BilJax Pro-Jax Utility Scaffold User manual

- Page 4 -

WARNING

• Bothsidebracesmustbepositionedatthesameheightontheframessothatplatformis

level.

• Besureall4Saf-T-Lok

®

pins are fully engaged in holes of end frames.

• Besureall4Saf-T-Loksareinthelockedposition.

STEP TWO — Attach second side brace Bto both end frames Afollowing the same Step One

sequence.

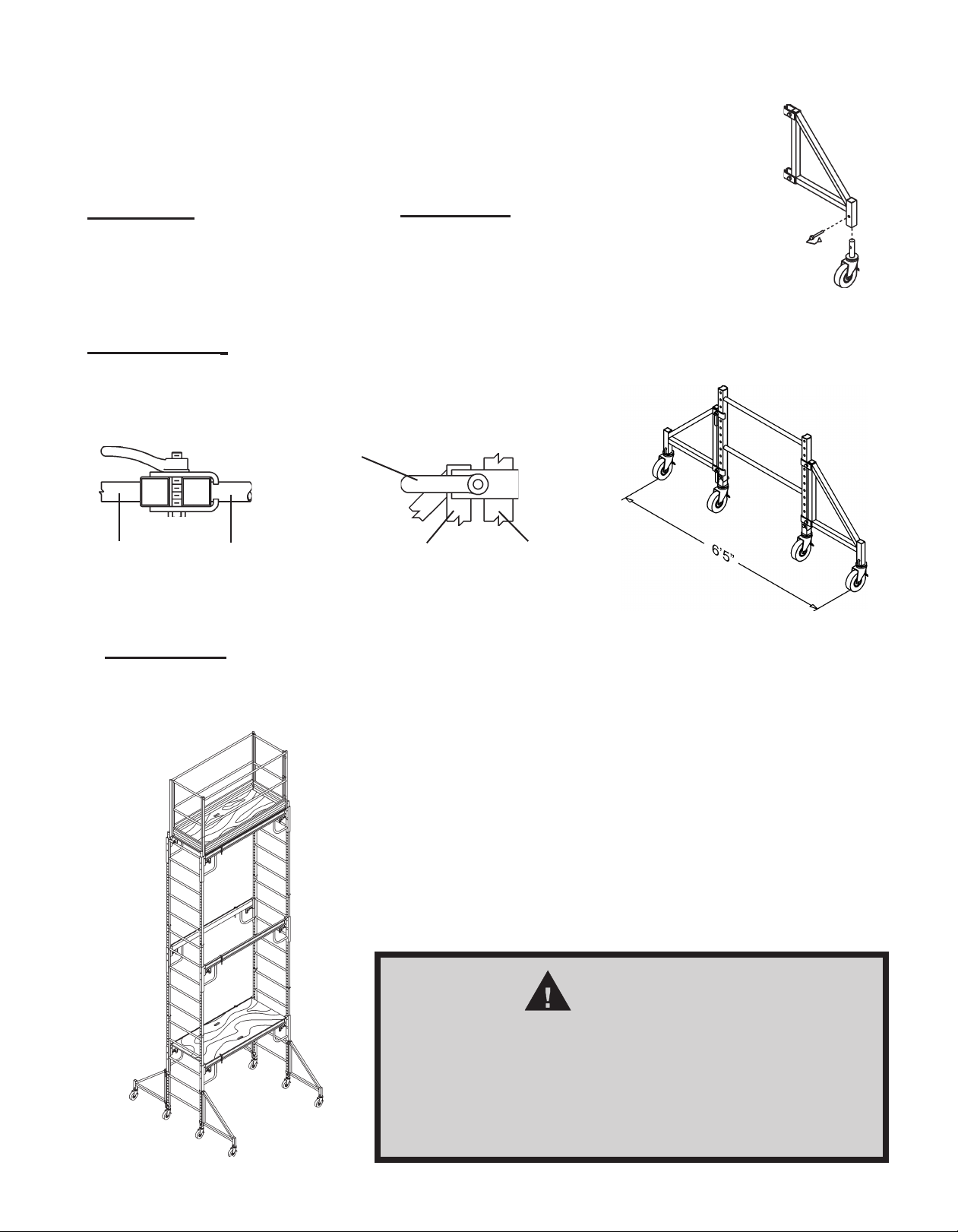

STEP ONE — Attach side brace Bto two end frames Aby

following this sequence:

- Pull Saf-T-Lok®pin at each end of side brace to the

disengaged position. (see decal)

- While holding lock pin in disengaged position, place U-

Channel on each end of side brace Baround leg of end

frame Aat desired platform height.

- Release lock pin and be sure that pin fully engages into

hole in end frame leg.

