Bin Master PROCAP I Series User manual

По вопросам продаж и поддержки обращайтесь:

Архангельск (8182)63‐90‐72

Астана (7172)727‐132

Белгород (4722)40‐23‐64

Брянск (4832)59‐03‐52

Владивосток (423)249‐28‐31

Волгоград (844)278‐03‐48

Вологда (8172)26‐41‐59

Воронеж (473)204‐51‐73

Екатеринбург (343)384‐55‐89

Иваново (4932)77‐34‐06

Ижевск (3412)26‐03‐58

Казань (843)206‐01‐48

Калининград (4012)72‐03‐81

Калуга (4842)92‐23‐67

Кемерово (3842)65‐04‐62

Киров (8332)68‐02‐04

Краснодар (861)203‐40‐90

Красноярск (391)204‐63‐61

Курск (4712)77‐13‐04

Липецк (4742)52‐20‐81

Магнитогорск (3519)55‐03‐13

Москва (495)268‐04‐70

Мурманск (8152)59‐64‐93

Набережные Челны (8552)20‐53‐41

Нижний Новгород (831)429‐08‐12

Новокузнецк (3843)20‐46‐81

Новосибирск (383)227‐86‐73

Орел (4862)44‐53‐42

Оренбург (3532)37‐68‐04

Пенза (8412)22‐31‐16

Пермь (342)205‐81‐47

Ростов‐на‐Дону (863)308‐18‐15

Рязань (4912)46‐61‐64

Самара (846)206‐03‐16

Санкт‐Петербург (812)309‐46‐40

Саратов (845)249‐38‐78

Смоленск (4812)29‐41‐54

Сочи (862)225‐72‐31

Ставрополь (8652)20‐65‐13

Тверь (4822)63‐31‐35

Томск (3822)98‐41‐53

Тула (4872)74‐02‐29

Тюмень (3452)66‐21‐18

Ульяновск (8422)24‐23‐59

Уфа (347)229‐48‐12

Челябинск (351)202‐03‐61

Череповец (8202)49‐02‐64

Ярославль (4852)69‐52‐93

Единый адрес: [email protected] Веб‐сайт: www.binmaster.nt-rt.ru

PROCAP I BinMaster

9250290 Rev A

PROCAP I Series

CAPACITANCE PROBE

OPERATING INSTRUCTIONS

PLEASE READ CAREFULLY

Price $5.00

925-0290 Rev A 2

TABLE OF CONTENTS

GENERAL SPECIFICATIONS .................................................................................................... 3

SAFETY SUMMARY................................................................................................................... 4

1.0 INTRODUCTION.................................................................................................................. 5

2.0 APPLICATIONS ................................................................................................................... 5

3.0 INSTALLATION .................................................................................................................... 5

3.1 Location and Mounting ............................................................................................ 5

3.2 Input Power and Field Wiring .................................................................................. 5

3.3 Grounding................................................................................................................ 6

4.0 FAIL-SAFE SELECTION ...................................................................................................... 7

4.1 Description .............................................................................................................. 7

4.2 Fail-Safe High.......................................................................................................... 7

4.3 Fail-Safe Low .......................................................................................................... 7

5.0 CALIBRATION...................................................................................................................... 8

5.1 Calibration Verification............................................................................................. 8

5.2 Calibration Procedure ............................................................................................. 8

5.3 Sensitivity Selection ............................................................................................... 8

6.0 EXTERNAL VIEW LED ....................................................................................................... 9

7.0 TIME DELAY ........................................................................................................................ 9

8.0 WARRANTY AND CUSTOMER SERVICE ........................................................................ 10

9.0 DISPOSAL ........................................................................................................................... 10

FIGURE 1.1 ................................................................................................................................ 11

FIGURE 1.2 ................................................................................................................................ 12

FIGURE 2.1 ................................................................................................................................ 13

