Bin Master SPL-100 User manual

925-0367 Rev A

1018

SPL-100

BATTERY-OPERATED LASER

OPERATOR’S MANUAL

BinMaster: Division of Garner Industries

7201 N. 98th St., Lincoln,NE 68507

402-434-9102 • info@binmaster.com

www.binmaster.com

INSTALLATION AND OPERATION INSTRUCTIONS

PLEASE READ CAREFULLY

925-0367 Rev A

1018

2

TABLE OF CONTENTS

Warnings ________________________________________________________ 3

Warning Labels ___________________________________________________ 3

FCC Information __________________________________________________ 4

Intended Use ____________________________________________________ 4

Highlights _______________________________________________________ 5

Applications _____________________________________________________ 5

Features ________________________________________________________ 5

Har dware Features __________________________________________________________ 5

Software Features __________________________________________________________ 6

System Architecture _______________________________________________ 6

Specifications ____________________________________________________ 7

Dimensions ______________________________________________________ 8

External Dimensions ________________________________________________________ 8

Weight ____________________________________________________________________ 8

Controls _________________________________________________________ 9

Configuration and Adjustments ______________________________________ 9

User Configuration __________________________________________________________ 9

Factory Configuration Settings ________________________________________________ 9

Assembly _______________________________________________________ 9

Installation______________________________________________________ 10

Operation ______________________________________________________ 10

Maintenance ____________________________________________________ 11

Service Warnings __________________________________________________________ 11

Battery Replacement _______________________________________________________ 11

Reconfiguration____________________________________________________________ 11

Cleaning _________________________________________________________________ 11

Manufacturer and Contact Information _______________________________ 12

925-0367 Rev A

1018

3

WARNINGS

• Caution—use of controls or adjustments or performance of procedures other than

those specified herein may result in hazardous radiation exposure.

• This product emits Class 2 laser radiation, <1mW from the shutter in a direction

perpendicular to the shutter.

• Do not stare into the laser during operation.

• If eyes are exposed to the laser, blink and turn away immediately.

• The unit may begin laser operation immediately upon connecting the battery or at any

time according to the software configurations applied.

• When servicing the unit, it is advised to first disconnect the battery in order to power

the unit off.

• When connecting the battery, first ensure the unit is not pointed toward eyes.

• Do not tamper with or remove the electronics cover.

• Do not tamper with or remove the shutter or shutter attachment means.

WARNING LABELS

This product contains the following warning and certification labels affixed to the exterior of

the body:

Label 1: Certification and Identification Label

The Certification and Identification label is located on the product body side.

925-0367 Rev A

1018

4

Label 2: Warning Logotype

The Warning Logotype label is located on the product body side.

Label 3: Aperture Label

The Aperture label is located on the product front adjacent to the aperture.

Label 4: Brand Label

The Brand label is located on the product body side.

FCC INFORMATION

NOTE: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

INTENDED USE

The SPL-100 is intended for mounting in fixed, known locations and for use in measuring

distances to solid materials in low and no-dust environments.

