Bin Master BMRX-100 User manual

BMRX-100

Rotary Level Indicator

OPERATING INSTRUCTIONS

PLEASE READ CAREFULLY

BinMaster: Division of Garner Industries

7201 N. 98th St.

Lincoln, NE 68507

402-434-9102

info@binmaster.com | www.binmaster.com

925-0415

925-0415 0823

BMRX-100 ROTARY LEVEL INDICATOR

GENERAL SPECIFICATIONS............................................................................................ 3

SAFETY SUMMARY .......................................................................................................... 4

1.0 INTRODUCTION ......................................................................................................... 5

2.0 INSTALLATION............................................................................................................ 5

2.1 Location and Mounting ............................................................................... 5

2.2 Input Power and Field Wiring ..................................................................... 7

2.3 Grounding ................................................................................................... 7

3.0 SPDT INDICATOR SWITCH ....................................................................................... 7

4.0 WARRANTY AND CUSTOMER SERVICE................................................................. 8

5.0 DISPOSAL ................................................................................................................... 8

TABLE OF CONTENTS

2

0823925-0415 0115

BMRX-100 ROTARY LEVEL INDICATOR

SPECIFICATIONS

BMRX-100 GENERAL SPECIFICATIONS

Power Supply: 115 VAC 50/60 Hz

230 VAC 50/60Hz

24 VAC 50/60Hz

Supply Tolerance: -15% to +10%

Load: AC Models 4 VA

Ambient Temperature: (Electronics) -40° F to +185° F (-40° C to +85° C)

Enclosure Type: 4X / IP66

Enclosure Material: Die cast aluminum, powder coat nish

Relay Output: SPDT contacts; 10 Amps 250 VAC

Mounting: 1-1/4” NPT

Conduit Entries: 3/4" NPT

Shaft Seal: 1/2 micron, 30 PSI

3

925-0415 0823

BMRX-100 ROTARY LEVEL INDICATOR

SAFETY

SAFETY SUMMARY

Review the safety precautions to avoid injury and prevent damage to equipment.

The product should be installed, commissioned, and maintained by qualied, authorized

personnel only.

Install according to instructions and comply with all National and Local codes.

Use electrical wire that is sized and rated for the maximum voltage and current of the appli-

cation. Properly ground the enclosure to an adequate earth ground.

Observe terminal and relay contact ratings on the nameplate and in the installation manual.

Ensure the enclosure cover is in place and secured tightly during normal operation. In poten-

tially wet environments, thoroughly seal all conduit entries.

If this product is used in a manner not specied by the manufacturer safety protection could

be compromised.

Safety Terms and Symbols

WARNING: Warning statements identify conditions or practices that could result

in injury or loss of life. Risk of electrical shock.

CAUTION: Caution statements identify conditions or practices that could result in

damage to this product or other property.

4

0823925-0415 0115

BMRX-100 ROTARY LEVEL INDICATOR

INTRODUCTION

1.0 INTRODUCTION

The BinMaster BMRX-100 is a rotary level sensor that provides reliable point level detection

in bulk solids, including powder, pellet, and granular materials.

The BMRX-100 motor rotates the drive shaft and paddle at 1 RPM (0.833 RPM at 50Hz).

When the material lls to the level of the indicator paddle, it causes the paddle to stop rotat-

ing indicating a covered condition. When the material falls away, the paddle resumes rotat-

ing to indicate an uncovered condition.

