Bioclimatic VIROXX E150++ User manual

air purifier

VIROXX E150++

instruction manual

version: 1.4

state: January 2019

2

manufacture and sales:

bioclimatic GmbH

Im Niedernfeld 4

31542 Bad Nenndorf

Germany

phone: ++49 - 57 23 - 94 40 - 0

fax: ++49 - 57 23 - 94 40 - 30

e-mail: info@bioclimatic.de

URL: www.bioclimatic.de

In case of any questions according to operation or maintenance of the

VIROXX E150++ please indicate the following information’s:

–unit model

–unit number.

You will find the unit model and number on the type designation plate at the

frontside of the unit.

©Copyright 01/2019.

Reproduction and copy, also in extracts, are only permitted for internal use.

The manufacturer of the VIROXX E150++ reserves all further rights.

Version 1.4 (January 2019)

3

Index

1device description of the VIROXX E150++ 5

1.1 purpose of use 5

2safety instructions 7

3Technical Data 8

4Safety instructions 9

5operation 10

5.1 switch-on and off 10

5.2 the control panel 10

5.3 decommissioning of VIROXX E150++ 11

5.4 recommissioning of VIROXX E150++ 11

6function control 12

7maintenance 13

7.1 cleaning and maintenance 13

7.1.1 maintenance schedule 13

7.1.2 cleaning 14

7.2 opening of the VIROXX E150++ 14

7.3 control and exchange of the catalyst 15

7.4 control and exchange of the ionization tubes 16

7.5 control and exchange of the UV-lamp 17

7.6 control and exchange of the prefilter 18

7.7 exchange of the fuse 18

8malfunctions and trouble shooting 19

8.1 list of malfunctions 19

8.2 disposal 19

9scope of delivery 20

9.1 standard scope of delivery 20

9.2 spare parts 20

10 technical specifications 21

11 declaration of the manufacturer 21

12 guarantee bond 22

13 EC Declaration of Conformity 23

4

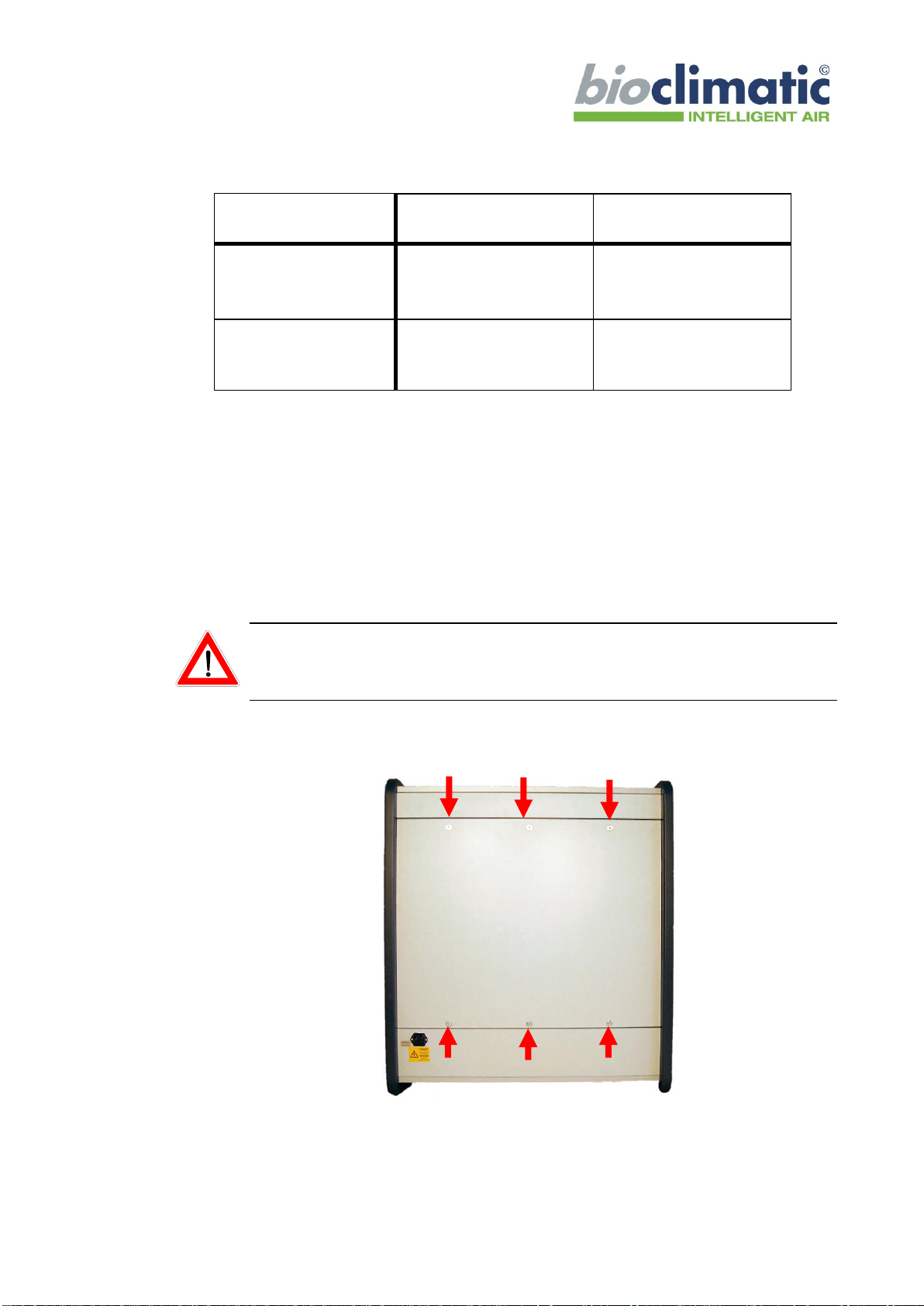

overview

front side

back side

1 castor

2 air inlet

5 power supply

and fuse

3 control panel

4 air outlet

6 maintenance

door

5

control panel

1device description of the VIROXX E150++

1.1 purpose of use

The VIROXX E150++ air purifier inactivates germs like viruses, bacte-

ria’s, moulds and yeasts and abates airborne pollutants and particles as well

as odours of the indoor air.

The combination of prefiltration, photochemical disinfection, catalytical

oxidation, high performance micro filtration and bipolar ionization purifies

the indoor air.

The air purification level of the VIROXX E150++ is adjustable to the real

air indoor contamination level. By use of an Air Quality Detector The mobile

and self-contained VIROXX E150++ can be installed in any kind of places.

