Elektral Tru-VEND Midi-Kafe Specification sheet

2

Contents Page

INTRODUCTION.............................................................................................3

OPERATION AND SAFETY WARNINGS......................................................4

1 - GENERAL DESCRIPTION........................................................................6

2 - MAIN UNITS .............................................................................................7

3 - TECHNICAL SPECIFICATIONS............................................................. 13

4 - INSTALLATION AND CLEANING ......................................................... 13

5 - PRODUCT LOADING AND INITIAL OPERATION................................ 15

6 - PROGRAMMING................................................................................... 15

7 –OPTIONAL PARTS............................................................................... 21

8 –MAINTENANCE AND REPAIR............................................................ 12

9 - MENU TREE .......................................................................................... 22

10 - SERVICE CENTRE AND CERTIFICATE OF WARRANTY ................. 24

3

INTRODUCTION

Dear User,

Thank you for purchasing the Midi-Cafe® vending machine, a product manufactured by

ELEKTRAL. As a company developing integrated production, our quality certified production

has continued since 1978 based on high technology. This integration can be broadly

described as R&D, Electronics, Electromechanics, Production Lines, Mechanics Workshop,

Moulding Workshop, Plastic Injection and Vacuum Forming Group. With T.R. State Planning

Organization's various incentives, the factory has reached an approximately 20,000 m2

production area with the capability of making many electronic machines and components for

professional use. Most of our machines have been produced for the first time in our

fatherland. Starting with Germany, our company is technologically cooperating in terms of

production, representation and OEM production with the sector’s leading companies from

UAE, Bulgaria, India, Great Britain, Iran, Israel etc. We have direct or indirect exports to

countries in Europe, Asia, America, Africa. Furthermore, to expand our direct sale markets in

foreign countries our intensive works and exhibition activities continue uninterruptedly. As a

result of our rapidly growing export potential, our company has been awarded with a first

place prize in 2004, during "Rising stars of e-commerce in Turkey" competition. The same

year we were awarded with the “25’th Anniversary Award of EBSO (Aegean Area Chamber of

Industry), “The Chamber of Industry, Innovation, Employment” with continuous R&D

projects being supported by TUBITAK (Turkish Scientific Research Council). In 2011 Istanbul

Chamber of Industry has chosen our company as "INNOVATION FINALISTS". In the year

2012, with its innovative Vending Machine project, Elektral has been awarded as a “TET

(Turkish Electro Technology) R&D Project Market Finalist” by the Ministry of Economy,

Turkish Export Assembly and IMMIB (Istanbul Mining and Metal Exporters Union). Another

award won by Elektral is “The year 2013 First Rank in Innovation” organised by IAOSB (Izmir

Ataturk Industrial Zone)-Ege University. Believing that real growth target is to be achieved

with a global industrial understanding and a global move, Elektral is motivating all its

employees with this understanding and continues rapidly with an intensive R&D work to

reach determined goals.

Tru-VEND® vending machines have been designed and produced to provide more spare

time to its owners. They ease your life in various situations with multipurpose and practical

use. Our products provide you profit and comfort for 24 hours continuously, loyal to the

owner, with no employee costs. Please note that as for all industrial machines, its

necessary to periodically check and maintain your machine. Please use the machine as

recommended in this manual.

Elektral Products are produced in environmental friendly facilities,

causing no harm to the nature and living creatures.

Made in Turkey

Alteration rights reserved

No claims can be accepted by our firm regarding the

applications of this instrument from the second or third

parties.

All rights Reserved

4

OPERATION AND SAFETY WARNINGS

Procedures & Safety Warnings before using the Midi-Kafe®

Technical specifications of Midi-Kafe®

Installation of the Midi-Kafe®

Programming and related procedures Midi-Kafe®

The arrow-end lightning symbol inside the

equilateral triangle informs that there is high

amount of ‘un-insulated’ dangerous voltage to

cause an electric shock inside the product.

The exclamation mark inside the equilateral

triangle informs the user that there are important

instructions of usage and information inside the

booklets given with the equipment.

5

Midi-Kafe®Pre use, to do list and safety warnings

Do not wet the Midi-Kafe®machine. Always unplug from the

electricity plug before proceeding and use only a damp cloth (not wet)

to clean the vending Machine.

This is an electrical machine and there is a risk of electricity shock. Only

authorized, qualified and well informed personnel may operate and

service the machine.

