UV_Home_(anglais) - DOC012472 - Ind. O03 - 27/04/2017 Copyright BIO-UV

Marque, Modèles et Brevets déposés - Produits exclusifs

Page 2

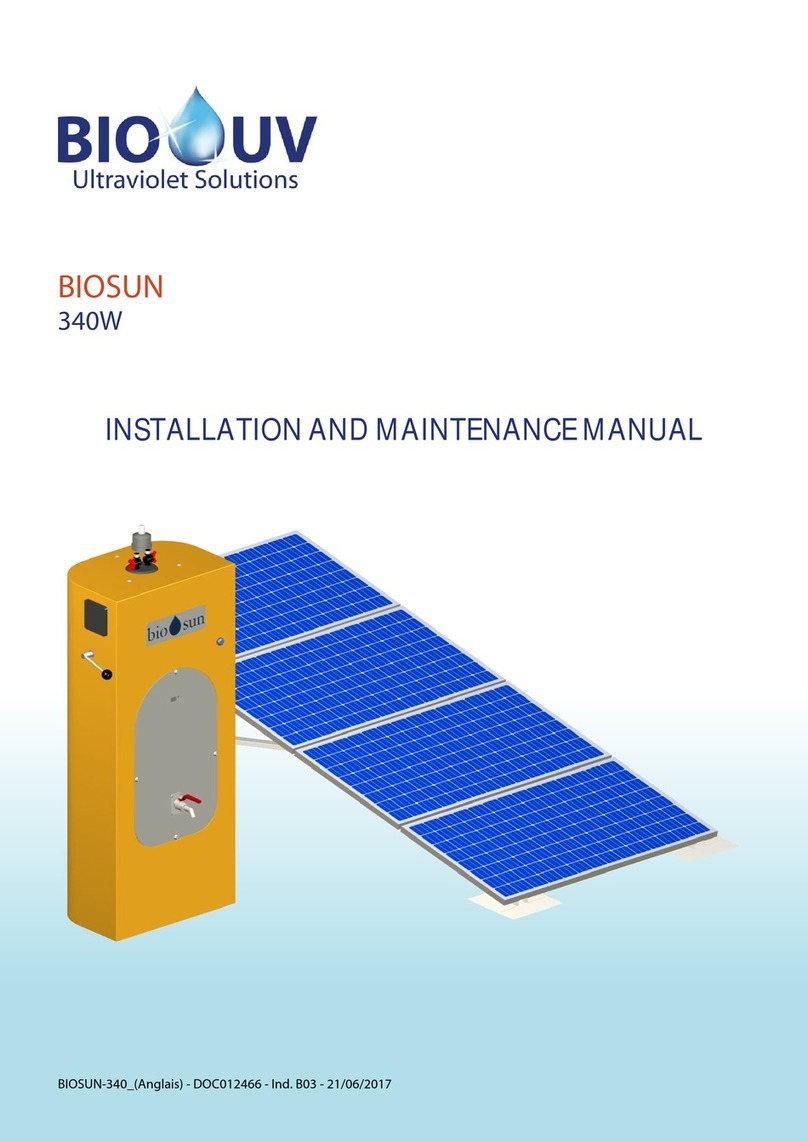

We thank you for choosing a BIO-UV reactor.

Our equipment has been designed to give you reliable and safe operation for many years to come.

According to the decree of the Health Ministry of the August 21st of 2008, concerning the case of rainwater collected on

roofs treatment, this water can not be used for human consumption.

The BIO-UV reactors have been designed for speed and ease of installation.

Their design also makes them easy to maintain.

Read these instructions carefully in order to optimize the operation of your reactor.

