Bilstein B8 5160 User guide

This manual suits for next models

5

Other Bilstein Automobile Accessories manuals

Bilstein

Bilstein 4600 Series User guide

Bilstein

Bilstein B8 8100 User guide

Bilstein

Bilstein 22-310408 User guide

Bilstein

Bilstein B8 5100 User guide

Bilstein

Bilstein E4-WM5-Y592A00 User guide

Bilstein

Bilstein 25-187632 User guide

Bilstein

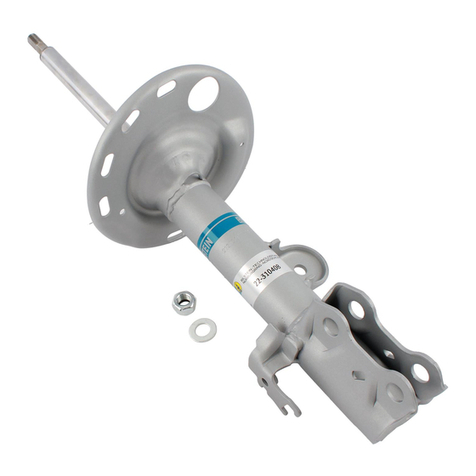

Bilstein E4-WM5-Y723A00 User guide

Bilstein

Bilstein E4-WM5-Y558A00 User guide

Bilstein

Bilstein B8 8100 User guide

Bilstein

Bilstein E4-WM5-Y715A00 User guide

Bilstein

Bilstein B8 5100 User guide

Bilstein

Bilstein E4-WM5-Y479A00 User guide

Bilstein

Bilstein 24-266659 User guide

Bilstein

Bilstein E4-WM5-Y116A00 User guide

Bilstein

Bilstein Blue Print ADC44288 User manual

Bilstein

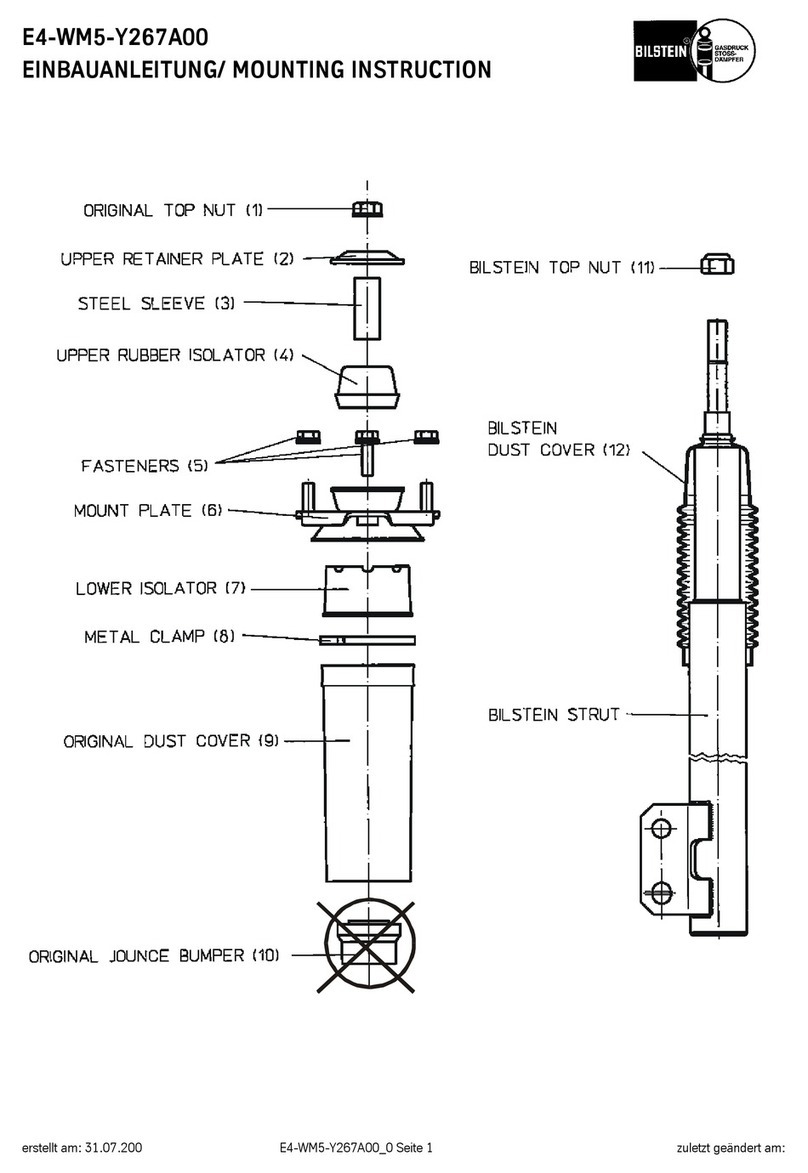

Bilstein E4-WM5-Y267A00 User guide