8 power switch

7 fan regulator

9 operation

time meter

10 ionization

regulator

11 air quality

level

6

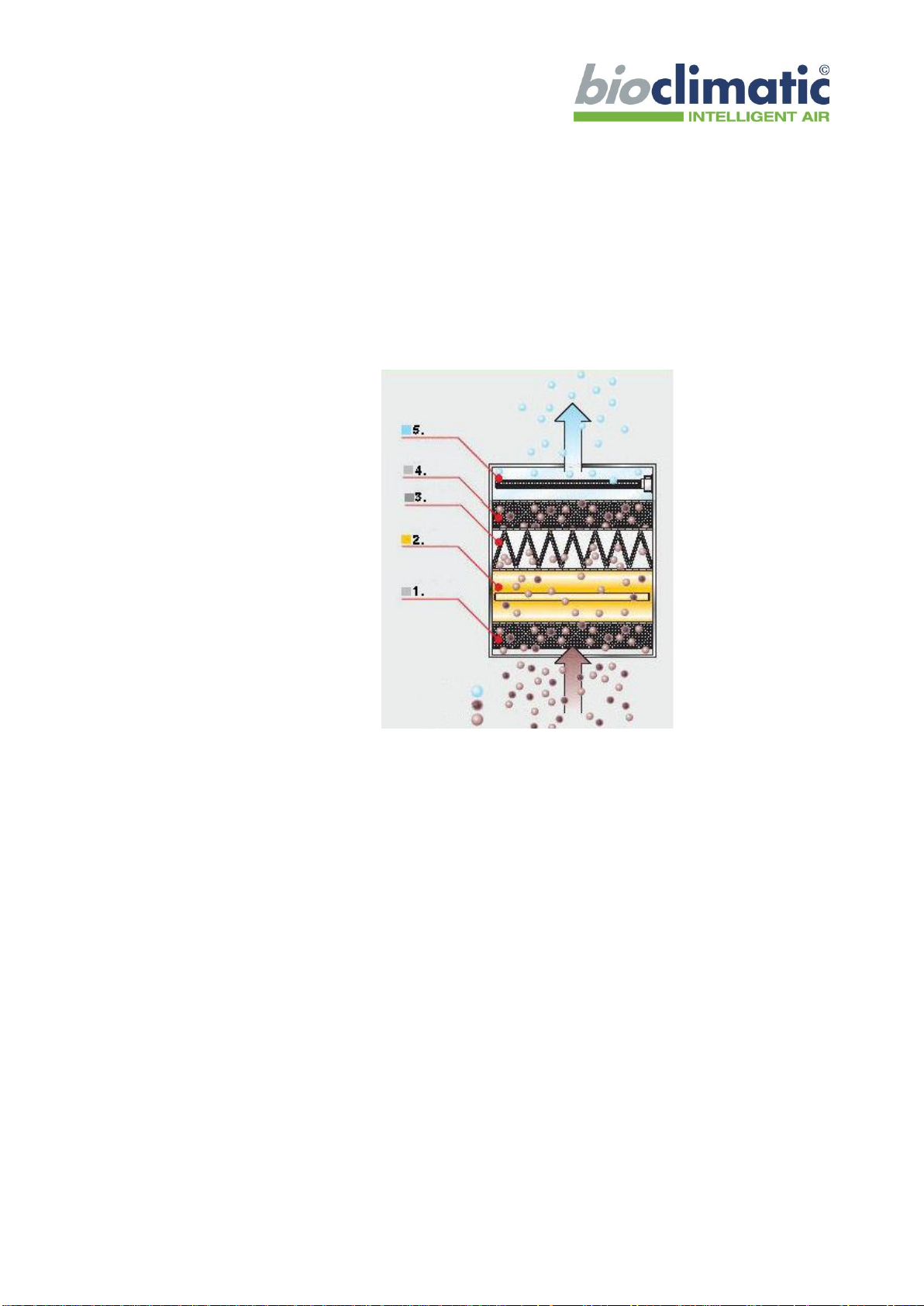

1.2 functional description

These chapter describes the main technical basics of the working function of

VIROXX E150++.

The patented VIROXX-Technology guarantees that, dangerous airborne

contaminants and microorganisms are inactivated and particles are abated

effectively.

pic. 1: VIROXX working function

1. step: prefiltration

A fine filter, installed at the entrance of the system (2), removes dust

particles from the incoming air.

2. step: photochemical disinfection

The combination of photo-oxidation and photo-catalysis allows the

simultaneous inactivation of micro-organisms and viruses and the

degradation of odour molecules. For achieving high abatement effi-

ciencies, lamps emitting powerful short UVC waves and photo-active

catalysts have been used.

3. step: catalytical oxidation

On the downstream side of the photo-chemical disinfection step, an

extra catalyst is installed in order to improve the abatement efficien-

cy.

7

4. step: high performance micro filter

The high performance micro filter guarantees the effective abate-

ment of airborne particles.

5. step: bipolar ionisation

This last air treatment step charges the disinfected air with healthy

air ions before its release in the ambiance. High concentrations of air

ions are not only healthy for humans but also abate micro-organisms

and viruses in the air and on surfaces and neutralize unpleasant

odours.

sensor supported regulation

The integrated Air Quality Detector adjusts the intensity of air purifica-

