Biosan FTA-1 User manual

Edition 1.-4.03 3

Contents

1. About this edition of user instructions.......................................................................3

2. Safety precautions ...................................................................................................4

3. General information..................................................................................................6

4. Getting started..........................................................................................................7

5. Operation ...............................................................................................................10

6. Specifications.........................................................................................................11

7. Ordering information ..............................................................................................12

8. Chemical compatibility............................................................................................13

9. Care and maintenance...........................................................................................16

10. Storage and transportation.....................................................................................17

11. Warranty.................................................................................................................18

12. EU Declaration of conformity..................................................................................19

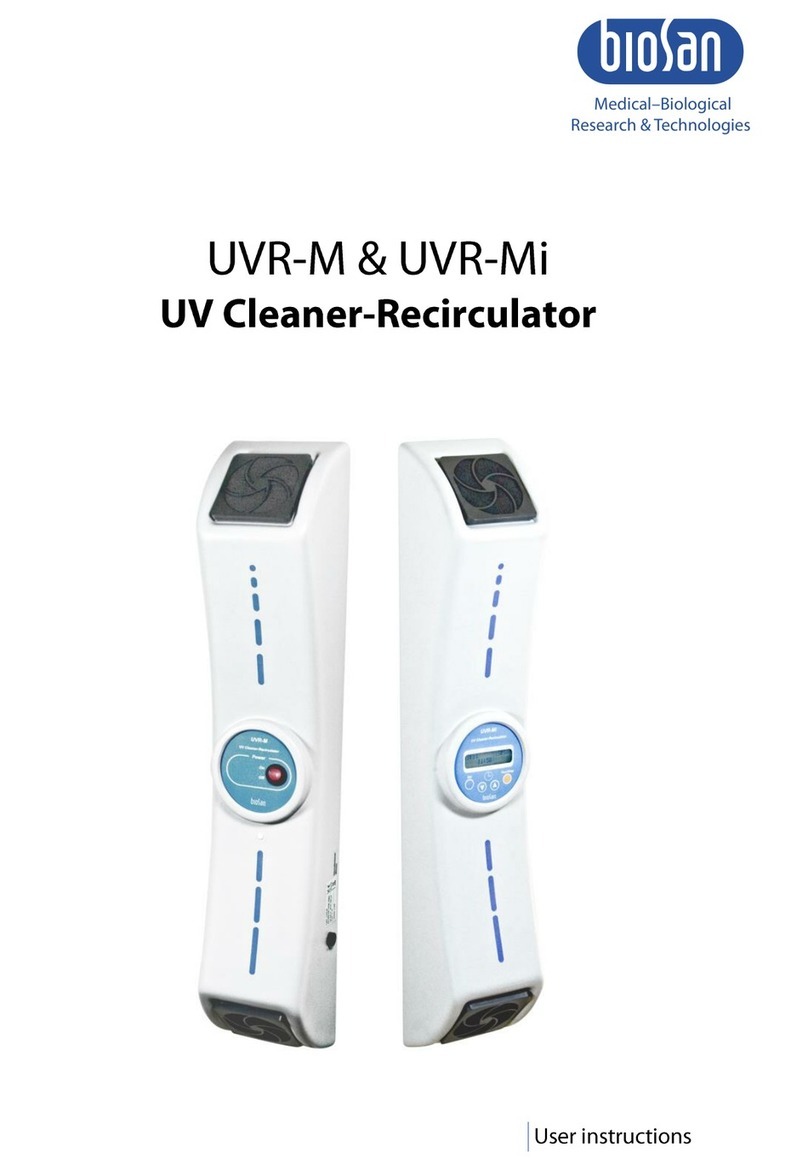

1. About this edition of user instructions

1.1 The current edition of the user instructions applies to the following models:

Model and name

Version

FTA-1, aspirator with trap flask

V.4AW

FTA-2i, aspirator with trap flask

V.1A01

1.2 Edition 1.-4.03 –July of 2022

4 Edition 1.-4.03

2. Safety precautions

Caution!

Make sure you have fully read and understood the present Manual before

using the equipment. Please pay special attention to sections marked by

this symbol.

