Revision 2012.02.27

8

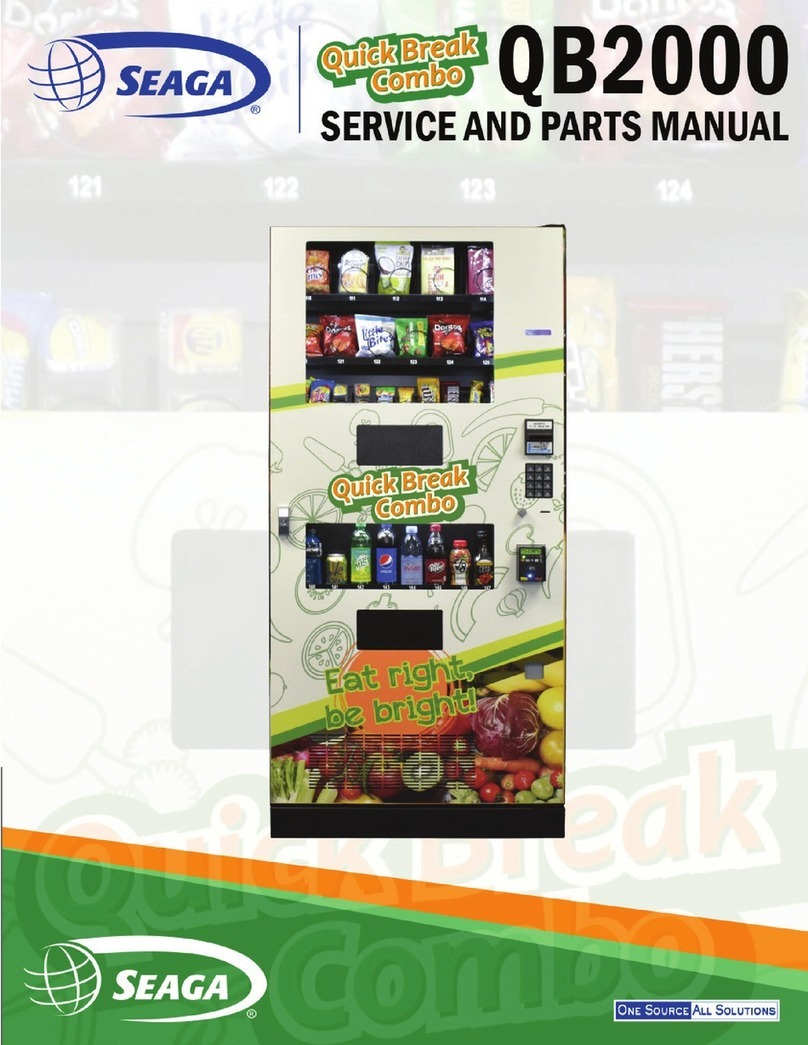

LOADING PRODUCTS

To present your product in as an attractive and professional manner as possible, do not load any damaged items, and

make sure items are facing forward for easy identification by your customer.

Note: The size of the item being vended must be larger than the Helix Coil, but smaller than the Product Chute, to vend

correctly. Never force an oversized item into the Helix Coil or Product Chute, nor attempt to vend an item that is smaller

than the Helix Coil as this will create problems and deter customers. (Fig.1)

1. To Load Product:

A.) Use the release latches and pull the desired Product Tray all of the way

forward. Product Tray will tilt down or can be removed and placed on the floor or a table.

Note: Pull out only one (1) Product Tray at a time.

B.) Place product in proper size Helix Coil. Note: Bottom of product must

rest on the Product Tray and not on the Helix Coil. (Fig. 12) Load each

Product Chute from front to back. Note: Do not leave any spaces between items.

C.) Once Product Tray is loaded, lift the front of the tray to level and push it

back in. Repeat above steps until all Product Trays are fully loaded.

D.) After loading the product, if you have removed the tray to do so, place the

Tray in the cabinet by aligning the wheels in the guide rails. Clear the wire harness

To the side so that it is not interfering with the tray below.

To increase the length of the Helix Coil, white plastic Product Pushers can be snapped on the end. A supply of Product

Pushers are provided in the vendors hardware bag.

Special Note: We suggest that you always partially fill the vendor with product and perform at least five (5) test vends.

Test vends can be performed easily by entering Service Mode and running "Individual Motor Testing". (See: Keypad and

LED Display, Individual Motor Testing.)

