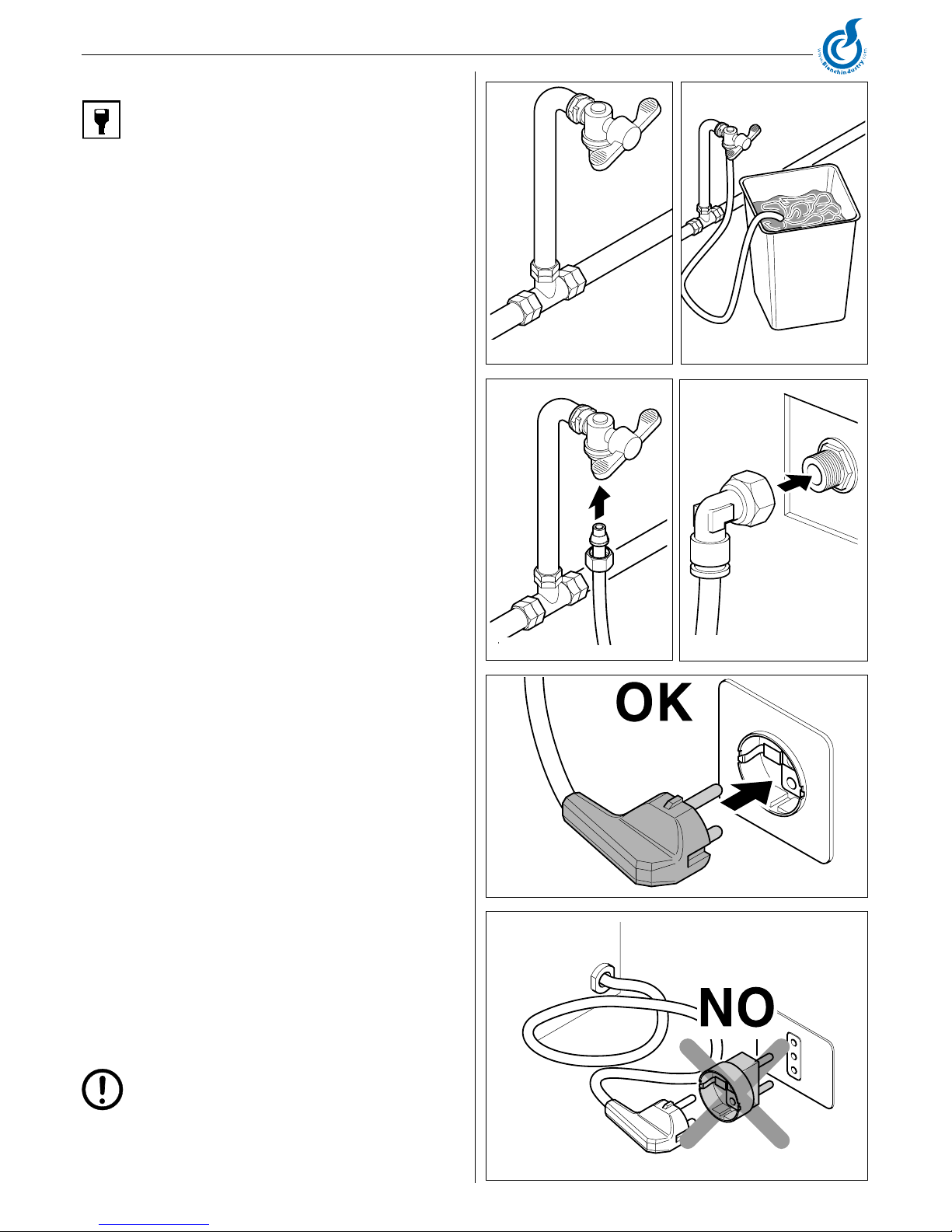

4.3 Main Power supply connection

The distributor is predisposed to function with mono-phase 230

Volt tension and is protected with 12,5A and 20A fuses. (10A and

20A for the single boiler and instant versions and 15A and 20A for

the instant hot/cold version).

We suggest to check that:

– the tension of net of 230 V doesn’t have a difference of more

than ± 6%

– The power supply output is able to bear the power load of the

machine.

– use a system of diversied protection

– position the machine in such a way as to ensure that the plug

remains accessible

The machine must be connected to earth in observance with the

current safety norms.

For this reason, verify the plant’s earth wire connection to ascertain

that it is efcient and it answers national and European safety

electric standards. If necessary require the intervention qualied

personnel for the verication of the plant.

– The distributor is equipped with a power supply cable of H05VV-

F 3x1,5mm², with SCHUKO plug (Fig.4.8).

– The sockets that are not compatible with that of the machine

must be replaced. (Fig.4.9).

– The use of extension, adapters and/ or multiple plugs is forbid-

den.

– In some models, specic plugs are assembled for the destination

place.

Bianchi Vending Group spa declines all responsibility for dama-

ges deriving for the complete or partial failure to observe these

warnings.

Should the power cable be found to be damaged, immediately

disconnect from the power socket.

The power supply cables are to be replaced by skil-

led personnel.

4.2 Connection to the main water supply

Before proceeding with the connection of the distributor to the

water main supply verify the following water characteristics:

– that it is drinkable (eventually through an laboratory’s analysis

certication)

– it has a pressure comprised between 0.5 and 6.5 (bar) ( if this

should not be the case, use a pump or a water pressure, reducer

according to the case).