tion automatically to the real air contamination level.

2safety instructions

For your own safety and regarding please note the following advices:

-Please study this instruction manual carefully. It’s a part of the

VIROXX E150++ and must be available every time.

-Use the VIROXX E150++ only for the described applications.

-The supply voltage of the unit and on site must correspond to each

other.

-The VIROXX E150++ sucks ambient air during operation. There-

fore do not cover the unit during operation.

-Please don’t use VIROXX E150++ in damp locations or outdoor.

-Please use the VIROXX E150++ only with products recommend in

this manual. Bioclimatic can not guarantee a malfunction free opera-

tion of the unit by using other products with the unit.

-The claims of guarantee and liability expire by using not recommend

or original products/spare parts with the

VIROXX E150++.

Do not throw or push the unit and don’t positioning it close to heat sources

or isolation directly.

bioclimatic assumes no guarantee for damage, which results from neglect of

this manual or from not intended use of the unit.

8

3Technical Data

Room volume

ca. 150 m³

Dimensions

ca. 710/335/815 mm (W x H x D)

weight

ca. 45 kg

Ambient temperature

operation

storage

+5 to + 40 °C

0 to + 50 °C

relative humidity

max. 85 %

Power supply

230 V AC / 50Hz

Power consumption (max.)

ca. 240 W

Air flow volume (max.)

ca. 250 m³/h

UV-lamp

1 x 430/A (ozone free)

Ionisation tube

2 x IRF

fuse

1.6 A (slow blow)

Radio shielding

EMC

DIN EN 55011

EN/IEC 61000-4-3

Degree of Protection

IP44*

* only electrical components with installed tube socket seal

Tab.

