5© ITW FINISHING SYSTEMS AND PRODUCTS

INSTALLATION

Regulator Assembly

1. Unbox the regulator assembly and mount

it on the manifold connecon with the

swivel connecon .

2. If BSP thread is required, aach adaptors

to the ball valve uid outlet ball valve and

the air inlet/outlet connecons on the

regulator.

3. For agitator models, connect the air hose

from the adjusng valve on the drive

motor to the swivel elbow on the

regulator.

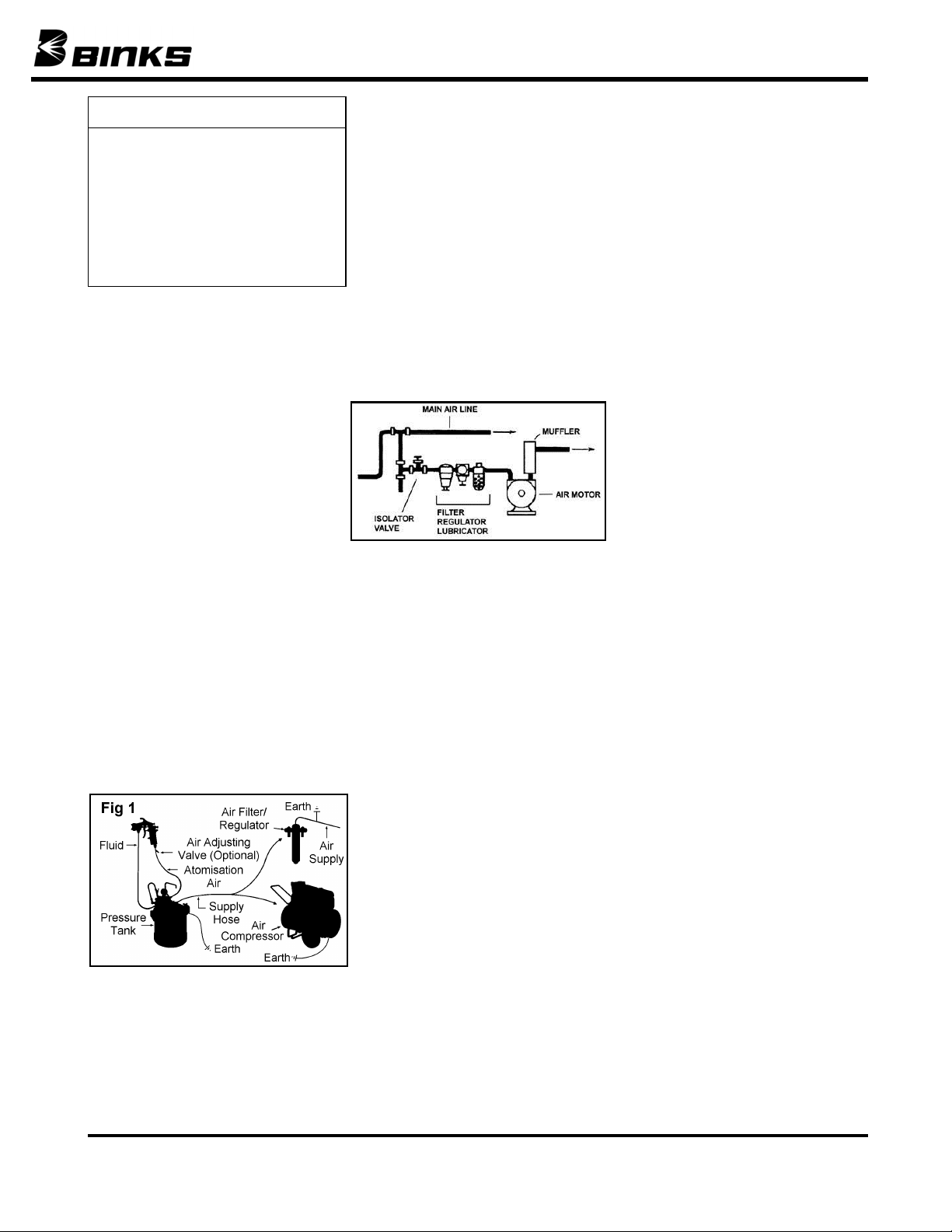

Air Supply

1. The air supply line should pass through an

air lter/regulator to lter dirt from air

and remove entrained water and oil.