DECLARATION OF CONFORMITY ........................................................................................... 14

925-0290 Rev A 3

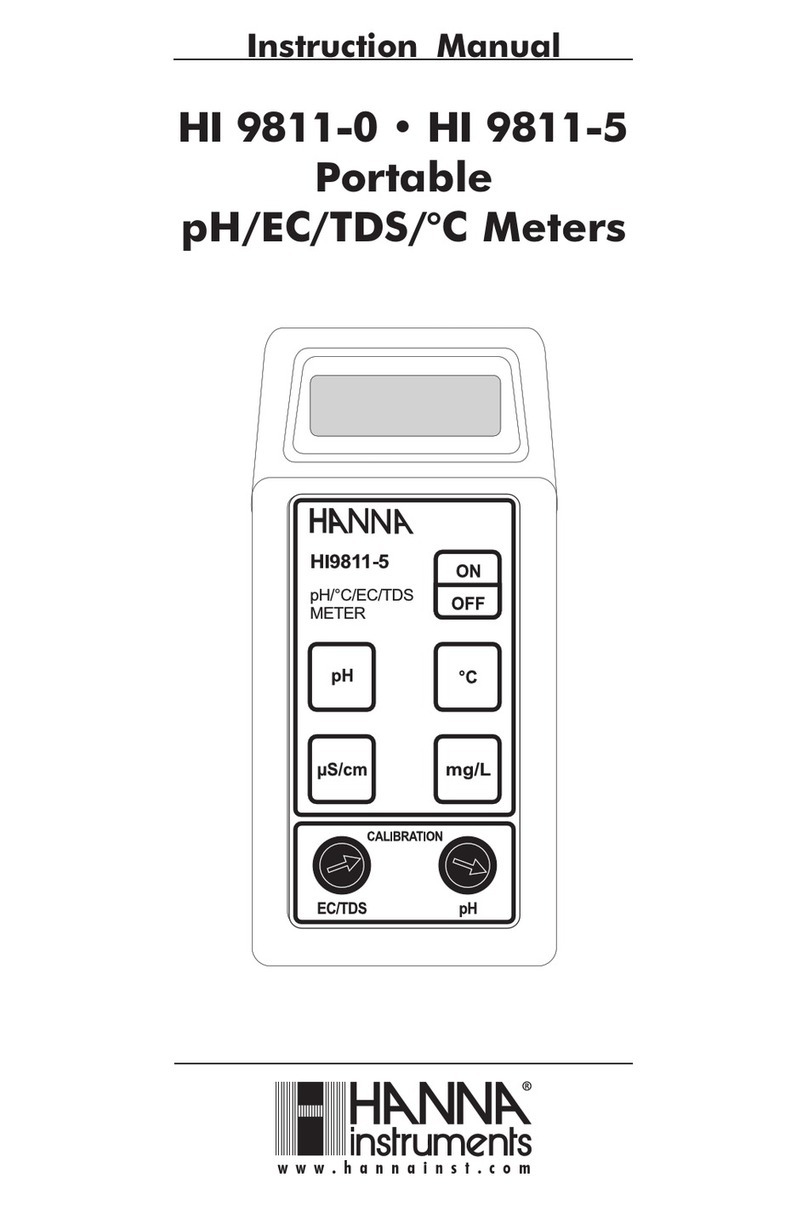

PROCAP I

GENERAL SPECIFICATIONS

Supply: 24 TO 240 VAC or VDC

Load: 4VA

Ambient Temperature: (Electronics) -20°F to +145°F (-28°C to +62°C)

Sensitivity: 1 picofarad

Enclosure: PROCAP I Type 4X, 5, 9, & 12 (HAZ LOC CL II E, F, & G)

PROCAP I X Type 4X, 5, 7, 9, & 12 (HAZ LOC CL I C&D; CL II E,F, & G)

Fuse F1: 0.4A 250V Time Delay 5 X 20MM BinMaster P/N 328-0064

Relay Contact Rating: DPDT contacts; 10 Amps 250 VAC maximum

Fail-Safe: Switch selectable "High" or "Low" level modes.

Calibration: Set when probe is uncovered:

COARSE adjust; single turn potentiometer

FINE adjust; single turn potentiometer

Status Indicator: Internal LED indicates material in contact with probe.

