SBBI-21-043-D Page 3

SPECIFICATIONS

Tank Size: 2-1/2 gal (actual capacity is 2.76 gal)

Height: 9-9/16", (10-1/2" to top of lid)

Maximum Working Pressure (MWP): 80 psi

Air Motor Consumption: 3-6 CFM at 60 psi

Maximum Agitator Air Inlet Pressure: 100 psi

Air Inlet Size: 1/4" NPS (M)

Fluid Outlet Size: 3/8" NPS (M)

Tank Net Weight:

83Z-210 28-1/4 lbs.

83Z-220 29-3/4 lbs.

83Z-211 32-3/4 lbs.

83Z-221 34-1/4 lbs.

MATERIALS OF CONSTRUCTION -

WETTED PARTS

316 S.S. - Fluid Tube, lid bushing, outlet

elbow and fitting; 303 S.S. - Agitator shaft

(agitated models); molded nylon propeller

(agitated models); polyethylene liner.

NON-WETTED PARTS:

Zinc plated carbon steel tank; #304 stainless

steel, electro- polished lid.

PT-427 AIR MOTOR DRIVEN AGITATOR

The agitator utilizes an air driven motor to

turn the agitator shaft to which a propeller is

attached. The rotation of the propeller mixes

materials which have a tendency to separate

or settle quickly. Material agitation may be

performed at the same time material is being

sprayed without any adverse effect. The air

motor is powerful and smooth running. An

air adjusting valve is included to control the

speed of the agitator. The air motor requires

low air consumption, approximately 3-6

C.F.M. at 60 P.S.l. (Max. input air pressure

100 P.S.l.)

INSTALLATION

Mix and prepare material to be used accord-

ing to manufacturer’s instructions. Strain

material through a fine mesh screen (60 or

90 mesh) to remove all foreign matter which

is likely to enter and clog material passages.

1. AIways relieve all air pressure in the

tank. Pull the ring on the safety valve

until pressure bleeds down.

2. Loosen thumb screws, tip lid clamps

back and remove lid assembly.

3. Pour material into the tank. See acces-

sories for disposable tank liners. A one

gallon container may also be used by

cutting 3/16" off end of fluid tube at an

angle.

4. Replace the lid assembly and tighten

clamps and thumb screws securely.

5. If possible, the air supply line should

pass through an air filter/regulator to

filter dirt from air and remove entrained

water and oil. See Accessories for

filters available. Connect the air supply

hose to the air inlet fitting on tank

regulator.

6. Connect the atomization air hose to the

air outlet fitting which is directly oppo-

site air inlet fitting.

