4

INJECTION HAZARD

1. The sprayer pumps coatings at high pressure.

If you spray yourself or anyone else at close

range, the stream of material can puncture

the skin and cause great harm (possible

amputation).

2. point the spray gun at yourself or

anyone else. The tip guard provides some

protection against injection injuries, but is

mainly a warning device. remove

the tip guard. point the spray gun

at your hands, fingers, or body.

keep the spray gun trigger safety catch

locked in the position when not in use.

3. cover the tip guard and attempt to

“blow back” fluid. This is not an air sprayer.

4. If injury occurs, see your doctor

immediately!

. Inform your doctor

specifically of what fluid was injected.

AVOID STATIC SPARKING

Static electricity charge builds up by high

velocity liquid flowing through a hose during

flushing, cleaning, or spraying operations.

Proper grounding of the airless system safely

dissipates this charge.

All high pressure airless systems must be

grounded to avoid dangerous static sparking,

explosion, or fire when spraying or flushing

with flammable liquids.

1. Use Binks conductive hose in all

airless spraying operations. Be sure gun and

hose have continuity. Check continuity

weekly with ohmmeter. Overall (end to end)

resistance of unpressurized hose must not

exceed 29 megohm (max.) for any coupled

length or combination of hose lengths.

2. Make sure the pump is grounded.

operate the unit when it is on a

non-grounded platform.

3. When flushing or cleaning with a

combustible solvent, always use an open

metallic container for receiving the waste

solvent. Ground the solvent receptacle.

4. Bond the spray gun to the waste container

with a grounding wire. Be sure there is good

metal to metal contact.

5. remove spray tip when flushing

the system. Operate the pump at the lowest

possible pressure.

GENERAL WARNINGS

1. leave a pressurized sprayer

unattended.

2. use fluids, coatings, or chemicals

that are not compatible with nylon hoses.

3. Be sure that all fluids and solvents to be used

are chemically compatible with the wetted parts

in the pump and fluid handling equipment.

4. Periodically inspect all hoses for leaks

and/or abrasions and tighten all connections

before use.

a defective hose. it

with another conductive hose.

5. Follow all warnings and precautions of the

coating and solvent manufacturers.

6. relieve pressure in the system by

turning bypass valve to or

triggering spray gun before disassembly of

any component parts.

REPLACEMENT PARTS

The pump is designed to use authorized parts

only. When using this pump with parts that do

not comply with the minimum specifications

and safety devices of Binks, the user assumes

all risks and liabilities.

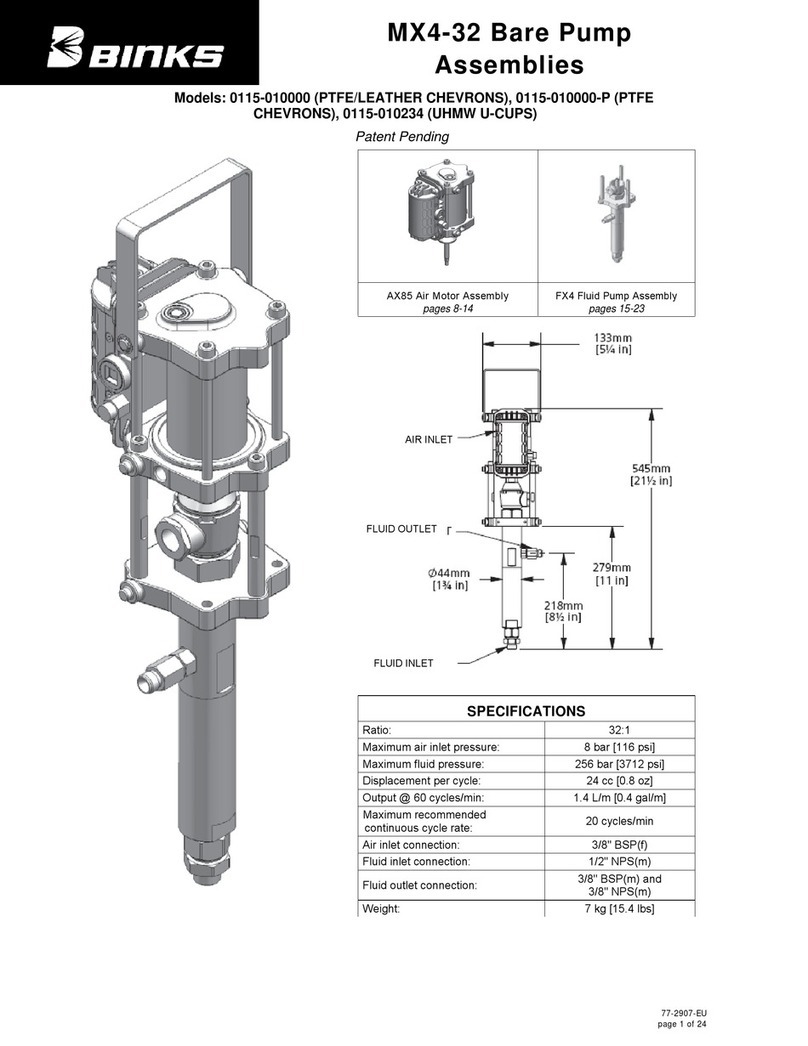

AIR AND LUBE REQUIREMENTS

"*)*,-&)+

1. Filtered air will allow the pump to operate

more efficiently and yield a longer life to

operating parts and mechanisms.