PROCAP I has an external LED also

Time Delay: Independently adjustable up to 30 seconds

Probe Shield: Automatically compensates for material buildup on the

probe

Mounting: 1 1/4” or 3/4" NPT - When used in liquid applications the

stainless steel threads must be used to insure a proper

seal.

Conduit Entries: 3/4" NPT

9250290 Rev A

SAFETY SUMMARY

Review the following safety precautions to avoid injury and prevent damage to the equipment.

The product should be installed, commissioned, and maintained by qualified and authorized personnel only.

Install according to installation instructions and comply with all National and Local codes.

Use electrical wire that is sized and rated for the maximum voltage and current of the application.

Properly ground the enclosure to an adequate earth ground.

Observe all terminal and relay contact ratings as called out on the nameplate and in the installation manual.

Insure that the enclosure cover is in place and secured tightly during normal operation.

If this product is used in a manner not specified by the manufacturer the safety protection could be compromised.

Safety Terms and Symbols

WARNING: Warning statements identify conditions or practices that could result in injury or loss of life. Risk of

electrical shock.

CAUTION: Caution statements identify conditions or practices that could result in damage to this product or other

property.

925-0290 Rev A 5

1.0 INTRODUCTION

The Bin-Master PROCAP I is a point level control used to detect the presence or absence of solids or liq-

uids. The PROCAP I operates on the capacitance principle and incorporates a "Quick Set" feature to sim-

plify calibration. The PROCAP I includes switch selectable Fail-Safe output contacts and "Probe Shield"

technology for ignoring material build up.

Upon installation the PROCAP I is set up with the probe uncovered. The "Quick Set" feature allows simple

setup and calibration of the unit to achieve low, medium, or high sensitivity settings. The PRO CAP I has

an adjustable time delay for monitoring covered or uncovered conditions.

2.0 APPLICATIONS

For applications in pressurized vessels up to 500 PSI, the PROCAP I should be mounted with the 3/4"

or 1 1/4” stainless steel threads. When the PROCAP I is used in liquid applications the stainless steel

threads must be used to insure a proper seal.

Process temperatures for the various probes are:

1. Delrin Sleeved Stainless Steel: 250 Deg. F

2. Teflon Sleeved Stainless Steel: 500 Deg. F

3. Flush Mount (Polyethylene): 180 Deg. F

4. Flush Mount (Teflon): 450 Deg. F

5. Bare Stainless Steel: 250 Deg. F

6. Flexible Extension: 250 Deg. F

The Delrin or Teflon sleeved stainless steel probe should be used when mounting the PROCAP I In a

highly corrosive atmosphere. Confirm that the sleeve material is rated for use in the corrosive nature of the

application. Bare metal Stainless Steel probes are suitable for granular or liquid material that is not electri-

cally conductive. For electrically conductive material, in some applications, a coated (insulated) probe may

need be used for the unit to effectively sense the material. Contact BinMaster if there are any questions

about which probe to use for a specific application.

3.0 INSTALLATION

3.1 Location and Mounting

The probe should be located out of the direct flow of material. The PROCAP I is designed to mount utiliz-

ing either a 1 1/4" NPT coupling or 3/4" NPT coupling. When the PROCAP I is used with the flush mount

probe, the flush mount probe mounts directly to the vessel wall using a 7" diameter bolt circle. Refer to Fig-

ures 1.1 and 1.2 for illustrations on installation, mounting options, and different probe combinations.

3.2 Input Power and Field Wiring

The PROCAP I can be powered from either an AC or a DC power source with a voltage range from 24 up

to 240 volts. The power source can be either grounded or ungrounded. If powered from a grounded

source the grounded circuit conductor should be connected to the N terminal. In this way the ungrounded

circuit conductor is fused on the circuit board. A disconnecting means should be provided to disconnect

incoming power to this device. Field wiring should conform to all national and local electrical codes and

any other agency or authority having jurisdiction over the installation. For power input, use wire that is

sized and rated for the maximum voltage and current as per equipment ratings and has a temperature rat-

ing of at least 70 degrees C For relay output, use wire that is sized and rated for the maximum voltage and

current as per application, up to 250VAC 10A, and has a temperature rating of at least 70 degrees C .

