BIO UV BIOSUN 340 Manual

BIOSUN-340_(Anglais) - DOC012466 - Ind. B03 - 21/06/2017

BIOSUN

340W

INSTALLATION AND MAINTENANCE MANUAL

BIOSUN-340_(Anglais) - DOC012466 - Ind. B03 - 21/06/2017 Copyright BIO-UV

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 2

We thank you for choosing BIOSUN.

Our equipment has been designed to give you reliable and safe operation for many years to come.

The BIOSUN terminals have been designed for speed and ease of installation.

Their design also makes them easy to maintain.

Read these instructions carefully in order to optimize the operation of your device.

TABLE OF CONTENTS:

Pages

A. Technical characteristics.................................................................................................................................................3

B. SafetyWarnings...............................................................................................................................................................4

C. BIOSUNterminal description..........................................................................................................................................5

1. Overview.........................................................................................................................................................................................................................5

2. Hydraulic diagram.......................................................................................................................................................................................................6

D. Installation guide ............................................................................................................................................................7

1. Foreword ........................................................................................................................................................................................................................7

2. Detail of provided elements....................................................................................................................................................................................7

3. Mounting of photovoltaic panels .........................................................................................................................................................................8

a.) Preparation .............................................................................................................................................................................................................8

b.) Assembly..............................................................................................................................................................................................................10

4. Wiring of photovoltaic panels.............................................................................................................................................................................22

5. Instruction to mount the BIOSUN 340 terminal ...........................................................................................................................................23

E. Instructions for the first commossioning of the BIOSUN 340 terminal ..................................................................... 25

F. Instructions to use the BIOSUN 340 terminal.............................................................................................................. 26

1. Production...................................................................................................................................................................................................................26

2. Start-up the terminal...............................................................................................................................................................................................26

G. Instructions for servicing of the BIOSUN 340 terminal.............................................................................................. 27

1. Backwashing the filter ............................................................................................................................................................................................27

2. Tank draining .............................................................................................................................................................................................................27

3. Solar panel cleanliness...........................................................................................................................................................................................28

4. Preventive disinfection ..........................................................................................................................................................................................28

5. Functional check of the photovoltaic power supply..................................................................................................................................28

H. Procedure for lap, quartz sleeve or seals replacement.............................................................................................. 29

I. Replacement of the filter cartridges (option)............................................................................................................... 32

J. Maintenance file............................................................................................................................................................ 33

K. Electrical description.................................................................................................................................................... 34

L. Blown up view ............................................................................................................................................................... 35

M. Errors and remedial action: regulator ........................................................................................................................ 36

N. Frequently asked questions ........................................................................................................................................ 38

O. Warranty terms............................................................................................................................................................. 39

ANNEX 1: Clearance dimensions, Blown up view, Designation .................................................................................... 41

ANNEX 2: Electrical diagrams.......................................................................................................................................... 43

BIOSUN-340_(Anglais) - DOC012466 - Ind. B03 - 21/06/2017 Copyright BIO-UV

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 3

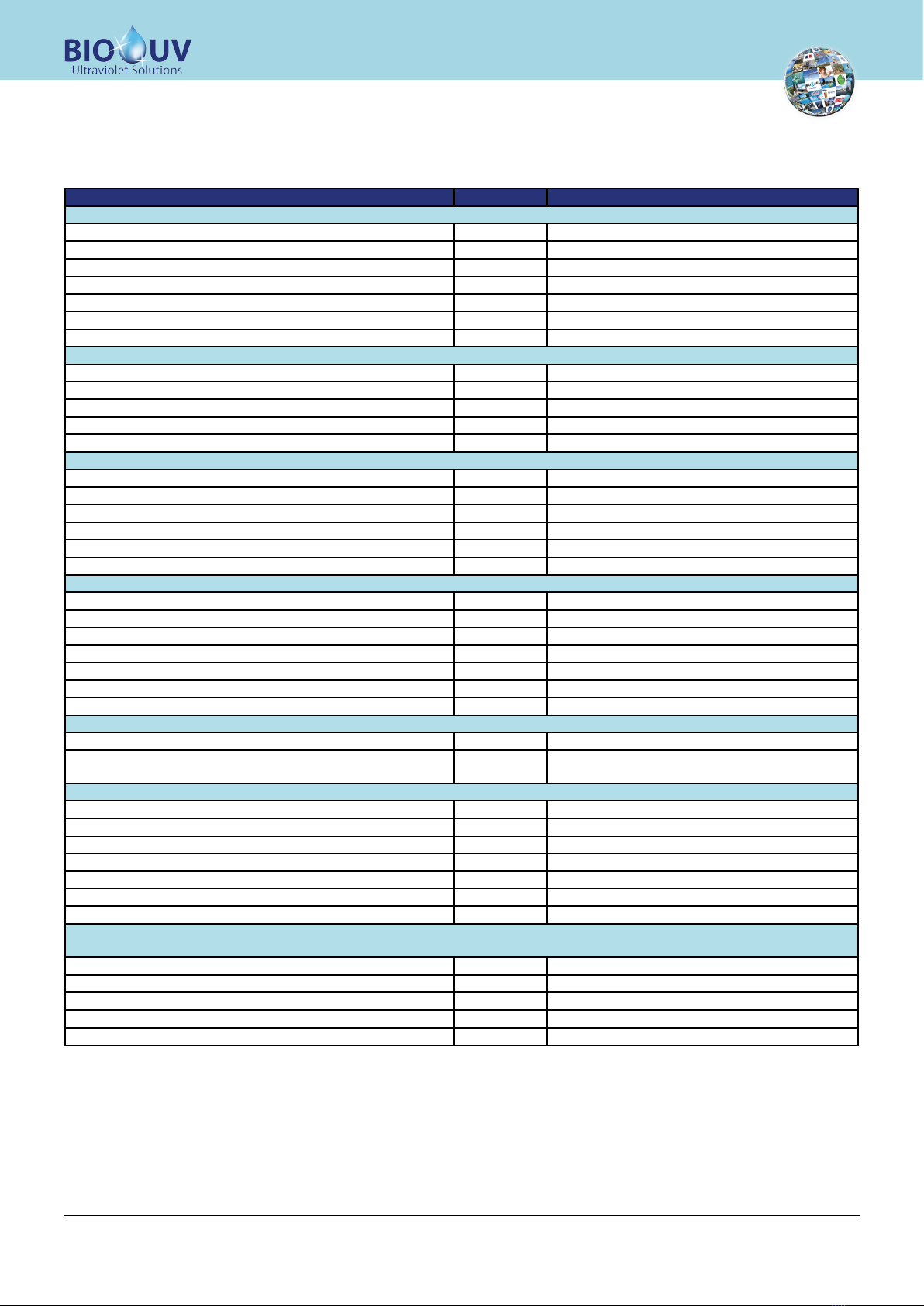

A. TECHNICAL CHARACTERISTICS

BIOSUN RANGE UNIT BIOSUN 340

FUNCTIONAL CHARACTERISTICS

Flowrate l/h 500

Number of hours of production per day h 4

Volume produced per day m3 2

Standalone operating time day 3

Draw-off - Standalone operating time

Volume meter - Draw-off

UV reactor ON/OFF switch - Yes, with integrated LED

WATER SUPPLY

Tank volume l 21

tankmaterials - 304L stainless steel

Supplytype - Manual or gravity filling < 1 bar

Max. pressure bar 1

Pump Vdc 24 (with a built-in pressure switch)

FILTERING

Filteringmedia - Zeolite

filter volume l 7

filteringthreshold

µm

<10

backwashing - With manual handle

cartridgesize (optional) inch 10

Filter cartridge type (optional)

-

10µm, activated carbon

UV REACTOR

UV lamp power W 14

UV power delivered

W

4.6

UV operating light - Yes

Dose delivered mJ/cm² 40

Ballast

-

Electronic (24VDC)

Supply voltage Vdc 24

Average life expectancyfor one stop/start perday year 1

FRAME

Dimensions mm 1400 x 600 x 400

Material - Fiberglass + polyester complex: special for outdoor

use

PHOTOVOLTAIC POWER SUPPLY

Panel size (unit) mm 1200 x 600

Number of solar panels - 4

Panel power W 85

Panel voltage V 12

Panel attachment - Remote support (roof, floor, etc.)

Number of batteries - 2

Batterytype - 70Ah(C100), 60Ah(C20), 12V

OPTION WITHOUT PHOTOVOLTAÏC PANELS

Recommendedspare parts listto be provided bythe customer

Solar panel - 4

Number of batteries - 2

Batterytype - 70Ah(C100), 60Ah(C20), 12V

Controller - According to panel model specified by the customer

Converter - 24Vdc 100W

BIOSUN-340_(Anglais) - DOC012466 - Ind. B03 - 21/06/2017 Copyright BIO-UV

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 4

B. SAFETYWARNINGS

•Switch off the device 10 minutes before any intervention to let the lamps cool down.

•Stop the system in the eventof a prolonged stop of the water flow

•Never expose yourself to the radiation of the ultraviolet lamps when lit. This may

cause severe injuries or burns and may even lead to loss of eyesight.