Use the vending machine on Earthed Electrical Supply only.

Please carefully read the articles where you see this Warning Sign in

the User’s Manual.

Midi-Kafe® is designed to operate between given electrical voltage

limitations only. 220 (±%10) VAC / 50 Hz

WARNING: Please follow the instructions given in the User’s Manual.

Incorrect usage can cause damage to the Vending Machine and/or

humans and the environment.

6

1. GENERAL DESCRIPTION

The Vending Machine that you have chosen has been produced by our factory using high

technology systems in parallel with other developing technologies and modern aesthetic

design providing versatile usage. Tru-VEND® Vending Machines can be used in all public

areas such as hotels, factories, hospitals, restaurants, clinics, cinemas, bus terminals, gas

stations, doctor & lawyer offices, malls, etc. Backwards traceability is also possible on the

performed machine modifications by the serial number on each machine.

International norms, in conformity with CE Norms and produced under ISO 9001: 2008

QMS.

All components are made of ROHS compliant Human Health Friendly production

materials.

10 Direct selection different hot drinks dispense ability

32-bit high performance ARM processor

6 levels sugar adjustment ability (No Sugar 0, Very Little 1,

Little 2, Medium 3, High 4, Plenty 5)

6 ingredient canisters with mixers (Coffee, Milk Powder,

Chocolate, Fruit Tea/Salep, Sugar, Tea)

4 mixers with special insertion mixer motors

Practical design allowing easy maintenance

LED illuminated polycarbonate sheet robust active

advertisement space

MDB, EVA DTS protocols compliant

Optional MDB Coins Payment System and Cashless

Payment System (Contactless Cards/Tokens)

LED backlit touch-sensitive keypad

Special frothy Turkish Coffee dispense feature

Protected with two fuses and door open switch off high

protection

Special design 2 arms automatic cup dispenser mechanism

with 230 cups capacity

Long-lasting Components designed specifically to prevent

calcification.

Powerful pump used for water suction (from carboy),

Insulated, thermostat protected, 4.5 L capacity boiler

Special design resistance for 220 VAC ~ 1800W heating

Metal trunk surface is done using galvanise surface

covering method and painted to obtain a robust and long

lasting physical design

900 x 520 x 520 mm dimensions, aesthetic design

55 kg approximate weight

Stock shelve, 2 carboys and a rubbish bin capacity in the

optional base stand

2 Years Manufacturers Warranty, 10 years parts supply & After Sales Services

Easy program installation with USB cloning, download option & log receiving.

Note: Visual representation of the bought machine may vary

7

2. MAIN UNITS

Figure 1: Front View

7- TOUCH

KEYPAD

6- LCD DISPLAY

9-HINGE

10-WASTE WATER

TRAY

8- COINS

PAYMENT

SYSTEM

3- PRODUCT

DISPENSE HOLE

11-ADJUSTABLE

CABINET FOOT

2- LED

ILLUMINATED

SHOWCASE

5-HINGE

4-LOWER LOCK

1- UPPER LOCK

8

Figure 2: Rare view of the front door

17-CUP SINK

16-CUP

DISPENSER

13-METAL

COVER

14-IR CUP SENSOR

12- PCB

15-COINS

PAYMENT

SYSTEM

9

Figure 3: Product Canisters

21-FRUIT

TEA/SALEP

22- SUGAR

23- TEA

20-CHOCOLATE

19- MILK POWDER

18- COFFE

31- MIXER

26- DRIP OUTLET

25- PRODUCT

FLOW HOPPER

33- COIN BOX

27-WATER

DISCHARGE HOSE

29- SAFETY

SWITCH

30-MENU

BUTTON

32- FAN

24-CLEAN

WATER HOSE

28- OVERFLOW

WATER HOSE

10

Figure 4: Rear view

49- CANISTER

MOTOR

51- MIXER MOTOR

46- WATER DRAIN

PIPE

52-WATER

FILLING PIPE

45-BOILER

40- ENERGY

SOCKET

39-

TRANSFORMER

41- WATER

DISTRIBUTER

37- SOLENOID

VALVE

36- RESISTANCE

38-TEMPERATURE

SENSOR

35- WATER LEVEL

SENSOR

34-MAIN BOARD

44- FAN

42- CLEAN

WATER HOSE

50- WATER PUMP

43- FUSE

51-USB SOCKET

48- WATER FLOW

PIPE

47- THERMOSTAT

11

2.1 Trunk

Main parts inside the trunk are explained hereunder.