TABLE OF CONTENTS :

pages

A. Technical characteristics.................................................................................................................................................3

B. SafetyWarnings...............................................................................................................................................................4

C. Installation guide.............................................................................................................................................................5

1. Foreword ........................................................................................................................................................................................................................5

2. Usage environment....................................................................................................................................................................................................5

3. Instructions for reactor installation ......................................................................................................................................................................5

4. Instructions for electrical connections................................................................................................................................................................6

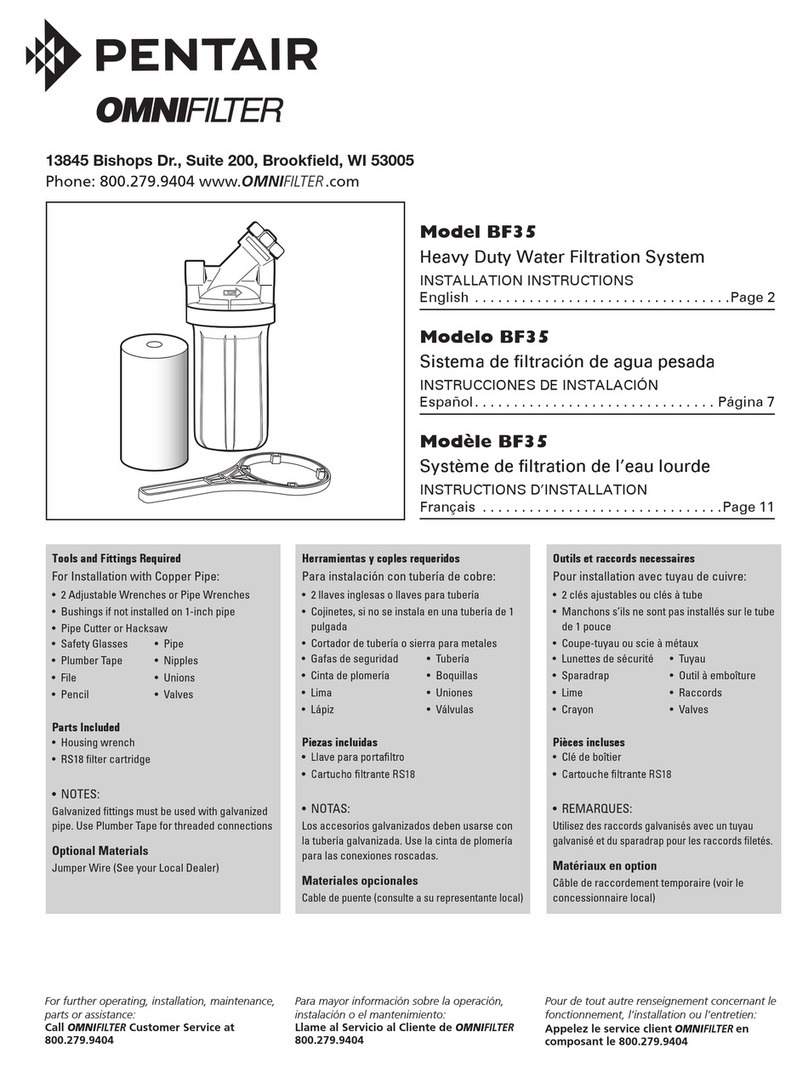

5. Filtration kit options ...................................................................................................................................................................................................7

a.) Mounting of the 2 filters kit for HOME 2 and HOME 3...........................................................................................................................7

b.) Mounting of the 3 filters kit for HOME 2 and HOME 3...........................................................................................................................8

c.) Installation procedure ........................................................................................................................................................................................9