•When the lamps are running, do not take the lamps of the reactor out or remove the

protection covers

•When dismounting UV lamp or quartz tube, it is necessary to wear protection gloves not

to let fingerprints that could affect the UV emissions quality

•Do not use the reactor if the power supply wire is worn or damaged. In this case it

should be replaced.

•To avoid electric short-circuits, do not place the electric wires or the reactor in the pool

water or in any other maintenance or cleaning fluid.

•Do not perform electrical measurement on ballast output (risk of overvoltage)

•Never disconnect solar panels during the charge

•Never unscrew the quartz tube sealing nut when the reactor is on load as the quartz

tube could be blown out of the reactor with force and injure you.

•In

case of a microleakage, the reactor must be isolated and drained to perform

maintenance as soon as possible.

•Do not use the BIO-UV reactor for any other use than that for which it was designed.

BIOSUN-340_(Anglais) - DOC012466 - Ind. B03 - 21/06/2017 Copyright BIO-UV

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 5

C. BIOSUNTERMINAL DESCRIPTION

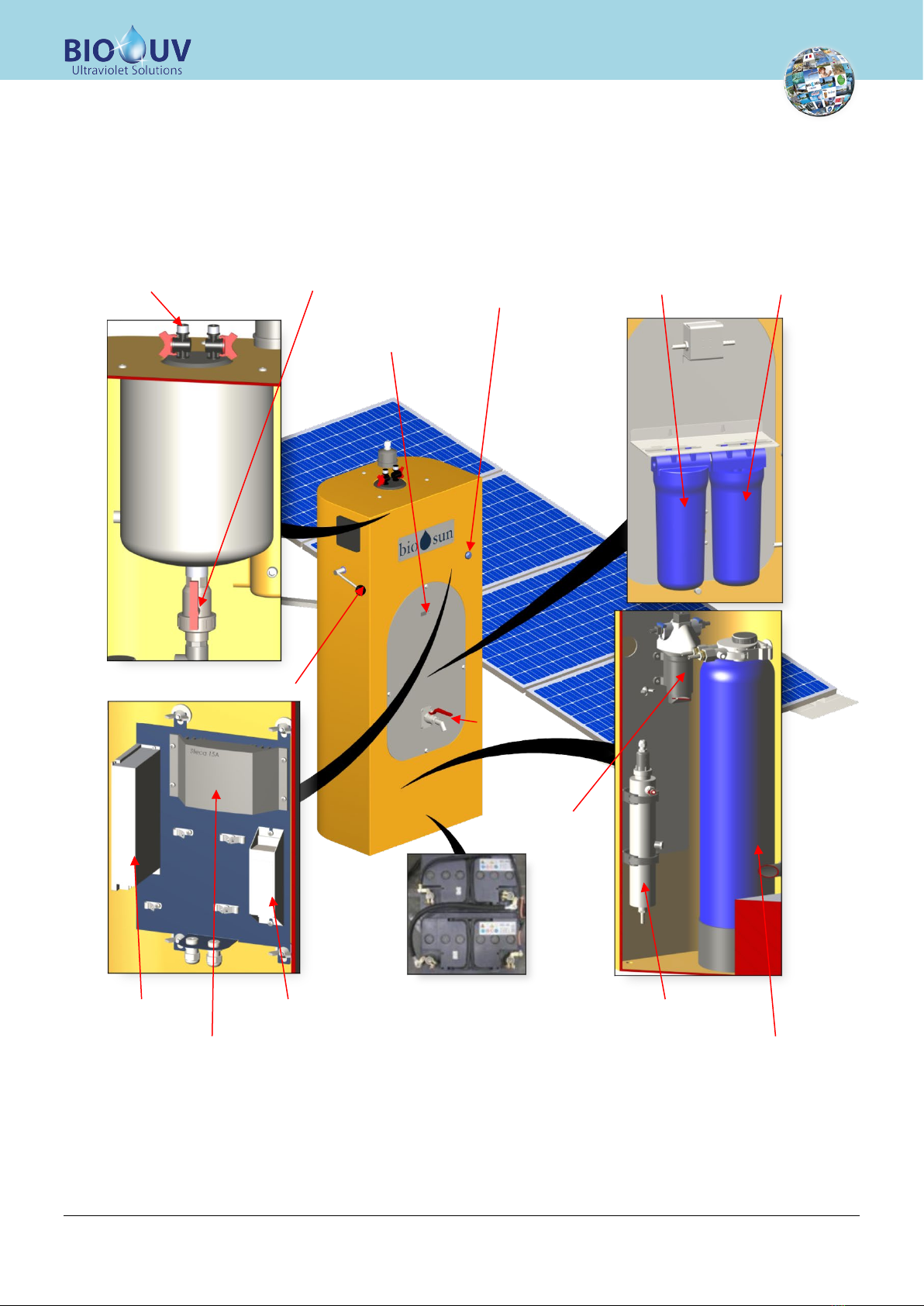

1. Overview

Handle for Filtration /

Cleaning position

Inlet valve

Intensity regulator

UV Ballast

Converter

UV ON/OFF light

switch

Zeolithe filter

UV Reactor

Batteries (x2)

Water counter

Treated

water valve

Pump

Draining valve 10µm filter

Active carbon filter

BIOSUN-340_(Anglais) - DOC012466 - Ind. B03 - 21/06/2017 Copyright BIO-UV

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 6

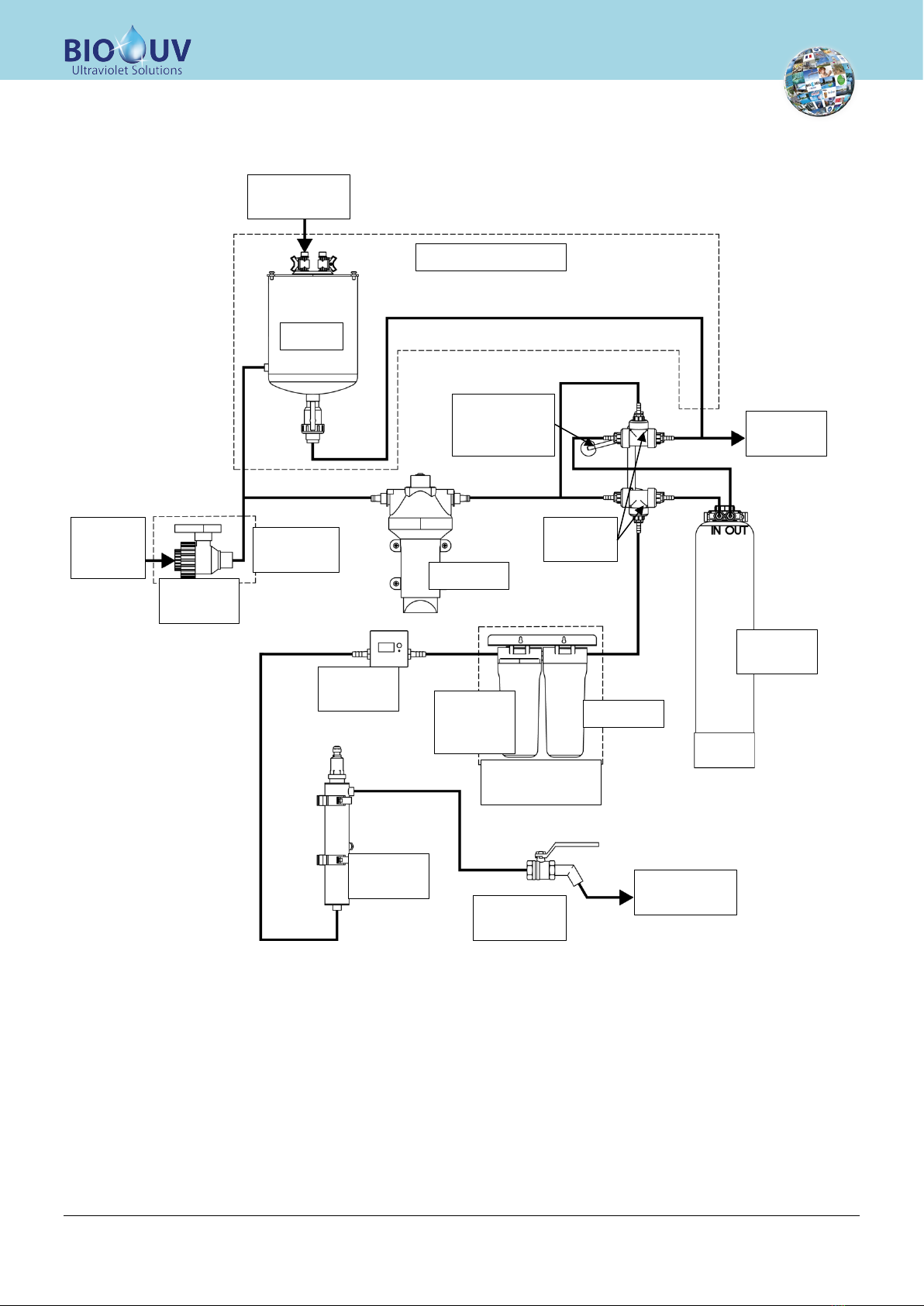

2. Hydraulicdiagram

With tank option

Without

tank option

Untreated

water inlet

Untreated

water

inlet

Draining

outlet

Treated water

outlet

Tank

Three

way valve

« Filtration /

cleaning »

handle

Zéolithe

filter

Pump

Manual

valve

10µm filter

Active

carbon

filter

Water

counter

UV

Reactor

Treated

water valve

Cartridge filters

option

BIOSUN-340_(Anglais) - DOC012466 - Ind. B03 - 21/06/2017 Copyright BIO-UV

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 7

D. INSTALLATION GUIDE

1. Foreword

Read all the instructions in this manual before switching on

the reactor.