2. Use an air regulator on the air supply to

control the pump cycle rate. This will help to

prolong the life of the pump.

3. Apply factory-approved 41-4458- grease to

all air logic components for smooth operation.

TRANSPORT AND STORAGE

1. Store in a dry place; do not remove product

from box during storage.

2. Do not remove protection caps from inlet and

outlet prior to installation.

3. Do not drop or damage box; handle with care.

HIGH PRESSURE CAN CAUSE SERIOUS INJURY IF EQUIPMENT IS INSTALLED OR USED INCORRECTLY—

READ, UNDERSTAND, AND OBSERVE ALL WARNINGS AND INSTRUCTIONS IN THIS MANUAL.

INSTALL, OPERATE OR SERVICE THIS EQUIPMENT ONLY AFTER

ALL INSTRUCTIONS ARE CLEARLY UNDERSTOOD.

It is the responsibility of the employer to place this information into the hands of the operator.

WARNING

!

Bonding Wire,

Gun To Solvent Container

Conductive Hose

To Airless Pump

Open

Metallic

Waste Solvent

Container,

Grounded

CAUTION

Hazards or unsafe practices which could

result in minor personal injury, product

or property damage.

!

WARNING

Hazards or unsafe practices which could

result in severe personal injury, death or

substantial property damage.

!

NOTE

Important installation, operation or

maintenance information.

WARNING

EXCESSIVE AIR PRESSURE

Can cause personal injury, pump damage

or property damage. Do not exceed

maximum inlet air pressure as stated on

motor model plate.

!

CAUTION

Never store de-ionized, distilled, reverse

osmosis or any pure grade of water in the

pump. These fluids may cause corrosion.

!

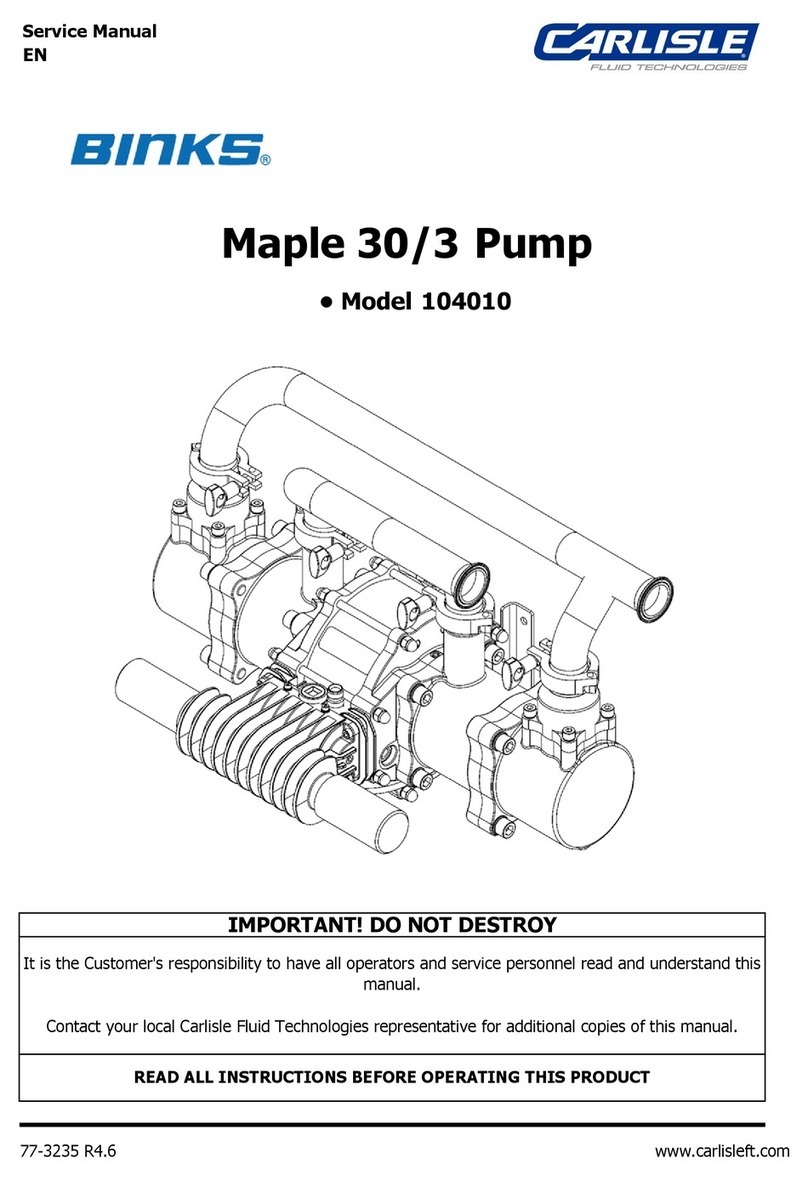

NOTE

Be sure that all fluids, solvents and fillers

to be used are chemically and physically

compatible with wetted parts in the Exel

pump. Consult your BINKS representative

for Exel pump materials of constructions

and compatibility information. Consult

the fluid manufacture for information

regarding the fluids to be used.

NOTE

BINKS is not responsible for misapplica-

tion of Exel pumps. Consult your BINKS

representative for application assistance.