Connect the air supply hose to the air inlet

ng on tank regulator. Connect the

atomisaon air hose to the air outlet

ng which is directly opposite air inlet

ng.

2. Connect material hose to the uid outlet

ball valve.

3. See Figure 1 below for a typical

installaon.

4. To avoid hazards from electrostac

discharges, the tank should be earthed

directly via an earth clamp. There is an

earth connecon point on the lower part

of the tank shell. See p7 for connecon

diagram. Air supply hoses should be

conducve to avoid creang electro stac

charges. Check connuity to earth before

using the equipment.

LUBRICATION – Agitated

Models

1. An automac air line lter/lubricator

should be installed in the air supply line no

more than 0.5m from the air motor. The

lter should be 5 micron. Install the

lubricator level with or above the motor

so the oil mist will blow directly into or

down into the motor (see Fig. 2).

2. Fill the oil reservoir with SAE 10W motor

oil. Adjust lubricator to feed 1 drop of oil

for every 1400 litres (50 cfm) of air or 1

drop per minute for connuous running.

PREPARATION

Mix and prepare material to be used

according to manufacturer’s instrucons.

Strain material through a ne mesh screen to

remove lumps, skin, and foreign maer that

might enter and clog uid passages and/or

spray equipment.

Follow pressure relief procedure on page 3..

To add material to the tank, remove the lid

and pour directly into the tank or container.

Replace the lid assembly and ghten thumb

screws securely.

Connect the material hose to the uid outlet

ball valve.

OPERATION

1. Close the air inlet valve to tank. Turn

handle on regulator counter clockwise

unl spring tension is relieved.

2. Turn on air supply to the tank.

3. Open the air inlet valve to the tank.

4. Open the uid outlet valve.

5. Turn handle on tank pressure regulator

clockwise to pressurize tank.

6. Turn on atomizaon air to spray gun at

source of supply.

7. Test spray. For further instrucons

consult literature provided with spray gun.

8. If an air motor driven agitator is used,

start the agitator by slowly opening up the

needle valve. Air motor speed should be

regulated according to the nature of the

material being agitated.

MAINTENANCE

To clean equipment, proceed as follows:

1. Turn o the air supply.

2. Follow the pressure relief procedure.

3. Turn T-handle adjusng screw on tank

uid pressure regulator counter clockwise

unl no spring pressure is felt.

4. Loosen thumb screws (17), p clamps (16)

back and p lid (11) to one side of tank.

Do not remove lid from tank.

5. To drain down the uid supply hose to the

gun, remove the Aircap and replace with

about 2 turns. Trigger the spaygun into

the booth , which will create a back

pressure in the uid line and force the

uid back into the tank.

6. Now remove the lid, empty and clean the

parts that have come into contact with the

material with compable cleaning

material.

7. When clean, pour a lile cleaning material

into the tank and replace the lid.

8. Repeat 1 to 5 of the OPERATION.

9. Do not turn on the atomising air to the

Gun. Make sure the Aircap is fully ght.

Trigger the gun and jet the cleaning

material into a container unl clean

material is visible.

10. Remove solvent and replenish with new

material as from INSTALLTION secon 1

onwards.

LUBRICATION – Agitated

Models

Refer to the service manual SBBI-E-19-095

provided with the air motor for lubricaon

informaon.

The bearings in the agitator bearing assembly

are impregnated with special non-gumming

oil. Addional lubricaon is not required.

The agitator sha seal does not require

lubricaon.

PREVENTATIVE MAINTENANCE

1. Keep the safety valve clean at all mes.

Check regularly by pulling the ring to

ensure the valve is free to operate.