1:

Technical Data VIROXX E150++

9

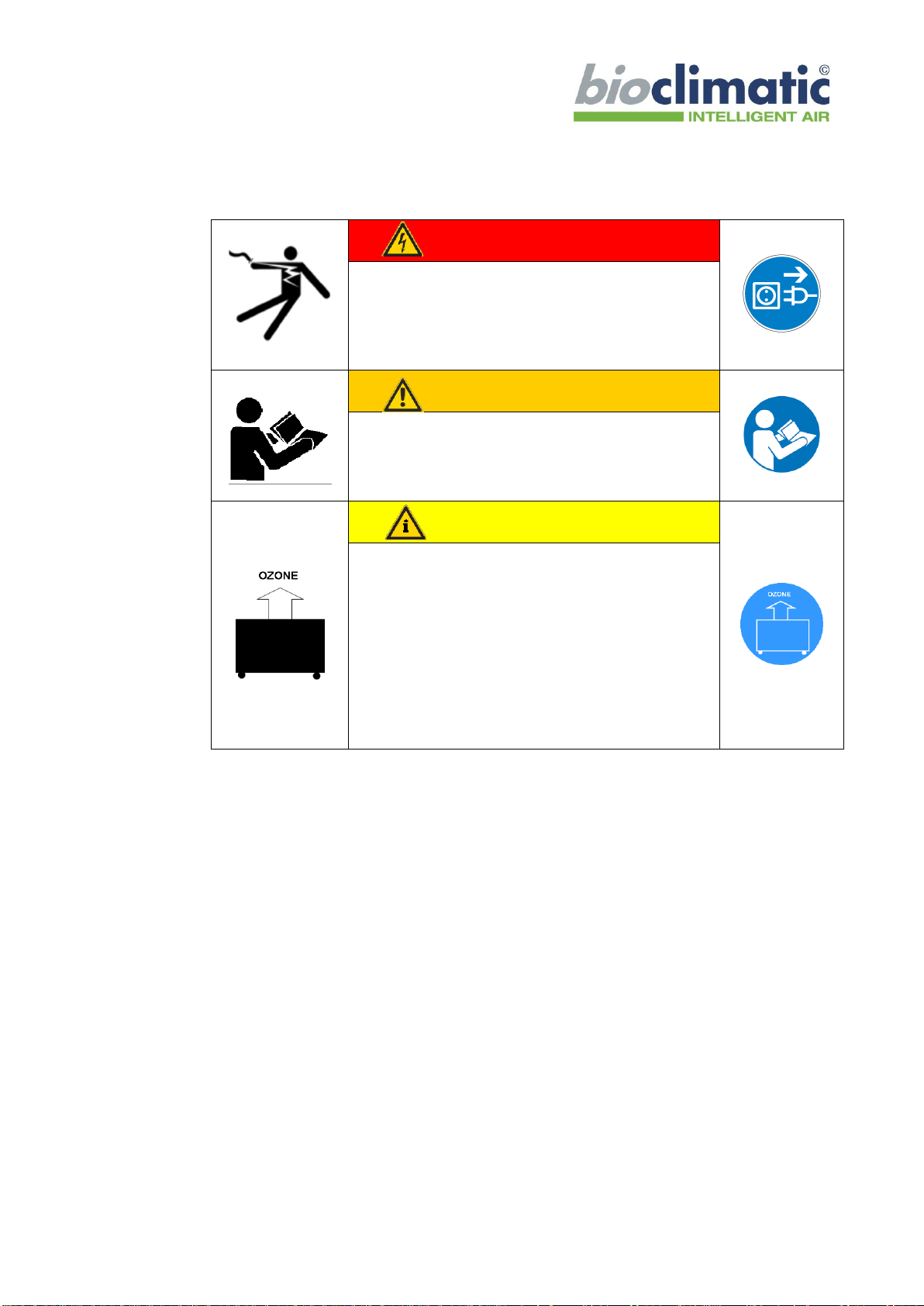

4Safety instructions

Caution, high voltage!

Electrical danger!

Unplug the mains plug before working on the

unit or moving it. Respectively all poles of the

the device must be disconnected from the

mains!

Warning

Only qualified staff may work on the device!

All works concerning mounting, start-up and

maintenance must be carried out by qualified

staff only.