Items supplied with the machine: 1 waste water sink, 4 cabinet feet, 1 power cable, 1

safety switch device (U shaped plastic piece), 1 user manual.

2.1.1 Boiler

The boiler tank capacity is 4,5 L and is equipped with an 1800 W Immersion Heater. The

safety of the Boiler Tank (See Figure 4 - 45) is controlled by a Temperature Sensor and Level

Probe. The tank is well fitted to the VM Trunk and it is well insulated. Energy usage has been

minimised therefore operating cost has been reduced.

Do not touch the Midi-Kafe®

Boiler Tank when it is hot.

When draining out the water in the boiler tank, the red cork inside the

end of the water hose needs to be removed. Proceed with CAUTION as

the hose contains VERY HOT water.

2.1.2 Ingredient Canisters and Motors

These storage containers are for powder form soluble drinks from where the soluble drinks

are being distributed into mixers via the canister motors. There are 6 canisters in a standard

Midi-Kafe coffee vending machine (See Figure 3 - 18, 19, 20, 21, 22, 23) and motors (See

Figure 4 - 49).

Product Placement into Canisters is as follows:

18-Coffee 19-Milk Powder 20-Chocolate 21-Fruit Tea / Salep 22- Sugar 23- Tea

The positions of Canisters and Canister Motors are not interchangeable.

Motors with various speeds are used depending on each ingredient

12

2.1.3 Mixers and Mixer Motors

Powder form soluble hot drinks are being prepared ready to be presented in mixer bowls

with hot water. There are 4 mixers and mixer motors in a standard Midi-Kafe coffee vending

machine (See Figure 4 - 31, 51)

The positions of Mixers and Mixer Motors are standard and not

interchangeable.

There is a steam lid on the top of the mixers. It takes away the vapour

forming on the mixer. This feature is important in terms of keeping the

ingredients safe and dry correctly for a long time.

Replace mixer washers (O-ring) once a year.

2.1.4 Water Pump

It performs the task of pumping the water to the boiler (See Figure 4 - 50). During inıtial

operation it has to pump 4.5 L of water. Then it pumps a cup amount of water after each

cup dispensed.

Operating the machine without water for a long time causes damage to

the pump and the pump needs to be replaced.

2.2 Front Door

The front door holds the electronic and electromechanic parts of the machine.

2.2.1 LCD Display

LCD (Liquid Crystal Display) is used for programming and throughout all payment and

product selection procedures (See Figure 1 - 6) thereafter it will be referred as “LCD”.

2.2.2 Payment System (Optional)

The cost of the desired product is defined and paid through a payment system (See Figure 1

- 8). These advanced payment systems only accept pre-defined coins and do not accept

counterfeit coins.

When requested by the customer, the Midi-Kafe can be equipped with MDB Supporting Coin

Selector, Tokens or Cashless Systems.

13

2.2.3 Touch Keypad

Used for programming and selecting products. Use of the keypad is described in details

under the programming section.

2.2.4 Electronic Modules

The machine is fully micro-processor controlled; the electronic modules are listed below:

a) Main Card Electronic Module: All functions of the machine are controlled here

b) Touch keypad Electronic Module

c) LCD Display Electronic Module

All models are being produced by Elektral. Spare parts and module replacements

have to be done by authorized personnel only, otherwise irreversible damage can

be caused to the machine and the guarantee becomes void

3. TECHNICAL SPECIFICATIONS

Operation: Electro-Mechanic Operating Principle

Power Supply: 220 VAC (± % 10) / 50 Hz.

Power: Stand By: ~ 25W - Resistance: ~ 1800W

Operating Temperature: -15° C +70°C

Humidity: % 95 non-condensing

Protection Class: IP20

Dimensions: 520 (W) x 900 (H) x 520 (D) mm

Weight: ~ 55 kg

4. INSTALLATION AND CLEANING

The vending machine has to be placed on a stable flat surface and operate in an

upright position. It is recommended to use the machine with its specially designed

base stand (optional). The equipment has a self-cleaning function (See chapter 6.9). It is

necessary to clean the Midi-Kafe periodically with short intervals since it is serving drinks to

people. During cleaning, do not use any cleaning materials and/or chemicals which are not

safe for human health.