IMPORTANT: BIOSUN 340 is designed to be connected to a low pressure system (< 1 bar)

If the operating pressure exceeds 1 bar, the BIOSUN 85 model must be used

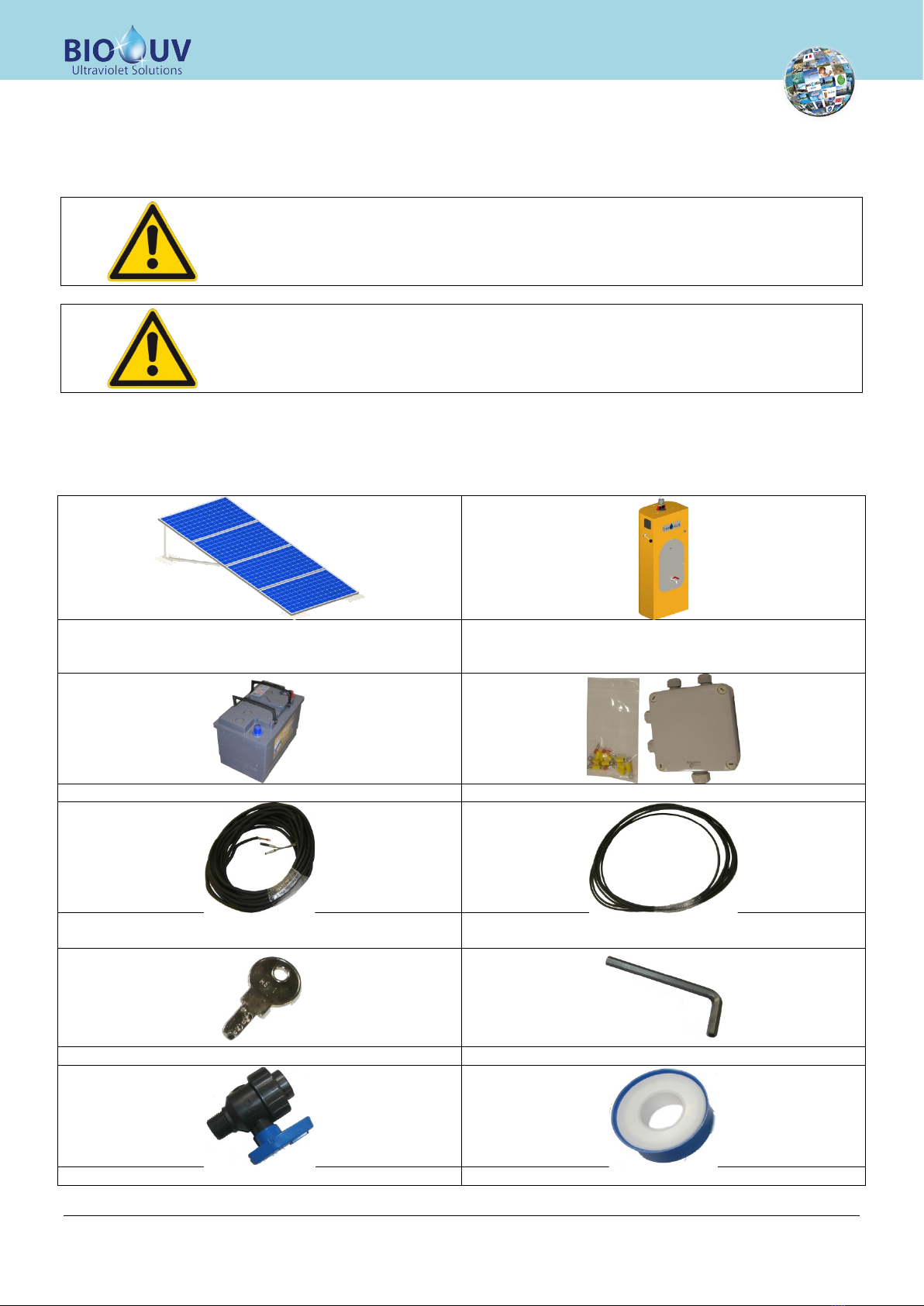

2. Detail of providedelements

Solar panels with frame (to be mounted and wired)

(The parts list of the frame supporting the solar panels is

specified on page 9.)

BIOSUN terminal

2 12V Batteries

Junction box with connecting lugs

Cables for terminal / solar panels connection

(Do not reduce length)

Cables to connect solar panels together

(Do not reduce length during wiring)

Switch key Anti-theft wrench

Supply valve (if no tank option) Teflon roll

BIOSUN-340_(Anglais) - DOC012466 - Ind. B03 - 21/06/2017 Copyright BIO-UV

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 8

3. Mountingof photovoltaic panels

a.)

Preparation

Before starting mounting, the concrete foundation should have been done first.

a-1.

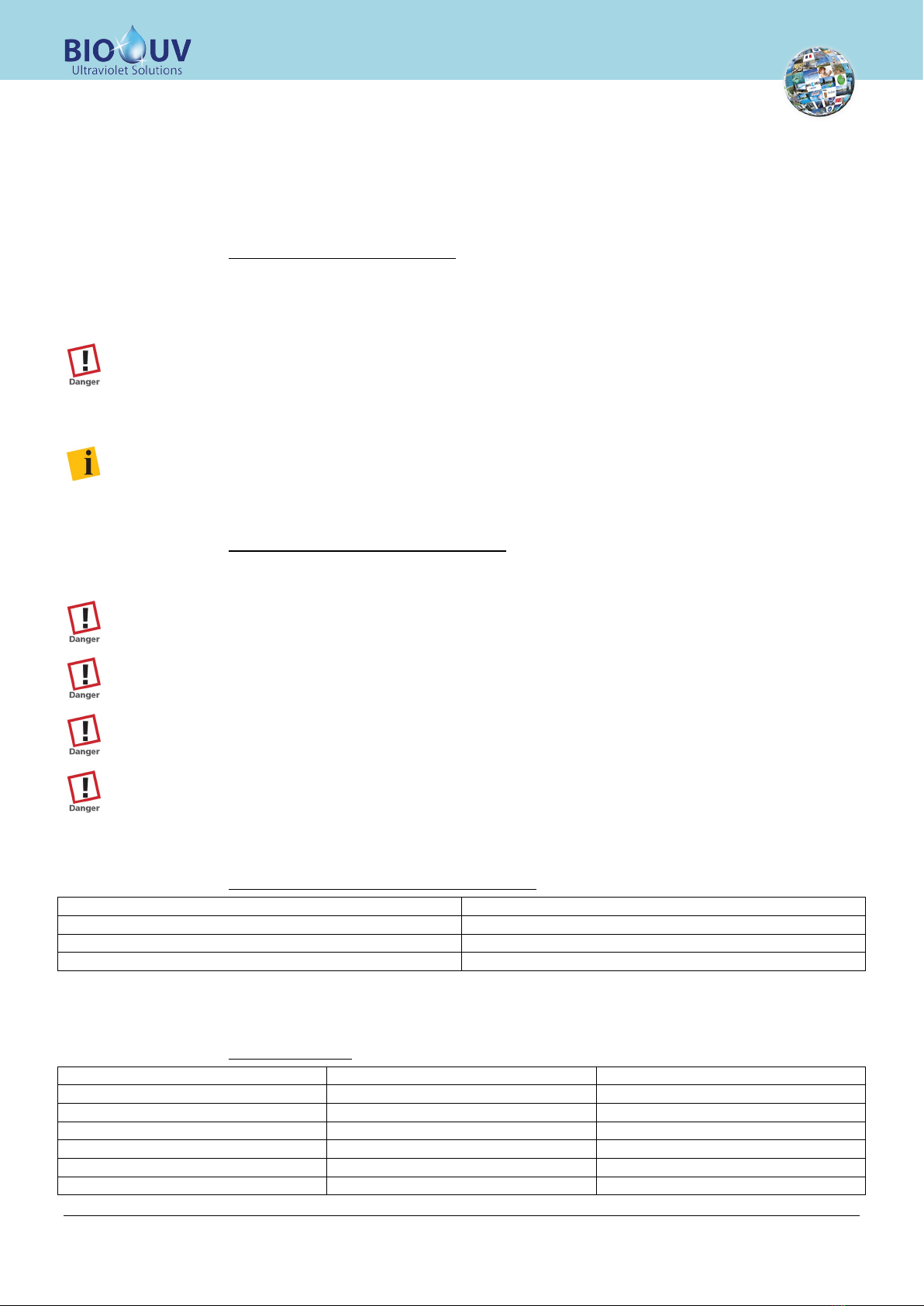

Description of the symbols used

Safetytips:

This symbol indicates a warning, which, if ignored, could result in risks to people or equipment. Read these passages

carefully.

