Use Loctite.

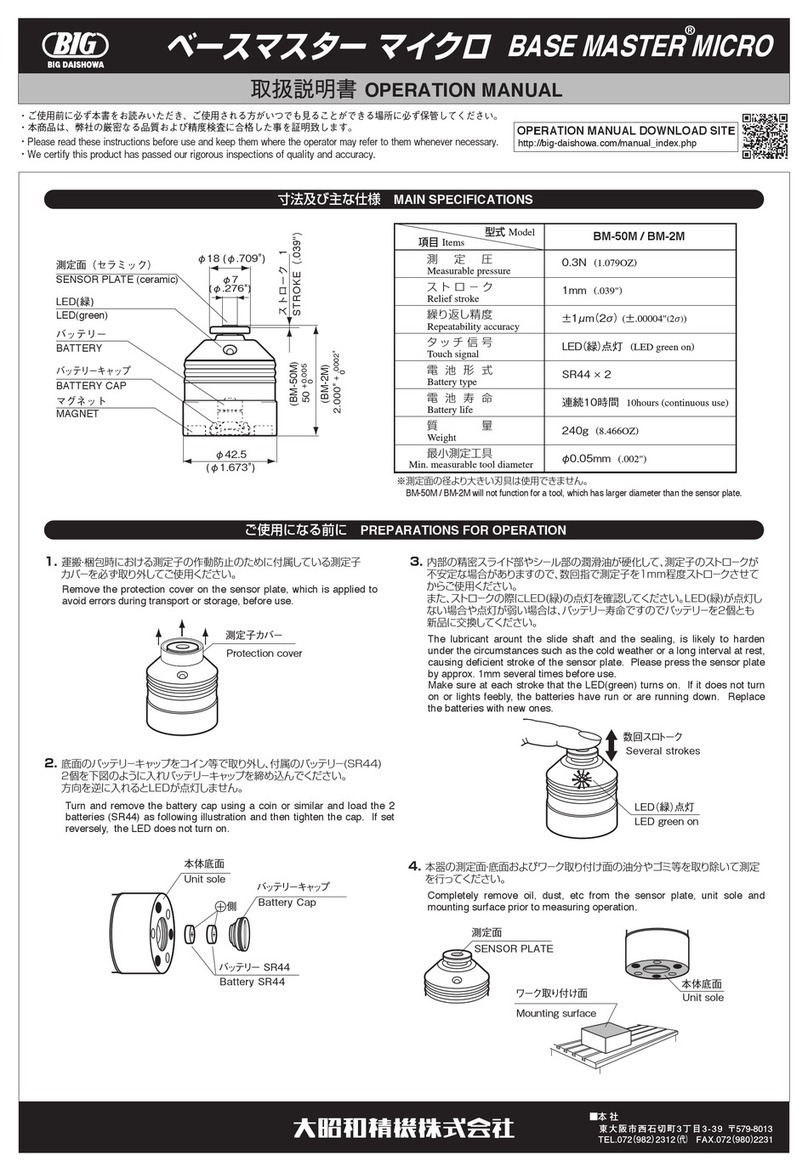

The appropriate clamping torque is important in order to prevent the

pullstud loosening and the taper shank form distorting.

1

TO ASSEMBLE PULLSTUD

Confirm the model of the pullstud.

Clean the thread and location diameter to which

the pullstud is to be fitted.

Remove any traces of oil or particles from the pullstud.

Apply Loctite.

2

3

4

5SHANK No.