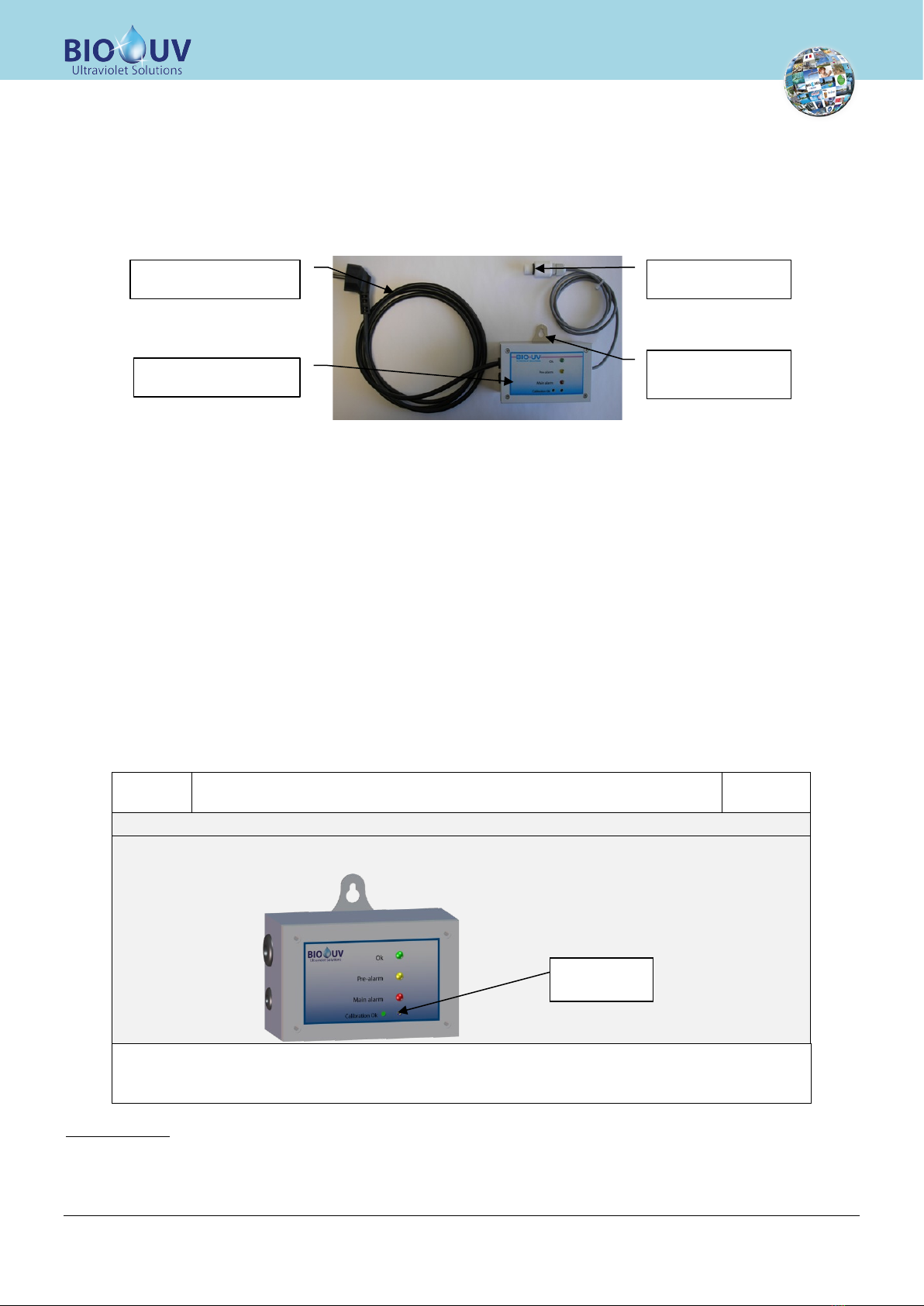

6. Option UV sensor and PRO3 monitor...............................................................................................................................................................10

D. Starting up.................................................................................................................................................................... 11

E. Procedure to replace the lamp, the quartz sleeve and the seal................................................................................. 12

F. Maintenance file............................................................................................................................................................ 14

G. Electrical description.................................................................................................................................................... 15

1. Electrical unit..............................................................................................................................................................................................................15