Example:

Risk of injuries

•Risk of serious injury to the hands

•

Wear protective gloves!

Information

This symbol indicates information on the most appropriate procedure.

Example:

Use a screwdriver to tighten the screws

a-2.

Use a screwdriver to tighten the screws

When assembling the aluminium structure and the module, be sure to follow these safety tips:

Risks of cuts

•Cuts to the hands due to incorrectly deburred parts.

•Wear safety gloves!

Risks of burns

•Risk of burns from parts exposed to high heat.

•

Check the temperature of parts and wear gloves!

Risks of explosions

•Risk of explosion due to improper use of batteries

•Do not smoke or bring a naked flame near the batteries!

Risks of chemical burns

•The acid in the batteries can cause chemical burns.

•

Wear an apron and ant-acid gloves!

a-3.

Table for adjusting the solar panel tilt angle

LATITUDE TILT ANGLE

Latitude < 20° 15°

20° < latitude < 35° Latitude + 10°

Latitude > 35° Latitude + 15°

The minimum tilt angle value of 15° provides for "self-cleaning" of the photovoltaic panel and limits the risk of residual

moisture.

a-4.

Dimensions table

Foundation Fixing points Profiles length

F1 : 1844 mm A : 80 mm Profile P1 (2 parts) : 2340 mm

F2 : 1245 mm B : 380 mm Profile P2 (2 parts) : 802 mm

F3 : 263 mm C : 1300 mm Profile P3 (2 parts) : 300 mm

F4 : 720 mm D : 80 mm Profile P4 (2 parts) : 1013 mm

F5 : 525 mm E : 160 mm Profile P5 (1 part) : 640 mm

F : 120 mm

BIOSUN-340_(Anglais) - DOC012466 - Ind. B03 - 21/06/2017 Copyright BIO-UV

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 9

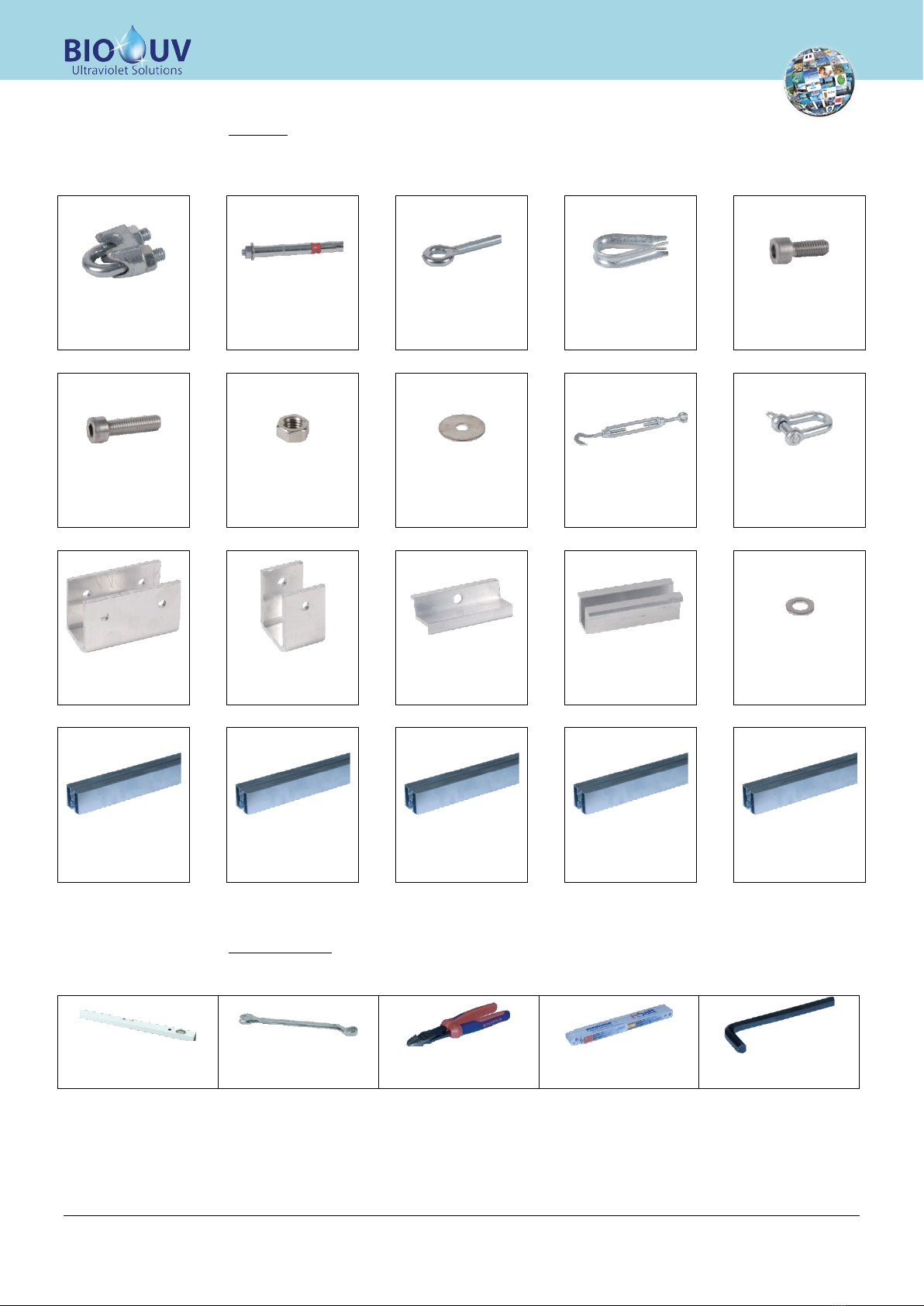

a-5.

Parts list

You will find the various parts of the structure supporting the modules

Rope clamp Clamping bolt Ring bolt Thimble Short screw

(20mm)

Short screw

(30mm) Nut HU M8 Flat washer L d=8 Tensioner Shackle

Large U profile Small U Profile I-module fixation T-module fixation Flat washer M

d=8

P1 type formed

section P1 type formed

section P1 type formed

section P1 type formed

section P1 type formed

section

a-6.

Required tools

The tools required to assemble the module support structure are indicated below

Spirit level Flat wrench (Size 13,

Size 10)

Cutting pliers Folding meter rule Allen wrench (Size 6)

BIOSUN-340_(Anglais) - DOC012466 - Ind. B03 - 21/06/2017 Copyright BIO-UV

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 10

b.)

Assembly

b-1.

Foundations for the aluminium support structure

Pre-tighten the screws during the assembly period and firmly tighten only after assembling the whole structure

with its modules.

Risks of cuts

•Cuts to the hands due to structural parts not deburred.

•

Wear safety gloves!

When the concrete foundation is completely dry, drill the attaching holes in the floor.

•Using figure 01, measure and make marks on the concrete

•Drill the concrete with a hammer drill using a 12 mm diameter drill bit.

b-2.

Assembling the aluminium support structure

b-2.1.

Mounting the base

For this step, you will need four anchoring studs, two narrow U formed sections (3 holes) and two wide U formed sections

(5 holes).

Before attaching, make sure you have properly positioned the wide U formed sections for the part pointing

towards the foundations pole and the narrow U formed sections for the part pointing towards the equator (see

Figure 01, red circles).

•Fit the four anchoring bolts in the four holes drilled in step 2.1, and make sure to attach them the right way round!

•Fit the U formed sections to the threaded rods (see figure 02) of the anchoring studs and then bolt the whole

assembly together.

Ä

The bolts are now attached in the holes.

Foundation

Concrete

foundation

U TYPE PROFILE

Clamping screw

Nut

Foundation

BIOSUN-340_(Anglais) - DOC012466 - Ind. B03 - 21/06/2017 Copyright BIO-UV

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 11

b-2.2.

Installing the two P2 type formed sections

In the next steps, install the P2 and P5 type formed sections. Figure 03 provides an overview of the structure showing the

use of the formed sections (red circles).

First assemble the three formed sections together on the floor. Then attach them to the foundations, otherwise the

screws cannot be tighten!

b-2.3.

Fitting the eye nuts to the P2 type formed sections

For this step, you will need four eye nuts (see figure 04, red circles), four L 8 mm dia plain washers, eight HU M8 nuts and

two P2 type formed sections.

Option: If you have the version with the GCB support (support for junction box), you also need to fit the support in

this step! (see next paragraph)

The following figure shows you what the structure should look like after this step.

•If you do not fit the GCB support - assemble the eye nuts (see figure 04).

Side view

Rear view

Rear viewCross-section view

Large

washer

Eye nut

Base plan for P2

type formed P2 type

Profile

Support for GCB (optional)

BIOSUN-340_(Anglais) - DOC012466 - Ind. B03 - 21/06/2017 Copyright BIO-UV

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 12

b-2.4.

Fitting the eye nuts and the GCB support

The eye nuts are fitted in the same way as in the previous step! But make sure to fit the support between the eye nuts on

the outside (rear view)

How to install the GCB support:

•Prepare two narrow U formed sections as shown in figure 05 (below).