Bilstein

Bilstein E4-WM5-Y711A00 User guide

Bilstein

Bilstein E4-WM5-Y722A00 User guide

Popular Automobile Accessories manuals by other brands

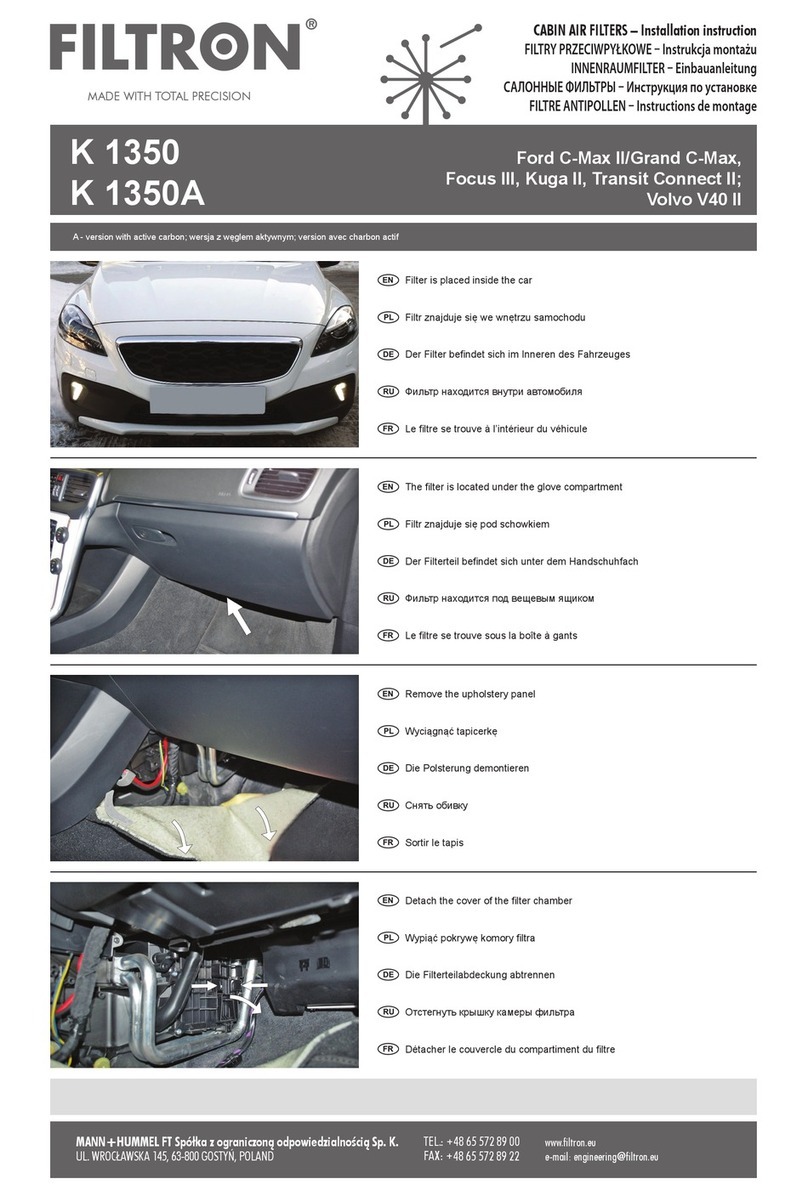

FILTRON

FILTRON K 1350A installation instructions

Rhino-Rack

Rhino-Rack RTD25L instructions

Burley

Burley EURO CAR SEAT ADAPTER Owner's instruction and safety manual

Buyers

Buyers 1718010 installation instructions

Pittsburgh

Pittsburgh 95987 Assembly and operation instructions

Rola

Rola 59970 Instruction guide

Vixen Horns

Vixen Horns VXO8330/3418B installation guide

SCHUBERTH

SCHUBERTH SRC SYSTEM quick start guide

Audiovox

Audiovox LCMR6CT installation manual

Black Horse Off Road

Black Horse Off Road TR-JECOOE installation instructions

Safe Fleet

Safe Fleet Prime Design AR1911 Assembly instructions

Extang

Extang Trifecta Installation sheet