3

VEGA

1.0 PREMISE

1.1 Important notices

This au oma ic dis ribu or has been designed and cons ruc ed in

full accordance wi h curren safe y regula ions and is herefore

safe for hose who follow he ordinary filling and cleaning

ins ruc ions as indica ed in his manual.

The user must not under an circumstances remove the

guards that require a tool for removal.

Some main enance opera ions ( o be done solely by specialized

echnicians and indica ed in his manual wi h a special symbol)

require ha specific safe y pro ec ions of he machine mus be

swi ched off .

In accordance wi h he curren safe y regula ions, cer ain

opera ions are he exclusive responsibili y of he ins alla ion

echnician, and he ordinary main enance echnician may have

access o specific opera ions on wi h specific au horiza ion.

The acquain ance and absolu e respec , from a echnical poin of

view, of he safe y ins ruc ions and of he danger no ices con ained

in his manual, are fundamen al for he execu ion, in condi ions

of minimum risk, for he ins alla ion, use and main enance of

his machine.

1.2 General Instru tions

Knowledge of the information and instructions contained in the

present manual is essential for a correct use of the automatic

vending machine on the part of the user .

Interventions b the user on the automatic vending machine

are allowed onl if the are of his competence and if he has

been dul trained.

The installation technician must be full acquainted with all

the mechanisms necessar for the correct operation of the

machine.

It is the bu ers responsibilit to ascertain that the users have

been trained and are informed and regulations indicated in

the technical documentation supplied.

Despite the full observance of the safet regulations b the

constructor, those who operate on the automatic dispensers

must be full aware of the potential risks involved in operations

on the machine.

This manual is an integral part of the equipment and as such

must alwa s remain inside of the same, so as to allow further

consultations on the part of the various operators, until the

dismantlement and/or scrapping of the machine.

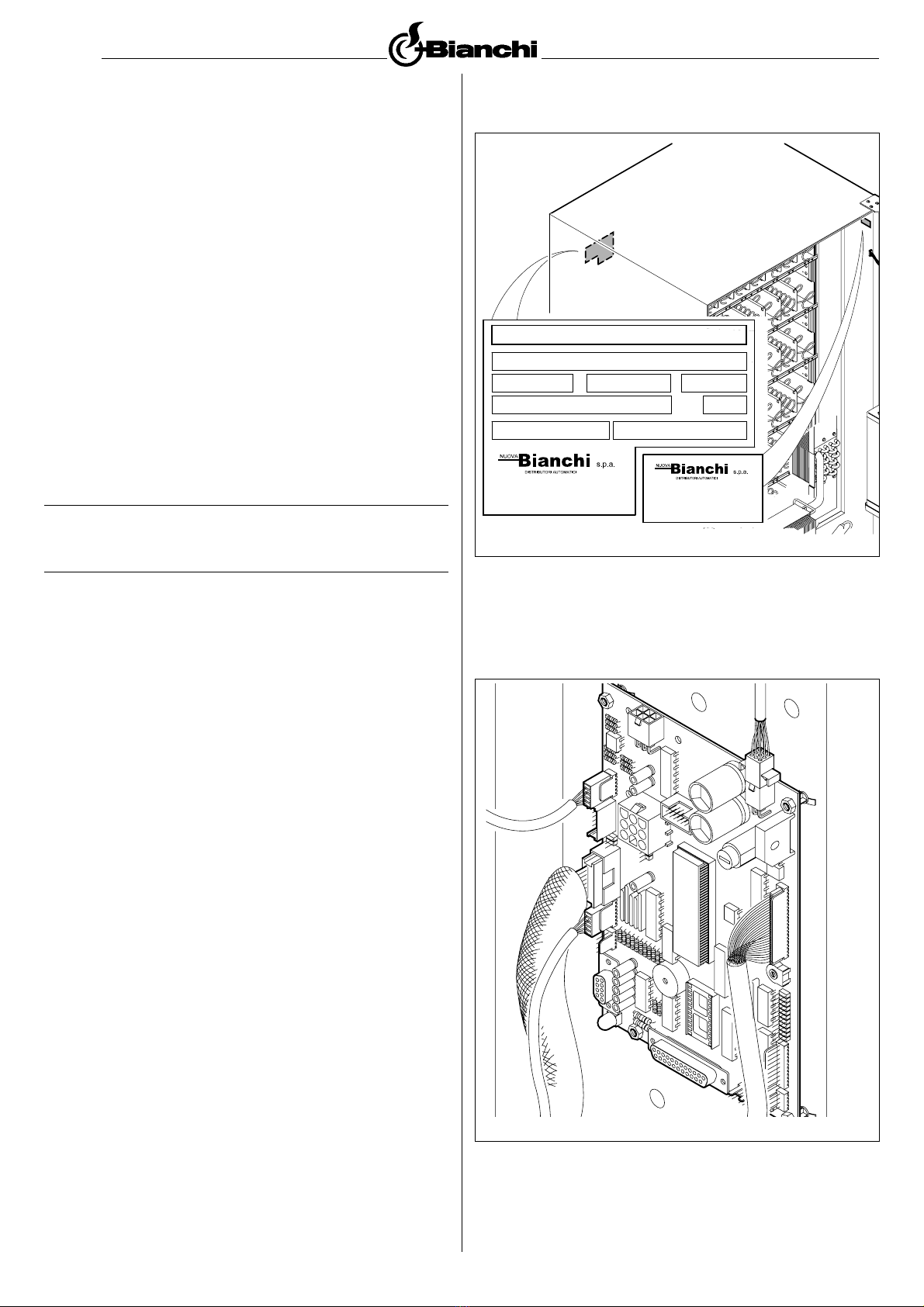

In case of loss or damage of the present manual it is possible

receive a new cop making application to the manufacturer,

with prior indication of the data registered on machines serial

number.