•Fit the GCB support to the two U formed sections as shown in the following diagram (figure 06)

•After fitting the first eye nut, fit the GCB support with the two U formed sections to the two P2 type

formed sections (rear view) (see figure 07)

Nut Small washer

Short screw

U type Profile

U type formed section (side view)

U type formed section (side view)

GCB Support

Cross-sectional view from above

Floor plan for P2 type formed section

Floor plan for U type formed section

GCB plate support

BIOSUN-340_(Anglais) - DOC012466 - Ind. B03 - 21/06/2017 Copyright BIO-UV

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 13

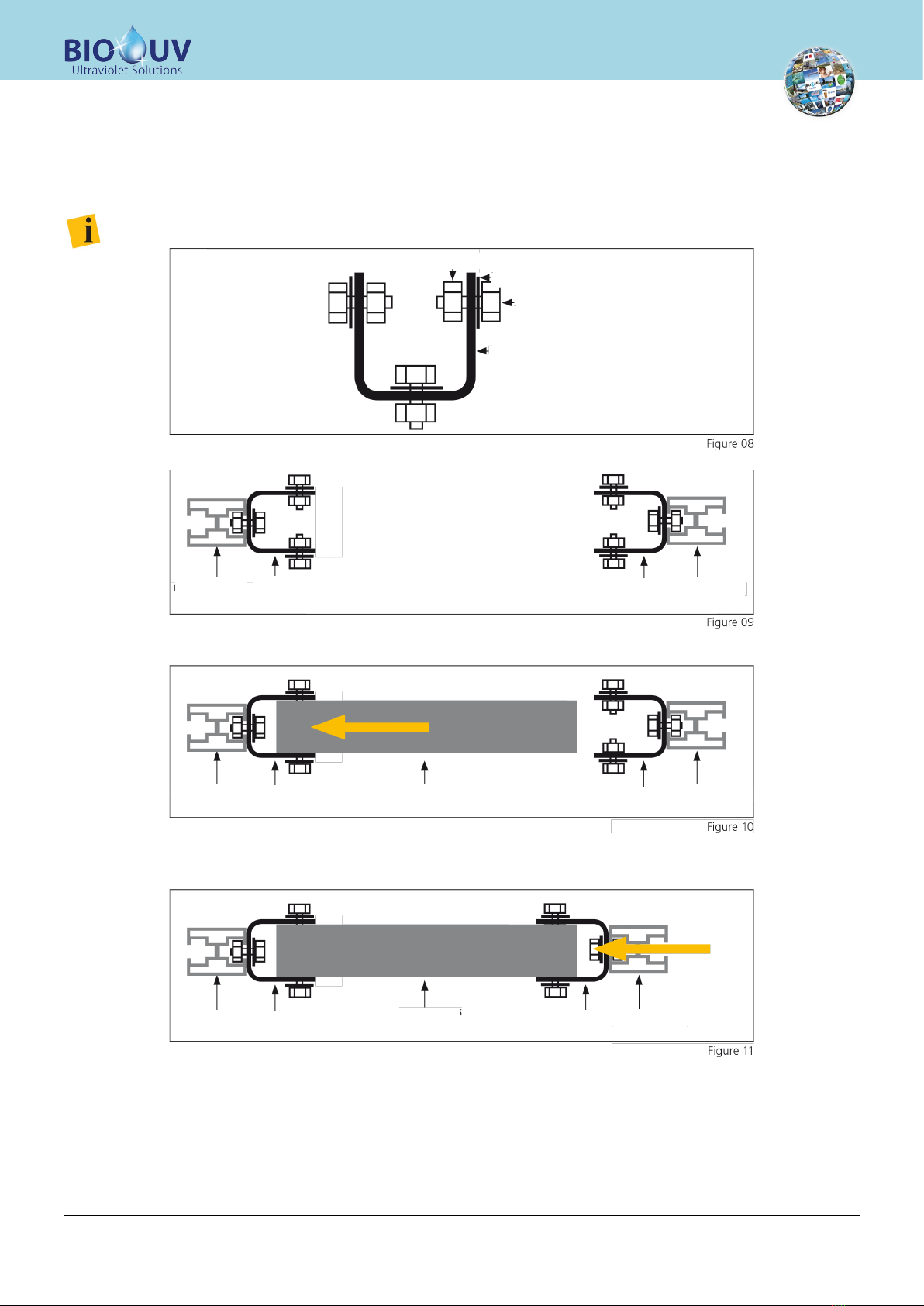

b-2.5.

Fitting the P5 type formed section

For this step you need the P5 type formed section, two narrow U formed sections, six short screws, six M plain washers d=

8 and six HU M8 nuts.

Figure 03 shows you where the formed sections are located in the overall construction (red circles)

•Prepare two narrow U formed sections as shown in the following figure (figure 08)

Do not tighten nuts at this point, as you will have to handle the formed sections in the next step!

•Fit the two U formed sections prepared with the two P2 type formed sections, as shown in figure 09.

•Attach the P5 type formed section to one of the U formed sections (see figure 10 below) - the attachment

is similar to the attachment you performed previously.

•Tighten the nuts of the U formed section, in which you attached the P5 type formed section

•Attach the P5 type formed section to the second U formed section, which is itself already attached to the

second P2 type formed section

Nut

Flat washer M d=8

Short screw

U type formed section

P2 formed

section

P2 formed

section

U formed

section U formed

section

P2 formed

section

P2 formed

section

U formed

section U formed

section

P5 formed

section

P2 formed

section

P2 formed

section

U formed

section

U formed

section

P5 formed

section

BIOSUN-340_(Anglais) - DOC012466 - Ind. B03 - 21/06/2017 Copyright BIO-UV

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 14

•Tighten the nuts of the U formed section, in which you attached the P5 type formed section

Ä

Your structure should look as shown in the diagram below!

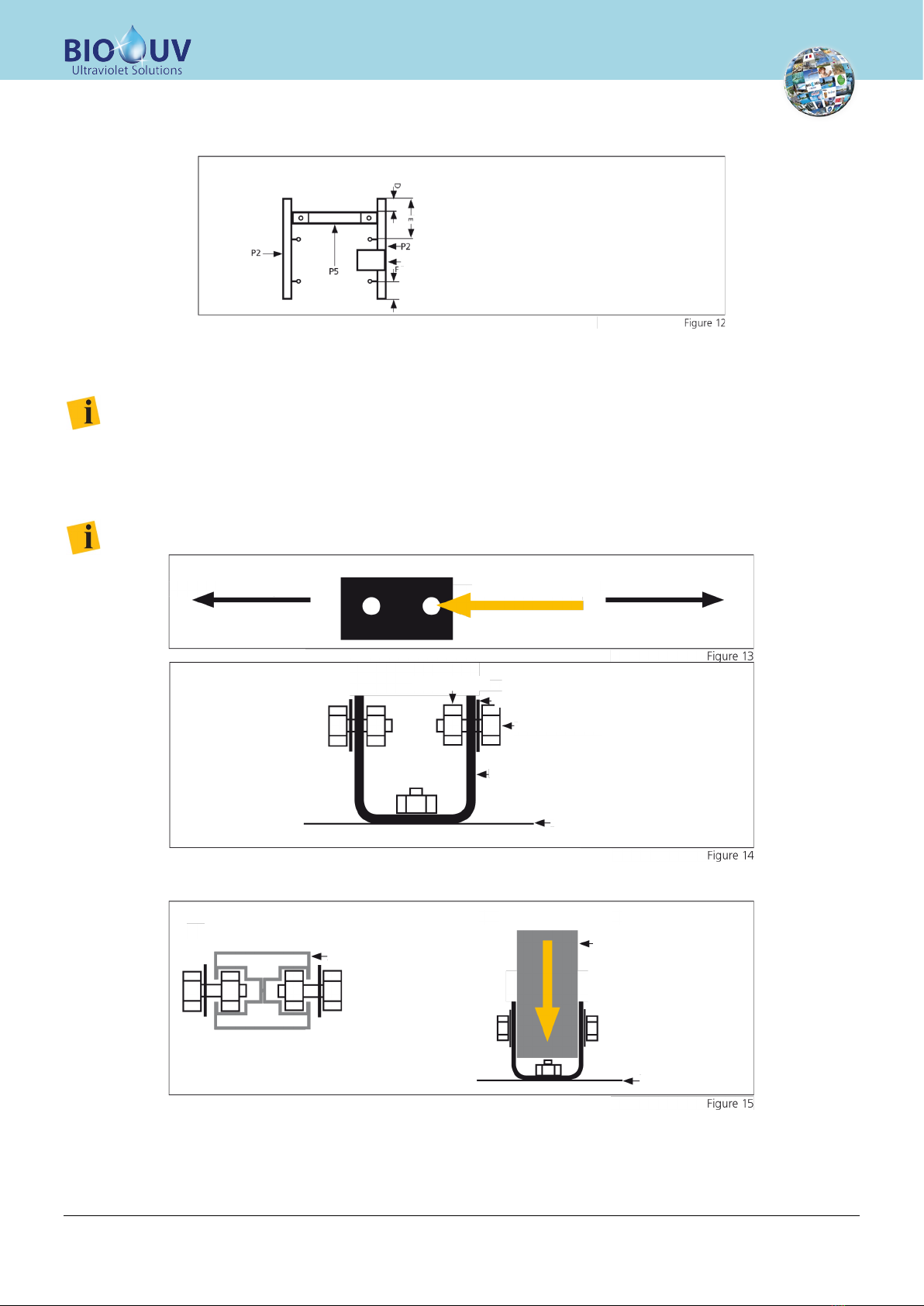

b-2.6.

