Bikefun ROCK MACHINE RM-E02 User manual

SERVICE

MANUAL

ROCK MACHINE

RM-E02

SERVICE MANUAL

ROCK MACHINE

Rock Machine would like to congratulate you on the purchase of your new product. We place

great emphasis on the choice of materials and their processing so as to ensure the highest

quality of our products, a long service life and great functionality. Our name is a symbol of a

captivating design, concept and appearance.

To enjoy unlimited riding pleasure with your high-quality Rock Machine product

for many years to come, it is necessary to observe certain rules defined and specified in the

Service Manual. You have received the Operating Manual with your bike.

Rock Machine supplies high-quality bicycles exclusively for specialized shops. These products

are already partially pre-assembled.

The final assembly of the bike can only be carried out by an authorized Rock Machine dealer.

This particularly applies to the basic configuration of suspension components, the front

and back derailleurs and braking systems. This will ensure maximum safety when using the

product.

WARNING

WARNINGS RELATED TO

MECHANICAL WORK

Specialized skills and tools are required to

configure and tune the bike. These tasks

should only be carried out by employees

at an authorized service station. Riding a

bike that has not been correctly configured

and assembled can be dangerous. Even a

seemingly minor deficiency, such as a loose

screw, can cause a crucial part to break over

time and the loss of control of the bike, leading

to an accident. Therefore, we recommend that

you leave any repairs and maintenance for your

bicycle to an authorized service centre. Your

safety depends on the correct maintenance

of the bike. Employees of authorized service

stations have special qualifications and know-

how.

WARNING

Any adjustments and modifications can lead

to the frame, fork or other parts becoming

unsafe. The use of an unapproved component

or the incorrect assembly of parts can lead

to excessive wear and tear of the bike or its

parts. Adjustments to the frame, fork or other

components can have a negative impact on

the handling of the bike and may lead to a

fall. Do not grind off, drill or file any parts; do

not remove backup safety elements, do not

install incompatible forks and do not make

any other similar unauthorized changes.

Before you install any accessories on your

bicycle, or replace any part, always consult the

service centre staff to make sure the particular

accessory or part is compatible and safe to

use.

Type-3 operating conditions

Riding on trails, crossing small obstacles and technical courses of

medium difficulty as well as stretches where the tyres do not make

contact with the ground for a short period of time; jumps and drops not

exceeding 61 cm (24").

BIKE CATEGORY

e-Blizz

Mountain bikes are equipped with a rear suspension and are constructed for “standard”,

“racing”, “cross-country” or “singletrack-trail” rides, assuming adherence to type-3 operating

conditions:

PREVENTING DAMAGE

If you are transporting the bike in a box, make sure that the bike is kept safe, for instance by

using a soft foam cover. Make sure that there are no foreign items or that excessive pressure

or force from these items cannot damage the frame. Please keep in mind that the warranty

does not apply to damage caused during transit.