Installation shall be done by qualified personnel.

925-0290 Rev A 6

3.3 Grounding

An equipment grounding connection (earth ground) must be supplied to the unit for safety and to insure

proper operation of the unit. A green ground screw is provided in the enclosure for connection of an equip-

ment grounding conductor as shown in the figure above. This unit uses earth ground as a reference for

calibration and detecting a covered or uncovered condition. Therefore, the vessel in which the PROCAP I

is mounted must be made of metal, or a suitable metal ground plate must be installed where the PROCAP

I is mounted.

1NC

1C

1NO

2NC

2NO

2C

N

L

COARSE FINE

INTERNAL

COVERED

LED

EXTERNAL

COVERED LED

Ground wire

DELAY

COVEREDUNCOVERED

FUSE

925-0290 Rev A 7

4.0 FAIL-SAFE SELECTION

4.1 Description

A Fail-Safe condition means that the relay contact positions are set up so that in the event of a power fail-

ure the relay will be de-energized and the contacts will indicate a condition that is deemed safe for the

application. (Refer to FIGURE 2.1 for the location of the Fail-Safe selection switch.)

4.2 Fail-Safe High

Fail-Safe High means that the relay will be energized when the probe is uncovered and will de-energize

when the probe is covered. In this mode, a power failure will cause the relay contacts to indicate that the

probe is covered whether it is or not.

4.3 Fail-Safe Low

Fail-Safe Low means that the relay will be de-energized when the probe is uncovered and will energize

when the probe is covered. In this mode, a power failure will cause the relay contacts to indicate that the

probe is uncovered whether it is or not.

NC C NO NO C NC

1 1 1 2 2 2

NC C NO NO C NC

111222

UNCOVERED COVERED

FAIL SAFE "HIGH" RELAY CONTACT POSITION

NC C NO NO C NC

1 1 1 2 2 2

NC C NO NO C NC

111222

UNCOVERED COVERED

FAIL SAFE "LOW" RELAY CONTACT POSITION

925-0290 Rev A 8

5.0 CALIBRATION

The PROCAP I Quick Set calibration uses two single turn potentiometers making calibration very simple.

One potentiometer labeled COARSE is used to compensate for the capacitance of the empty vessel. The

other potentiometer labeled FINE is used to set in the desired sensitivity. Refer to FIGURE 2.1 for the

location of these potentiometers on the printed circuit board.

NOTE: Accurate calibration requires that the appropriate probe is attached to the PROCAP I and

the unit installed in the vessel. The probe must be UNCOVERED and material well below it.

5.1 Calibration Verification

Following calibration adjustment, the sensitivity setting that you have selected should be checked by veri-

fying that the PRO CAP II senses a covered probe condition with your material.

5.2 Calibration Procedure

WARNING: During Calibration, this unit will need to be energized. Care should be taken to not

come in contact with any live voltage in the area around the terminal blocks and fuse!

CAUTION: The Calibration potentiometers are delicate electronic devices, do not use excessive

force when adjusting.

1. Turn both the COARSE and FINE potentiometers fully counter clockwise (CCW). The internal COV-

ERED indicator light should be OFF.

2. Turn the COARSE potentiometer slowly clockwise (CW) to the point where the COVERED indicator

light just turns ON and stays on.

3. Turn the FINE potentiometer slowly clockwise (CW) until the COVERED indicator light just turns OFF.

(If the COARSE potentiometer has been carefully adjusted, this should occur when the FINE potenti-

ometer is between the 8 and 10 O'clock position.) Now continue to turn the FINE potentiometer clock-

wise (CW) to the desired sensitivity setting.

HIGH sensitivity: 1/16 turn

MEDIUM sensitivity: 1/8 turn

LOW sensitivity: 1/4 to 1/2 turn

NOTE: It may be convenient to think of the FINE potentiometer as a clock face and envision the distance

between consecutive hour numbers. Turning the FINE potentiometer clockwise one hour position past the

point at which the COVERED indicator just turns OFF would provide a high sensitivity setting. Two-hour

positions past that point would provide a medium sensitivity setting..