Fitting the P2/P5 constructions to the foundations

Fit the screws, the nuts and the plain washers in the holes in the opposite direction to the equator of the wide U

formed sections!!! See figure below (figure 13)

•Fit the two short screws (20mm) in the "Pole" holes of one of the wide U formed sections that you have

already fitted to the foundations. You will need a nut and an M 8 mm dia plain washer for each screw.

Figure 14 shows how to assemble the bolts.

Do not tighten the screws at this point, as you will need to handle the formed sections in the next step!

•Repeat this procedure for the other U formed section!

•Attach the screws to the two sides of the P2 type formed section, as indicated in figure 15

•Make sure that the construction makes a right angle (90) relative to the foundation

•Tighten the screws on both sides

Ä

Both P2 formed sections are now firmly secured to the base (floor).

Rear view

GCB support (optional)

Equator

PoleIt is the hole on the right

HU M8 nut

Flat washer M8

20mm short screw

U formed section

Foundation

Cross-sectional view Front view

Base plan for the formed

section P2 type

P2 type formed section

Foundation

BIOSUN-340_(Anglais) - DOC012466 - Ind. B03 - 21/06/2017 Copyright BIO-UV

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 15

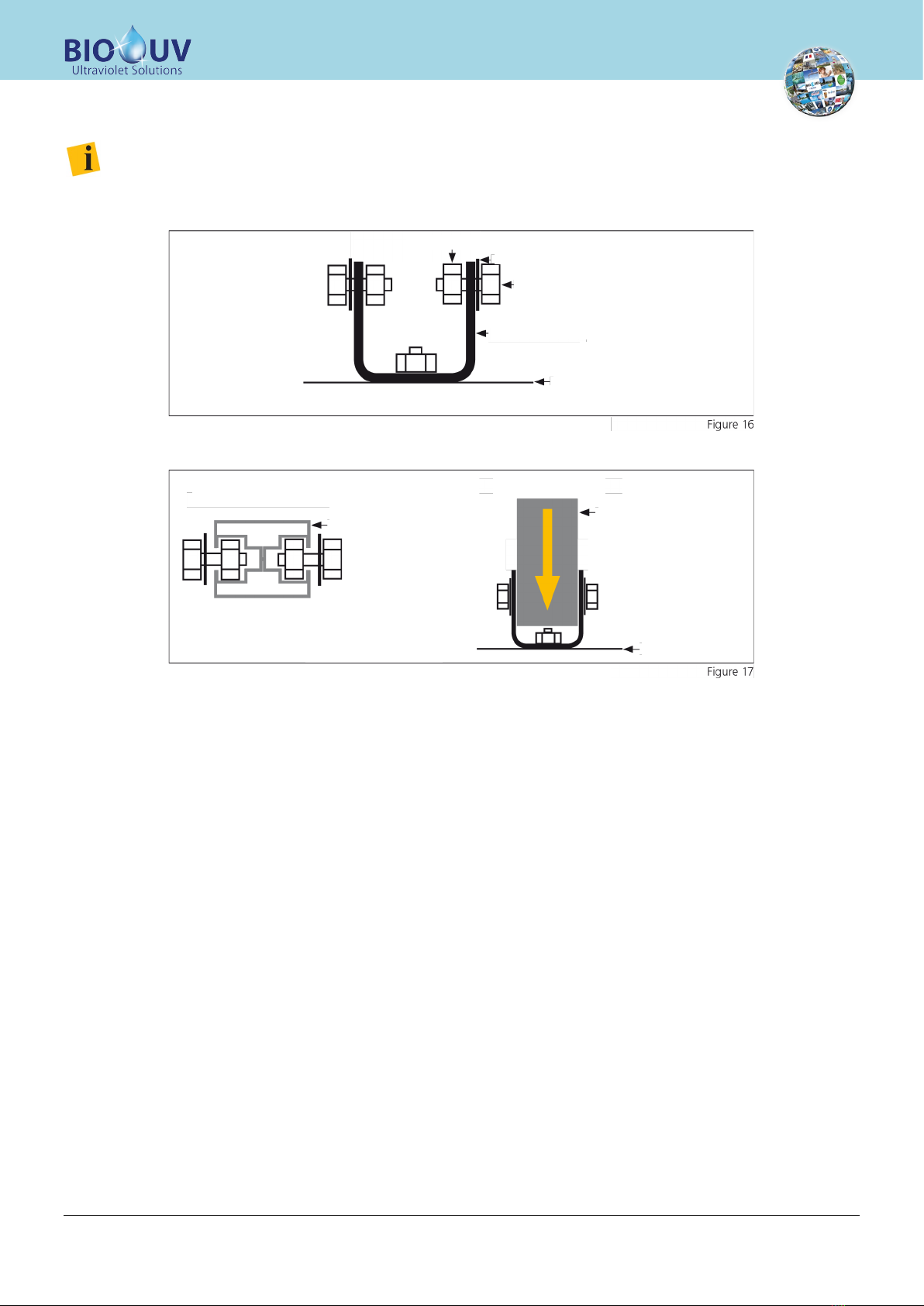

b-2.7.

Fitting the P3 type formed sections

Do not tighten the screws at this point, as you will need to handle the formed sections in the next step!

•Fit two short screws (20mm) to the U formed sections you previously fitted to the foundations. You will

need a nut and a small washer for each screw.

Figure 16 shows how to assemble the screws.

•Repeat this procedure for the other narrow U formed section!

•Attach the screws to the P3 type formed section as indicated in figure 17 on both sides

•Make sure that the construction makes a right angle (90) relative to the foundation

•Attach the screws on both sides

Ä

Both P3 formed sections are now screwed to the floor

Nut

Small washer

Short screw

U type formed section

Foundation

Cross-sectional view Front view

Base plan for the formed

section P2 type

P2 type formed section

Foundation

BIOSUN-340_(Anglais) - DOC012466 - Ind. B03 - 21/06/2017 Copyright BIO-UV

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 16

b-2.8.

Preparing the P1 type formed sections

For this step, you will need P1 type formed sections, six narrow U formed sections, 18 short screws and 18 small washers.

Figure 18 shows you where the formed sections should be installed in the overall structure (red circles).

•Prepare six narrow U formed sections as shown in figure 19.

Do not tighten the screws at this point, as you will need to handle the formed sections in the next step!

•Install three of the prepared U formed sections to the first P1 type formed section (see figure 20) - Make

sure to comply with the distances A, B and C (see figure 21).

•Repeat this procedure with the other P1 type formed section

•Tighten the screws fitted to the P1 type formed sections

Ä

Both P1 type formed sections are now ready to be assembled to the P3 and P2/P5 type formed

section

Side view

Nut

Small washer

Short screw

U type formed section

P1 type formed

section

U type formed

section

U type formed

section

U type formed

section

U type formed

section

P1 type formed

section

BIOSUN-340_(Anglais) - DOC012466 - Ind. B03 - 21/06/2017 Copyright BIO-UV

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 17

b-2.9.

Fitting the P4 type formed sections

For this step, you need P4 type formed sections, 4 small washers and 4 nuts.

Figure 22 shows where the formed sections are fitted in the overall structure (red circle).

•Fit the short screws (20mm) in the remaining hole in one of the wide U formed sections that you have

already attached to the foundations. You will need a nut and a small washer for each screw. Figure 23

shows how to assemble the screws.

Do not tighten the screws at this point, as you will need to handle the formed sections in the next step!

•Mount the Profile P4 into the U-Profile like shown in figure 15 (angle is not so important yet and will be

arranged in the next steps automatically

•Repeat this procedure for the other Profile P4

Ä

The Aluminum Support Structure is ready to mount the Profiles P1

Side view

Nut

Small washer

Short screw

U type formed section

Foundation

BIOSUN-340_(Anglais) - DOC012466 - Ind. B03 - 21/06/2017 Copyright BIO-UV

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 18

b-2.10.

Fitting the P1 type formed sections

For this step, you will need the previously prepared P1 type formed sections.

•Fit the P1 type formed sections to the P4, P2 and P3 formed sections as shown in figure 24 below.

Slight differences can be balanced by adjusting the U formed sections. But make sure that the parts are fitted the

right way round!