The functional reliabilit and optimization of machines services

are guaranteed onl if original parts are used.

Modifications to the machine not previousl agreed on with the

construction compan and undertaken b the installation

technician and/or manager, are considered to be under his

entire responsibilit .

INDEX

1.0 PREMISE

1.1 User ins ruc ions

1.2 General Ins ruc ions

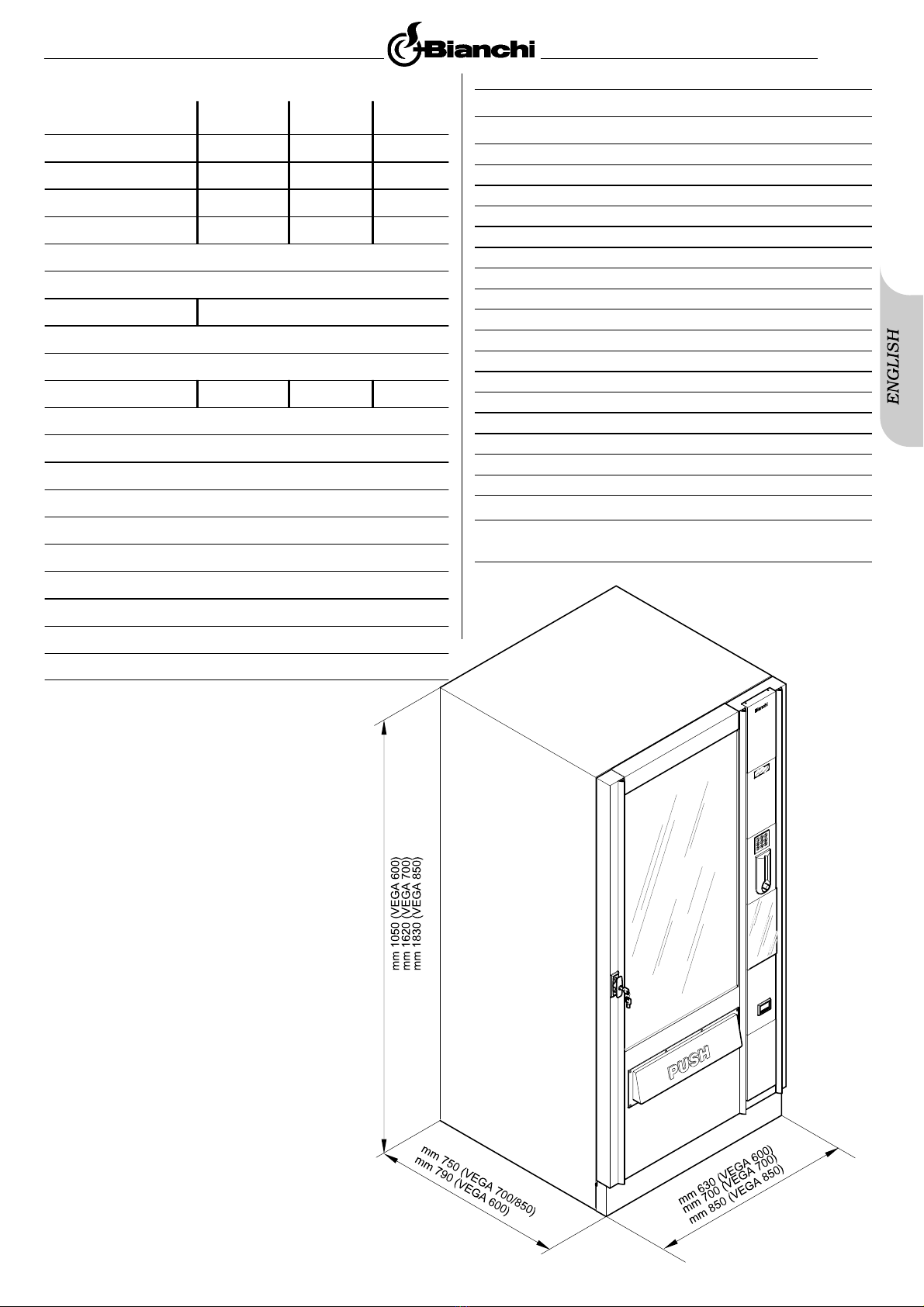

2.0 TECHNICAL CHARACTERISTICS

3.0 DESCRIPTION OF THE MACHINES TECHNICAL

CHARACTERISTICS

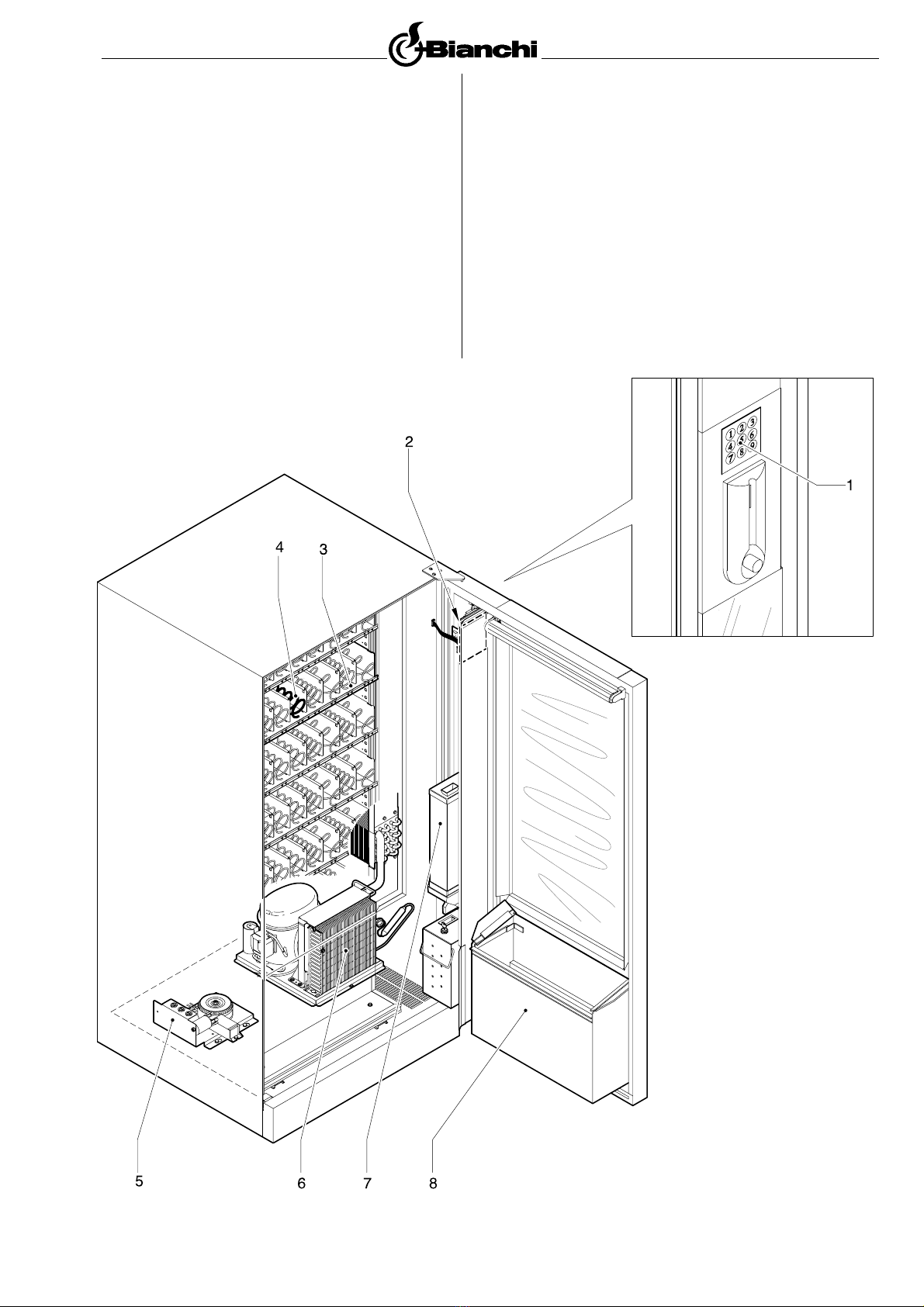

3.1 Descrip ion of he machine

3.2 Scheduled Use

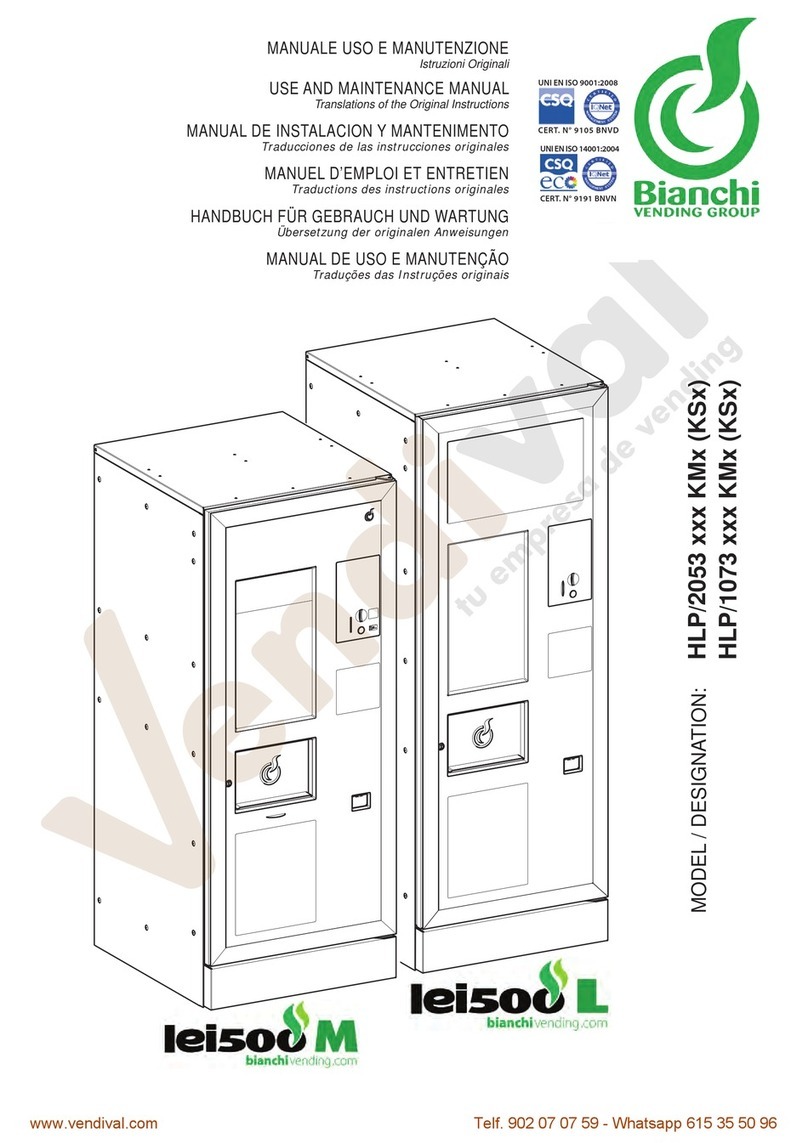

3.3 Models