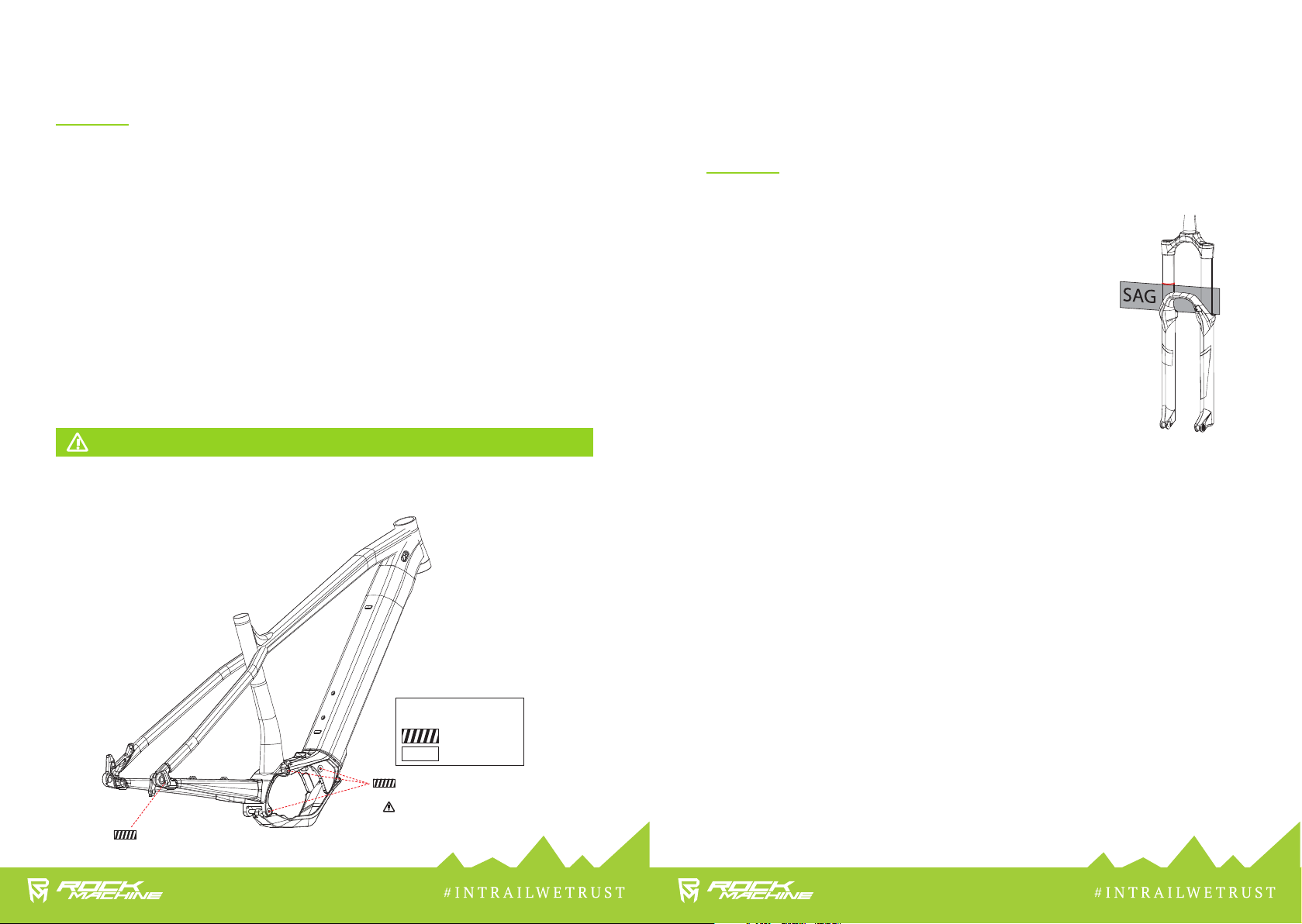

WARNING

The warranty may be voided if the service intervals and prescribed torques are not adhered to.

SERVICE INTERVALS

• Large-scale service – at a service centre, 1× per year or after 200 hours of riding.

• Check the tightening of moving parts before and after each ride. The prescribed torques

of individual joints (see the diagram below) must be strictly observed.

• Bearings and pivots should be lubricated 1× per half a year.

• Consult your dealer about the exact service plan and maintenance schedule of your

bicycle. The dealer shall propose the schedule depending on the model of your bicycle

and the way you use it. The service intervals stated above are the recommended

maximum intervals for regular bicycle maintenance, i.e. they cannot be extended under

any circumstance. If you ride your bicycle more intensively, or if your dealer advises

you to, we recommend that you shorten the intervals and extend the scope of tasks

carried out. For example, if you ride your bicycle in adverse climatic conditions, over hard

terrain or if you have equipped your bicycle with specific components with a different

service interval and scope of regular maintenance stated by their manufacturer (exact

instructions regarding the service of particular components will be provided by your

dealer).

REAR SHOCK AND FORK

ADJUSTMENT

CONFIGURING THE FORK AND REAR SHOCK STIFFNESS

(SAG)

• Depending on your riding style and the way you use your bike,

the sag should range between 20-30%.

• This value is specified directly on the shock absorber body or

on the inner side of the fork right-hand leg.

• The fork and the rear shock must always be unlocked while

being configured.

• Move the rubber indication ring located on the inner fork leg

and the damper body to the dust cap.

• Sit on the bicycle with your full weight and then get off it

carefully, without rocking the bike.

• Check the position of the ring and make sure that the fork and

the rear shock are set in accordance with the values stated

in the chart (see below), or adjust the pressure in the fork as

needed.

