Bin Master CNCR-210 User manual

CNCR-210 • Two-wire 4

-

20 1

Operating Instructions

Radar sensor for continuous level measurement

CNCR-210

Two-wire 4

-

20 mA

Document ID: 925-0395 Rev B

CNCR-210 • Two-wire 4

-

20 2

Contents

1 About this document ............................................................................................................. 3

2 For your safety ....................................................................................................................... 3

2.1 Authorized personnel ....................................................................................................... 3

2.2 Appropriate use................................................................................................................ 3

2.3 Warning about incorrect use ............................................................................................ 4

3 Product description ............................................................................................................... 4

3.1Conguration.................................................................................................................... 4

3.2 Principle of operation ....................................................................................................... 5

3.3 Adjustment ....................................................................................................................... 5

4 Mounting................................................................................................................................. 6

4.1 General instructions ......................................................................................................... 6

4.2 Mounting versions............................................................................................................ 6

5 Connecting to power supply................................................................................................. 9

5.1 Preparing the connection ................................................................................................. 9

5.2 Connecting..................................................................................................................... 10

5.3 Wiring plan ..................................................................................................................... 11

6 Setup with smartphone/tablet (Bluetooth) ........................................................................ 11

6.1 Preparations................................................................................................................... 11

6.2 Connecting..................................................................................................................... 12

6.3 Parameter adjustment.................................................................................................... 13

7 Menu overview ..................................................................................................................... 14

8 Diagnostics and servicing .................................................................................................. 15

8.1 Maintenance .................................................................................................................. 15

8.2 Status messages ........................................................................................................... 15

9 Removal ................................................................................................................................ 17

10 Certicates and approvals .................................................................................................. 17

10.1 Radio licenses.............................................................................................................. 17

11 Supplement .......................................................................................................................... 17

11.1 Technical data .............................................................................................................. 17

11.2 Dimensions................................................................................................................... 19

CNCR-210 • Two-wire 4

-

20 3

Information, note, tip: This symbol indicates helpful additional

information and tips.

Note: This symbol indicates notes to prevent failures, malfunctions,

damage to devices or facility.

Caution: Non-observance may result in personal injury.

Warning: Non-observance may result in serious or fatal personal injury.

Danger: Non-observance of the information marked with this symbol

results in serious or fatal personal injury.

Ex applications

This symbol indicates special instructions for Ex applications.

List

The dot set in front indicates a list with no implied sequence.

Sequence of actions

Numbers set in front indicate successive steps in a procedure.

Battery disposal

This symbol indicates special information about the disposal of

batteries and accumulators.

1 About this document

2 For your safety

2.1 Authorized personnel

Alloperationsdescribedinthisdocumentationmustbecarriedoutonlybytrained,qualied

personnel authorized by the plant operator. Required personal protective equipment must always

be worn when working on or with the device.

2.2 Appropriate use

CNCR-210 is a sensor for continuous level measurement. Operational reliability is ensured only if

theinstrumentisproperlyusedaccordingtothespecicationsintheoperatinginstructions.

CNCR-210 • Two-wire 4

-

20 4

Safety instructions for Ex areas

TakenoteoftheExspecicsafetyinstructionsforExapplications.Theseinstructions

are attached as documents to each instrument with Ex approval and are part of the

operating instructions.

2.3 Warning about incorrect use

Inappropriateorincorrectuseofthisproductcanresultinapplication-specichazards,e.g.vessel

overllbyincorrectmountingoradjustment.Damagetopropertyandpersonsorenvironmental

contamination can result.