3.4 Basic ins ruc ions for he machine opera ion

4.0 TRANSPORTING THE AUTOMATIC VENDING

MACHINE

4.1 Moving and Transpor

4.2 S ocking

4.3 Packing

4.4 Recep ion

4.5 Unpacking

5.0 SAFETY RULES

6.0 INSTALLATION

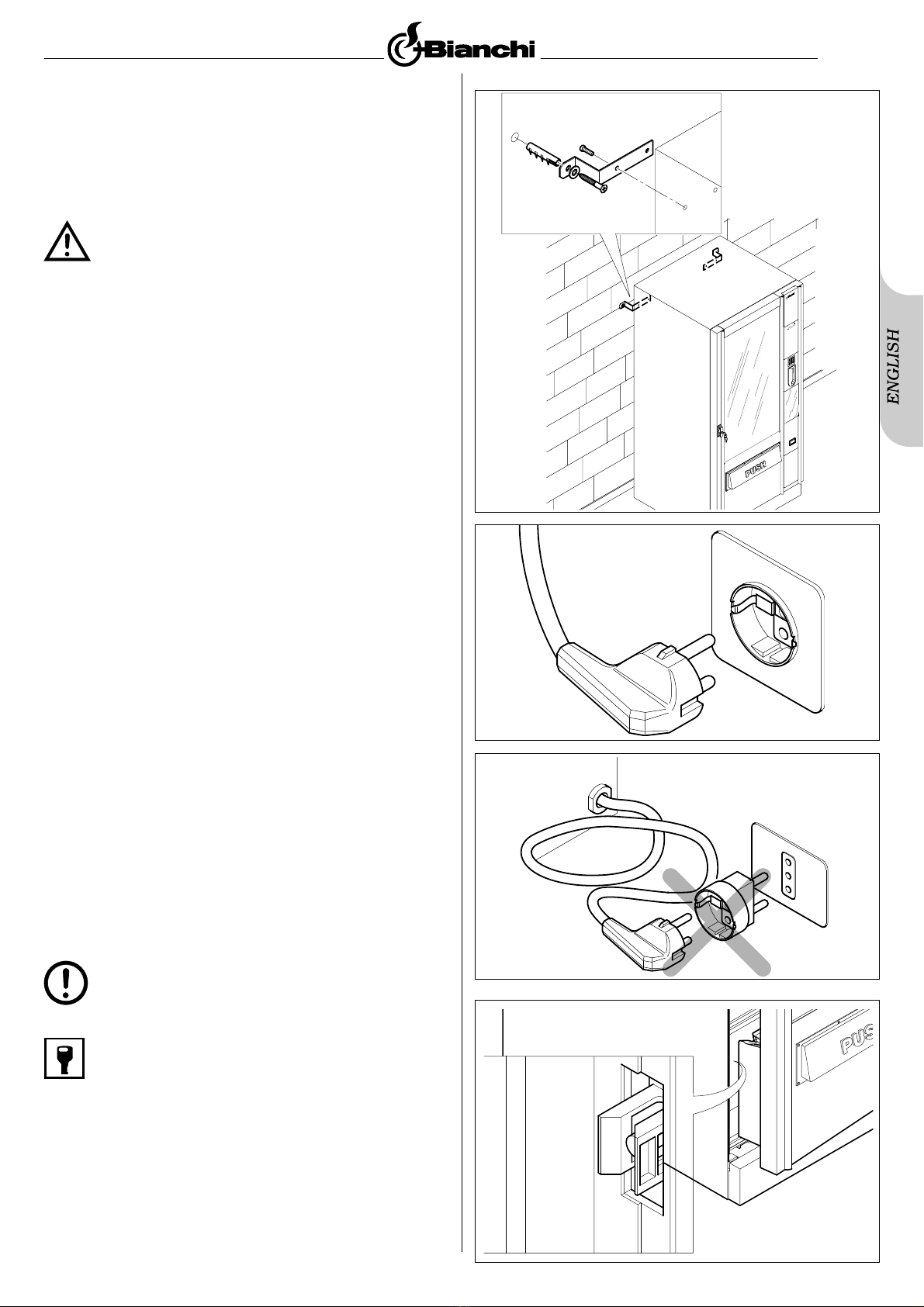

6.1 Posi ioning

6.2 Power supply connec ion

6.3 Machine s ar ing up

6.4 Produc loading