BIOSUN-340_(Anglais) - DOC012466 - Ind. B03 - 21/06/2017 Copyright BIO-UV

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 19

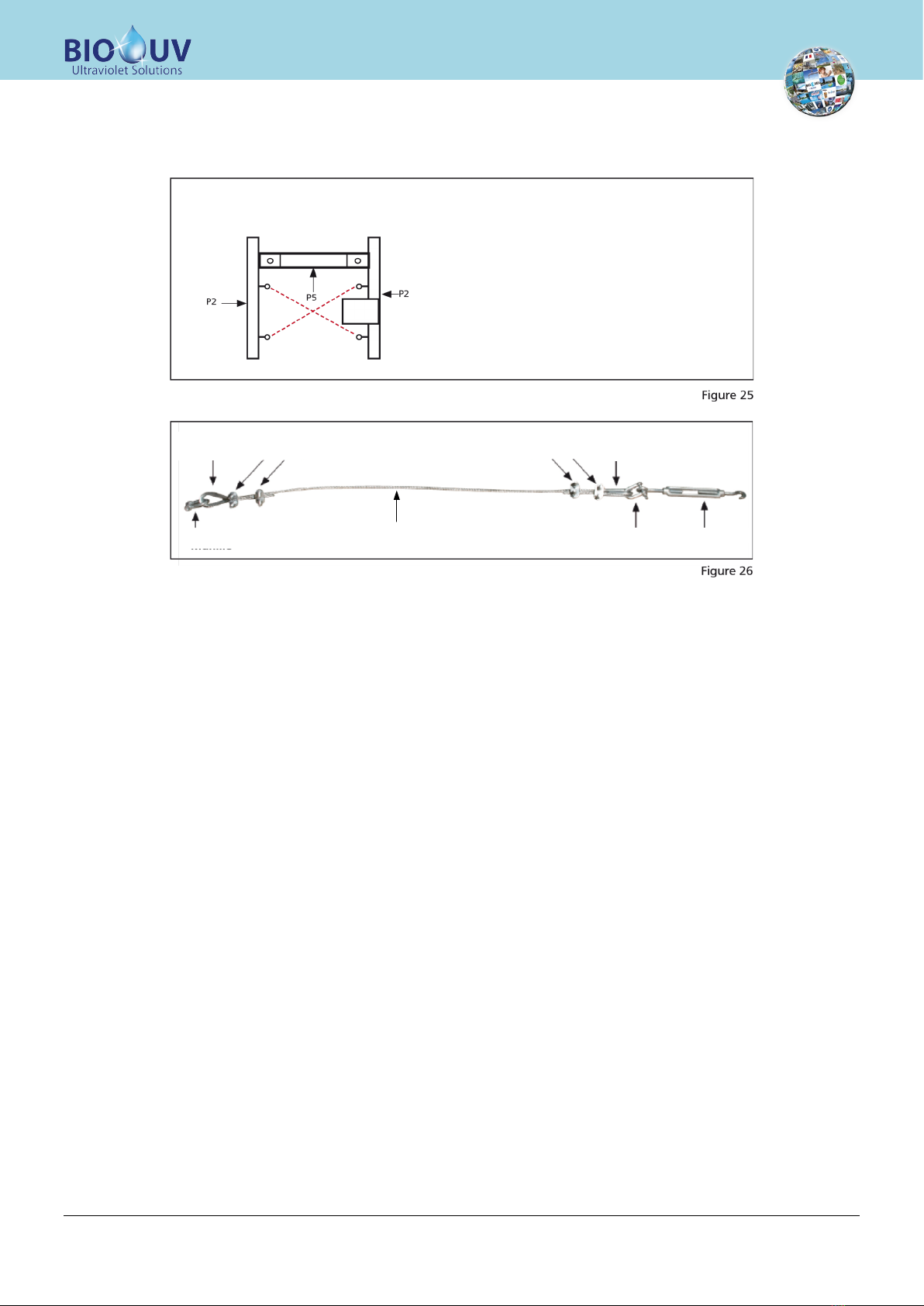

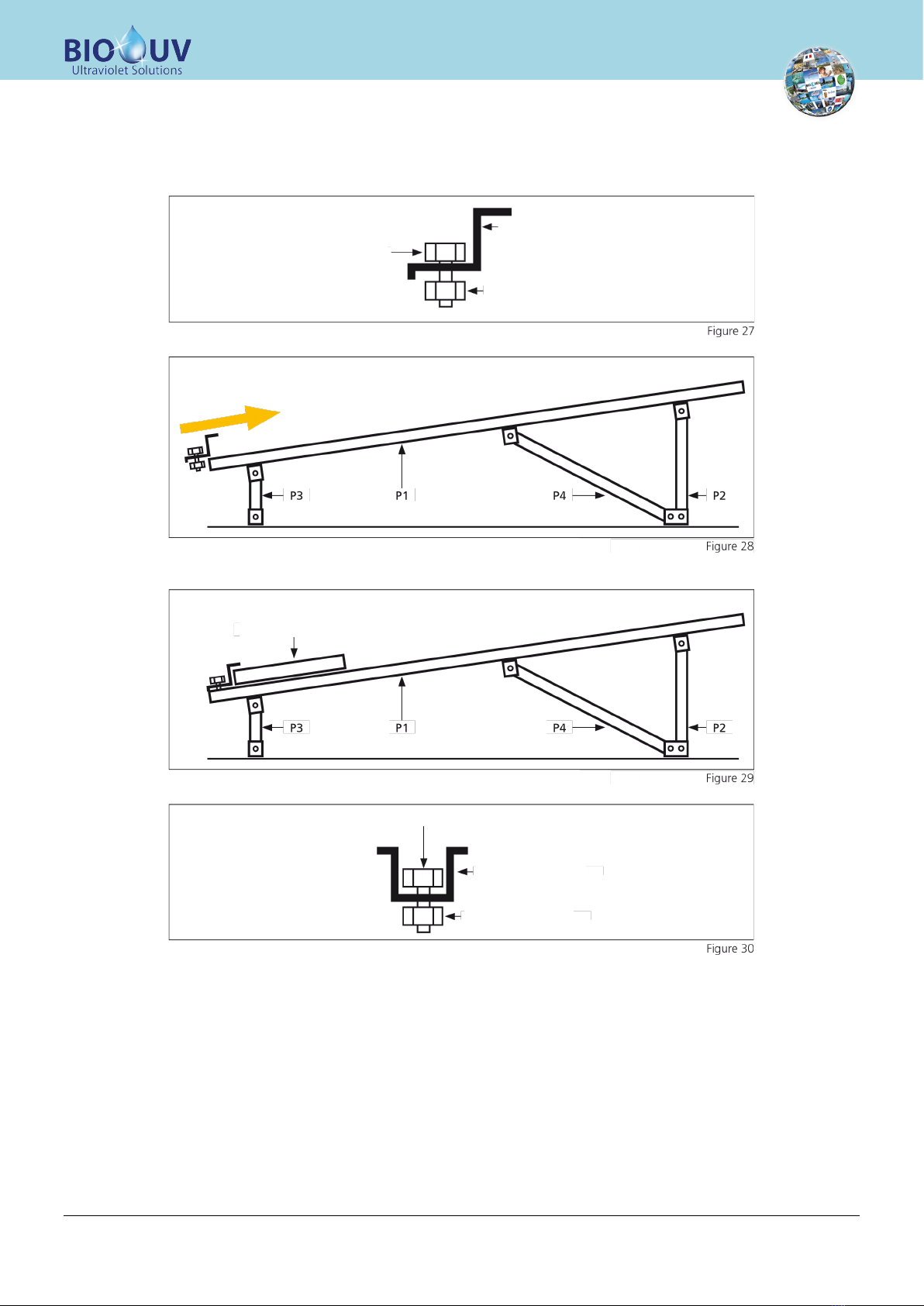

b-2.11.

Fitting the safety cables

For this step, you need four shackles, four core lugs, eight cable clamps, two turnbuckles and steel cable.

•Check the length between the eye nuts (diagonally), (see figure 25 - red lines)

•Assemble the wiring as shown in Figure 26, and make sure that they are the right length.

•Attach both cables as shown in figure 25 (red dashed lines) and tighten the cables using the tensioners