3 Product Description

3.1 Conguration

Fig. 1: Components of CNCR-210

1 Radar antenna

2 Processtting

3 Process seal

4 Electronics housing

5 Ventilation/pressure compensation

CNCR-210 • Two-wire 4

-

20 5

3.3 Adjustment

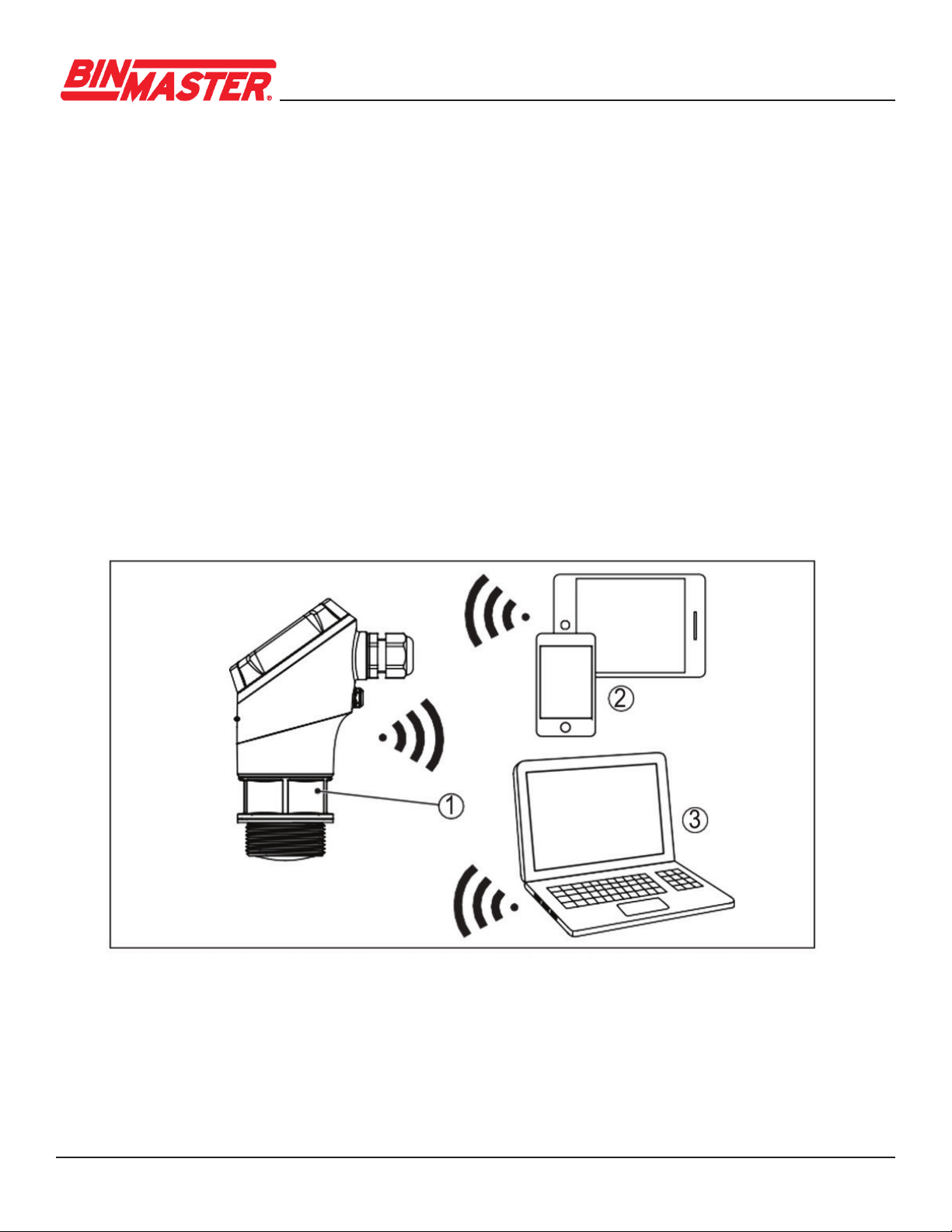

Devices with integrated Bluetooth module can be adjusted wirelessly via software adjustment tools:

• Smartphone/tablet (iOS or Android operating system)

• PC/notebook with Bluetooth USB adapter (Windows operating system)

Fig. 2: Wireless connection to standard operating devices with integrated Bluetooth LE

1 Sensor

2 Smartphone/Tablet

3 PC/Notebook

3.2 Principle of operation

CNCR-210 is a radar sensor for continuous level measurement. It is suitable for liquids and sol-

ids in practically all industries.

The instrument emits a continuous, frequency-modulated radar signal from its antenna. The emit-

tedsignalisreectedbythematerialandreceivedbytheantennaasanechowithamodied

frequency. The frequency change is proportional to the distance to the material.

CNCR-210 • Two-wire 4

-

20 6

4.2 Mounting

The radar emits pulses of electromagmetic waves which are polarized. By adjusting the rotation of

the instrument the polarization can be changed to reduce false echoes.

The narrow portion of the radar signal is in the middle of the conduit entry on the instrument. This

should be pointed towards the center of the vessel or any obstacle that may cause any unwanted

reectionstominimizefalseechos,forexample,thesidewallorvesselstructure.

4 Mounting

4.1 General instructions

The instrument is suitable for standard and extended ambient conditions according to DIN/EN/IEC/

ANSI/ISA/UL/CSA 61010-1. It can be used indoors as well as outdoors.

Protect your instrument against moisture ingress through the following measures:

• Use a suitable connection cable

•Tightenthecableglandorplugconnectorrmly

• Face the cable connection or conduit entry downward, never upward

This applies mainly to outdoor installations, in areas where high humidity is expected (e.g. through

cleaning processes) or on cooled or heated vessels.

Fig. 3: Polarization position

Cable / conduit entry

Note:

Whenthehousingisrotated,thedirectionofpolarizationchangesandhencetheinuenceofthefalse

echo on the measured value. Please keep this in mind when mounting or making changes later.