5

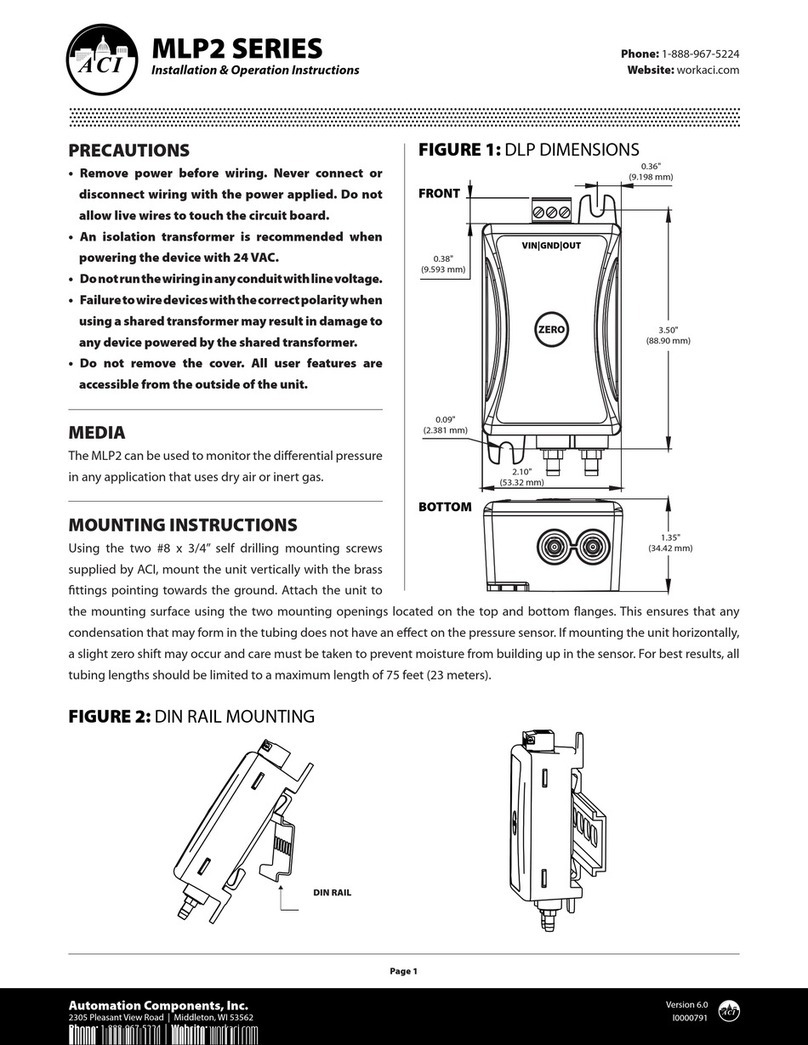

SIDE MOUNT

1. Determine location and cut hole inside of bin to t outside diameter of 1-1/4”

pipe coupling (1.950").

2. Weld on half of standard 1-1/4” pipe coupling to bin wall ush with inside of bin.

3. Insert hub into coupling and turn rotary so conduit entries are pointed down

toward the ground.

4. Screw paddle into place and replace lock pin.

5. Shaft and paddle should be shielded in low level mounting to protect from

material ow.

6. For side mounting, a solid coupler is recommended.

Figure 1

2.0 INSTALLATION

2.1 Location and Mounting

925-0415 0823

BMRX-100 ROTARY LEVEL INDICATOR

TOP MOUNT

1. Determine mounting location and cut a hole in top of bin to t outside diameter of

1-1/4” pipe coupling (1.950”).

2. Position coupling halfway into bin and weld to bin.

3. Turn rotary so conduit openings are in desired location.

4. Add 1/4” extension pipe of desired length with standard 1/4” coupling on bottom end.

5. Cut 1-1 /4” support pipe approximately 4” shorter than overall length of 1/4” pipe

shaft if used with exible coupling.

6. Insert 1-1/4” pipe into coupling and tighten.

7. Insert paddle into 1/4” coupling and drill holes for lock pins.

Figure 2

2.0 INSTALLATION

2.1 Location and Mounting

6

0823925-0415 0115

BMRX-100 ROTARY LEVEL INDICATOR

Conduit Seal

When installing the rotary in environments where moisture or moist air may enter the unit

through the electrical conduit, the conduit openings should be sealed with an appropriate duct

seal compound or putty.

For use with all rotary

level controls. Full

coupling is used for

top of bin installa-

tions where shaft

extensions and shaft

guards are used.

For use with all

rotary level

controls. Half

coupling is used

primarily for side of

bin installations.

Figure 4 Figure 5

Half CouplingFull Coupling

Mounting Plates

Mounting plates are needed when a completely assembled rotary is mounted on the bin wall

from the outside. Cut a 5-1/2” hole in the bin. Drill six bolt holes around the hole to match the

mounting plate. Bolt the plate, with the unit attached, into place. Mounting plates are available

in carbon or stainless steel

MOUNTING ORIENTATION (Side Mount)

To prevent moisture or humidity from entering the unit, the rotary MUST be mounted with the

conduit entries facing down.

7

925-0415 0823

BMRX-100 ROTARY LEVEL INDICATOR

2.2 Input Power and Field Wiring

2.3 Grounding

An equipment grounding connection (earth ground) to the rotary is required for safety. Connect

the ground conductor to the green grounding screw inside in the enclosure.