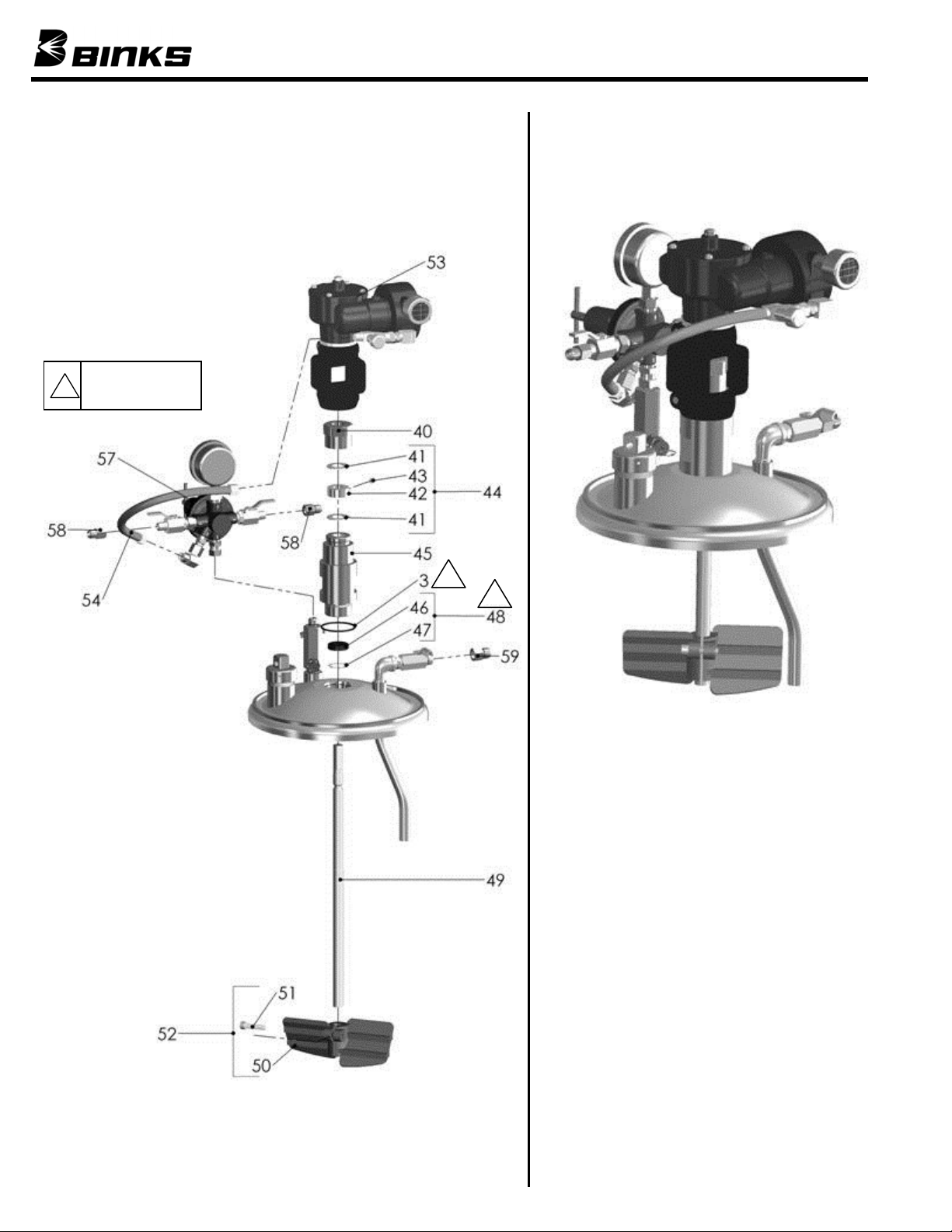

WARNING

High pressure can cause serious injury.

Pressure is maintained in a pressure

tank aer the system has been shut

down.

Follow the pressure-relief procedure on

page 3 before opening the lid or ll port

or performing maintenance on the tank.

Fig 2