CNCR-210 • Two-wire 4

-

20 7

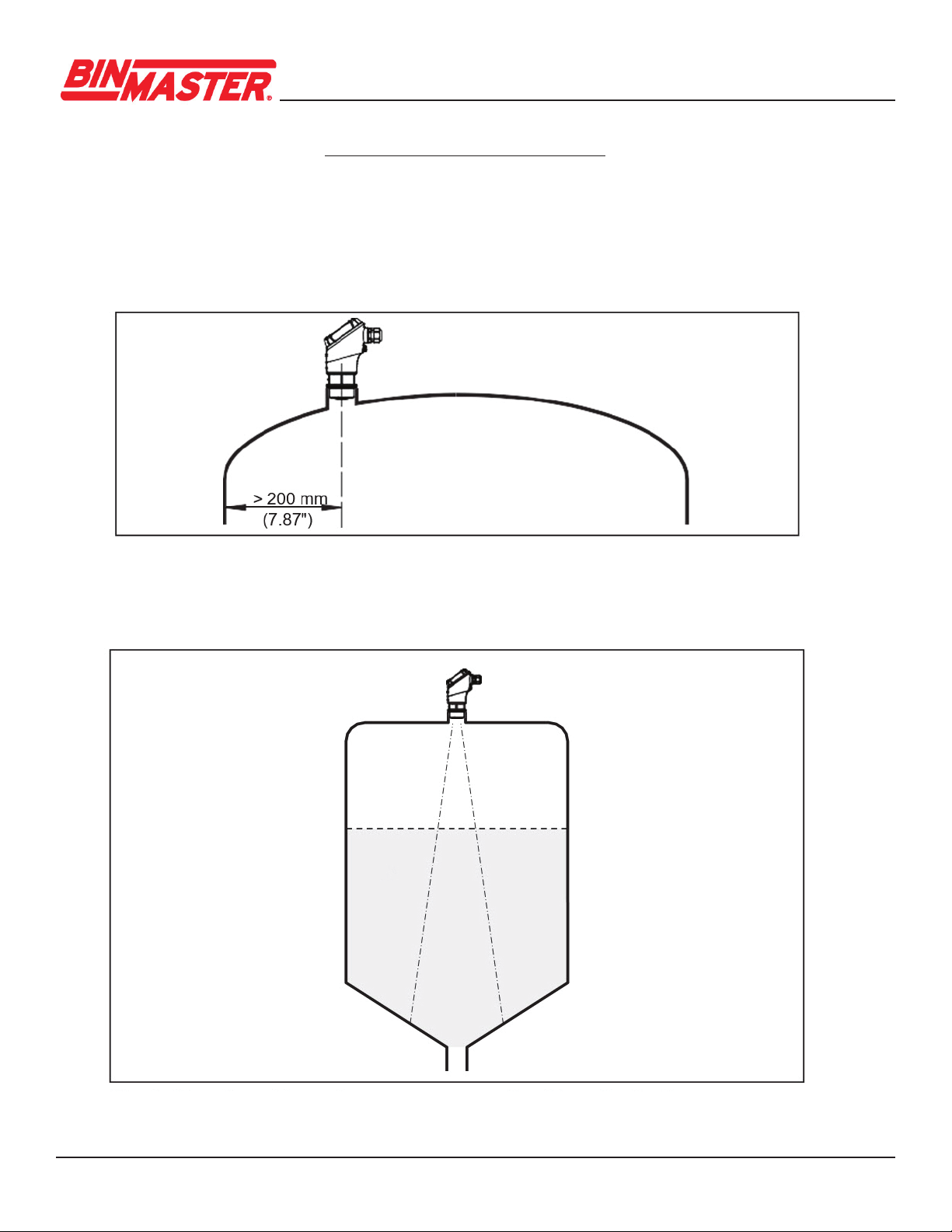

In vessels with cone bottoms, the sensor can be mounted in the center of the vessel to mea-

sure material down to the outlet.

When mounting the sensor, distance it at least 200 mm (7.874 in) from the vessel wall. If the sensor

is installed in the center of dished or round vessel tops, multiple echoes can arise. However, these

can be suppressed by a false signal suppression (see chapter “Setup”).

If you cannot maintain this distance, you should carry out a false signal suppression during initial

setup. This applies particularly if buildup on the vessel wall is expected. If this is the case, we

recommend repeating the false signal suppression later with the additional buildup.

Fig. 5: Mounting the radar sensor with conical bottom

Fig. 4: Mounting the radar sensor on round vessel tops

CNCR-210 • Two-wire 4

-

20 8

Donotmounttheinstrumentinorabovethellstream.Makesurethatitispointedtowardsthe

materialsurface,notthellstream.

