Bio-Art BioWash User manual

USER’s MANUAL

Ultrasonic Washer - Mod. STD

BioWash

01 - INTRODUCTION ...............................................................01

02 - BENEFITS OF THE ULTRASONIC CLEANING................01

03 - APPLICATIONS.................................................................01

04 - PACKAGE CONTENTS.....................................................02

05 - INSTALLATION AND CARE ..............................................02

06 - DIRECT AND INDIRECT USAGE METHODS ..................03

07 - INSTRUCTIONS FOR USE...............................................03

08 - THREE DIFFERENT FORMS OF CLEANING..................05

09 - MAINTENANCE AND SUGGESTIONS.............................05

10 - TECHNICAL SPECIFICATIONS........................................06

11 - PARTS LIST.......................................................................07

12 - WARRANTY ......................................................................08

13 - AUTHORIZED SERVICES ...............................................08

ÍNDICE

In search of convenience and quality in the cleaning of instruments, especially those used in

medical and dental care, we developed a device called “ultrasonic vat”.

The mode of action of BIOWASH (Bio-Art ultrasonic washer) is based on the conversion of

electrical energy into mechanical, through a piezoelectric crystal (ultrasonic transducers) that

generates high frequency waves (vibrations) in the stainless steel vat, which in turn should contain

water or a crust removing cleaning solution (chemical detergents - optional). These waves exceed

the capacity of the liquid to move with the same speed due to water mass inertia, causing the

formation of microscopic air and water vapor bubbles. These bubbles propagate into the

instruments acting like small brushes that work in all directions and attack the whole surface to be

cleaned, entering areas of difficult access removing various types of organic and inorganic waste

in a process called “ultrasonic cavitation”. BioWash is easy to use, however to get the most out of

the purchased product, we recommend reading the User's Manual before starting any cleaning

operation.

The ultrasonic method is faster and more efficient than the manual method in the following

aspects:

• Speed and optimization in the process of cleaning instruments used routinely in offices, clinics

and laboratories, including the areas of difficult access;

• Removes organic and inorganic waste impregnated in the instruments, which interfere in the

chemical reactions of the materials to be manipulated;

• Avoids grooves in the instruments caused by manual brushing methods thus preventing waste

impregnation them;

• Avoids early wear of the cutting wire of the instrumental, caused by abrasion of manual

methods;

• Security against cross-infection.

• Medical and Odontological Clinics:

Cleaning of pieces and instruments in general, not for disinfection purposes.

• Manufacturers of jewelry and precious stones stores:

Cleaning during the finishing process of necklaces, rings, earrings, etc. With the heating device

of the machine at 65 ° C, the polishing wax of the product surface will be removed.

• Chemical Laboratory:

Cleaning of test tubes and glassware in general.

• Home:

Efficient cleaning of baby bottles, pacifiers, children's toys, among others.

• Restaurants:

A quality cleaning can be achieved in cutlery, cleaning of coffee machine filters, among others.

01 - INTRODUCTION

02 - BENEFITS OF THE ULTRASONIC CLEANING

03 - APPLICATIONS

- 01 -

• Repair of Precision Machinery :

A good cleaning and removal of dirt and grease can be achieved in the cleaning of pneumatic

valves, control valves, power steering valves, flow nozzles, precision gears and bearings. It

revives lubricating greases giving new life to the pieces.

• This washer performs the cleaning of instruments and does not perform the disinfection process

and / or sterilization of instruments.

• The site for installation shall be ventilated, spacious, flat and away from heat sources, water and

other machines, to avoid possible damages to the product.

• Check that the voltage of your device is compatible with the local power grid.

• Do not put flammable liquids or solvents in the vat. Use only products suitable for this type of

procedure.

• Do not put your hand inside the vat while the machine is running.

• Never disassemble the Ultrasound. The internal high voltage may cause accidents.

• Never actuate the washing machine without water. This will lead to a loss of warranty, since this

may damage or shorten the life of the equipment.

• Keep the unit unplugged from the power supply while filling with water. Do not exceed the

maximum level of filling (“MAX” in the vat).

• To avoid electrical shock, never touch the power cord or plug with wet hands.

WHAT CANNOT BE CLEANED:

NOTE: The oxidation of metals can not be removed. To improve the process,

we recommend the use of chemicals.

!

CAUTION!

If the equipment is not used as specified in this manual, the protection

provided by the equipment may be impaired.

!

Jewelry (tortoiseshell, pearl, emerald, ivory, coral,

agate ...)

Precious metals (welding metals, electro plating,

alloys ,...)

Watches (except waterproof below 50m deep or

more)

Other (wood, glass, contact lenses, camera color

filters)

may suffer loss of color and brightness due to

friction.

weld or alloy spots may break. Electroplating breaks

may suffer enlargement after cleaning.

water can penetrate the watch, even if it's

waterproof.

apparent cracks apparent in wood, ceramic objects

or laminated lenses, may suffer enlargement (this

will not happen if the object is in perfect condition).