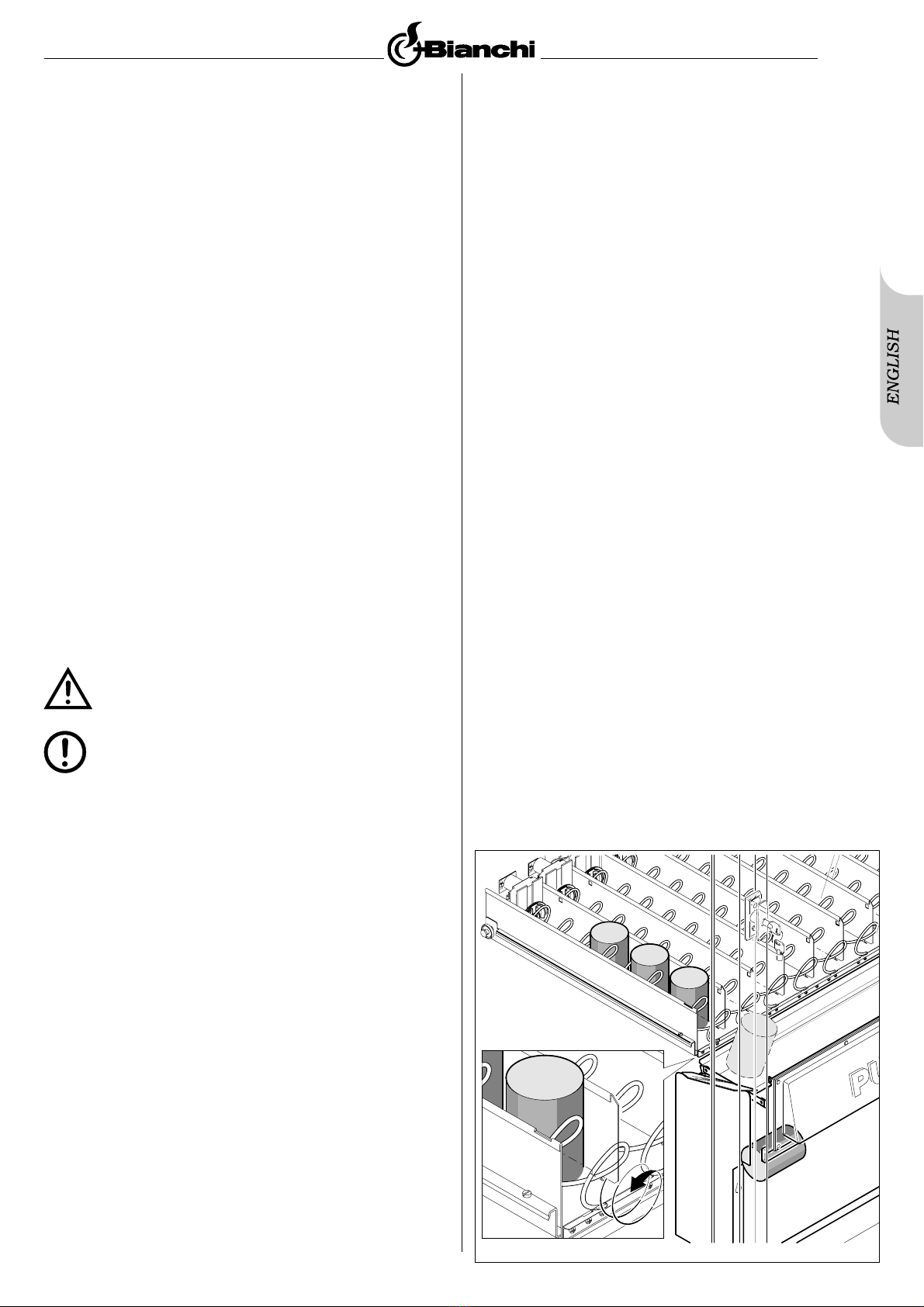

6.4.1 Drawer loading

6.4.2 Label applica ion

6.4.3 Pa ment s stem installation

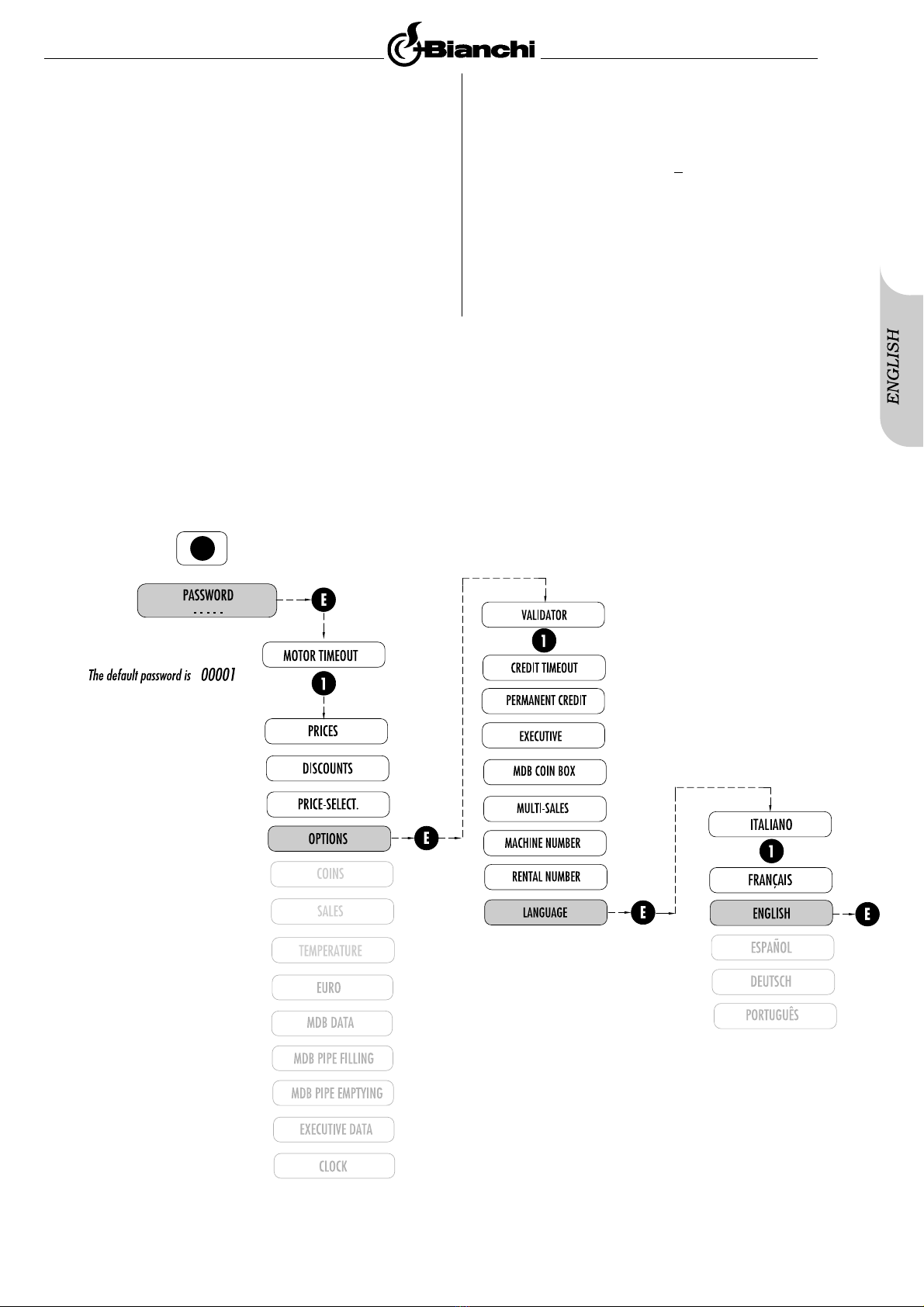

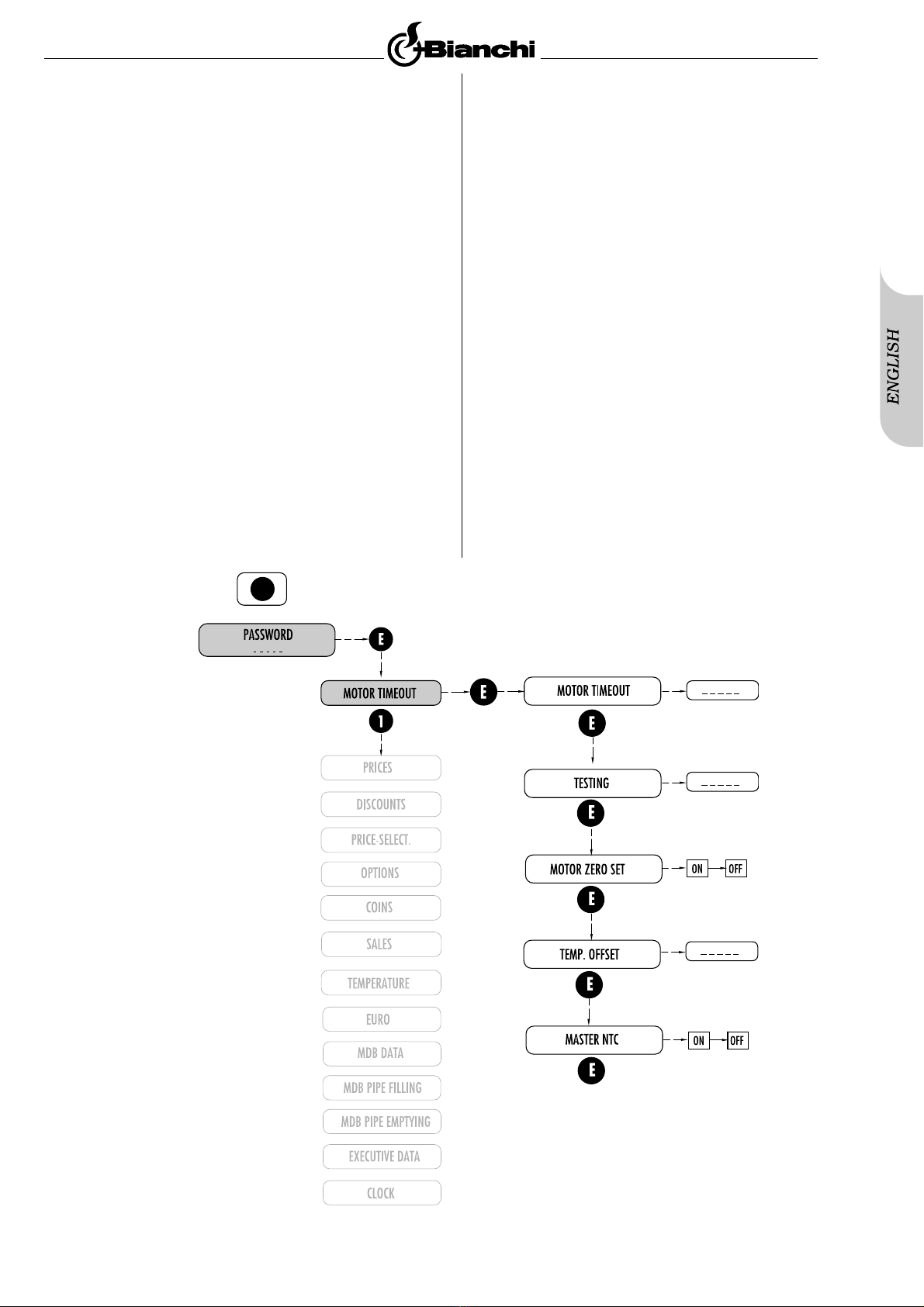

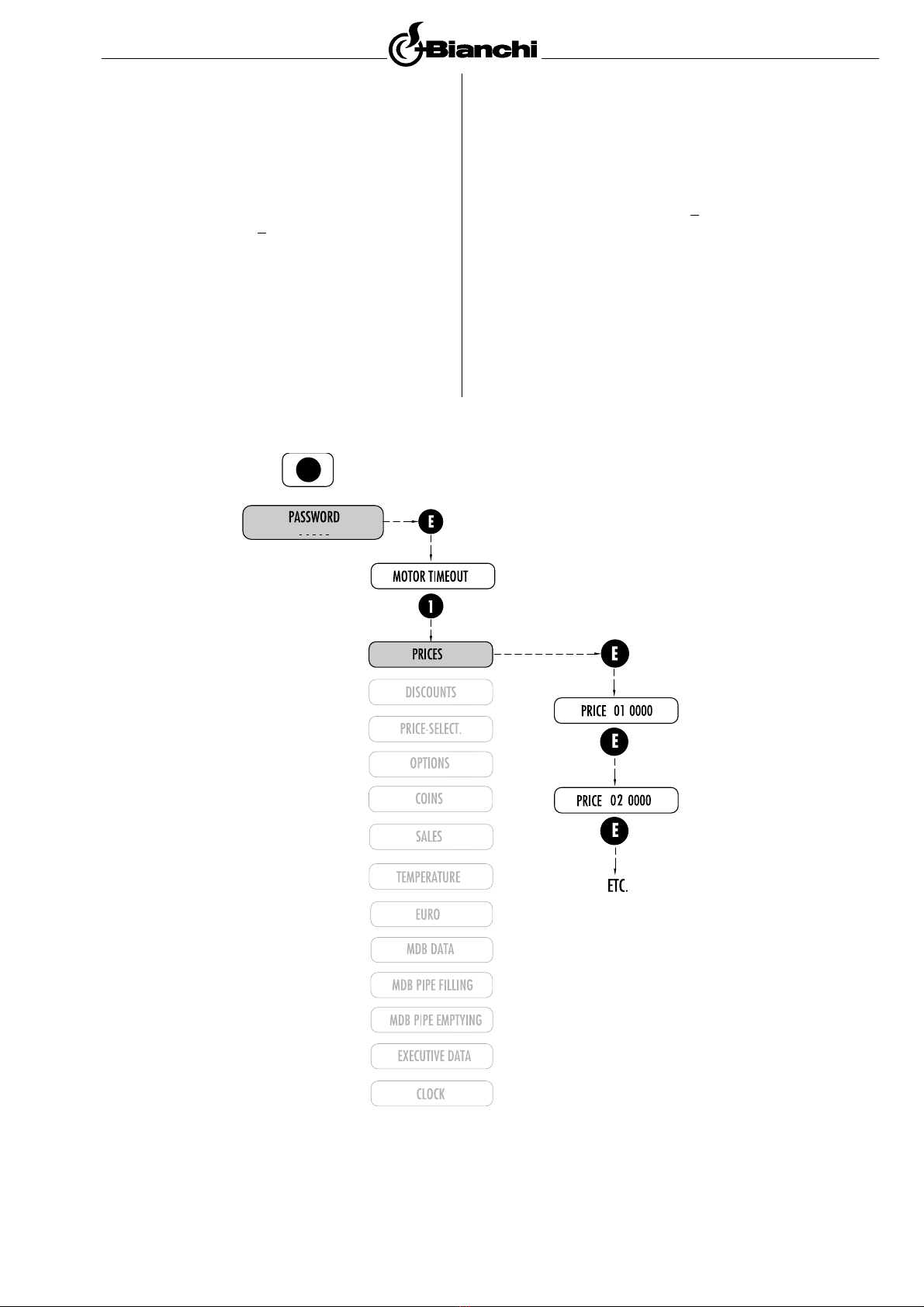

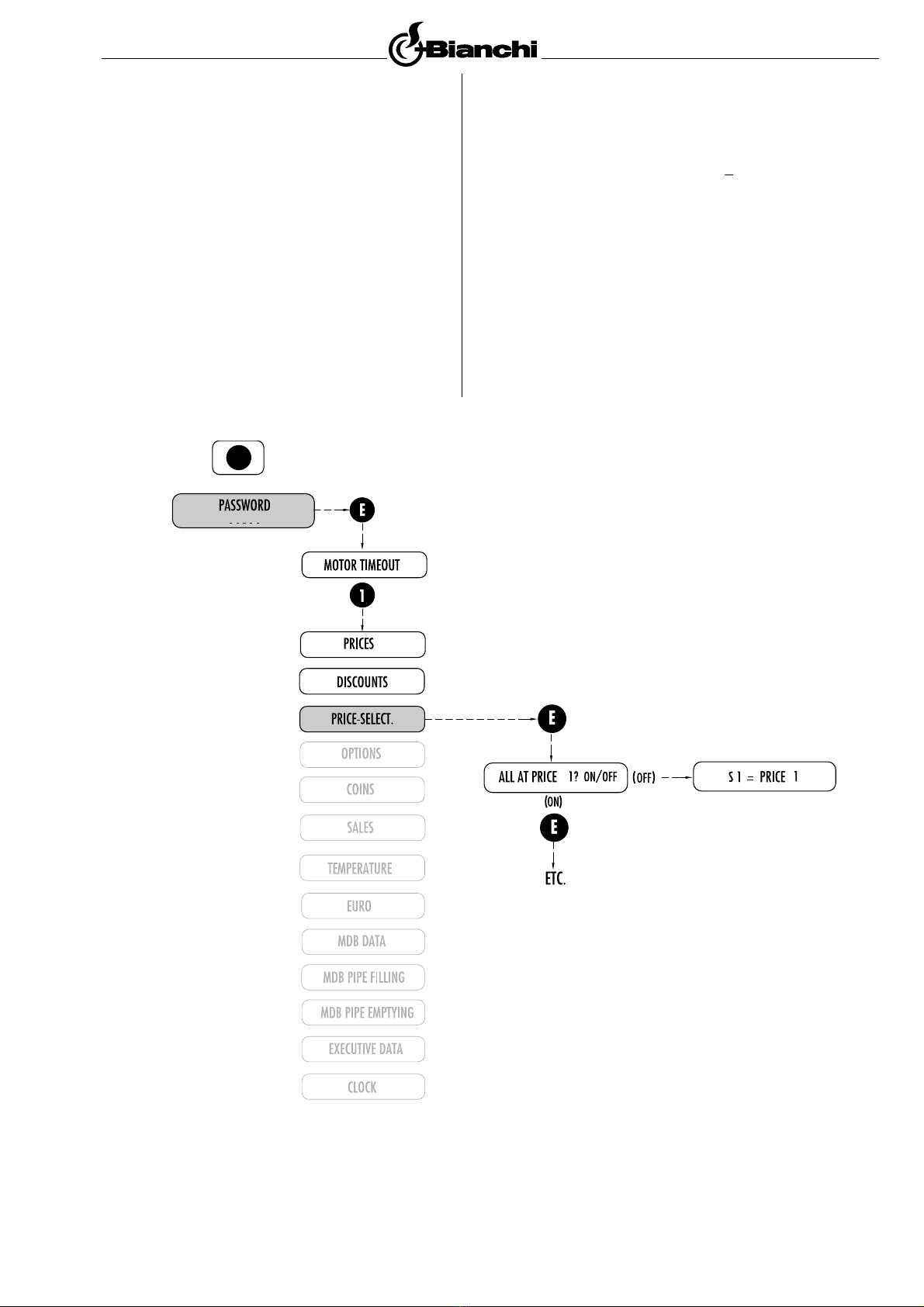

7.0 PROGRAMMING

7.1 General descrip ion and preliminary opera ions

