created: 12.06.19 E4-WM5-Y631A00_0 Page 1 of 23 latest revision:

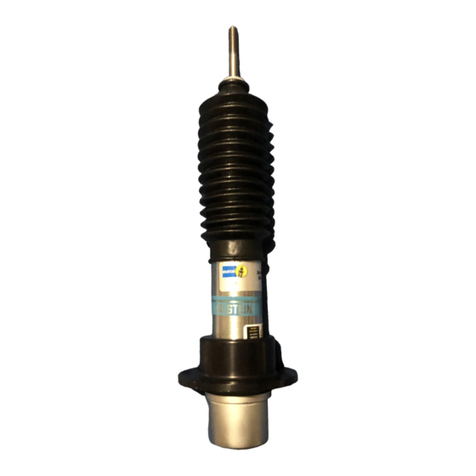

This instruction is for both left front (driver) 25-287806 and right front (passenger) 25-287813

B8 8100 shocks. A bill of materials (BOM) of the included mounting parts kits is shown on the

next page.

IMPORTANT! READ THIS FIRST!

Installation of shock absorbers requires special tools and expert knowledge. Accordingly, installation of all BILSTEIN

products must be performed by a qualified suspension specialist.

When replacing other brands, BILSTEIN shock absorbers should always be installed as a set. All BILSTEIN products

must only be used for the specific, intended application as indicated in the application guide. Any use of any BILSTEIN

product other than for its intended use may result in serious bodily injury or death.

Always use a chassis hoist for the installation of BILSTEIN products and make certain that the raised vehicle is securely

attached to the hoist and/or supported to prevent the vehicle from slipping, falling, or moving during the installation

process.

If you choose to install any BILSTEIN product without the necessary special tools, expertise or chassis hoist, you

may subject yourself to the risk of serious bodily injury or death. If you elect not to use a chassis hoist, at least make

sure the vehicle is on level ground, that all tires on the ground during installation are blocked to prevent movement, that at least

two tires are on the ground at all times, and that adequately secured safety stands (jack stands) are used to support the chassis.

NEVER get under the vehicle until you have checked to make sure all of these steps are performed.

BILSTEIN suspension products are gas-filled and are highly pressurized.

Never place any BILSTEIN product in a vise or use a clamp on any BILSTEIN product.

Never apply heat near any BILSTEIN product.

Never attempt to open or repair any BILSTEIN product, in order to prevent serious bodily injury or death.

Any attempt to misuse, misapply, modify, or tamper with any BILSTEIN suspension product voids any warranty and may result

in serious bodily injury or death.

While installing any BILSTEIN product:

Do not use impact tools for loosening or tightening fasteners, because this may destroy the screw threads.

Self-locking fasteners must only be used once!

Reuse original equipment components only if they are in good condition, otherwise replace them with new components.

Never remove the slight film of oil on the piston rod and seal.

All mounting fasteners for shocks and struts must be securely tightened before the vehicle is operated.

After installing any BILSTEIN product:

The suspension caster and camber must be checked and/or adjusted to comply with the vehicle manufacturer’s

specifications.

The (load dependent) brake compensator and the anti-lock brake system must be checked and/or reset to comply with

the vehicle manufacturer’s specifications.

The headlight aim must be checked and adjusted.

B8 8100 bypass shocks feature a proprietary BILSTEIN zinc plated finish. This finish must be serviced in order to

maintain its luster. Particularly in moist climates, a protective coating, such as a wax or lubricating oil should be

periodically applied to prevent tarnishing. This finish is not covered under warranty.

It is normal to hear a slight audible clicking noise during compression and rebound strokes in the B8 8100 bypass

shocks, most notably during low velocity events. This is due to the internal check pistons opening and closing to

create the externally adjustable compression and rebound zones.