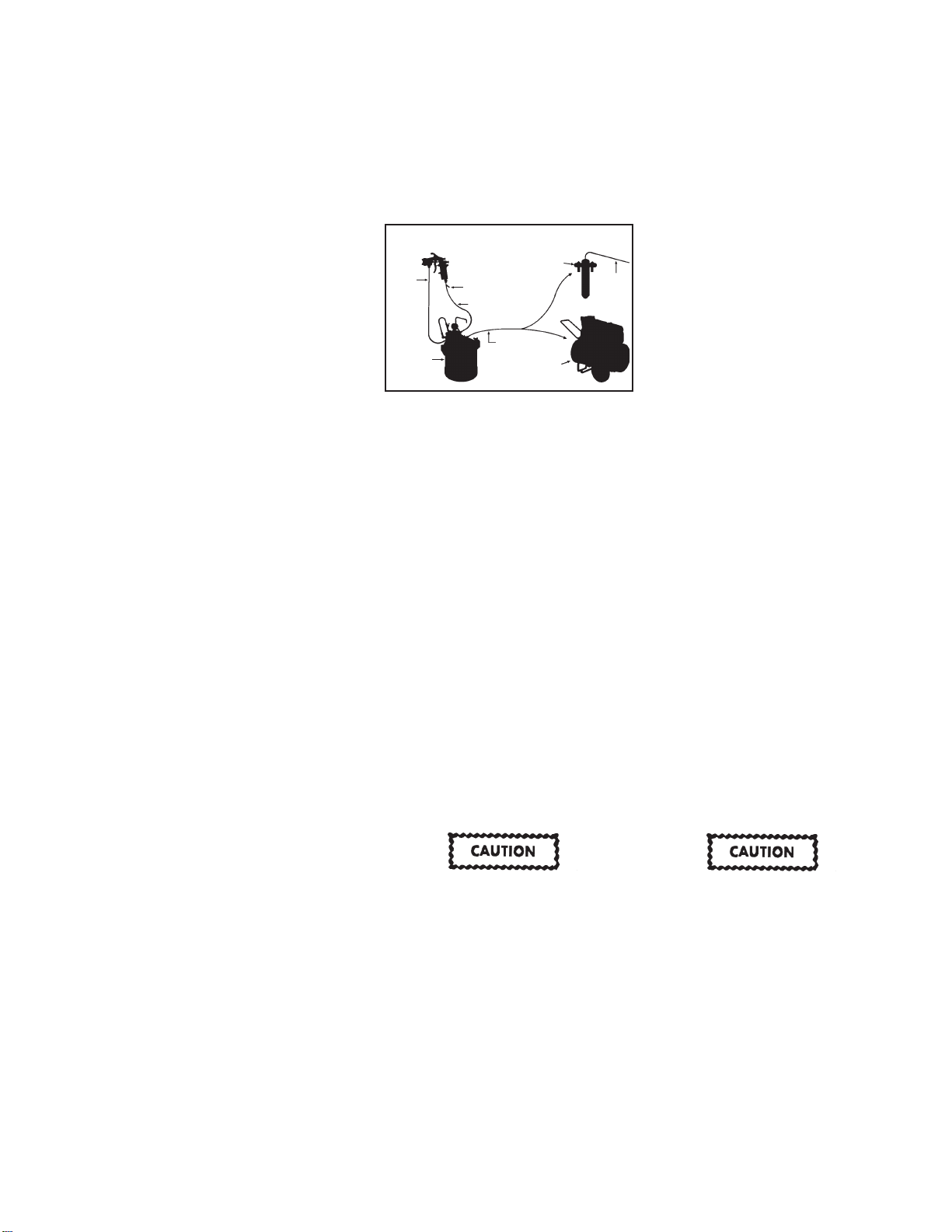

Figure 1

OPERATION

1. Turn on the air supply.

2. Turn T-Handle adjusting screw clock-

wise on the tank regulator to increase

material pressure: turn it counter clock-

wise to decrease pressure. Maximum

tank pressure is 80 PSI.

3. For tank with air motor agitator, turn the

knob of the air adjusting valve (8) coun-

terclockwise to set the desired agitator

speed. Operate the agitator at the mini-

mum speed required to keep the mate-

rial thoroughly mixed. Do not over-

agitate the material. Air bubbles may

form in the material, causing a poor

finish.

4. Atomization air for the spray gun can be

adjusted at the gun by means of an air

adjusting valve (P-H-5516) or, with the

additional air regulator provided with

“dual regulation” tank models (83Z-220

or 83Z-221-WB).

5. See Spray Gun instructions for opera-

tion of the gun.

If using an air quick disconnect

(Q.D.) at the inlet to the regulator

at the pressure tank, do not dis-

connect the Q.D. while the tank is

pressurized, unless the ball valve

is closed. Doing so will allow tank

pressure to quickly relieve, and

can potentially pull paint back

through the air regulator and air

motor, depending upon the liquid

level in the tank. Tank pressure

should always be relieved by turn-

ing the regulator fully counter-

clockwise, or pulling the safety

valve ring.

Fluid

Pressure

Tank

Air Filter/Regulator

AirAdjusting

Valve(Optional)

AtomizationAir

Air

Compressor

SupplyHose

Air

Supply

7. Connect material hose to the fluid out-

let fitting.

8. See Figure 1 for a typical hookup.

Note

See Pg. 4 for air and fluid hook-up

information on the tank.

REPLACEMENT OF PARTS

(Air Motor Assembly, See Page 5)

Do not pry front plate (40) or end plate (46)

from air motor body (43) with a screwdriver;

this will dent the surface of the plates and

body causing leaks. A puller tool should be

used to remove the plate from the motor

body while maintaining the position of the

shaft. Holes must be drilled for dowel pins

(42) after assembling front plate (40) on new

body (43) for alignment of parts. Always

install new end plate gaskets (41) when re-

assembling air motor.

PREVENTIVE MAINTENANCE

To Clean Equipment:

1. If tank is equipped with agitator, turn

off air to agitator first. This will prevent

the possibility of paint contamination of

the agitator air motor.

2. Turn off the main air supply to the tank.

3. Turn T-handle adjusting screw on tank

regulator counterclockwise until no

spring tension is felt.

4. Relieve all pressure from the tank by

pulling the ring on the safety valve until

the pressure bleeds down.

5. Loosen thumb screws, tip clamps back

and tip tank lid to one side.

6. Loosen spray gun air cap retaining ring

about three turns.

7. Turn on the air supply to spray gun.

8. Place cloth over air cap on the gun and

pull trigger. This will force material back

through the hose, into the tank.

9. Empty and clean tank and parts which

come in contact with material. Use a

suitable cleaning material.

10. Pour cleaning material into the tank.

11. Replace lid and tighten thumb screws

and clamps.

12. Spray until clean solution appears.

13. Repeat steps 5 through 8.

Keep the safety valve clean at all times.

Air Motor Assembly

Failure to properly lubricate the

air motor will result in prema-

ture motor failure and will void

warranty.

Lubricate air motor daily by add-

ing 4 or 5 drops of SAE 10 weight

oil into air inlet fitting.

CIean the agitator shaft (54, Pg. 5) and the

propeller (56) at the end of each day. Occa-

sionally remove and clean the muffler strainer

felt (60) or replace, if necessary.