Binzel Neutrix User manual

Page 1

NEUTRIX INSTRUCTION MANUAL

Page 2

Contents

1. Manufacturers recommended use

1.1 Safety

2. Drawings & parts description

3. Application

4. Technical data & contents of standard package

5. Before use :-

5.1 Selection of grinding position

5.2 Selection of electrode diameter

5.3 Selection of grinding angle

6. Using the Neutrix

6.1 Operating the Neutrix

6.2 How to grind the electrode

7. Maintenance: -

7.1 Replacing the filter.

7.2 Replacing the diamond wheel

8. Parts diagram

9. Parts list

Supplied in Australia and New Zealand by:

Binzel Pty Ltd.

ACN: 13 006 341 297

42 Hinkler Road

Mordialloc

VIC 3195

Australia

Phone:+61 (0)3 9580 6500

Fax: +61 (0)3 9580 8796

http://www.Binzel.com.au/

Page 3

Manufacturers recommended use

Neutrix has been designed for the sole purpose of grinding tungsten

electrodes. Any use, which is not described in this manual, is strictly

prohibited.

It is very important that the user reads and understands the contents of

this instruction manual.

1.1 Safety: -

!Check that the machine is undamaged.

!Do not use the machine without the filter.

!Change the filter in accordance with the instruction manual.

!Only turn the machine on when the electrode holder is in the grinding

chamber.

!Do not remove the electrode holder before the motor has come to a

complete stop.

!Repairs and maintenance must only be carried out by authorised

personnel.

!Do not use the machine in humid places.

!Only use original replacement parts.

!Unplug the machine from the mains supply before any maintenance work

is undertaken.