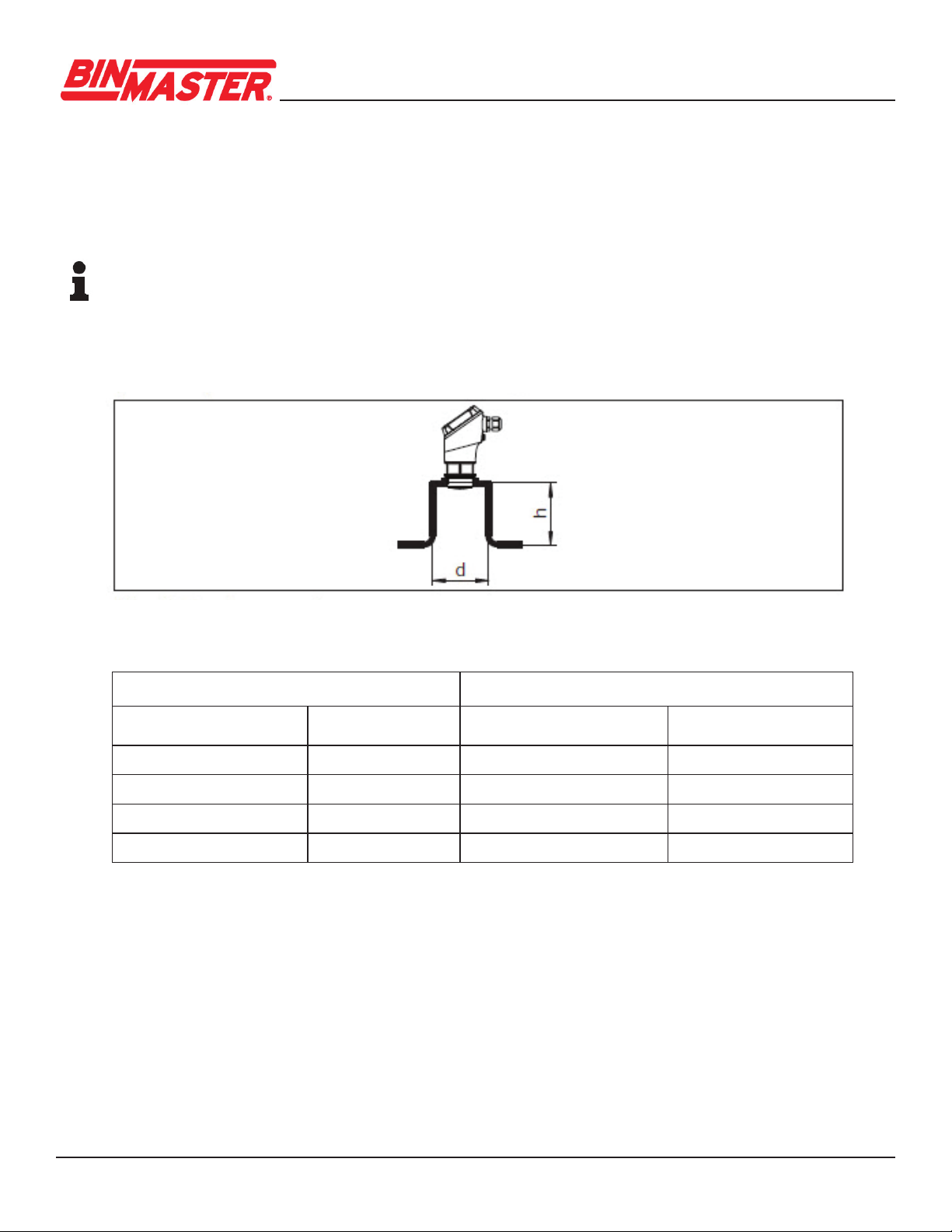

For socket or stand pipe mount, the pipe should be as short as possible and its bottom end

roundedtoreducefalsereectionsfromtheendofthepipe.

When using a threaded coupling, the antenna end should protrude at least 5 mm (0.2 in) out

of the coupling.

Fig. 6: Reference plane

1 Reference plane

Fig.7:Mountingtheradarsensorwithinowingmaterial

The lower side of the radar antenna is the reference plane for the min./max. adjustment, see

following diagram:

CNCR-210 • Two-wire 4

-

20 9

Socket diameter d Socket length h

40 mm 1½” ≤150mm ≤5.9in

50 mm 2” ≤200mm ≤7.9in

80 mm 3” ≤300mm ≤11.8in

100 mm 4” ≤400mm ≤15.8in

150 mm 6” ≤600mm ≤23.6in

Ifthereectivepropertiesofthematerialaregood,youcanmounttheCNCR-210onsockets

or stand pipes longer than the antenna. The pipe end should be smooth, burr-free and the end

rounded.

Note:

When mounting on longer sockets, we recommend carrying out a false signal suppression after

install (see chapter “Parameter adjustment”).

Recommended values for socket or stand pipe lengths and heights are in the following table. The

values come from typical applications.

Fig. 8: Mounting the radar sensor with stand pipes

5 Connecting to power supply

5.1 Preparing the connection

•Electricalconnectionshouldbecompletedbytrained,qualiedpersonnelauthorizedby

the plant operator.

• If overvoltage surges are expected, overvoltage arresters should be installed.

CNCR-210 • Two-wire 4

-

20 10

Warning:

Only connect or disconnect in de-energized state.

Note:

Power the instrument via an energy-limited circuit (power max. 100 W) according to IEC 61010-1,

e.g.

• Class 2 power supply unit (acc. to UL1310)

• SELV power supply unit (safety extra-low voltage) with suitable internal or external limitation

of the output current

UseroundcabletoensureeectivesealingofthecableglandtotheappropriateIPratingand

checkthecablediameterversusthecableglandbeforewiringforpropert.

The instrument is connected with standard two-wire cable.

If electromagnetic interference is expected which is above the test values of EN 61326-1 for

industrial areas, shielded cable should be used.

Note:

If the temperatures are too high, the cable insulation can be damaged.

5.2 Connecting

Fig. 9: Connection

CNCR-210 • Two-wire 4

-

20 11

5.3 Wiring plan

Connect the instrument as described in the following wiring plan.

Fig. 10: Connection compartment CNCR-210

1 Voltage supply +24 VDC, signal output

6 Setup with smartphone/tablet (Bluetooth)

6.1 Preparations

Make sure that your smartphone/tablet meets the following system requirements:

• Operating system: iOS 8 or newer

• Operating system: Android 5.1 or newer

• Bluetooth 4.0 LE or newer

DownloadtheWirelessDeviceConguratorappfromthe“AppleAppStore”or“GooglePlay

Store” to your smartphone or tablet. To enable the Bluetooth software enter the BinMaster

company ID code BMYQXZ.