5.3 Sensitivity Selection

Sensitivity Setting (typical) Dielectric Constant of Material

HIGH sensitivity: 4 or less

MEDIUM sensitivity: 4 to 10

LOW sensitivity: 10 or higher

925-0290 Rev A 9

6.0 EXTERNAL VIEW LED

PROCAP I models include an external view LED. PROCAP I X models do not have an external view LED.

This LED provides an externally visible status indication for the PROCAP I. When this LED is flashing, it

indicates a normal Uncovered condition. When this LED is ON steady, it indicates a Covered condition.

When this LED is OFF, it indicates a power failure or fault condition. This external LED is affected by any

time delay set for the relay contacts.

7.0 TIME DELAY

The PROCAP I has two single turn adjustable time delay potentiometers. The Delay potentiometer labeled

UNCVR is for applying a time delay on going from a covered indication to an uncovered indication.

The Delay potentiometer labeled CVR is for applying a time delay on going from an uncovered indication

to an covered indication. Each potentiometer can be set for a time delay of up to approximately 30 sec-

onds. This time delay affects the relay contacts and external LED only. The internal Covered LED

will immediately respond to a change in covered or uncovered condition regardless of the time delay set-

ting.

Minimum time delay is when the DELAY potentiometers are set fully counter-clockwise. (Refer to the Fig-

ure below for the location of the DELAY potentiometers.) Maximum time delay is with the DELAY potenti-

ometer set fully clockwise.

DELAY COARSE FINE

INTERNAL

COVERED

LED

EXTERNAL

COVERED LED

COVEREDUNCOVERED

925-0290 Rev A 10

8.0 WARRANTY AND CUSTOMER SERVICE

8.1 Limited Warranty

The manufacturer warrants this equipment for two (2) years according to the following terms:

1.) This warranty extends to the original purchaser only and commences on the date

of original purchase. The original purchaser must mail to the manufacturer the "Warranty

Registration" card to confirm the equipment purchase. Failure to do so may void the war-

ranty.

2.) The manufacturer will repair or replace any part of this equipment found to be

defective, provided such part is delivered prepaid, to the factory. Manufacturer's obligation

is limited to the cost of material and labor to repair or replace and does not include trans-

portation expenses.

3.) This warranty shall not apply to any product that has, in our judgment, been tam-

pered with, altered, subject to misuse, neglect or accident. In addition, the warranty does

not extend to repairs made necessary by normal wear.

4.) This warranty is in lieu of all other warranties, expressed or implied.

EXPLOSION HAZARD-SUBSTITUTION OF COMPONENTS MAY

IMPAIR INTRINSIC SAFETY

9.0

DISPOSAL

This product consists of materials that can be recycled by specialized recycling companies. It

uses recyclable materials and the electronics is designed to be easily separated. Consult local

authorities for proper disposal locations.

925-0290 Rev A 11

Figure 1.1

When the PROCAP I is used for liquid applications the stainless steel threads must be

used to insure a proper seal.

925-0290 Rev A 12

Figure 1.2

9250290 Rev A

FINE POT.

COARSE POT.

FAIL SAFE

SWITCH

TIME DELAY

POT.