7.2 Func ion descrip ion

8.0 SERVICE

9.0 MAINTENANCE AND INACTIVITY

9.1 Cleaning and loading

9.1.1 Procedure for distributor cleaning

9.1.2 Periodic cleaning b the maintenance

technician

9.1.3 Cleaning and maintenance

9.1.4 Product loading

9.1.6 Product storage advice

9.1.6 Ordinar and Extraordinar Maintenance

9.2 Adjus men s

9.2.1 Spirals

9.2.2 Spiral replacemen

9.2.3 Change he number of spirals per drawer

9.2.4 Change heigh be ween drawers

9.2.5 Accessories

9.3 Neon ligh replacemen

9.4 Inac ivi y

10.0 COMBINATION WITH HOT DRINK DISTRIBUTOR

10.1 Technical fea ures of LUX 700 model

(combined wi h An ares model)

10.2 Descrip ion of he machine

10.3 Connec ion for Mas er/Slave func ion

(Combined wi h An ares model)

10.4 Technical fea ures of Vega 600 model

(combined wi h Pegaso model)

10.5 Descrip ion of he machine

10.6 Connec ion for he Mas er/slave func ion

(Combined wi h Pegaso mod.)

11.0 DISMANTLEMENT

12.0 TROUBLESHOOTING GUIDE FOR THE FAILURES

OR MOST COMMON ERRORS