CNCR-210 • Two-wire 4

-

20 12

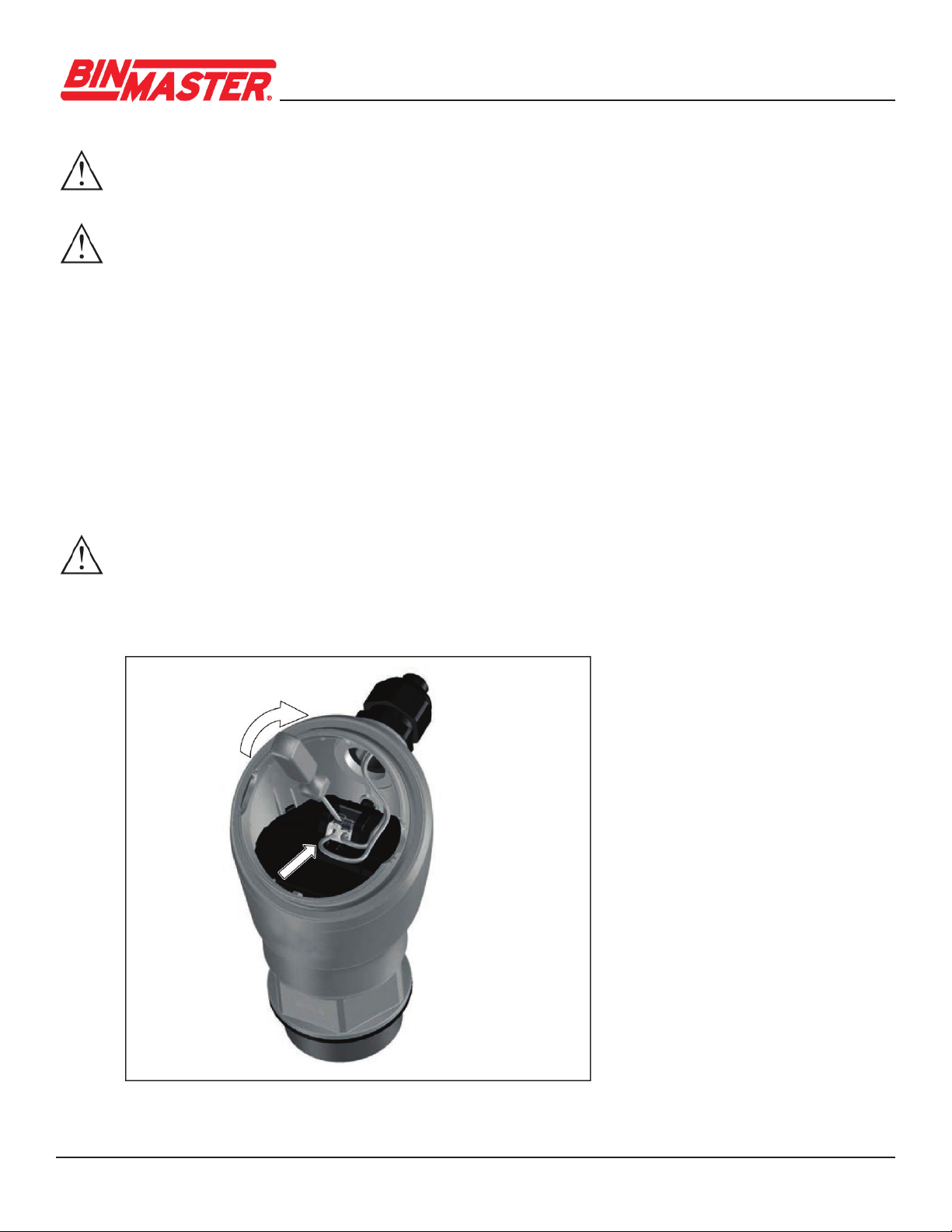

6.2 Connecting

Start the adjustment app and select the function “Setup”. The smartphone/tablet searches

automatically for Bluetooth-capable instruments in the area.

The message “Connecting …” is displayed.

The devices found are listed and the search is automatically continued.

Select the requested instrument in the device list.

Whenestablishingtheconnectionforthersttime,theoperatingtoolandthesensormust

authenticateeachother.Aftertherstcorrectauthentication,eachsubsequentconnectionis

made without a new authentication query.

Forauthentication,enterthe6-digitBluetoothaccesscodeinthenextmenuwindow.Youcannd

the code on the outside of the device housing and on the setup information sheet in the device

packaging.

Note:

If an incorrect code is entered, the code can only be entered again after a delay time and the delay

gets longer after each incorrect entry.

The message “Waiting for authentication” is displayed on the smartphone/tablet.

After connection, the sensor adjustment menu is displayed on the smartphone/tablet.

If the Bluetooth connection is interrupted, e.g. due to a too large distance between the two devices,

this is displayed on the smartphone/tablet. The message disappears when the connection is restored.

Parameter adjustment of the device is only possible if the parameter protection is deactivated, which

is default. Parameter protection can be activated later if desired.