Ensuring safe and healthy usage of the machine can be achieved by strictly following below

instructions. Apart from the periodic cleaning instructions below, visible marks on the

machine must be wiped using a soft, hygienic and slightly damp cloth. Especially during

frequent usage of the machine, the cleaning has to be done more often as described in

below periodic cleaning instructions.

14

The water temperature during self-cleaning (automatic) process of the

mixers has to be hot (as same as when the machine is in operation)

Chemical solutions must not be used during cleaning the machine by

hand. Only warm water should be used.

Disconnect the machine from the electricity supply when the machine is

cleaned by hand.

Do not connect and operate the machine if the power supply is not an

earthed electricity supply

4.1. Daily Cleaning

Choose "AUTO CLEANING" from the menu to clean the mixers. Check if the product canisters

are full. Take away the water from the excess water tray.

4.2. Weekly Cleaning

Take the mixers off and wash with hot water. Wash the product flow routers. Clean the

excess water tray with hot water. Clean the product powder fallen inside the machine.

4.3. Monthly Cleaning

Take off the product canisters and do functioning test. Wash and dry the canisters. Test and

check if the extractor fans are functioning. Open the back cover and clean around the

electronic board with the help of a small vacuum cleaner. Do not neglect monthly graph

checks.

4.4. Annual Cleaning

Check the boiler, the solenoid, the water distributers etc… in the machine for lime scale.

Clean if needed. Change the parts listed for periodic replacement in the user manual. Check

the usage labels and the physical state of the machine.

5. PRODUCT LOADING AND INITIAL OPERATION

Before connecting your Midi-Kafe coffee vending machine to the electricity power

supply, proceed with the following:

Open the front door of the machine. There is a water intake hose at the lower section

of the Midi-Kafe. Insert the water intake hose into a carboy full of water.

Load powder form soluble ingredients into canisters. The ingredients have to be

suitable for vending machines. (See chapter 2.1.2 Product Placement into Canisters)

Load suitable size carton or plastic cups one within another, into the four columns on

the top of the Cup Dispenser Mechanism

15

The cups have to be slick, not wet and not crushed. Do not mix plastic and

carton cups

Plug the machine to an earthed electricity power supply.

When the front door is closed the machine automatically starts working.

Note: If you need the machine to operate while the front door is open, the safety

key lid has to be placed on the key.

The boiler operates only when the water inside is above a

certain level. The status is displayed on the LCD once

operation starts. If there is not enough water in the boiler, the

pump starts pumping in water. If the Boiler Tank does not fill

up within 6 Minutes then “No Water” message will appear on

the LCD. To fill up the boiler tank, switch off the machine from

the mains and switch it on again. Initial heating may take

some time. Once completed ready to operate message appears

on LCD.

When there is sufficient amount of water in the boiler the

heating process starts and the LCD displays "HEATING IN

PROGRESS".

When the heating process is completed the device is ready to use the LCD displays

“INSERT COIN”

Select the sugar level of your choice and enter the product code to take a product. For

Midi-Kafe equipped with a Payment System, money has to be inserted first.

Press the button of the desired beverage and take the cup with the beverage in it.

6. PROGRAMMING

All Programming and Operation controls of Midi-Kafe® can be done using the

Touch Keypad. There is a button behind the front door of the device for menu

operations. After entering the menu with this button, the touch keypad is used

for menu operations.

To navigate up or down in the menu use buttons PRODUCT9/ SPECIAL / UP, PRODUCT10/

HOT WATER / DOWN, PRODUCT11 / SUGAR (+) / EXIT / NO, PRODUCT12 / SUGAR (-) /

SELECT/SAVE/YES.

SUGAR(+) button EXIT/NO,

HEATING IN PROGRESS

PUMP IN PROGRESS

STARTING

INSERT COIN

SUGAR: ***

16

SUGAR(-) button SELECT/SAVE/YES,

SPECIAL button is used to scroll UP in the menu,

HOT WATER button is used to scroll DOWN in the menu

Open the machine door in order to enter the menu. Put the safety key apparatus on the

safety key and press the red button in the top right corner of the machine.

6.1 Product Pricing

This menu is to set up the prices of sold products. Each product

can be priced differently.