– install, if not present, a tap in an accessible position to isolate

the machine from the water mains should it be found to be

necessary (Fig.4.4).

– before making water connections, make some water ow out

of the tap so as to eliminate possible traces of impurities and

dirt (Fig.4.5)

– connect the cock to the distributor, using a pipe in nylon material

suitable for food products and suitable for the mains pressure.

In the event of the use of a exible pipe it is necessary to t

the reinforcement bush supplied inside (Fig. 4.6).

– the foreseen connection is a 3/ 8 gas (Fig.4.7).

20

Fig. 4.10

Fig. 4.11

Fig. 4.12 Fig. 4.13

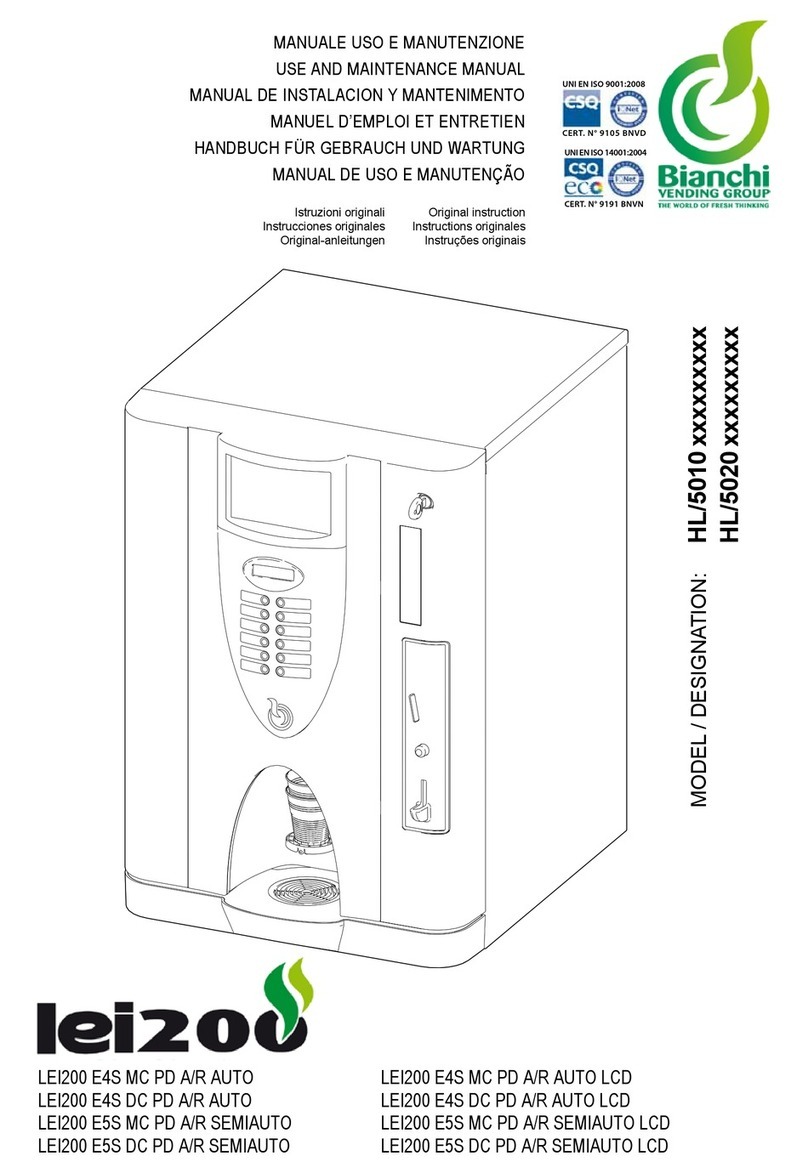

4.4 Starting up of the unit

The distributor is equipped with a safety switch (Fig.4.10) that

disconnects the machine whenever the door is opened ( see

electric schema).

In case of necessity, therefore, open the door or disconnect unplug-

ging of the machine from the power supply.

The clamp of the power cable junction box remain

under tension (Fig.4.11-pos.1) as well as the servi-

ce switch inside the distributor. (Fig.4.12-pos.2).

– For some operations is however necessary operate with the

door open but with the distributor connected.

It is possible for installation technician, to operate in this way,

by inserting the special plastic key, supplied with the distributor,

into the door switch and rotating it 90° (Fig.4.13-pos.3).

The opening and the possible connection with the distri-

butor’s door open must be performed only by authorized

in carrying out these operations.

Don’t leave the distributor open and unguarded.

Give the key only to qualied personnel.

Any time the distributor is switched on there is a diagnosis cycle

to check the state of DA peripherals and perform the restoration

of moving parts.

This manual suits for next models

1

Table of contents

Other BIANCHI VENDING Coffee Maker manuals

BIANCHI VENDING

BIANCHI VENDING LEI200 E4S MC PD A/R AUTO User manual

BIANCHI VENDING

BIANCHI VENDING SOFIA ESPRESSO User manual

BIANCHI VENDING

BIANCHI VENDING SOFIA ESPRESSO User manual

BIANCHI VENDING

BIANCHI VENDING BVM 901 LEISA User manual

BIANCHI VENDING

BIANCHI VENDING EP 4100 BIANCHI M User manual

BIANCHI VENDING

BIANCHI VENDING Lucia 2 Groups User manual

BIANCHI VENDING

BIANCHI VENDING BVM 333 User manual