Fig. 11: Enter Bluetooth access code

CNCR-210 • Two-wire 4

-

20 13

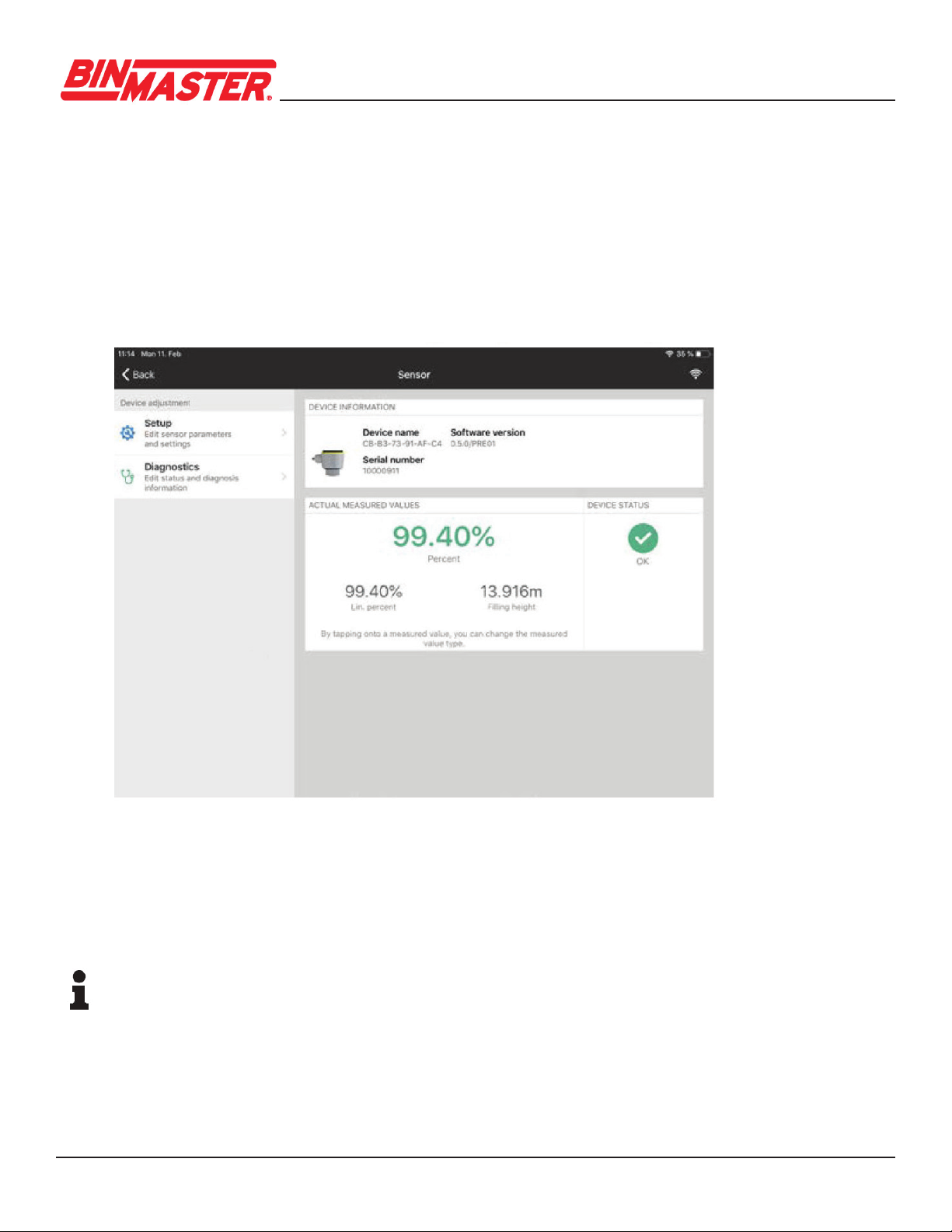

6.3 Parameter adjustment

The sensor adjustment menu is divided into two areas, which are arranged next to each other or

one below the other, depending on the smartphone/tablet.

• Navigation section

• Menu item display

The selected menu item can be recognized by the color change.

Entertherequestedparametersandconrmviathekeyboardortheeditingeld.Thesettingsare

then active in the sensor.

Close the app to terminate connection.

Note

IftheCNCRfailstoconnecttotheWirelessDeviceCongurationApp(WDCA)viaBluetooth,

close the (WDCA), power cycle the CNCR and attempt to reconnect.

If further action is required, power cycle the Bluetooth on your device, and repeat the steps above.

Fig. 12: Example of an app view - Setup sensor adjustment

CNCR-210 • Two-wire 4

-

20 14

Menu item Selection Default settings

False signal suppression False signal suppression 0 m

Sounded distance to the material 0 m

Reset Delivery status, basic settings -

Menu item Selection Default settings

Measurement loop name Alphanumeric characters Sensor

Medium Liquid

Bulk solid

Liquid

Application liquid

Storage tank, agitator tank, dosing tank, pumping

station/pumpshaft,rainoverowbasin,tank/collection

basin, plastic tank (measurement through tank top),

mobile plastic tank (IBC), level measurement in waters,

owmeasurementume/over-ow,demonstration

Storage tank

Application bulk solid Silo (slim and high), bunker (large

volume), stockpile (point measurement/

proledetection),crusher,demonstration

Silo

(slender and high)

Units Distance unit of the device

Temperature unit of the instrument

Distance in ft.

Temperature in °F

Adjustment Max. adjustment (distance A) - 20mA (100%)

Min. adjustment (distance B) - 4mA (0%)

Distance from sensor

Max. adjustment 0.0 m

Min. adjustment 8.0 m

Menu item Selection Default settings

Damping Integration time 0 s

Current output Output characteristics 4 to 20 mA = 0% to 100%

Current range Min. current 4 mA and

max. current 20.5 mA

Reaction when malfunctions occur Failure mode < 3.6 mA

Linearization Linearization type Linear

Scaling Scaling size

Scaling unit

Scaling format

0% correspond to 0 l

100% correspond

to 100 l

Display Menu language

Displayed value

Backlight

English

Distance

On

Access protection Bluetooth access code -

Parameter Protection Deactivated

Menu item Selection Default settings

Status Sensor status

Measured value status

Status output

Status additional measured values

-

Echo curve Indication of echo curve -

7 Menu overview

CNCR-210 • Two-wire 4

-

20 15

Code

Text message Cause Rectication

F013

No measured value

available

No measured value in the boot

up phase or during operation

Check or correct installation and/

or parameter settings

Clean the antenna system

F017

Adjustment span

too small

Adjustment not within

specication

Change adjustment according to the

limitvalues(dierencebetweenmin.