1-To enter the menu press SUGAR(-) (SELECT) button

2- Using buttons UP(SPECIAL) and DOWN(HOT WATER) choose

the product to amend its price and press button SUGAR (-)

(SELECT)

3- Enter the new price using buttons UP(SPECIAL) and

DOWN(HOT WATER)

4- Press button SUGAR(-) (SELECT) to save, press button

SUGAR(+)(EXIT) to exit the menu without saving

6.2 Product Dosage

This menu allows adjusting the amount of water, coffee,

chocolate, etc. ingredients (in terms of seconds) mixer rotation

settings (in terms of %) used in the machine.

The settings have to be done correctly in order to obtain the taste

and consistency required.

1- To enter the menu press SUGAR(-) (SELECT) button

2- Using buttons UP(SPECIAL) and DOWN(HOT WATER) choose

the menu to make alterations and press button SUGAR(-)

(SELECT)

3- Enter the new settings using buttons UP(SPECIAL) and

DOWN(HOT WATER)

4- Press button SUGAR(-) (SELECT) to save, press button

SUGAR(+)(EXIT) to exit the menu without saving

6.3 Statistics Menu

6.3.1 Counters

Each product sold is counted individually and as a total. Sale

counts can be seen in this menu. Counters menu contains the

number of drinks dispensed; Global Counter, Total Counter, Cash

Vend, Cashless Vend and individual number for each product

dispensed.

The Global Counter cannot be reset. Product counters can be

reset.

1-To enter the menu press SUGAR(-) (SELECT) button

PRICES

[1]

AMERICANO

[1/1]

AMERICANO

000000.50 EUR

DOSES

[2]

AMERICANO

[2/1]

[5]

COFFEE DOSE

[2/1/1]

COFFEE DOSE

0.8s

COUNTERS

[3/1]

GLOBAL COUNTER

46 Pcs.

AMERICANO

9 pcs.

STATISTICS

[3]

17

2- Using buttons UP(SPECIAL) and DOWN(HOT WATER) choose the menu to make

alterations and press button SUGAR(-) (SELECT)

3- Press button SUGAR(-) (SELECT) in the menu showing total

counters to reset, press button SUGAR(+)(EXIT) to exit the menu

without resetting

Global Counter: Shows the number of drinks dispensed from the time the machine has

started operating. This value cannot be reset.

Total Counter: Shows the number of drinks after the last reset.

Cash Vend: The count of drinks dispensed that were paid in cash.

Cashless Vend: The count of drinks paid by cashless card.

Other Counters are the number of drinks dispensed after the last reset as Americano,

Espresso, Cappuccino, Mochaccino, Chocolate, Chocomilk, Latte, Tea and Hot Water, for

each drink individually.

6.3.2 Audits

This menu shows Vends Total, Vends Partial, Coin Box Partial,

Coin Vend, Cashless Vend, Card Recharge and an option to reset

audits.

Vends Total: The net revenue amount collected from the time

the machine had started operating. Vends Total value cannot be

reset.

Vends Partial: The revenue amount collected after the last reset. This value can be reset.

Coin Box Partial: This value is the total amount of money collected in the cash box. This

value can be reset.

Coin Vend: Monetary value of sales in coins. This value can be reset.

Cashless Vend: Monetary value of cashless sales. This value can be reset.

Card Recharge: Cashless card loadings total done in the machine. This value can be reset.

6.4 Settings Menu

6.4.1 Validator Settings

The Validator menu consists of Free Vend, Maximum Credit, Accepted Coins, Validator

Config, Decimal Point and Currency.

1-To enter the menu press SUGAR(-) (SELECT) button

2- Using buttons UP(SPECIAL) and DOWN(HOT WATER) choose

the menu to make alterations and press button SUGAR(-)

(SELECT)

3- Enter the new settings using buttons UP(SPECIAL) and DOWN(HOT WATER)

AMERICANO

RESET?

VENDS TOTAL

0.00 EUR

RESET AUDITS

APPLY?

SETTINGS

[4]

FREE VEND

[4/1/1]

VALIDATOR

[4/1]

18

4- Press button SUGAR(-) (SELECT) to save, press button

SUGAR(+)(EXIT) to exit the menu without saving

Free Vend: Enabling or Disabling Free Vend is done here.

Maximum Credit: The maximum amount of money to be

accepted by the machine can be adjusted in this menu.