3.0 SPDT INDICATOR SWITCH

The SPDT indicator switch is a set of switch contacts where the C terminal makes a connection

to the NC terminal when the paddle is uncovered. When the paddle becomes covered, the C

terminal breaks the connection to the NC terminal and makes a connection to the NO terminal.

The voltage on the C terminal is present on the NC terminal when the paddle is uncovered and

when the paddle is covered the voltage on C terminal is present on NO terminal.

Figure 6

The BMRX-100 is available in 115 VAC, 230 VAC, and 24 VAC supply voltages. See the volt-

age rating on the nameplate for the supply voltage. Field wiring should conform to all national

and local electrical codes and codes of any other agency or authority with jurisdiction over the

installation. For power input, use wire sized and rated for the maximum voltage and current

according to equipment ratings with a temperature rating of at least 70°C. For SPDT switch

output, use wire sized and rated for the maximum voltage and current for the application, up

to 250 VAC 10A, and has a temperature rating of at least 70°C. Installation must be done by

qualied personnel. NOTE: Open the screw terminals fully before inserting wiring.

BMRX-100 Wiring

Input Power

Power input to the BMRX-100 is con-

nected to the POWER terminals labeled

L and N.

AC Models

On AC models if one of the conductors

is grounded, connect to the N terminal.

Connect the ungrounded conductor to

the L terminal. If neither conductor is

grounded, connect one to the N terminal

and the other to the L terminal.

8

0823925-0415 0115

BMRX-100 ROTARY LEVEL INDICATOR

4.0 WARRANTY AND CUSTOMER SERVICE

4.1 Limited Warranty

LIMITED PRODUCT WARRANTY. Products manufactured by Seller are warranted for a

period of one (1) year from date of shipment against defective materials and workmanship

(the “Warranty Period”). SELLER MAKES NO OTHER WARRANTY, EXPRESS OR IM-

PLIED, AND ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICU-

LAR PURPOSE IS HEREBY DISCLAIMED AND EXCLUDED.

This limited warranty does not extend to labor charges or other costs related to the re-

moval and/or replacement of defective products or services. Any technical advice or

services furnished by Seller with respect to the products is given without charge, and

Seller assumes no obligation or liability for the advice given or results obtained, all such

advice being given and accepted at Buyer's sole risk and expense. If the products are

being acquired for resale, Buyer will make, in connection with any such resale, only those

warranties contained herein and will indemnify Seller and its ocers, directors, agents,

employees, aliates, successors, and assigns against any claims, causes of actions and

judgments which arise from any representations, warranties, or agreements made by or

entered into by Buyer, other than those contained herein.

WARRANTY EXCLUSIONS. Notwithstanding Seller’s Limited Product Warranty, products

that have been or are (1) damaged by accident, corrosion, the elements, abuse, misuse,

misapplication, vandalism, negligence, improper transportation, handling, storage, use or

lack of proper and reasonable maintenance, (2) repaired or altered by anyone other than

Seller or its authorized service providers, (3) modied or altered without Seller’s written

authorization, or (4) specially manufactured by Seller as per specications provided by

Buyer, are expressly excluded from Seller’s Limited Product Warranty.

4.2 Customer Service

BinMaster's toll-free Customer Service phone number is 1-800-278-4241. Call the Techni-

cal Service Department for support Monday through Friday from 8:00 AM to 5:00 PM Cen-

tral Time. International customers call 1-402-434-9102 or techsupport@binmaster.com.

5.0 DISPOSAL

This product contains recyclable materials and electronics that can be easily separated and

recycled by specialized recycling companies. Consult local authorities for proper disposal

locations.

9

925-0415 0823

BMRX-100 ROTARY LEVEL INDICATOR

BinMaster: Division of Garner Industries

7201 N. 98th St.

Lincoln, NE 68507

402-434-9102

info@binmaster.com | www.binmaster.com

This manual suits for next models

1

Table of contents

Other Bin Master Measuring Instrument manuals

Bin Master

Bin Master 3DLevelScanner-MVL User manual

Bin Master

Bin Master CNCR-210 User manual

Bin Master

Bin Master DPM-500 User manual

Bin Master

Bin Master NCR-80 User manual

Bin Master

Bin Master GWR-3000 User manual

Bin Master

Bin Master DPM-200 User manual

Bin Master

Bin Master CNCR-110 User manual

Bin Master

Bin Master PROCAP I Series User manual

Bin Master

Bin Master SMARTBOB TS1 User manual

Bin Master

Bin Master DPM-500 User manual