andmax.≥10mm)

F025

Error in the

linearization table

Linearization values are not

continuously rising, for example

illogical value pairs

Check linearization table

Delete table/Create new

F036

No operable software

Checksum error if software update

failed or aborted

Repeat software update

Send instrument in for repair

F040

Error in the electronics

Limit value exceeded in signal

processing

Hardware error

Restart instrument

Send instrument in for repair

F080

General software error

General software error Restart instrument

8 Diagnostics and servicing

8.1 Maintenance

If the device is used properly, no special maintenance is required in normal operation.

Insomeapplications,buildupontheantennasystemcaninuencethemeasurement.

Depending on the sensor and application, be careful to avoid heavy soiling of the antenna

system. If necessary, clean the antenna system periodically.

8.2 Status messages

The status messages are divided into the following categories:

• Failure

• Function check

•Outofspecication

• Maintenance required

Failure

CNCR-210 • Two-wire 4

-

20 16

Code

Text message Cause Rectication

S600

Impermissible electronics

temperature

Temperature of the electronics out of

speciedrange

Check ambient temperature

Insulate electronics

S601

Overlling

Dangerofvesseloverlling Makesurethatthereisnofurtherlling

Check level in the vessel

S603

Impermissible

operating voltage

Terminal voltage too low Check terminal voltage,

increase operating voltage

Code

Text message Cause Rectication

C700

Simulation active

A simulation is active Finish simulation

Wait for the automatic end after 60 mins.

Code

Text message Cause Rectication

F105

Determine

measured value

The instrument is still in the boot up

phase, the measured value could not

yet be determined

Wait for the end of the boot up phase

Duration up to 3 minutes depending on

the measurement environment and

parameter settings

F260

Error in the calibration

Checksum error in the calibration values

Error in the EEPROM

Send instrument for repair

F261

Error in the instrument

settings

Error during setup

False signal suppression faulty

Error when carrying out a reset

Repeat setup

Reset instrument

F265

Measurement function

disturbed

Program sequence of the

measuring function disturbed

Device restarts automatically

Code

Text message Cause Rectication

M500

Error in the delivery status

M501

Error in the delivery status

M504

Error at a device interface

Hardware defect Check connections

Replace the electronics

Send instrument in for repair

Failure

Function check

Out of specication

Maintenance

CNCR-210 • Two-wire 4

-

20 17

9 Removal

The device is made of recyclable materials that can be disposed of by specialty recycling companies.

Observe the applicable local regulations for proper disposal.

10 Certicates and approvals

10.1 Radio licenses

Radar

The device has been tested and approved in accordance with the current edition of the applicable

country-specicnormsorstandards.

Bluetooth

The Bluetooth radio module in the device has been tested and approved according to the current edition

oftheapplicablecountry-specicnormsorstandards.

11 Supplement

11.1 Technical data

Note for approved instruments

The technical data in the respective safety instructions which are included are valid for approved

instruments(e.g.withExapproval).Thesedatacandierfromthedatalistedherein,forexample

regarding the process conditions or the voltage supply.

Code

Text message Cause Rectication

M505

No echo available

Sensor does not detect an echo

during operation

Antenna dirty or defective

Clean the antenna

Use a more suitable antenna/sensor

Remove possible false echoes

Optimize sensor position and orientation

M507

Error in the instrument

settings

Error during setup

Error when carrying out a reset

False signal suppression faulty

Reset instrument and repeat setup

M508

Data error in program

memory Bluetooth controller

M509

Software update

M510

No communication with

the sensor

CNCR-210 • Two-wire 4

-

20 18

Fig. 13: Data of the input variable

1 Reference plane

2 Measured variable, max. measuring range

Materials and weights

Materials, wetted parts

–Antenna,processtting PVDF

– Process seal FKM

Materials, non-wetted parts

– Housing Plastic PBT (Polyester)

– Housing seals O-rings (silicone)

– Cable gland PA

– Sealing, cable gland NBR

– Blind plug, cable gland PA

– Weight 0.7 kg (1.543 lbs)

Torques

Max. torque mounting boss 7 Nm (5.163 lbf ft)

Max. torque for NPT cable glands and conduit tubes 10 Nm (7.376 lbf ft)

Input variable

Measured variable

The measurement range is the distance between the

antenna face of the sensor and the material surface.

The antenna face is also the reference plane for

the measurement.

Max. measuring range4) 8 m (26.25 ft)

Recommended measuring range5) up to 5 m (16.4 ft)

CNCR-210 • Two-wire 4

-

20 19

Output

Output signal 4 to 20 mA

Range of the output signal 3.8 to 20.5 mA (default setting)

Signalresolution 0.3μA

Resolution, digital 1 mm (0.039 in)

Faultsignal,currentoutput(adjustable) ≤3.6mA,>=21mA,lastvalidmeasuredvalue

Max. output current 22 mA

Load See load resistance under Power supply

Startingcurrent ≤3.6mA;≤10mAfor5msafterswitchingon

Damping (63 % of the input variable), adjustable 0 to 999 s

Ambient conditions

Ambient temperature -40 to +60 °C (-40 to +140 °F)

Storage and transport temperature -40 to +80 °C (-40 to +176 °F)

Process conditions

Fortheprocessconditions,pleasealsonotethespecicationsontheprintedlabel.Thelowestvalue

(amount) always applies.