Caution

Take the ozone concentration in the room into

account!

Take the dimensioning specifications into

account, as the device produces ozone during

operation.

If the dimensioning table is taken into account

and the device is set in accordance with the

User Manual, the ozone produced will not

exceed the maximum admissible concentration.

10

5operation

5.1 switch-on and off

The operation panel (3) of the VIROXX E150++ is located on the side of

the unit.

In order to put the VIROXX E150++ into operation press the power

switch (8).

-The orange power control lamp (8) shines continuously.

-The unit is now in operation and works continuously.

-The flow rate of the VIROXX E150++ could be adjusted in 4 steps

by use of the fan regulator (7).

-The output of activated oxygen could be adjusted in 8 steps by use of

the ionization regulator (10).

5.2 the control panel

pic. 2: control panel of the VIROXX E150++

power switch (8):

-by use of the power switch the unit gets in operation

-the red power control lamp (8) shines continuously.

-in case of a malfunction the power control lamp don’t shines (see list

of malfunctions 6.1). Please contact your specialist dealer.

8 power switch

7 fan regulator

9 operation

time meter

10 ionization

regulator

11 air quality

level

11

fan regulator (7):

-The flow rate of the unit could be adjusted in 4 steps by use of the fan

regulator (7).

ionization regulator (10):

-The output of activated oxygen could be adjusted in 8 steps by use of

the ionization regulator (10). The sensor will regulate the ionisation

from step “1” up to the chosen step.

-This is an push / pull switch! If it is pulled out, the sensor is not in

function. The ionisation works always according to the chosen step.

operation time meter (9):

For control of the service intervals; display in hours and minutes,

the maximum display is 99,999.99 h.

Air Quality Level(11):

For indication of air quality level in 9 Steps.

5.3 decommissioning of VIROXX E150++

If you don’t want to use the unit for longer time, cover the unit to protect it

for contamination with dust and store it at a dry place.

5.4 recommissioning of VIROXX E150++

Check if the air inlet and outlet is free of impurities. Please clean the unit

from dust agglomerations with a brush.

12

6function control

The maintenance and function control jobs need to be done by

qualified personnel only!

4.000 hours of operation after commissioning, after every mainte-

nance and quarterly check the function of the unit.

1. Press the power switch (7) to turn on the VIROXX E150++

-The red power control lamp (7) is shining.

-The ventilator and the UV-lamp are in operation.

2. Check the flow rate of the ventilator by using the fan regulator

switch (7). Switch up to step 4, the flow rate increases.

3. Check if the characteristic crackle of the ionization tubes could be

heard at the air outlet of the unit. By increasing of the ionization in-

tensity (9) the crackle sound increases.

4. Check the display of the operation time meter (4) if it‘s count up af-

ter one minute of operation.

If the unit doesn’t work properly, please contact your specialist dealer.

13

7maintenance

7.1 cleaning and maintenance

The maintenance jobs need to be done by qualified personnel of your

specialist dealer only.

For every maintenance job pull the plug. Caution, in case the unit is not

separated from power and still switched on, there is a high

voltage charge (up to 3,0 kV) at the ionization tube.

7.1.1 maintenance schedule

service interval

maintenance descrip-

tion in chapters

function control

after the first 2.000

operation hours

then quarterly

4

control of the UV-

lamp *

after the first 2.000

operation hours

then quarterly

contact specialist dealer

exchange of the UV-

lamp *

after 8.000

operation hours or

after 1½ years

contact specialist dealer

control of the

ionization tube

after the first 2.000

operation hours

then quarterly

contact specialist dealer

exchange of the

ionization tube *

after 16.000

operation hours or

after 3 years

contact specialist dealer

control of the

prefilter *

after the first 2.000

operation hours

then quarterly

contact specialist dealer

exchange of the

prefilter

after 3 to 6 month

contact specialist dealer

control of the

catalyst *

after the first 2.000

operation hours

then quarterly

contact specialist dealer

exchange of the

catalyst

after 3 to 6 month

contact specialist dealer

14

service interval

maintenance descrip-

tion in chapters

control of the high

performance micro

filter *

after the first 2.000

operation hours

then quarterly

contact specialist dealer

exchange of the high

performance micro

filter

after 3 to 6 months

contact specialist dealer

* Spare parts could be purchased and disposed by bioclimatic respec-

tively.

7.1.2 cleaning

Clean the unit from time to time with a damp cloth.