925-0367 Rev A

1018

5

HIGHLIGHTS

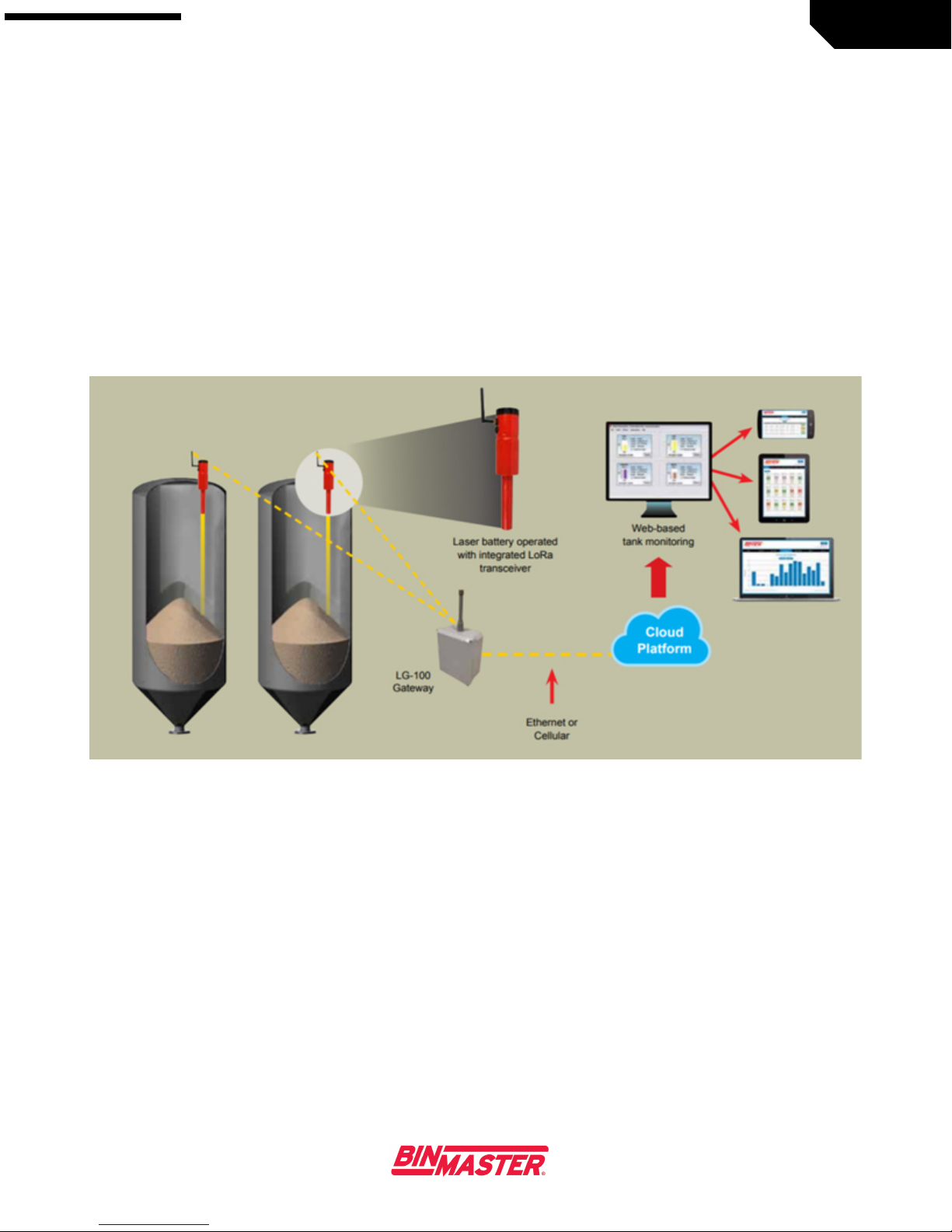

The SPL-100 is a fully wireless, battery-powered automatic single point laser level measuring

sensor. The unit features a dust tube for dust protection. The unit operates at a configurable

time, captures a measurement, and sends the measurement using the integrated LoRa

transceiver to the LoRa modem that may be connected to the LG-100 gateway. The gateway

may be configured to send and receive data and configuration files via BinView.

The unit is supplied with SPL-100 configuration software that runs on modern Windows PCs.

To reduce installation costs and complexity, the unit is completely wireless; neither power

wires nor communications cables are required.

APPLICATIONS

Granules, pellets and solids contained in bins, tanks, silos, or hoppers in low and no-dust

environments. Applications may include:

Plastics

Dry Chemicals

Food Processing

Grain Storage

Paper Processing

FEATURES

Hardware Features

•Single point measuring

•LoRa communication transceiver

•Battery powered

•30 meter (98 feet) measuring range

•Visible range red laser

•Available matched LoRa modem

•2.0" standard NPT Female thread-in mounting

•Sealed to IP67

•¼ Wave whip antenna, IP67 rated

925-0367 Rev A

1018

6

Software Features

•General error reporting

•Fully configurable by MicroUSB

•Partially re-configurable by LoRa

•Configurable LoRa wake-up & measure times

•Cloud-based access (configuration & data)

SYSTEM ARCHITECTURE

Figure 1: System Conf iguration

925-0367 Rev A

1018

7

SPECIFICATIONS

•Measurement range: 30m (98 feet)

•Measurement Accuracy: ±5mm (0.20 inches)

•Data I/O: LoRa

•Configuration I/O: LoRa and Micro USB (under sealed cover)

•Wireless Communications Range:

o>10km (>6 miles) Line-of-Sight (LOS)

o>1.6km (>1 mile) Non-Line-of-Sight (NLOS) (Dependent upon terrain and line of

sight obstacles)

•Power Source: 3.6V, 19AH Internal Li-Ion battery

•Battery Life (Est.): ~10 years, one measurement per day

•Antenna: ¼ Wave Whip

•Dust Tube: Available

•Ingress Protection: IP67

•Ambient Operating Temperature: -30 to +85C

•Ambient Storage Temperature: -40 to +85C

•Battery Voltage Reporting: Configurable

•Receiver Addressing: Configurable

•Hazardous Location: Not rated for hazardous locations

•Mounting: 2.0" NPT standard threaded nose, multiple mounting flange types

•Laser Beam Size: 2.5 x 5 mm @ 3 meter (FWHM)

•Laser Wavelength: 635 ± 10nm

•Laser Safety: <1 mW (Class 2)

•Laser Emissions Direction: Collimated and perpendicular to the aperture face.