Process temperature -40 to +60 °C (-40 to +140 °F)

Process pressure -1 to 3 bar (-100 to 200 kPa/-14.5 to 43.51 psig)

Voltage supply

Operating voltage UB

– at 4 mA 12 to 35 V DC

– at 20 mA 9 to 35 V DC

Reverse voltage protection Integrated

Electrical protective measures

Altitude above sea level 5000 m (16404 ft)

Protection class III

Pollution degree 4

CNCR-210 • Two-wire 4

-

20 20

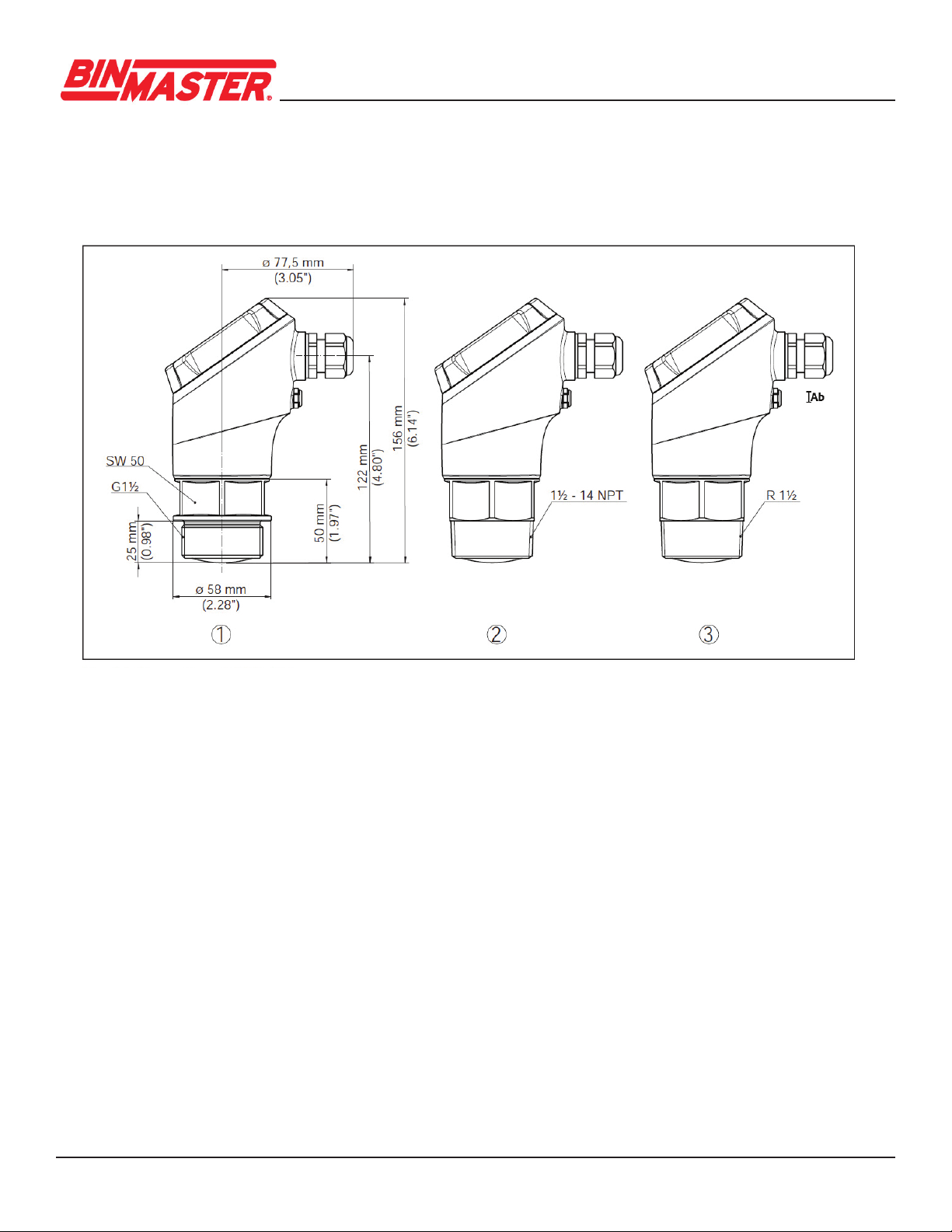

11.2 Dimensions

CNCR-210

Fig. 14: Dimensions CNCR-210

1 Thread G1½

2 Thread 1½ NPT

3 Thread R1½

Table of contents

Other Bin Master Measuring Instrument manuals

Bin Master

Bin Master SMARTBOB TS1 User manual

Bin Master

Bin Master 1000 User manual

Bin Master

Bin Master BMRX Series User manual

Bin Master

Bin Master BMRX-100 User manual

Bin Master

Bin Master DPM-500 User manual

Bin Master

Bin Master DPM-500 User manual

Bin Master

Bin Master GWR-2000 User manual

Bin Master

Bin Master PROCAP I Series User manual

Bin Master

Bin Master 3DLevelScanner-MVL User manual

Bin Master

Bin Master DPM-200 User manual