CLAMPING TORQUE(N m)

BT/DV/CV 30

BT/DV/CV 40

BT/DV/CV 45

BT/DV/CV 50

25

-

30

77

-

89

100

-

120

140

-

160

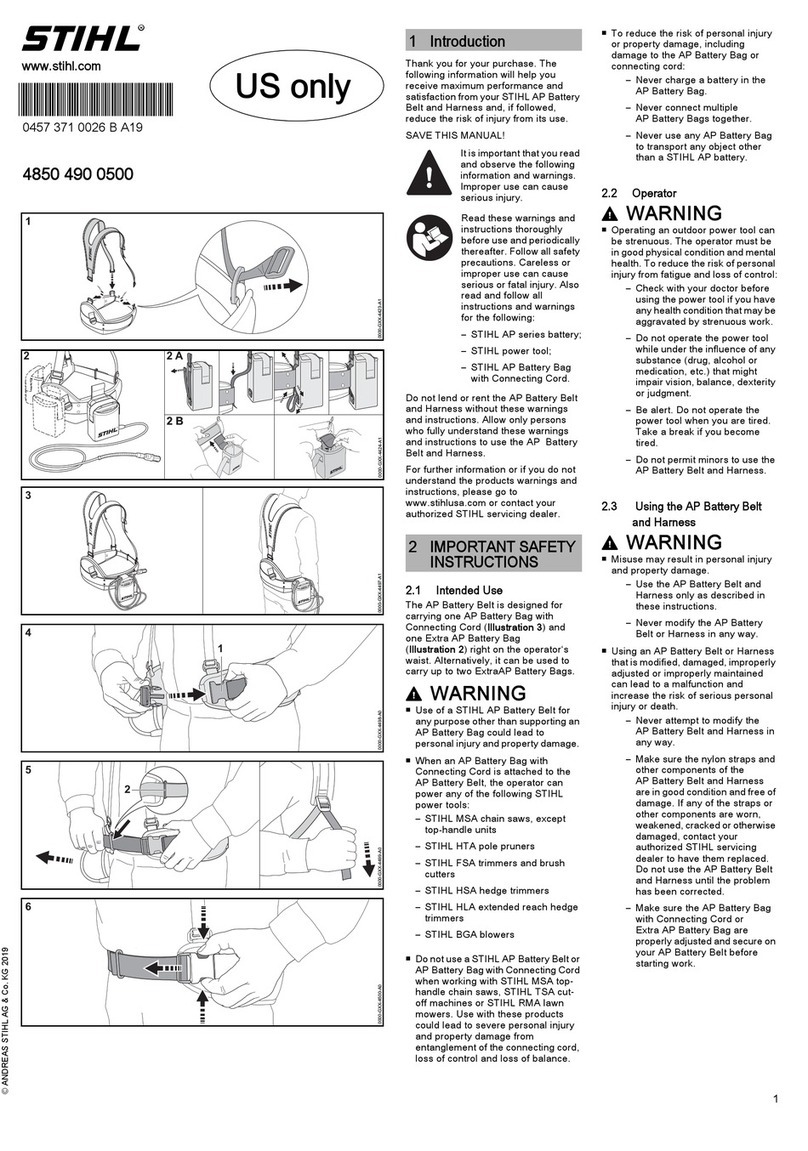

INSPECTION OF PULLSTUD

A pullstud is subjected to tons of drawbar force and force exerted by heavy

duty machining and vibration. For this reason the pullstud should be regarded

as an expendable item and regular replacement is recommended for safety.

Please inspect the pullstud at every change of the cutting tool as described.

APPLYING A TORQUE WRENCH

NEVER TIGHTEN AS FOLLOWS

Ensure to calibrate the torque wrench

on a regular basis in order to achieve

the appropriate torque.

Re-clamp the pullstud to ensure it is firmly fitted at every

change of the cutting tool or index or replacemant of inserts.

Please be aware that removing the pullstud from a #30 shank

may lead to insufficient taper contact since the cross section is

thin at the small end.

TOOL BODY

PULLSTUD

OPERATION MANUAL

Please read and follow the manufacturers instructions.

Should the torque wrench be applied at an inappropriate

angle to the pullstud then the correct tightening torque will not

be achieved.

The torque wrench should be examined regularly for safety.

LOCTITE

NEVER use an extension bar.

DAMAGE

LOOSENESS

This is particularly possible in spindle types with ball clamping mechanism. The pullstud

is apt to have an indentation mark. Please note this indentation could lead to breakage

of the pullstud.