UNCVR

CVR

FIGURE 2.1

9250290 Rev A

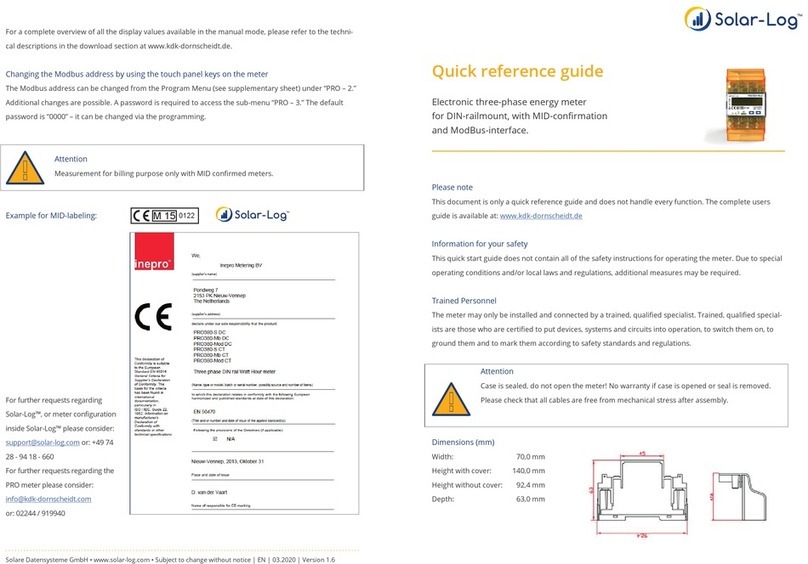

Declaration of Conformity

BinMaster declares that the PROCAP I and PROCAP IX level control devices as listed below

comply with the following directives and harmonized standards. This product if installed,

operated and maintained as described in this manual will provide a safe and reliable point

level control device for bulk solid materials.

Product: Capacitance point level control device.

Models: PROCAP I and PROCAP IX

All test reports and documentation are held and can be obtained from BinMaster.

9250290 Rev A

Mounting Instructions

Always Mount Unit With

Conduit opening down

When installing this level indicator in environments where it is possible for

moisture or moist air to enter the enclosure through the electrical conduit, the

conduit opening should be sealed with a duct seal compound or putty

appropriate for the purpose.

Conduit Seal

По вопросам продаж и поддержки обращайтесь:

Архангельск (8182)63‐90‐72

Астана (7172)727‐132

Белгород (4722)40‐23‐64

Брянск (4832)59‐03‐52

Владивосток (423)249‐28‐31

Волгоград (844)278‐03‐48

Вологда (8172)26‐41‐59

Воронеж (473)204‐51‐73

Екатеринбург (343)384‐55‐89

Иваново (4932)77‐34‐06

Ижевск (3412)26‐03‐58

Казань (843)206‐01‐48

Калининград (4012)72‐03‐81

Калуга (4842)92‐23‐67

Кемерово (3842)65‐04‐62

Киров (8332)68‐02‐04

Краснодар (861)203‐40‐90

Красноярск (391)204‐63‐61

Курск (4712)77‐13‐04

Липецк (4742)52‐20‐81

Магнитогорск (3519)55‐03‐13

Москва (495)268‐04‐70

Мурманск (8152)59‐64‐93

Набережные Челны (8552)20‐53‐41

Нижний Новгород (831)429‐08‐12

Новокузнецк (3843)20‐46‐81

Новосибирск (383)227‐86‐73

Орел (4862)44‐53‐42

Оренбург (3532)37‐68‐04

Пенза (8412)22‐31‐16

Пермь (342)205‐81‐47

Ростов‐на‐Дону (863)308‐18‐15

Рязань (4912)46‐61‐64

Самара (846)206‐03‐16

Санкт‐Петербург (812)309‐46‐40

Саратов (845)249‐38‐78

Смоленск (4812)29‐41‐54

Сочи (862)225‐72‐31

Ставрополь (8652)20‐65‐13

Тверь (4822)63‐31‐35

Томск (3822)98‐41‐53

Тула (4872)74‐02‐29

Тюмень (3452)66‐21‐18

Ульяновск (8422)24‐23‐59

Уфа (347)229‐48‐12

Челябинск (351)202‐03‐61

Череповец (8202)49‐02‐64

Ярославль (4852)69‐52‐93

Единый адрес: [email protected] Веб‐сайт: www.binmaster.nt-rt.ru

This manual suits for next models

2

Table of contents

Other Bin Master Measuring Instrument manuals

Bin Master

Bin Master MAXIMA+ Series User manual

Bin Master

Bin Master DPM-500 User manual

Bin Master

Bin Master 1000 User manual

Bin Master

Bin Master NCR-80 User manual

Bin Master

Bin Master DPM-500 User manual

Bin Master

Bin Master CNCR-210 User manual

Bin Master

Bin Master BMRX Series User manual

Bin Master

Bin Master SMARTBOB TS1 User manual

Bin Master

Bin Master BMRX-300 User manual

Bin Master

Bin Master GWR-2000 User manual