Fig. 5

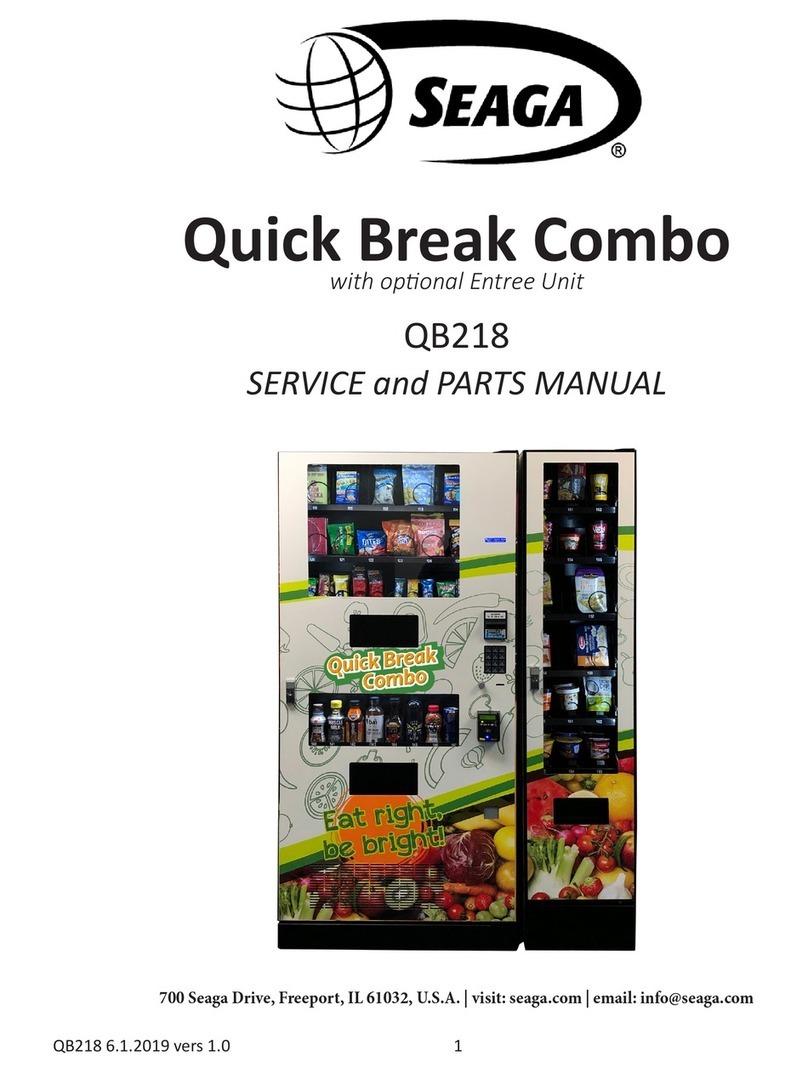

PRODUCT PUSHERS

Product pushers assist in moving the top of the product forward while it is being vended on the bottom, helping it fall

smoothly from the shelf. Product pushers are also good for products that have the wrapper flaps on the ends of the

package. Packaging such as this benefits from the extra momentum from the product pushers to keep the flaps from

hanging up the product on the spiral. The pusher is installed approximately 15mm from the front end of the coil with the

tab extending forward (see Fig. 6). Locate the pusher in its proper position, hold it against the coil wire and push the semi-

circular part around the coil wire. Note: Boxed items will not need a product pusher.

Figure 6 – Product Pusher Installation

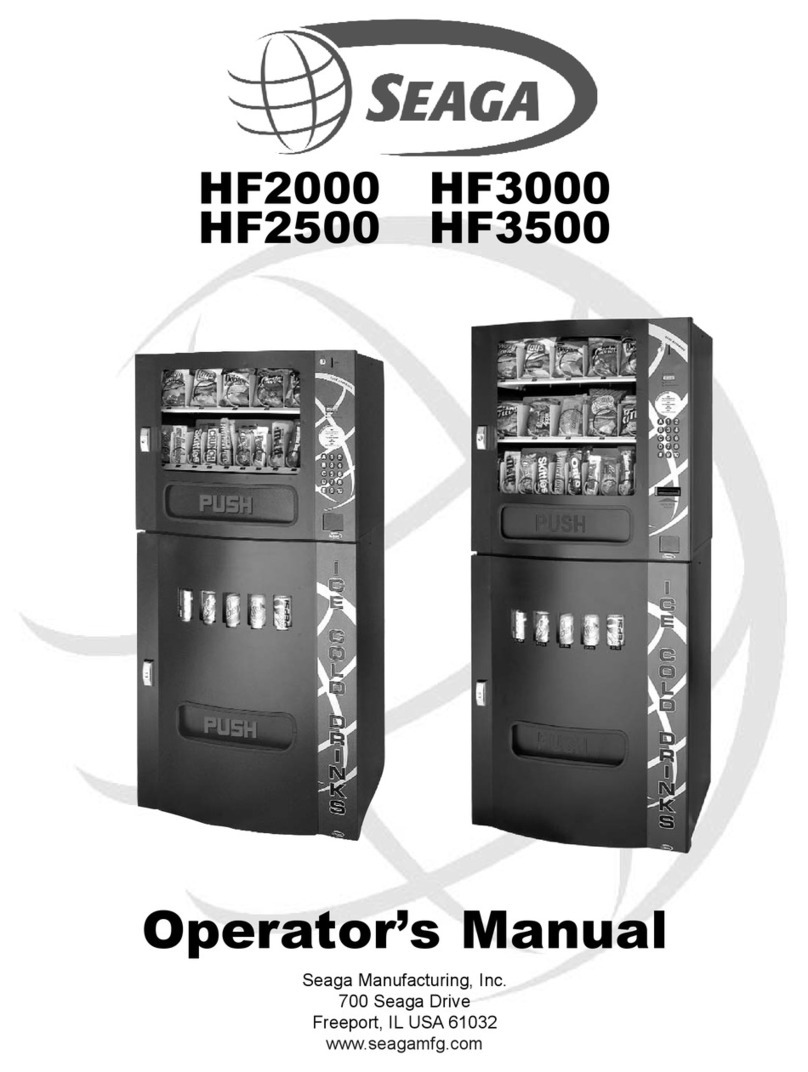

Correct – load

product

between Helix

Coils, resting

on the product

tray.

Helix Coil

Product Tray

Columns

Incorrect