Accepted Coins: Coins to be accepted by the vending machine

can be selected in this menu.

Validator Config: Validator configuration for Automatic or

Manual use.

Decimal Point: Decimal point location can be determined here.

Currency: Currency to be used is selected in this menu.

6.4.2 Language Selection

This menu is used for choosing the language to be used in the

machine. Turkish or English can be selected.

1-To enter the menu press SUGAR(-) (SELECT) button

2- Using buttons UP(SPECIAL) and DOWN(HOT WATER) choose

the new language

3- Press button SUGAR(-) (SELECT) to save, press button SUGAR(+)(EXIT) to exit the menu

without saving

6.4.3 Temperature Setting

These settings are used to adjust the temperature of the water

used in the machine.

The temperature value shown on the bottom left part of the LCD

is the water temperature in the boiler at that time. The value

shown on the bottom right part of the LCD is the adjusted

(required) water temperature value in the boiler. The temperature can be adjusted between

60 - 90 °C.

Recommended maximum Temperature

During summer 80 ⁰C During winter 85⁰C

1-To enter the menu press SUGAR(-) (SELECT) button

2- Using buttons UP(SPECIAL) and DOWN(HOT WATER) choose the menu to make

alterations and press button SUGAR(-) (SELECT)

3- Enter the new settings using buttons UP(SPECIAL) and DOWN(HOT WATER)

4- Press button SUGAR(-) (SELECT) to save, press button SUGAR(+)(EXIT) to exit the menu

without saving

ACCEPTED COINS

[4/1/3]

MAXIMUM CREDIT

[4/1/2]

LANGUAGE

[4/2]

LANGUAGE

ENGLISH

TEMPERATURE

[4/3]

TEMPERATURE

78 ⁰C 80⁰C

VALIDATOR CONFIG

[4/1/4]

DECİMAL POINT

[4/1/5]

CURRENCY

[4/1/6]

19

6.4.4 Limit Temperature

Using this feature dispensing of drinks is allowed only within

certain temperature limits. When the water temperature drops to

the specified minimum limit figure, dispensing of drinks stops and

when the temperature reaches above the minimum limit,

dispensing of drinks starts again.

6.4.5 Cup Sensor

This menu is used to make the cup sensor active or passive.

Another drink is not allowed to be dispensed when the cup sensor

is active.

6.4.6 Change Password

This menu allows changing the password. The old (current)

password is entered first, then the new one.

6.4.7 Power Save Mode

This menu allows enabling or disabling the Power Save Mode.

Once Power Save Mode is enabled, the start time and the stop

time can be determined.

6.4.8 RS 232 Protocol

This menu allows selecting EVA-DTS protocol or EXTERNAL SALE.

Telemetry feature can be used with EVA-DTS.

Using an external device (such as a computer) is enabled with

EXTERNAL SALE option.

6.4.9 Date & Time Settings

This menu is for date and time adjustments. It is important to

adjust the correct time and date to allow correct error recordings.

LIMIT

[4/4]

LIMIT

80 ⁰C 85⁰C

CUP SENSOR

[4/5]

CUP SENSOR

ENABLED

CHANGE PASSWORD

[4/6]

OLD PASSWORD

0***

POWER SAVE MODE

[4/7]

POWER SAVE

[4/7/1]

POWER SAVE START

[4/7/2]

POWER SAVE STOP

[4/7/3]

RS 232 PROTOCOL

[4/8]

RS 232 PROTOCOL

EVA-DTS

RS 232 PROTOCOL

EXTERNAL SALE

CLOCK CONFIG

[4/9]

CLOCK CONFIG

01.04.2015

20

6.4.10 Factory Reset

This menu allows a factory reset which resets all settings to factory

default except the Global Counter and Vends Total.

6.5 Testing and Cleaning

6.5.1 Manual Cleaning

Manual cleaning mixers are used for performing manual cleaning

procedure. After pressing the SUGAR(-) (SELECT) button choose

the required mixer displayed on the screen then press the

SUGAR(-) (SELECT) button again to complete the procedure.

6.5.2 Self Cleaning

In the Automatic Cleaning Menu press the SUGAR(-) (SELECT)

button for the machine to start cleaning its mixers using the water

in the boiler.

Place a 200 –300 ml sized empty cup under the

drinks dispenser when performing SELF cleaning procedure.