SETTING THE REBOUND FOR THE FORK

• Rebound is a term used to describe the speed of the fork returning to its original position

after absorbing a shock. The control for adjusting the rebound is usually located on the

bottom side of the fork leg.

• When sitting on the saddle, ride off an edge of approx. 10 -15 cm in height.

• If the fork rocks 1 or 2 times, the rebound is set correctly.

• If the fork rocks more than 3 times, the rebound is too fast.

• If the fork does not rock at all, the rebound is too slow.

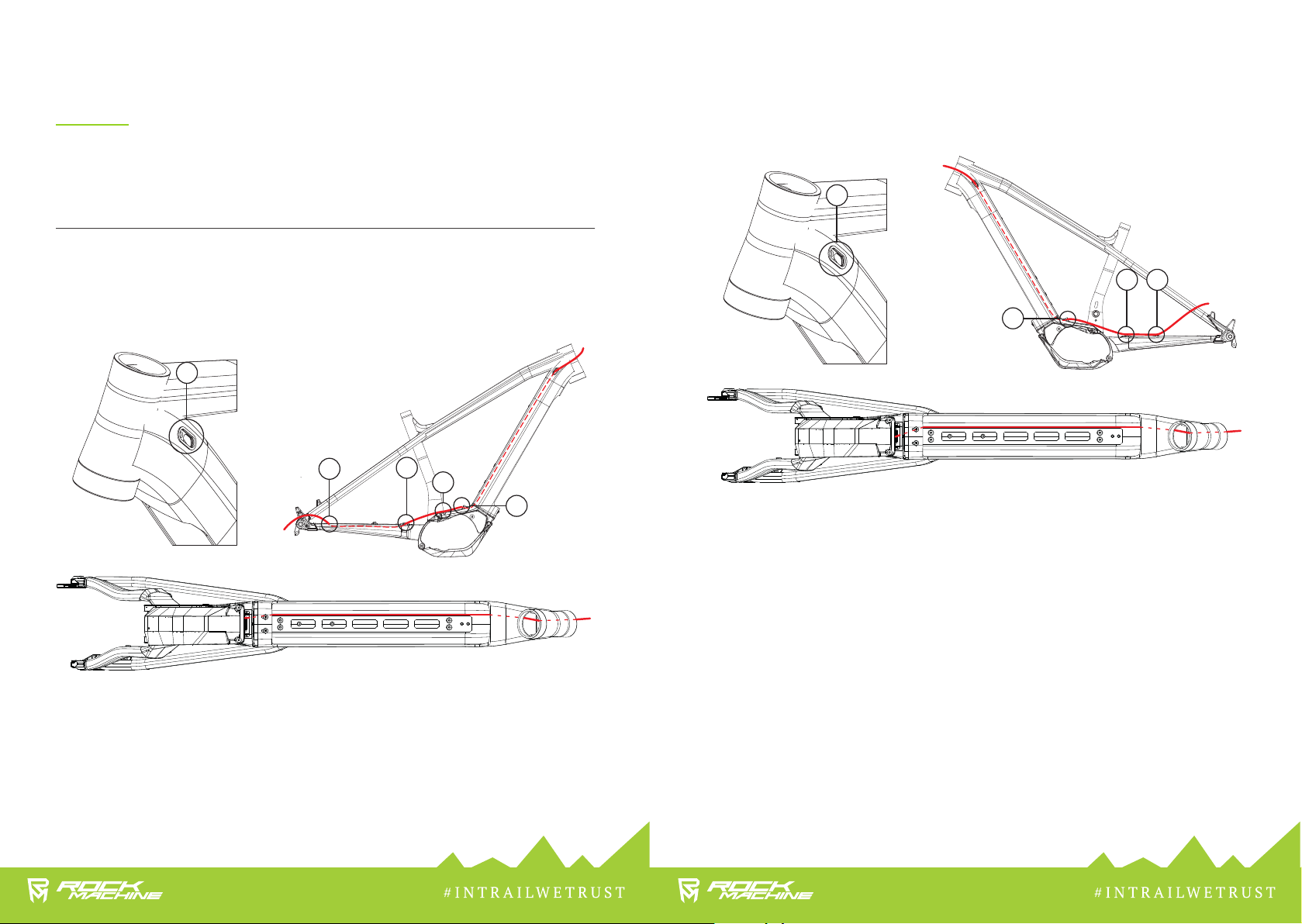

4 Nm (no laser marking)

MOTOR SCREWS

10 - 12.5 Nm

It is necessary to tighten the

screws on the right side rst,

then the screws on the left side!