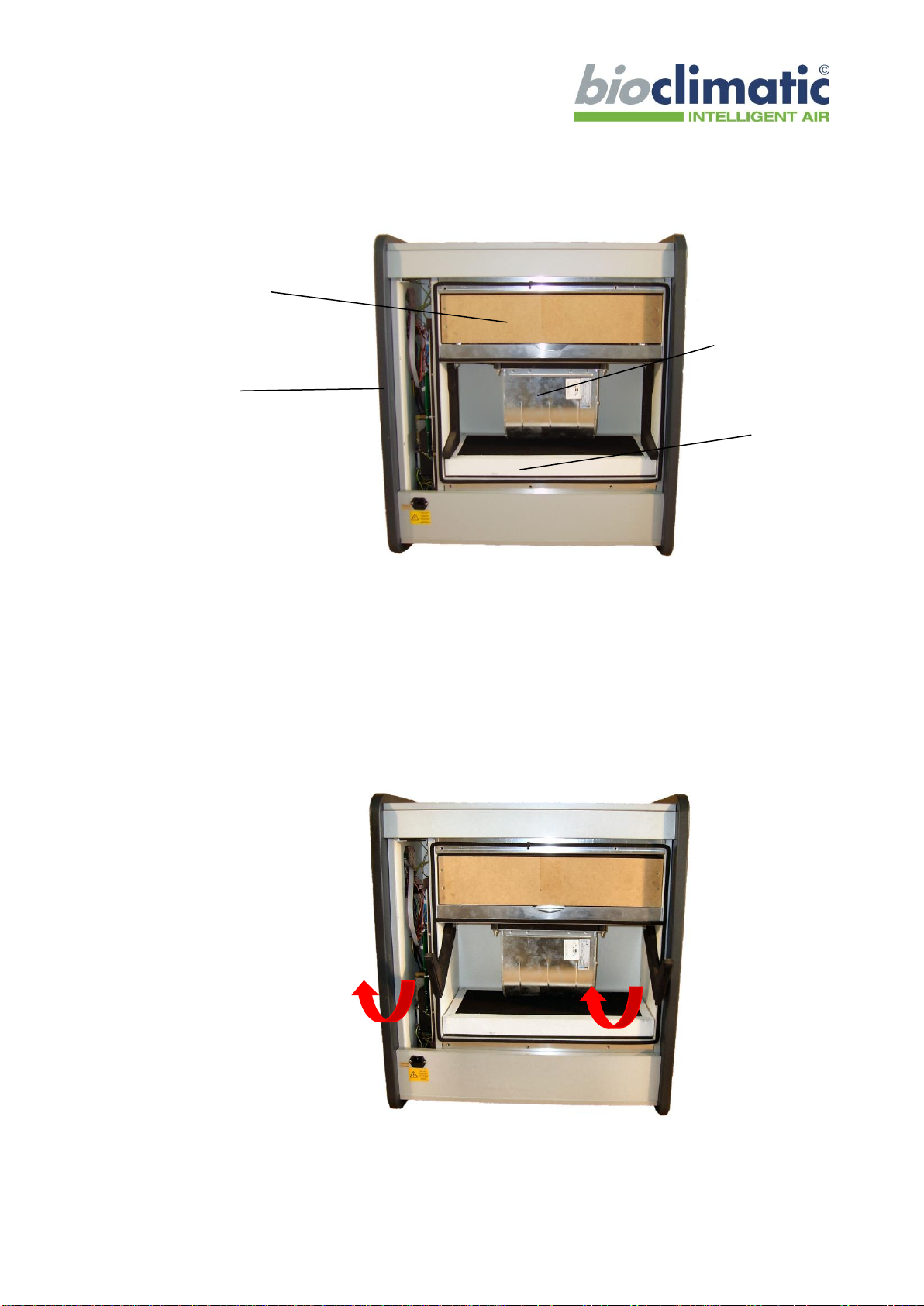

7.2 opening of the VIROXX E150++

For every maintenance job pull the plug. Caution, in case the unit is not

separated from power and still switched on, there is a high voltage

charge (up to 3 kV) at the ionization tubes.

To open VIROXX E150++ for maintenance jobs remove the six screws at

the back side of the unit (see pic. 3.2.1).

pic. 3.2.1

Afterwards remove the maintenance door carefully.

Now all compounds of the VIROXX E150++ are reachable.

15

pic. 3.2.2

7.3 control and exchange of the catalyst

To check if the catalyst is damaged or contaminated with impurities please

open the unit (see chapter).