The pullstud is subjected to forces during ATC and vibration in operation. Please

confirm the pullstud is tight and re-tighten at least on every occasion the cutting tool or

inserts are changed or indexed.

FOR HIGH SPEED CUTTING OR HEAVY CUTTING

TORQUE WRENCH

EXTENSION BAR

NEVER tap the tightening wrench.

HAMMER

WARNING

CAUTION CAUTION

Thank you for purchasing PULLSTUD.

Please read these instructions before use and keep them where the operator may refer to them whenever necessary.

Tighten the pullstud.

Ensure to use a torque

wrench in order to

tighten the pullstud

within the torque range

shown below.

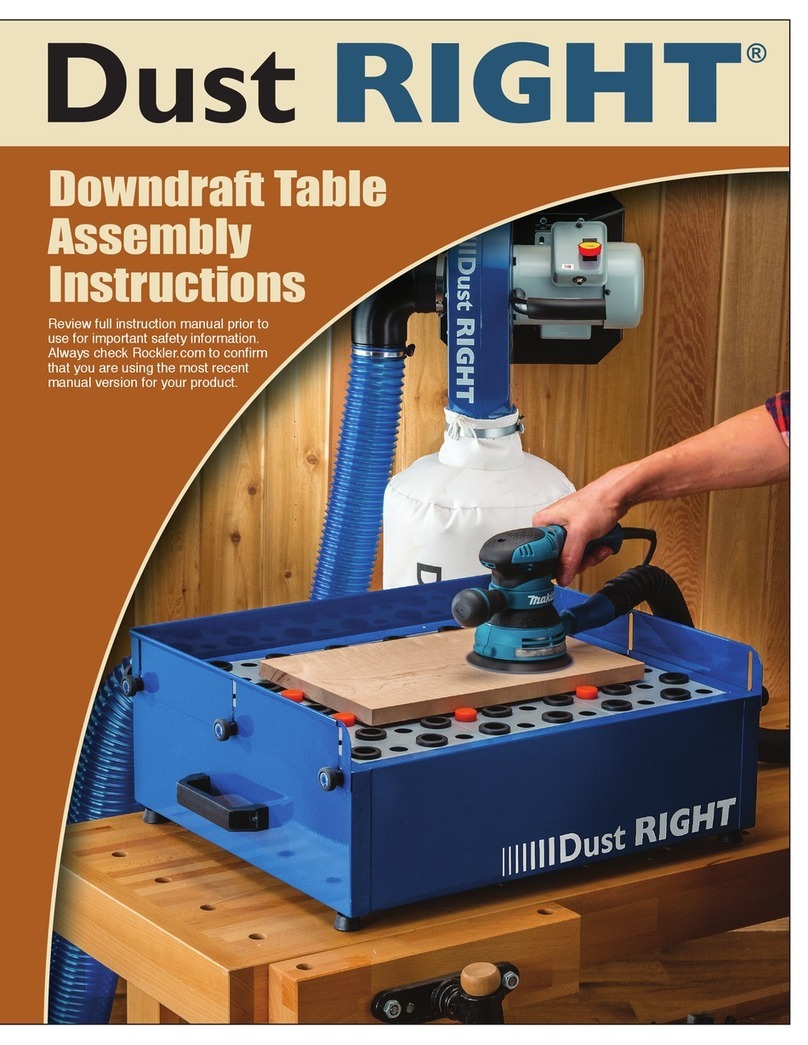

The small end of the taper will be distorted,

so that only partial contact will be made with

the machine spindle.

This will cause chatter and vibration.

The small end of the taper will be distorted,

so that only partial contact will be made with

the machine spindle.

This will cause chatter and vibration.

No.0711PDF

EXPORT DEPARTMENT

TEL (+81)-72-982-8277

Toolholders may be pulled out of the machine

spindle at high speeds due to strong centrifugal

forces.

Strong MEGA PULLSTUDS are recommended

to protect against this possibility.