- Push in and rotate Saf-T-Lok®counter clockwise until U-

shaped end clears the brace locking pin support bracket

as shown (LOCKED).

- To release, push in and rotate Saf-T-Lok®clockwise until

U-shaped end unseats from around the brace locking pin

support bracket as shown (UNLOCKED).

For proper assembly, your basic Pro-Jax Utility Scaffold

must be comprised of 13 individual parts (plus guard

rail panels when required).

Letter Part Qty.

A End Frame 2

B Side Brace 2

C Platform 1

D 5” Caster 4

E 2” Snap Pin 4

C

BA

B

A

E

D

ASSEMBLY INSTRUCTIONS

BUILDING A ONE FRAME HIGH SCAFFOLD

0202-0506

CTO

WARNING

L

Patents Pending

FAILURE TO FOLLOW THESE INSTRUCTIONS MAYRESULT IN

PLATFORM COLLAPSE CAUSING SERIOUS INJURY OR DEATH.

Do not use in this position

Work position

1. Check to be sure brace locking pin is fully

engagedinto frame leg.

2. Push in and rotate Saf-T-Lok

TM

counter

clockwiseuntil U-shaped end clears the

bracelocking pin support bracket as

shown(LOCKED).

3. To release, push in and rotate Saf-T-Lok

TM

clockwiseuntil U-shaped end unseats from

aroundthe brace locking pin support

bracketas shown (UNLOCKED).

© Bil-Jax, Inc. 2004

0202-0506

CTO

WARNING

L

Patents Pending

FAILURE TO FOLLOW THESE INSTRUCTIONS MAYRESULT IN

PLATFORM COLLAPSE CAUSING SERIOUS INJURY OR DEATH.

Do not use in this position

Work position

1. Check to be sure brace locking pin is fully

engagedinto frame leg.

2. Push in and rotate Saf-T-Lok

TM

counter

clockwiseuntil U-shaped end clears the

bracelocking pin support bracket as

shown(LOCKED).

3. To release, push in and rotate Saf-T-Lok

TM

clockwiseuntil U-shaped end unseats from

aroundthe brace locking pin support

bracketas shown (UNLOCKED).

© Bil-Jax, Inc. 2004

- Page 5 -

STEP THREE — Install platform C on side

braces Bso that platform is fully seated within

inner channel on top of side braces.

STEP FOUR — Rotate the platform clips

into the engaged position.

PUSH

DISENGAGED

ENGAGED

STEP SIX — (When recommended or required) When platform height exceeds 4 ft., guard

railing is recommended, but is not required. However, OSHA requires guard rails for all platforms

10 ft. or higher. Install each guard rail panel (2 required) into sockets in side braces Band secure

with lock pin. Be sure that guard rail gate swings inward over the platform.

GUARD RAIL SOCKET

IN SIDE BRACE

STEP FIVE — Install 4 casters Dinto legs of end frames Aand pin with snap pins E. Set brake

on each caster.

GUARD RAIL LEG

SIDE BRACE

PLATFORM

CHANNEL

• RecheckallsidebracelockpinsforfullengagementandthattheSaf-T-Lok

®

is in the locked

position before accessing platform.

• Recheckplatformtobesureitisproperlyseatedwithinsidebracechannelandtheplatform

clips are fully engaged before accessing.

• Whenaccessingplatform,climbovertopofendframeladder—do not swing around side

of end frame. Swinging around side of end frame will cause scaffold to tip over resulting

in serious injury or death.

WARNING

WARNING

Guard rail must be installed so that gate swings inward over platform. Failure to install guard

rail properly may result in serious injury or death!

Unique design allows the guard railing to stay at the platform level at all times.

Guardrailingdoesnottontheframebutinthesocketsontheplatformbrace.

GUARD RAIL PANEL

Panel Guard - 1 unit shown

(2 required per work level)

- Page 6 -

STACKING PRO-JAX®UNITS FOR ADDITIONAL HEIGHT

According to OSHA, all scaffolds must be restrained from tipping. This can be accomplished in one

of three ways:

1. For free standing scaffolds, the maximum platform height must not exceed 3 times* the narrowest

base dimension.

2. Guying the scaffold.

3. Tying the scaffold to a wall or other solid structure.

*Federal OSHA allows a maximum platform height of 4 times the narrowest base dimension. However, Bil-Jax recommends

that the maximum height be limited to 3 times the narrowest base dimension on all Pro-Jax utility scaffolds.

When additional platform height is required on a free standing scaffold, outriggers may be used to

extend the base dimensions. Bil-Jax has different size outriggers available for use with Pro-Jax

units. 18” wide outriggers are for use with two-frame high scaffolds and 24” wide outriggers are for

use with three-frame high scaffolds.