Rear view

Core terminal

lug

Core terminal

lug

Cable clamp Cable clamp

Shackles Shackles TensionerSteel cable

BIOSUN-340_(Anglais) - DOC012466 - Ind. B03 - 21/06/2017 Copyright BIO-UV

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 20

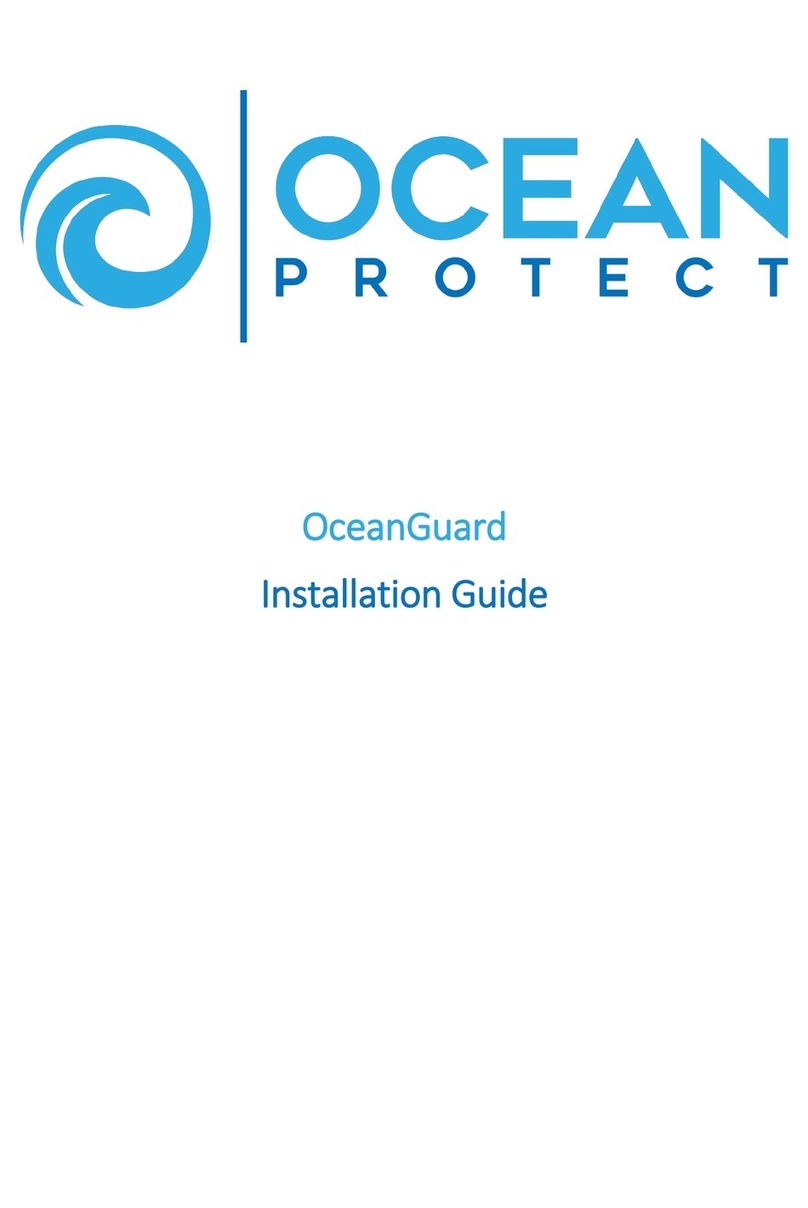

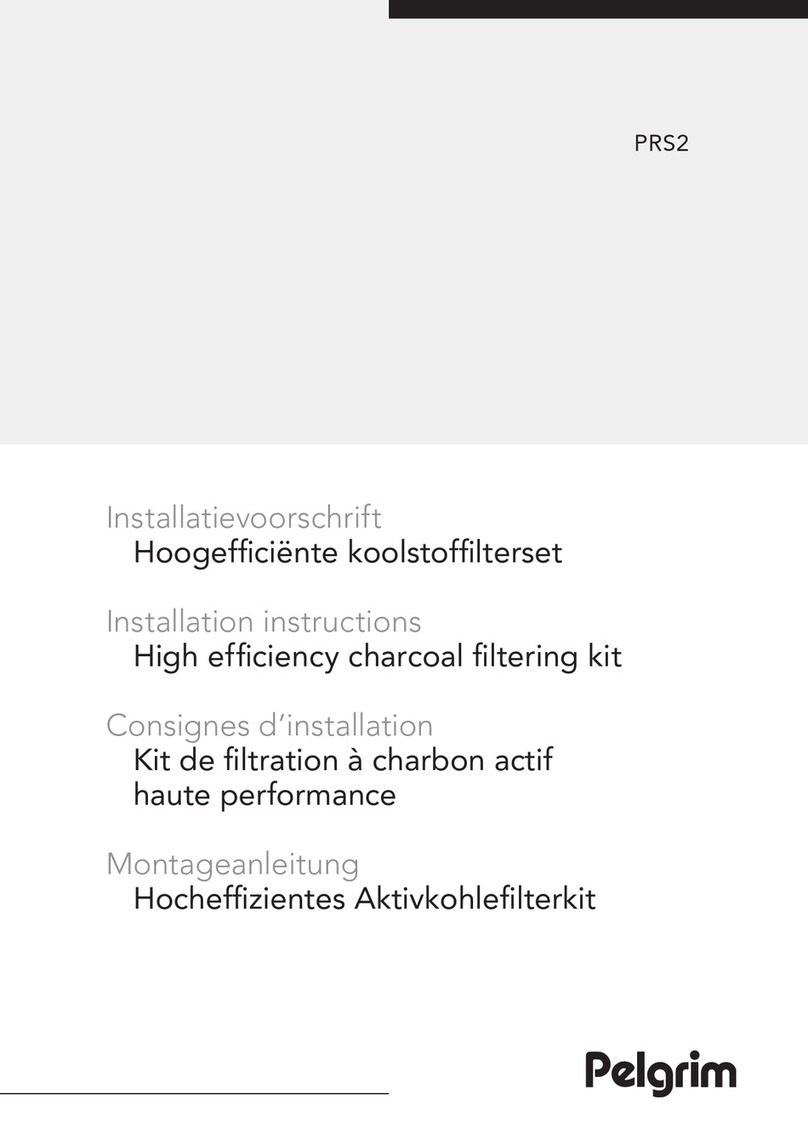

b-2.12.

Fitting the photovoltaic modules

For this step, you will need fasteners for T and L type modules. Make sure that you have screws and nuts - long screws for

attaching T modules and short screws for attaching L modules.

•Prepare two L fasteners as shown in figure 27.

•Screw the L fasteners into each of the two P1 type formed sections as shown in figure 28.

•Fit the photovoltaic module to the two P1 type formed sections and tighten the L attaching screws (see

figure 29)

•Prepare two T fasteners (see figure 30)

Short screw

L module attachment

Nut

Solar panel

T module fastener

Long screw

Nut

Table of contents

Other BIO UV Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Ocean Protect

Ocean Protect OceanGuard installation guide

Weller

Weller FT LASERLINE Series Translation of the original instructions

Pelgrim

Pelgrim PRS2 installation instructions

Premier Tech Aqua

Premier Tech Aqua Rewatec Fl-1 Installation and operating instructions

Insignia

Insignia NS-APFL2 Quick setup guide

SuperFish

SuperFish Deco-Filter Amphora user manual

Aquadistri

Aquadistri SuperFish Aqua Pro Feeder quick start guide

IBC Water

IBC Water AFB16-180 Installation & operating instructions

ProSystems

ProSystems 38247 owner's manual

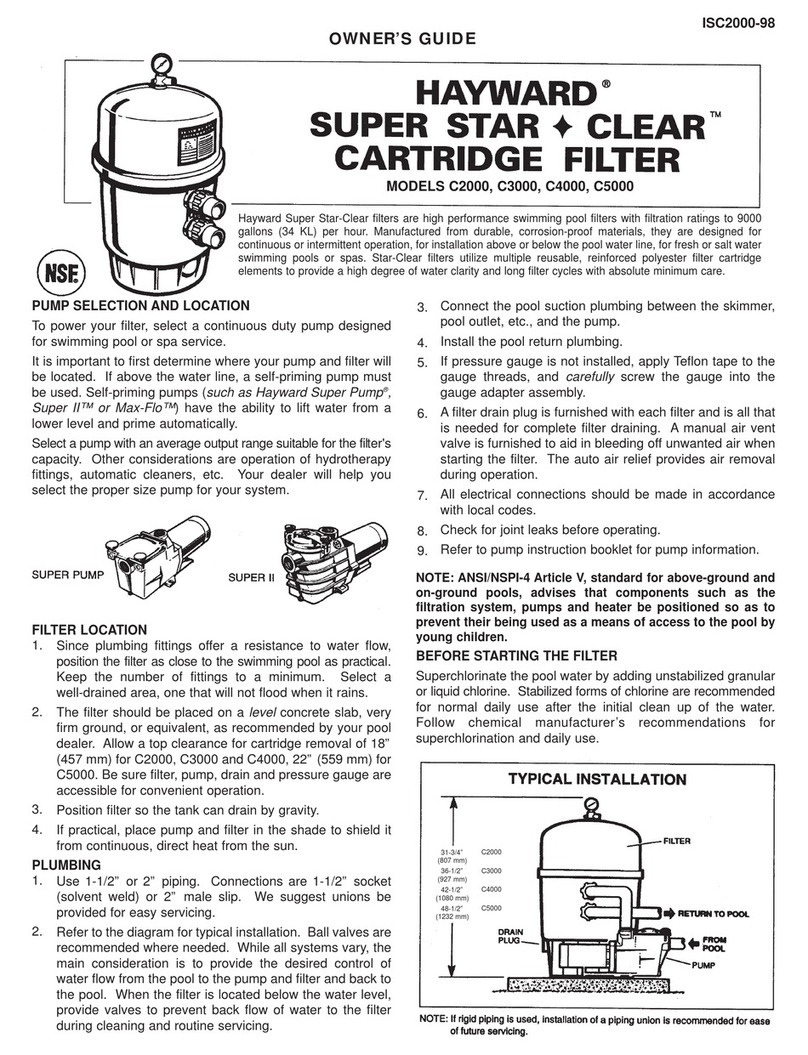

Hayward

Hayward Super Star Clear C2000 owner's guide

Aquacal

Aquacal ST-220 owner's manual

Spasciani

Spasciani 100 Series quick start guide