Page 4

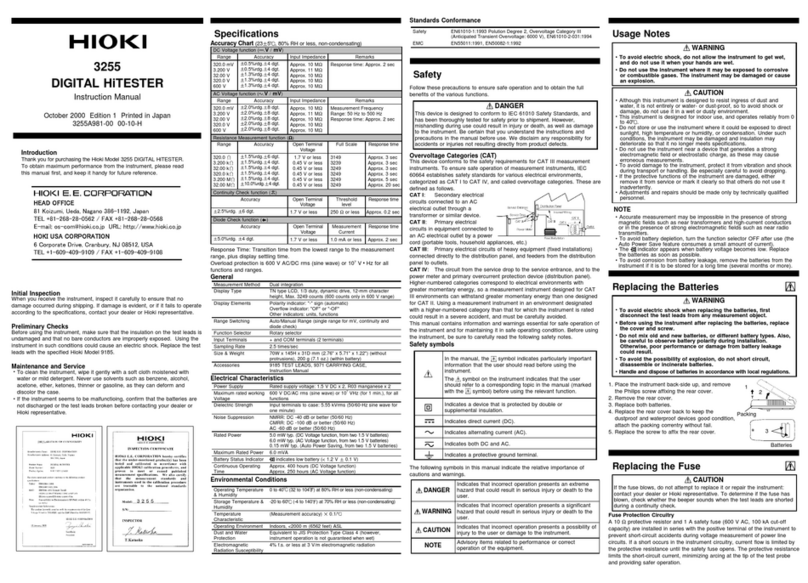

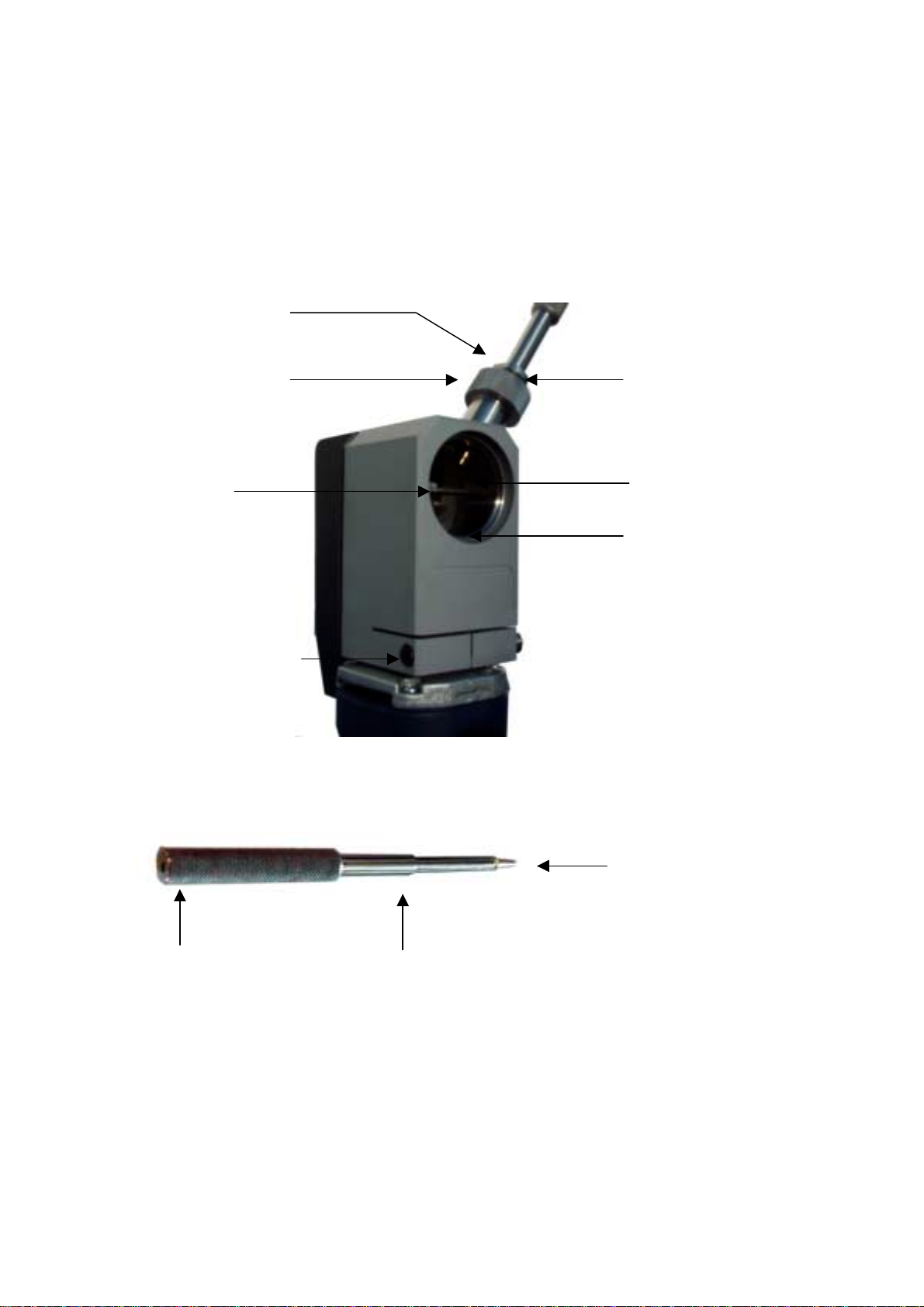

2. Drawing & parts description

6

20

2

12

15

1.1

1.2

Electrode holder guide

Eccentric plate to select

grinding position

Grinding head

Depth setting gauge.

Allen screw to tighten

the grinding head

On/Off switch

Mains cable

25

26

25.2

25.3

1

Filter housing

Angle degree

scale

(1 step= 5 °)

Filter cassette

Machine

number

Filter cover

Allen screw to

fix the filter

cover

Motor

Adjustment of

turning speed

Page 5

6

22

29

19

Electrode holder

guide

Knurled wheel

Inspection

cover

Allen screw

14

3

5

Grinding stop

Diamond wheel

Spindle for

diamond

wheel

Electrode clamp

5 Electrode holder Stop

Part Nos for electrode clamps

16.1 for 1.0 mm

16.2 for 1.6 mm

16.3 for 2.0 mm

16.4 for 2.4 mm

16.5 for 3.2 mm

16.6 for 4.0 mm

Page 6

3. Application

Neutrix is manufactured to offer the following options:

!Grinding of oxidated or pure tungsten electrodes.

!Grinding electrodes with diameters from 1,0 – 4,0 mm.