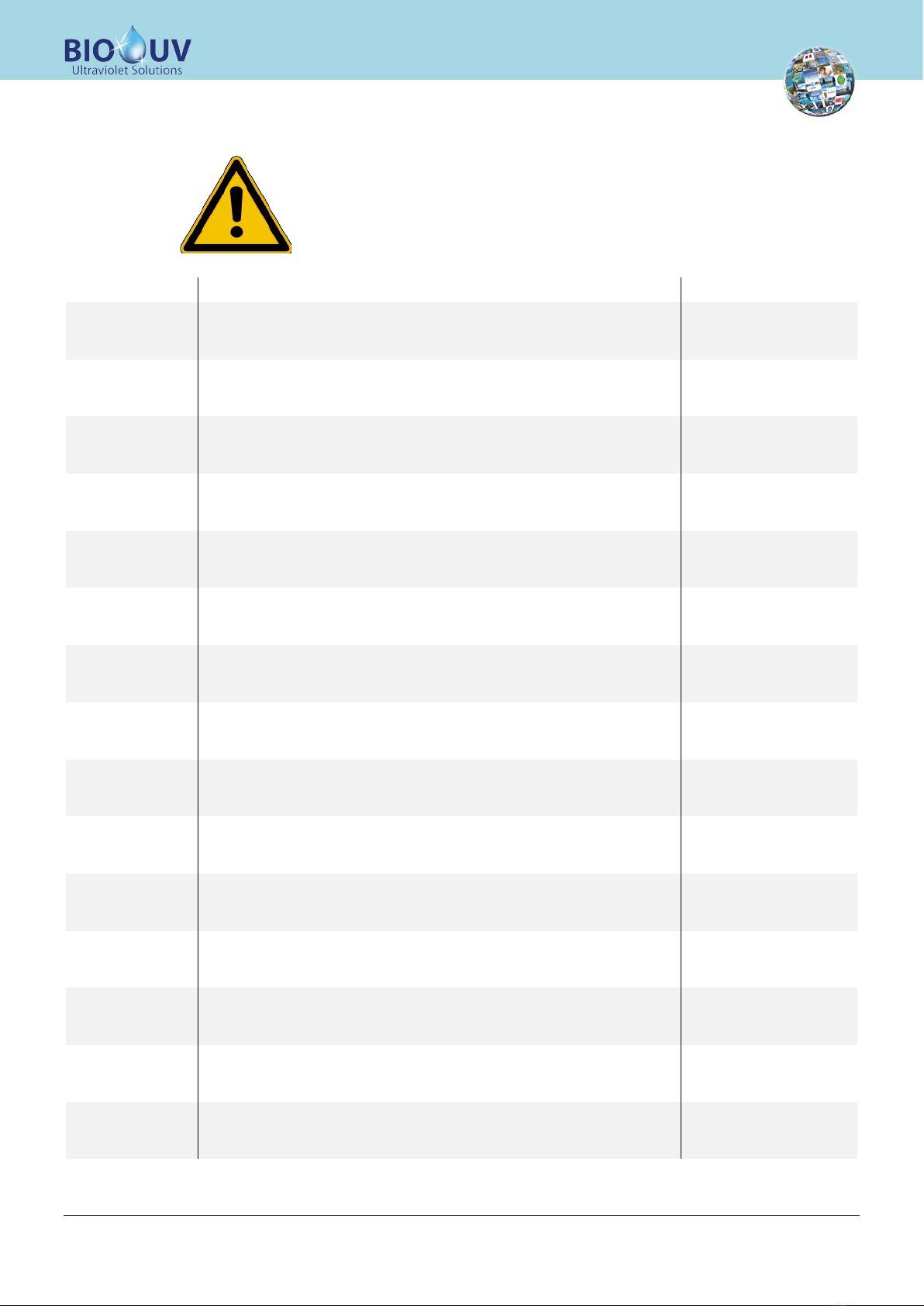

2. Wiring of an alarm contact on PRO3 monitor option ................................................................................................................................16

H. Blown up view with UV sensor option ........................................................................................................................ 17

I. Dimensions..................................................................................................................................................................... 18

J. Warranties...................................................................................................................................................................... 19