Pull the two levers which fix the catalyst and the high efficiency micro filter

(see. pic. 3.5.1).

pic. 3.2.3

12 micro filter

13 electronic

14 fan

15 catalyst

16

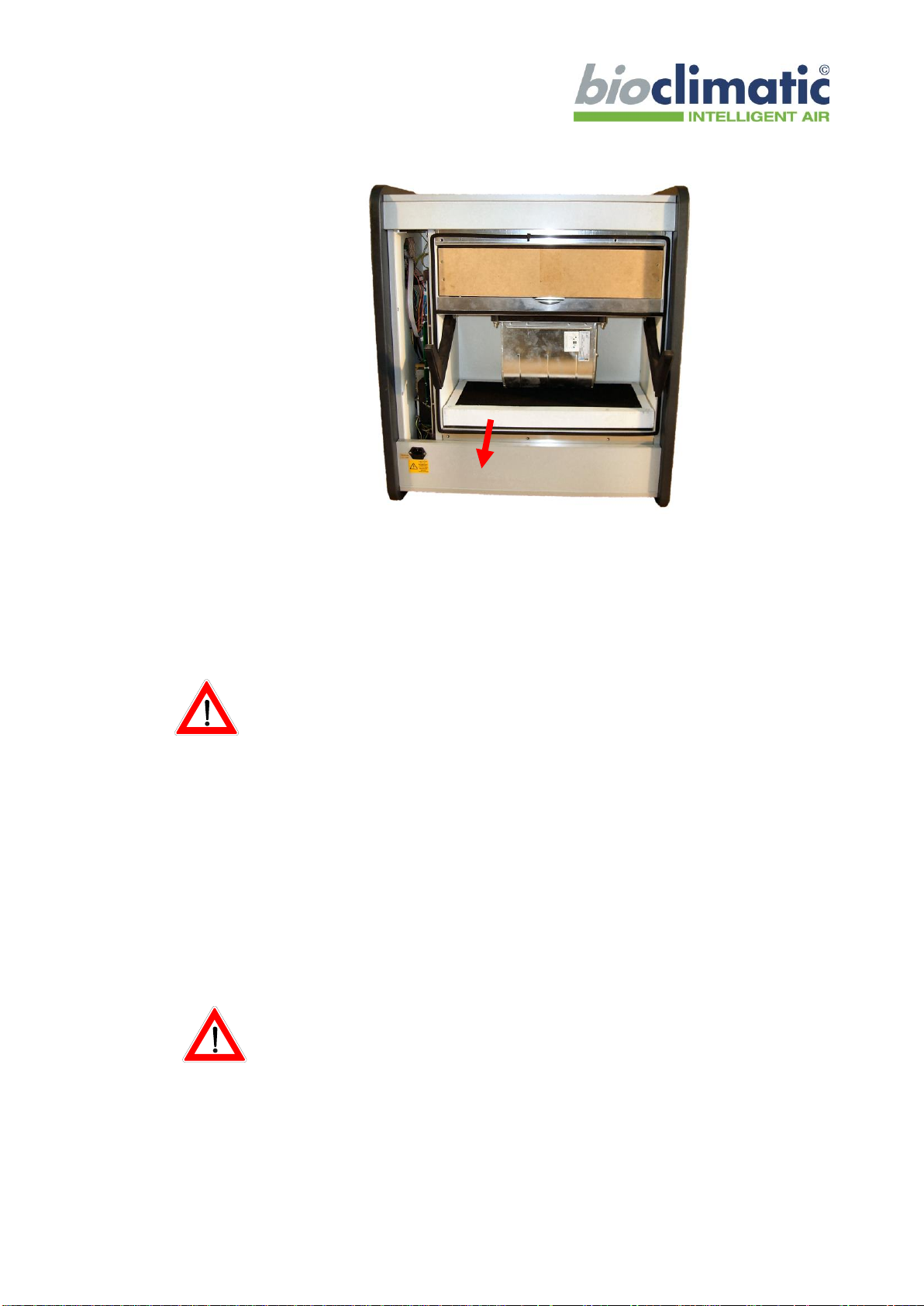

pic. 3.2.4

Now the catalyst can be pulled out (see pic. 3.2.4).

In case of the catalyst is polluted with impurities exchange the catalyst.

By insertion of the catalyst, please take care, that the seal at the rear

side of the catalyst would not be damaged.

Afterwards assemble the unit in reverse order.