•Housing Material: Aluminum and Injection molded plastic

925-0367 Rev A

1018

8

DIMENSIONS

External Dimensions

Figure 2: Dimensions (units in mm)

Weight

Approximate weight:

1.8kg

4 pounds

925-0367 Rev A

1018

9

CONTROLS

The unit has no user controls. Factory supplied configuration may be changed using SPL-100

configuration software as described in Configuration below.

CONFIGURATION AND ADJUSTMENTS

Before installation, users may wish to change the factory confirmation.

User Configuration

The following configurations may be set by users:

•Measurement times and frequency

•Power consumption reporting to help predict when the battery must be replaced.

•Transmission frequency

The unit may be configured using the supplied configuration software via the MicroUSB

connector located under the Battery Cap or over LoRa.

The LoRa configuration method is intended primarily to allow units installed in field

applications to be reconfigured. New configurations will only be received and applied when

the unit wakes at its previously configured wake time.

Factory Configuration Settings

Measurement time: 8AM US EST

Measurement frequency: 24 hours

Power consumption reporting: On

ASSEMBLY

The unit is supplied fully assembled and requires no user assembly other than attachment of

antenna and insertion of battery.

925-0367 Rev A

1018

10

INSTALLATION

The unit may be installed using the 2.0” NPT female threaded nose by threading the unit into

a suitable flange equipped with a 2.0” NPT male threaded receptacle. Using this method, the

unit should be hand-tightened-only to compress the O-ring seal for water-tightness. The unit

should be rotated and additional 1/8 – 1/4 turn after the mounting flange assembly contacts

the O-ring.

The laser may be temporarily continuously activated for 1 minute during mounting to facilitate

aiming. Continuously activating the laser consumes battery power and may reduce the life of

the laser emitter and should be used sparingly to avoid excessive power consumption. Each

time the battery cover is closed, the laser will activate for ~1 minute.

OPERATION

The unit is factory supplied with no battery installed.

When the battery is installed and the battery cover is closed, the unit will begin normal

operation following factory or user-applied configuration settings. The laser will come on for

60 seconds to aid in aiming the unit.

During normal operation the unit is programmed to wake, make and send a measurement,

then return to low-power sleep mode.

When a measurement is initiated the following sequence will occur:

1. The laser is activated

2. A measurement is taken

3. Measurement data is transmitted along with any reporting codes

4. Any available reconfiguration files are received and applied

5. The unit returns to low-power sleep mode

To start the unit:

1. Remove the battery cap

2. Open the battery cover

3. Insert the battery

4. Close the battery cover

5. Replace the Battery Cap

925-0367 Rev A

1018

11

MAINTENANCE

The unit may require periodic servicing for the following reasons:

1. Battery replacement

2. Reconfiguration

3. Cleaning

The unit does not require maintenance or servicing to remain in compliance with CFR Title 21

1040.10.

Service Warnings

Disconnect the battery before servicing the unit.

If it is impossible to disconnect the battery prior to servicing, take precautions to prevent the

laser aperture located on the shutter from being pointed at eyes.

Do not tamper with or remove the electronics cover.

Do not tamper with or remove the shutter or shutter attachment means.

Battery Replacement

For battery replacement, remove the battery cap. Open the battery cover. Remove the

battery and replace with a new battery. Close the battery cover and replace the battery cap.

Batteries can be purchased from BinMaster. Contact your RSM for pricing and availability.

Reconfiguration

Reconfiguration of the unit may be accomplished over LoRa or using the MicroUSB

connector located under the MicroUSB cover on the back end of the unit.

Cleaning

The exterior of the unit may require periodic cleaning. Simply wipe the unit with a soft damp

cloth. Mild detergent may be used as required.

925-0367 Rev A

1018

12

MANUFACTURER AND CONTACT

INFORMATION

BinMaster

7201 North 98th Street

PO Box 29709

Lincoln, NE 68507

Phone: 402-434-9102 / 800-278-4241 (toll-free in the U.S. only)

Fax: 402-434-9133

Email: info@binmaster.com

www.binmaster.com

Table of contents