6.5.3 Function Test

During the function test the canister motors and the mixer motors

rotate in turns. Motors test is done this way. To prevent powder

products spillage on the mixers, Ingredient Canisters should be

empty when performing Function Test.

6.5.4 Cup Dispenser Test

Cup Dispenser Test is used to test if the Cup Dispenser is operating

normally

6.5.5 Trial Mode

The Trial Mode allows dispensing drinks without any payment.

6.6 USB Menu

This menu allows software upgrade via a USB disk and also allows

the statistical data to be transferred to a computer.

USB MENU

[6]

DAFAULT

SETTINGS APPLY?

DAFAULT SETTINGS

[4/10]

CUP DISPENSER

[5/4]

SELF CLEANING

[5/2]

FUNCTION TEST

[5/3]

TEST & CLEANING

[5]

MANUEL CLEANING

[5/1]

[5/31]

CLEAN MIXER 1

[5/31]

SELF CLEANING

APPLY?

TRIAL MODE

[5/5]

Table of contents

Other Elektral Vending Machine manuals

Popular Vending Machine manuals by other brands

Animo

Animo PRIMO MAXI Quick reference guide

AutoCrib

AutoCrib RoboCrib 2000 E Operation manual

Westomatic

Westomatic Sigma Touch Operator's & installation manual

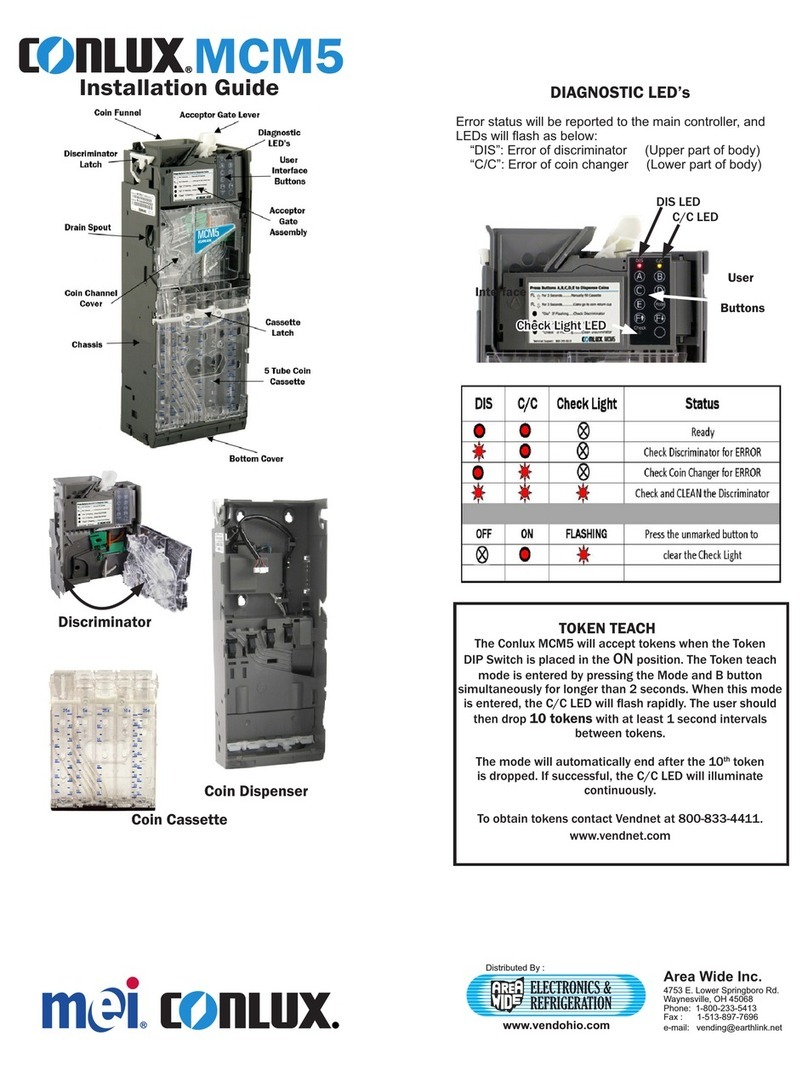

MEI

MEI Conlux MCM5 installation guide

NW Global Vending

NW Global Vending Festival Installation - use - maintenance

Dixie Narco

Dixie Narco P Series manual