WARNING

WheneverPro-Jaxunitsarestacked,outriggersarerequired!Donotusea

Pro-Jax utility scaffold over 1 frame high without outriggers. Failure to use

outriggers will make scaffold more likely to tip over causing serious injury

or death!!

BUILDING A TWO FRAME HIGH SCAFFOLD

Top View

Outrigger Frame

Side View

Outrigger

Tighten

Securely

Frame

Leg

STEP THREE — Clamp outrigger to end frame at a 90°angle to the side brace.

Tighten clamp securely. Clamp must be ush against scaffold leg and casters must be

in contact with the surface.

STEP ONE — Erect the base

unit (one frame high scaffold) by

following the previous instruction.

STEP TWO — Install casters into all

four (4) outriggers and secure with snap pin

provided with each caster. Set caster brake.

If the platform height needed is between 6’ and 11’ 6”, it will be necessary to install 18” wide

outriggers and a second scaffold level prior to use.

STEP FOUR — Add

second scaffold level by

stacking end frame over

insert pins in top of base

unit end frames. Secure

in place with snap pins.

STEP FIVE — Install

side braces (minimum two),

platform, and guard railing at

desired height per the previous

instructions (Building a One

Frame High Scaffold).

- Page 7 -

STEP FOUR — Add additional scaffold end frames, side braces, platforms, and guard

railing (at each work level) per the previous instructions (Building a One Frame High Scaffold

and Building a Two Frame High Scaffold). Side braces should be evenly spaced in pairs

throughout the scaffold tower.

Top View Side View

Outrigger Frame

Tighten

Securely

Frame Leg

Outrigger

STEP THREE — Clamp outriggers to end frame with two piece clamp. Tighten clamp securely.

Clamp must be ush against scaffold leg and casters must be in contact with the surface.

If the platform height needed is over 11’ 6”, it will be necessary to install 24” wide

outriggers prior to stacking additional scaffold levels to the base unit.

WARNING

There must be a minimum of two side braces

installed in each scaffold level and evenly spaced

throughout the scaffold. Lack of adequate

bracing could cause scaffold to collapse with

serious injury or death to the user.

STEP ONE — Erect the base

unit (one frame high scaffold) by

following the previous instructions.

STEP TWO — Install casters into all four

(4) wide outriggers and secure with snap pin

provided with each caster. Set caster brake.

BUILDING A THREE FRAME HIGH SCAFFOLD

Table of contents

Other BilJax Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Magnaflux

Magnaflux A-2030 Series installation guide

Sealey

Sealey YK20F.V3 instructions

Appleton

Appleton FSQC 30 A Installation & maintenance instructions

STS

STS M3-H Operator's manual

Renishaw

Renishaw RENGAGE OMP600 quick start guide

ChipBLASTER

ChipBLASTER STANDARD UNIT D30-80-1 Installation, operation and service manual

Honeywell

Honeywell VR9105V installation instructions

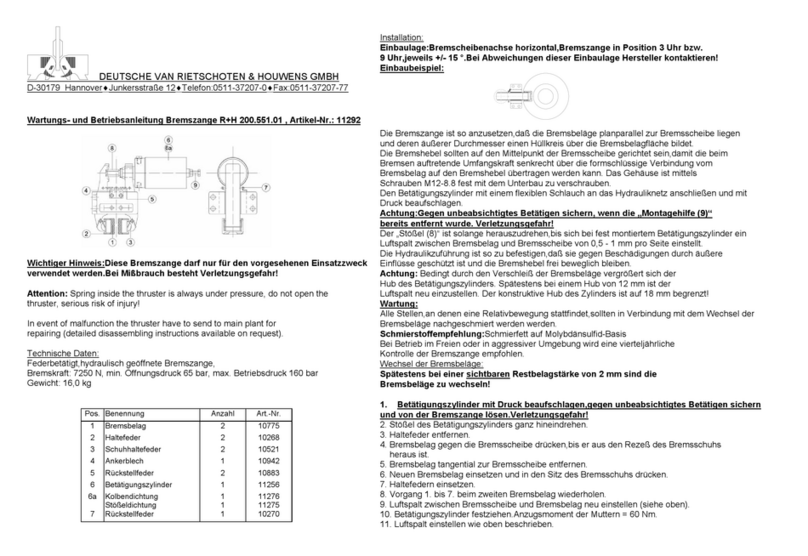

DEUTSCHE VAN RIETSCHOTEN & HOUWENS

DEUTSCHE VAN RIETSCHOTEN & HOUWENS R+H 200.551.01 Maintenance and operating manual

Viessmann

Viessmann 5071 Operation manual

TradeQuip

TradeQuip 1019T owner's manual

Condair

Condair AX Installation and operating manual

DecoRad

DecoRad Handmate UV 1800 user manual