!Variable angle adjustment from 15° to 180°.

!If it is necessary to grind electrodes shorter in length than 15mm–

a special electrode clamp can be supplied.

!Integrated filter to remove the grinding dust.

!To be able to grind tungsten electrodes on site.

!To achieve an exact and longitudinal ground tip.

4. Technical data & contents of standard package

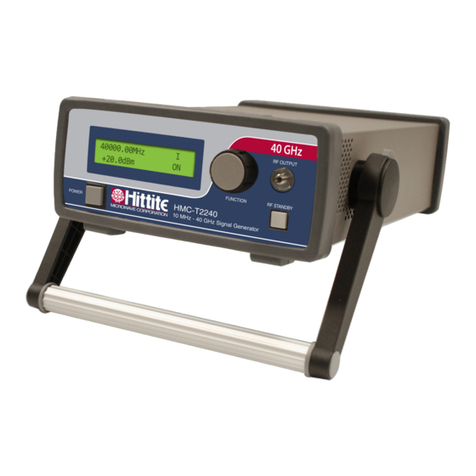

Motor: 850 Watt

Power: 230V, 50 Hz. Insulation according to EEC 50144.

Rpm: Adjustable between 7000 and 32000

Weight: 2.5 kg

Filter: Inhalation filter.

Diamond wheel: Ø 40 mm

•NEUTRIX

Containing: - Motor Type 850E

-Grinding head with filter housing and filter

-Diamond wheel Ø 40 mm

-Electrode holder

-Electrode clamps 1.6, 2.4, 3.2 mm

•Tools -Allen key 8 mm

-Allen key 4 mm

-Spanner 13/17 mm

-Spanner 13/14 mm

•Plastic bag to remove the filter

Page 7

5. Before use

Note: Ensure that the grinding head (2) is centred and tightly fixed

with the allen screw (15) to the motor.

5.1 How to select grinding position

With the Neutrix it is possible to select 3 different grinding positions

!Unscrew the knurled wheel (22)

!Lift the eccentric plate (20) and turn through 90° to the next position,

place the eccentric plate back in the slide of the angle adjustment.

!Tighten the knurled wheel (22)

Eccentric plate to select the grinding position

1

(left mark) 2

(centre mark) 3

(right mark)

Inside grinding

position Centre grinding

position Outside grinding

position

Page 8

5.2 Selection of electrode diameter

There are 3 different electrode clamps (1.6, 2.4, 3.2 mm) supplied with the

machine.

Unscrew the electrode clamp from the electrode holder and replace with the

required size.

5.3 Selection of angle

!Loosen slightly the knurled wheel (22).

!Place the degree sign of the guide (20) at the selected angle.

!Tighten the knurled screw (22).

Note: 15° is the smallest included angle of the electrode, that can be

ground.

180° position makes a flat on the electrode point.

(1 step = 5°)

6. Using the Neutrix

!Connect the machine to the power supply.

!Adjust the machine speed according to the recommendations on page 8.

!Select the electrode clamp to suit the tungsten to be ground.

6.1 How to operate Neutrix

!Place the tungsten electrode in the electrode holder (5) with

approximately 35 mm protruding.

!Push the electrode clamp into the depth setting gauge (12) until the clamp

is located into the allen screw (15), turn clockwise to tighten.

!Put the electrode holder through the electrode holder guide (6) until the

tungsten is touching the diamond wheel, this operation can be observed

through the inspection cover (29).

!Start the motor (11).

Page 9

6.2 How to grind the electrode

!Turn the electrode holder, whilst pushing the electrode against the

diamond wheel. Do not push too hard in order to avoid blueing of the

electrode. This can be viewed through the inspection cover

!The grinding is completed when the stop of the electrode holder (14)

touches the end face of the electrode holder guide (6).

!Switch off the motor and remove the electrode holder when the motor has

come to a complete stop.

!Place the electrode holder in the depth setting gauge. Turn anti clockwise

and the electrode can be removed.

Recommended turning speed

Diam. of the electrode 1.0 mm 1.6 mm 2.0 mm 2.4 mm 3.2 mm 4.0 mm

Speedadjustment 665544

Note: Do not press too hard at the electrode holder before the stop (14)

has been reached.