Blue nylock

No nylock

THREAD LOCKING AGAINST

SPONTANEOUS RELEASE

1 REPLACING THE REAR DERAILLEUR CABLE

1.1 Slide the old cable out from the guide in the frame.

1.2 Slide a new cable in the frame through the hole A1 and pull it out through the hole A2.

1.3 Fix the cable to the hitch A3 using a tying strip.

1.4 Slide the cable through the hole A4 in the rear swingarm and pull it out through the hole A5.

2 REPLACING THE HYDRAULIC HOSE OF THE REAR BRAKE

2.1 Slide the old hose out from the guide in the frame.

2.2 Slide a new hose in the frame through the hole A1 and pull it out through the hole A2.

2.3 Fix the cable to the hitch B1.

2.4 Fix the cable to the hitches B2 and B3 using tying strips.

SERVICE

REPLACING THE CABLES AND HOSES

Ducts are made using guiding tunnels inside of the bicycle frame. The ducts allow easy and

quick replacement of cables and hoses within their full length without need to break them.

A1

A2

A4

A3

A5

A1

B2

B1

A2

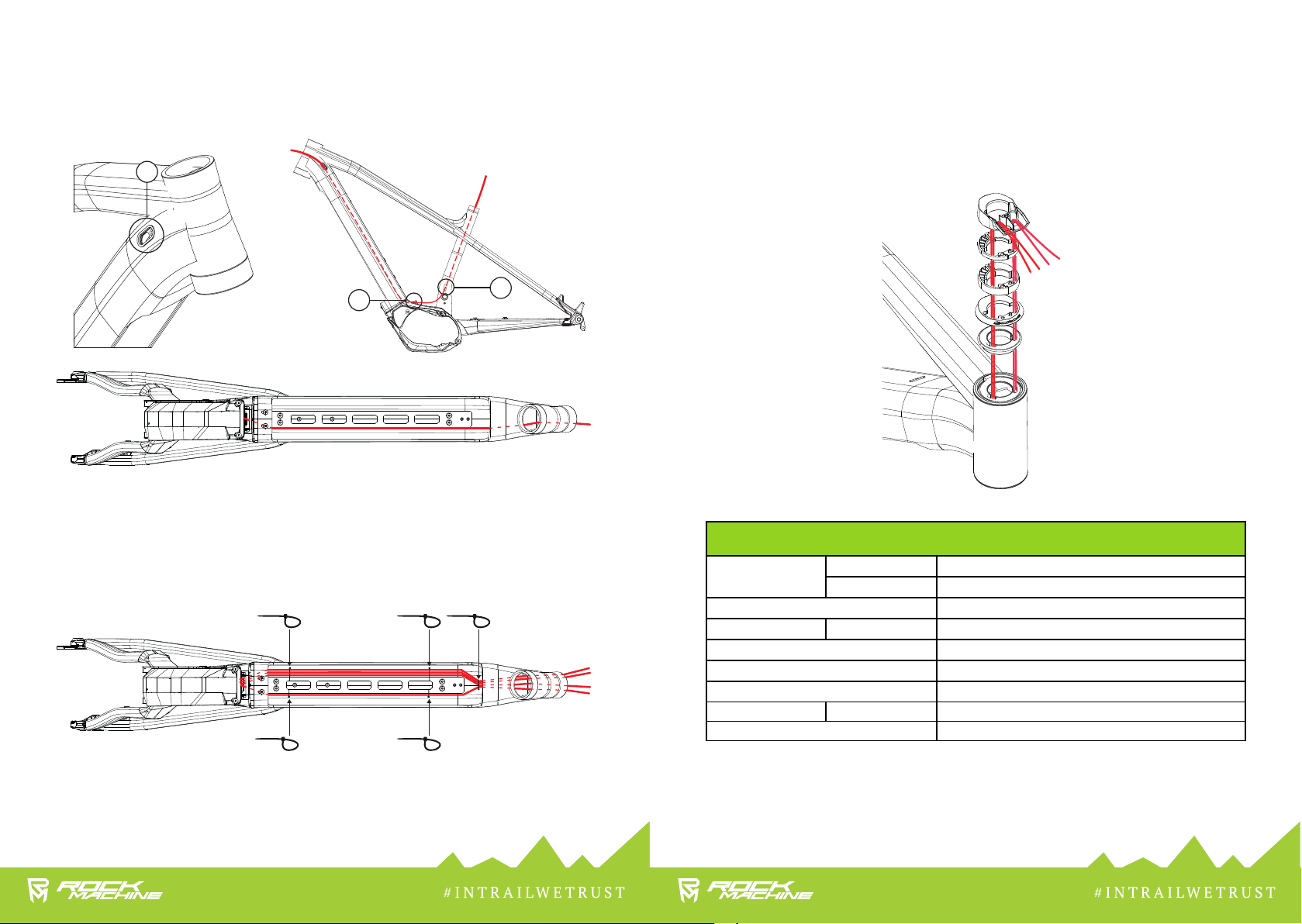

3 REPLACING THE TELESCOPIC SEATPOST CABLE

3.1 Slide the old cable out from the guide in the frame.

3.2 Slide a new cable in the frame through the hole C1 and pull it out through the hole A2.

3.3 Slide the cable in through the hole C2 and pull it through the seatpost tube.

C1

C1

A2