04 – PACKAGE CONTENTS

05 - INSTALLATION AND CARE

01 A STD BioWash washer with lid

01 Electrical Cable

01 Instrument basket-holder

01 User's manual

- 02 -

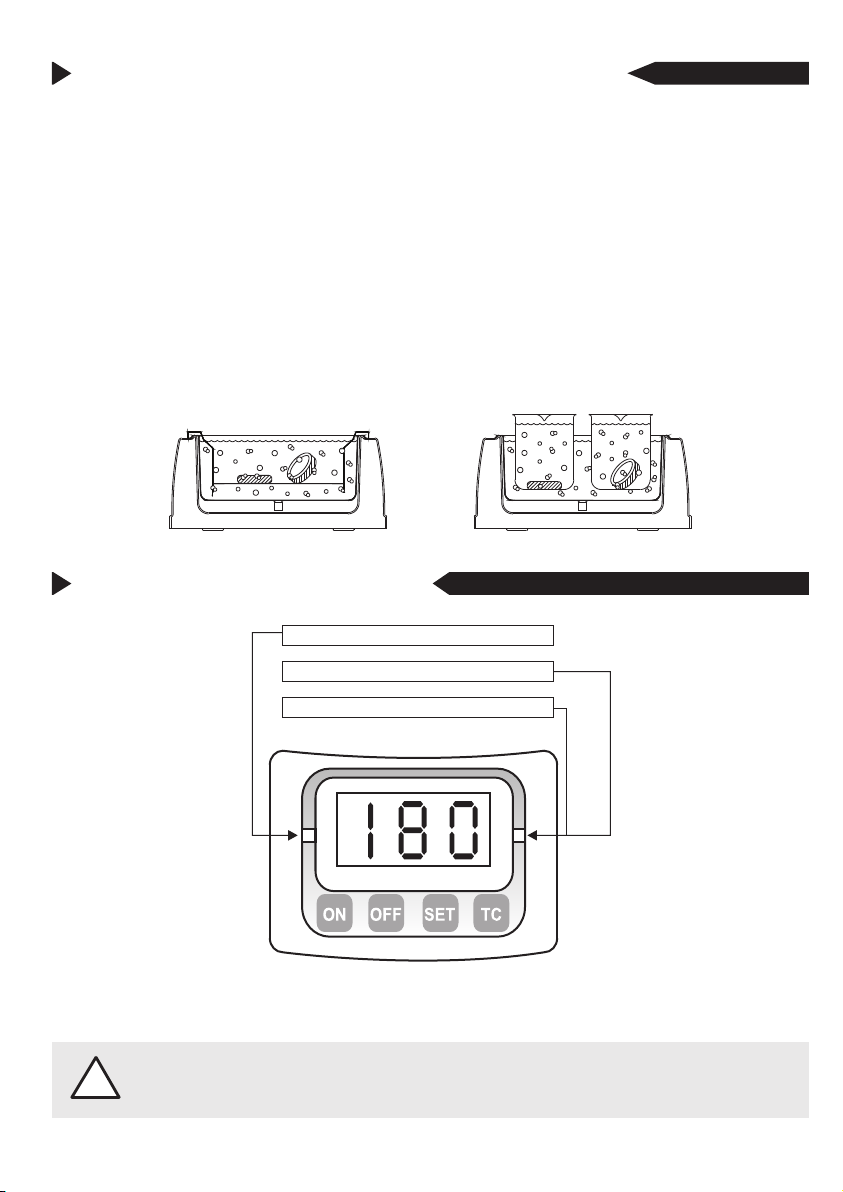

DIRECT METHOD:

The solution is placed in the vat and the materials in the tray or hanging pierced basket, picture 1.

It provides efficiency in cleaning and ease operation, but you can only use one cleaning solution at

a time, and all removed dirt stays in the vat, which may suffer corrosion if highly caustic or acid

solutions are used.

INDIRECT METHOD:

The crust removing solution and instrumentals are placed in becker-type containers (not

included), picture 2.

The vat is filled with water and cleaning solution to improve the cavitation, and the dirt stays in the

containers (becker) that can be filled with different crust removing solutions. Another advantage of

the indirect method is that the containers (becker) can be autoclaved to avoid cross-contamination

of prosthetic parts, appliances and other devices that may later be used by patients.

06 - DIRECT AND INDIRECT USAGE METHODS

07 - INSTRUCTIONS FOR USE

PICTURE 2 PICTURE 1

Heating indicator

Ultrassonic indicator

Overload protection indication

Red LED

Red LED

Green LED

STD Model

• Select and position the support basket as needed (direct or indirect method);

• Place the instruments to be cleaned in the basket and cover;

Note: Do not put large number of instruments (overlaid), as this may

compromise the efficiency of the cleaning process, cause friction between

them, leading to loss of brightness of these instruments.

!

- 03 -

Table of contents