Remember to put the electrode holder into the grinding chamber

before you start the machine and to keep it there until the motor

has stopped. (Otherwise grinding dust may come out of the

chamber).

Page 10

7. Maintenance

Remove the plug from the power supply before carrying out any

maintenance or repairs.

7.1 Replacing the filter

The filter has to be changed when the amount of dust makes it difficult to

watch the grinding process through the inspection cover (29).

1. Loosen the allen screw (25.3) at the filter housing (25).

2. Remove the filter cover (25.2).

3. Remove the filter cassette (26) and put it into the plastic bag for

disposal.

4. Insert a new filter cassette so that the rubber seal is sitting tight to the

grinding head (2).

5. Mount the filter cover and tighten the screw.

7.2 Replacing the diamond wheel

1. Remove the electrode holder (5).

2. Loosen the knurled screw (22)

3. Unscrew the electrode holder guide (14) using the spanner (SW 17)

4. Remove the grinding chamber (10) including the inspection cover

(29).

5. Unscrew the nut retaining the diamond wheel, using the spanners

(SW14 & SW13), two flats are located on the motor spindle behind

the diamond wheel for this purpose.

6. Remove the diamond wheel.

7. Insert a new diamond wheel and replace the retaining nut.

8. Replace the grinding chamber and inspection cover

Replace the electrode holder guide

9. If the grinding head chamber is too dirty it can be cleaned with an

alkalised solution and rinsed with water. If doing so remember to

remove the filter first

Page 11

8. Parts diagram:-

Page 12

9. Parts list

Pos. Description Part No.

0 Neutrix 1 piece N-88896022

1 Motor 1 piece N-44510010

1.1 On/Off switch 1 piece N-44510011

1.2 Power cable 1 piece N-44510012

1.3 Brush for motor 2 pieces N-44510013

2 Grinding head 1 piece N-44510020

3 Diamond wheel Ø 40 mm 1 piece N-44510030

5 Electrode holder 1 piece N-44510050

8 Spindle for diamond wheel (SW 13) 1 piece N-44510080

10 Grinding chamber 1 piece N-44510100

14 Guide for electrode holder (SW 17) 1 piece N-44510140

15 Allen key to tighten the grinding head 1 piece N-44510150

16 See below

16.2 Electrode clamp Ø 1,6 mm 1 piece N-44510162

16.4 Electrode clamp Ø 2,4 mm 1 piece N-44510164

16.5 Electrode clamp Ø 3,2 mm 1 piece N-44510165

19 Allen screw (M5 x 30) 1 piece N-44510190

20 Eccentric plate to select grinding position 1 piece N-44510200

22 Screw 1 piece N-44510220

25 Filter housing 1 piece N-44510250

25.2 Filter cover 1 piece N-44510252

25.3 Allen key to fix the filter cover (M 5 x 6) 1 piece N-44510253

26 Filter cassette 1 piece N-44510260

29 Inspection cover 1 piece N-44510290

31 Spring 1 piece N-44510310

32 Rubber seal big 1 piece N-44510320

33 Screw to fix filter cassette 4 pieces N-44510330

34 Sticker „Neutrix“ 1 piece N-44510340

35 Safety sticker 1 piece N-44510350

36 Degree scale 1 piece N-44510360

37 Screw to fix diamond wheel (M 8, SW 13) 1 piece N-44510370

38 Rubber seal small 1 piece N-44510380

Accessories

39 Case for machine with foam 1 piece N-44510390

40 Spanner (SW 13, SW 17) 1 piece N-44510400

41 Spanner (SW 13, SW 14) 1 piece N-44510410

42 Allen key 8 mm 1 piece N-44510420

43 Allen key 4 mm 1 piece N-44510430

44 Plastic bag for disposal of filter 1 piece N-99140003

16.1 Electrode clamp Ø 1,0 1 piece N-44510171

16.3 Electrode clamp Ø 2,0 1 piece N-44510172

16.6 Electrode clamp Ø 4,0 1 piece N-44510174

Table of contents