4 FASTENING THE CABLES, HYDRAULIC HOSE AND DISPLAY CABLE

4.1 Fasten the cables, hydraulic hose and display cable to the docking

station bar using tying strips.

4.2 Tighten the telescopic seatpost cable so that it would remain movable.

4.3 Put the foam Jagwire SFA07A5M sleeve on the cables, hydraulic hose and display cable in

length only up to the headset.

5 PULLING THE CABLES, HYDRAULIC HOSE AND DISPLAY CABLE THROUGH

THE HEADSET AND SPACER RINGS

5.1 Pull the cables, hydraulic hose and display cable through the headset bearing lid and spacer

rings so that the telescopic seatpost cable and display cable would be positioned on the right-

hand side when viewing from the front (1).

5.2 Pull the shifting cable and rear brake hydraulic hose through so that they would be positioned

on the left-hand side when viewing from the front (2).

1

2

COMPATIBILITY

Brake Rotors Front Ø 180 - 203 mm

Rear Ø 180 - 203 mm

Tyre max. 29” x 2,6”

Chainring 1× max. number of teeth 36

Headset BC 1-1/8” *1.5” ACROS AZX-220 ZS44, BLOCK-LOCK

Bottom Bracket Shimano STePS Middle Drive Unit

Seatpost Clamp Ø 34.9 mm

Seatpost Ø 30.9 mm min. insertion 100 mm

Rear Thru-axle Shimano BOOST 12 x 148 mm

SMART TIPS

To improve handling and comfort and to prevent defects, we recommend installing a tubeless system.