7.4 control and exchange of the ionization tubes

Switch on the VIROXX E150++ and adjust with the ionisation regulator

(4) to ionisation level one.

Check if the characteristic crackle could be heard at the air outlet (1).

By increasing of the ionization intensity with the ionization regulator (4)

(the switch has to be pulled out!) the crackle must increase with a delay of

approx. 5 seconds.

Pull the plug.

Caution, in case the unit is not separated from power and still

switched on, there is a high voltage charge (up to 3 kV) at the

tube socket!!!

Open the air outlet.

Check if the ionization tubes are contaminated or damaged.

17

For the cleaning of the ionization tubes, take them from the socket by

turning anti clockwise. During this procedure you need to lift the contact

spring.

For cleaning of the ionization tubes please follow the next steps:

•Remove outer mesh from the tube carefully. If the mesh sticks to the

tube, take them into both hands and move hands in opposite direc-

tion. Once loose, strip the mesh.

•Clean the mesh with antifat detergent, so that the possible fat layer

can be removed completely. Hold the tube into rising warm water for

cleaning.

•Dry well, so no humidity remains in the mash or on the tube.

•Fix again the mesh in a way that the top end of the inner and

outer mesh matches.

•Fix the tubes tight to the socket.

7.5 control and exchange of the UV-lamp

For the function control of the UV-lamp open the VIROXX E150++ at the

backside or remove the grid of the air inlet.

•In a distance of approx. 1.5 –2 m switch on the unit for a short

moment, to check if the UV-lamp is working.

•Pull the plug of the VIROXX E150++ afterwards.

•Remove the UV-lamp

•Check if the UV-lamps are contaminated with impurities.

By dismounting and mounting, as well as by cleaning of the UV-lamps

please touch them only at the ceramics at the end of the UV-lamps (Don’t

touch the glass, also few impurities can decrease the life span!).

18

To clean the UV-lamp use a damp cloth and dry them afterwards sufficient.

Afterwards assemble the UV-lamp in reverse order.

7.6 control and exchange of the prefilter

The prefilter is integrated into the air inlet. Then check the prefilter of

impurities or damages removes the grid of the air inlet.

7.7 exchange of the fuse

You will find the fuse of the VIROXX E150++ in the power supply at the

backside of the unit. The fuse holder can only be opened if the power cord is

removed!

For the exchange of the fuse see the following steps:

1. Disconnect the power cord

2. Open the fuse holder with a screwdriver or similar

3. Change the fuse

4. Push the fuse holder back

5. Connect the power cord

19

8malfunctions and trouble shooting

8.1 list of malfunctions

malfunction

reason

trouble shooting

no ventilator sound, red

power control lamp

turned off

malfunction of fuse

control / change the fuse

no supply voltage

connect the unit to the

supply voltage

line cord damaged

contact specialist dealer

no or very low flow rate

though highest

ventilator level is

switched on

- malfunction of the

ventilator

- micro filter blocked

- catalyst blocked

- prefilter blocked

contact specialist dealer

no or very low abate-

ment of particles

high performance

micro filter blocked or

damaged

contact specialist dealer

no characteristic

crackle of the ioniza-

tion tube could be

heard at the air outlet

malfunction of the

ionization tube

contact specialist dealer

no supply voltage

connect the unit to the

supply voltage

malfunction of fuse

control / change the fuse

8.2 disposal

For the appropriated disposal of the VIROXX E150++ please contact

your specialist dealer of bioclimatic.

20

9scope of delivery

9.1 standard scope of delivery

2 x ionization tube type IRF

1 x UV-lamp type 430/A

1 x catalyst

1 x prefilter

1 x high performance micro filter

1 x instruction manual

9.2 spare parts

The following spare parts could be sourced by bioclimatic.

parts.: spare part name

IRF- ionization tube

UV-lamp

prefilter

high performance micro filter

catalyst

Table of contents

Other Bioclimatic Air Cleaner manuals

Popular Air Cleaner manuals by other brands

Hamilton Beach

Hamilton Beach 4160 Use & care guide

NANO HUB

NANO HUB ESPERO 100 LIFT User and maintenance manual

Fellowes

Fellowes AeraMax Pro AM4 PC quick start guide

lakeair

lakeair CM2-RC2 120 Volt Operating and service manual

Olimpia splendid

Olimpia splendid AURA ABSOLUTE Instructions for use and maintenance

AllerAir

AllerAir Air Filter 5000 EXEC brochure