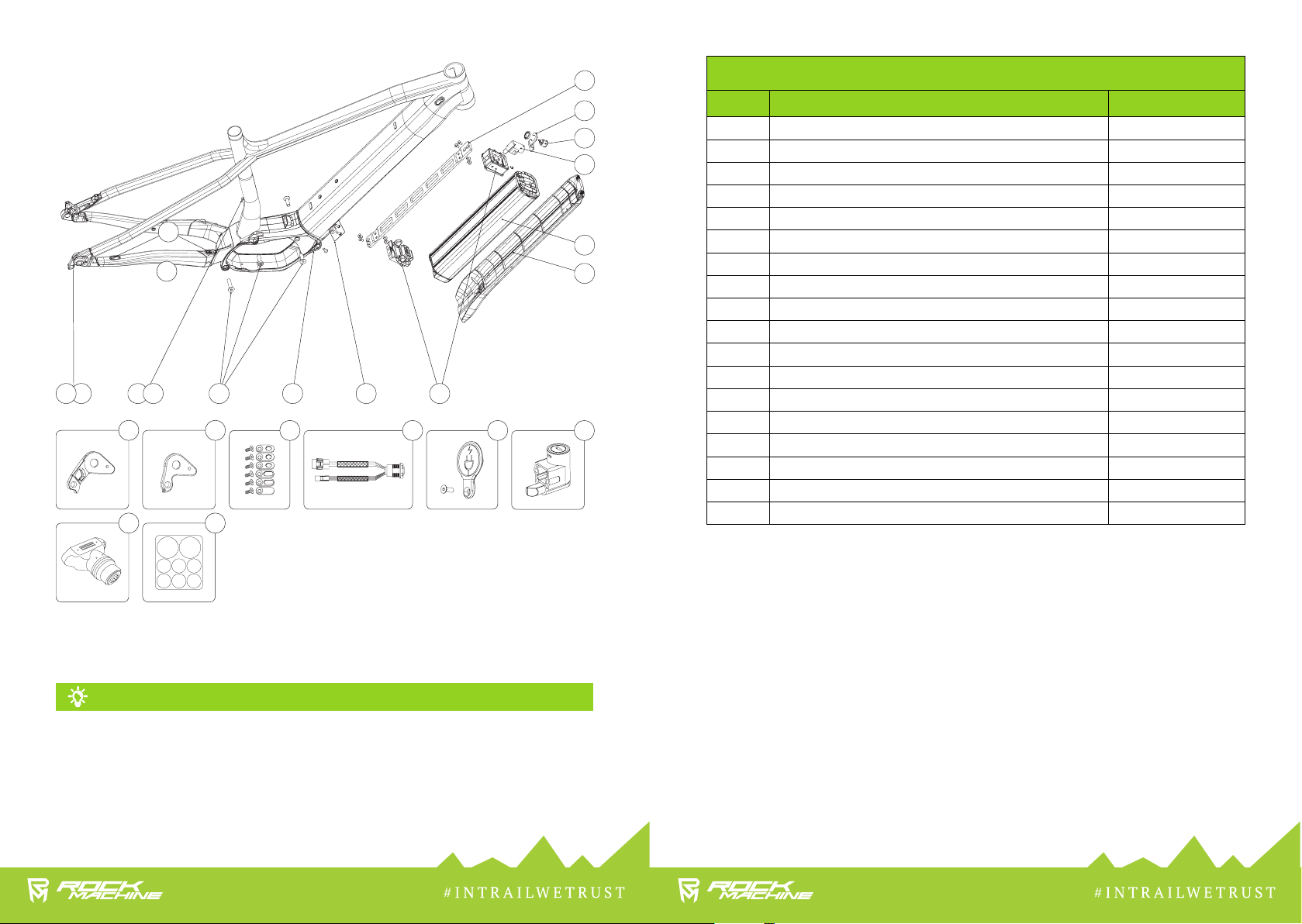

ORIGINAL ACCESSORIES

ART. NO. DESCRIPTION BFI PRODUCT CODE

1 CHAIN STAY PROTECTOR 087.8001.00001-196

2 SHIMANO DIRECT MOUNT DERAILLEUR HANGER 013.0002.00089-377

3 SRAM/SHIMANO DERAILLEUR HANGER 013.0002.00137-372

4 INTERNAL CABLE ROUTING SET 013.0003.00095-372

5 SKID PLATE 013.0019.00001-372

6 MOTOR SCREW SET 598.1303.00022

7 CHARGER 095.0008.00019-396

8 CHARGER COVER 095.0010.00023-372

9COVER LOCKHOLD 013.0017.00016-372

10 DOCK PLATE 095.0010.00018-372

11 POWER SWITCH HANGER 095.0010.00019-372

12 BATTERY MOUNT 095.0013.00022-396

13 BATTERY MOUNT LOCK 098.0002.00093-276

14 BATTERY 503 WH 095.0003.00073-396

15 BATTERY COVER 013.0020.00003-196

16 POWER BUTTON 095.0016.00003-396

17 CHARGING ADAPTER 095.0012.00007-396

18 PROTECTION DECAL SET 087.7000.00009-196

4 7 8

18

32 6

4

5 9 12

15

78

10

11

16

14

13

1

2 3 13

17

#INTRAILWETRUST

Rock Machine is a registered trade mark of

BIKE FUN International

Areál Tatry 1445/2

742 21 Kopřivnice

www.rockmachine.us

Table of contents

Other Bikefun Bicycle Accessories manuals