2.1 Icons used on the unit and packaging

CE marking, manufacturer affirms conformity with European health, safety, and

environmental protection standards, see 12.1

WEEE directive marking, see 12.1

Polarity of the power connector

Equipment uses direct current

Pump exhaust on FTA-2i, connect to the means of air filtration, see 8.1

2.2 General safety

•The protection provided can be ineffective if the operation of the appliance does not

comply with the manufacturer's requirements.

•Save the unit from shocks and falling.

•Store and transport the unit as described in section 10. Storage and transportation

on page 17.

•Use only original parts and accessories, provided by manufacturer for this product.

•Before using any cleaning or decontamination methods except those recommended

by the manufacturer, check with the manufacturer that the proposed method will not

damage the equipment.

•Do not make modifications in design of the unit.

2.3 Electrical safety

•Connect only to the mains with voltage listed on the serial number label.

•Use only the external power supply provided with this product.

•Ensure that the power plug is easily accessible during use.

•Disconnect the unit from the mains before moving.

•If liquid penetrates into the unit, disconnect it from the mains and have it checked by

a repair and maintenance technician.

•Do not operate the unit in premises where condensation can form. Operating condi-

tions of the unit are defined in section 6. Specifications on page 11.

Edition 1.-4.03 5

2.4 During operation

•Do not operate the unit in environments with aggressive or explosive chemical mix-

tures. Please contact manufacturer for possible operation of the unit in specific at-

mospheres.

•Do not operate the unit if it is faulty or has been installed incorrectly.

•Do not use outside laboratory rooms.

•Do not use the unit for aggressive organic compounds, chlorinated solvents and

strong conjugated acids, see section 8. Chemical compatibility on page 14.

2.5 Biological safety

•The user is responsible to carry out appropriate decontamination if hazardous mate-

rial spills on or penetrates into the equipment.

•Empty the trapping flask when the liquid level reaches maximum. Take necessary

precautions utilizing waste liquid in accordance with general laboratory standards.

6 Edition 1.-4.03

3. General information

FTA-1 & FTA-2i aspirators with trap flask have been designed for liquid removal from

micro-test tubes (e.g., for supernatant removal during DNA/RNA extraction), ELISA plates

(e.g., performing several repeated well washing cycles), cell culture flasks (cell media ex-

change and washing during cell growth) and other vessels during various laboratory tech-

niques.

Model FTA-1 has a 1 L glass trap flask and is designed to be a low-cost solution.

Aspiration is possible with a single standard 200 μL tip and the 8-tipped MA-8 adapter.

Model FTA-2i comes with a 2 L polypropylene trap flask and a liquid overflow sensor

that stops collected material from damaging the filter. Aspiration is possible with single 200

and 1000 μL tip using the MA-U adapter or with the handheld vacuum controller HAS-1 with

different attachments such as 8-channel adapter with stainless steel tips, 8-channel adapter

for 200 μL tips, single channel adapter for 200 μL tips and others.

Microbiologic suction filter eliminates risks of contamination caused by bacteria, vi-

ruses, and infected particles from samples. Such contamination can be distributed by suction

pump or central vacuum units. Microbiological suction filter is hydrophobic and has very high

contamination removal bacterial efficiency –up to 99.99% of particles bigger than 0.027

micrometres (e.g., Hepatitis A, B and C, HIV, etc.).

In order to prolong performance and efficiency of device it is not allowed to use ag-

gressive organic compounds (e.g., phenol) and strong conjugated acids (e.g., guanidine) for

aspiration. Please, contact manufacturer in case of any questions regarding operation of

device.

Edition 1.-4.03 7

4. Getting started

4.1 Unpacking. Remove packing materials carefully and retain them for future shipment

or storage of the unit. Examine the unit carefully for any damage incurred during

transit. The warranty does notcover in-transit damage. Warrantycovers only the units

transported in the original package.

4.2 Complete set. Package contents:

4.2.1 FTA-1:

- FTA-1, aspirator with trap flask ........................................................................1 pce.

- Hydrophobic filter set .........................................................................................1 set

- Aspiration tips, 200 µL....................................................................................50 pcs.

- Holder tubes (1.5 ml) .....................................................................................10 pcs.

- Spare hydrophobic filter ...................................................................................1 pce.

- External power supply .....................................................................................1 pce.

- Operating instructions, certificate ...................................................................1 copy

- MA-8, 8-channel aspiration tip with holder................................................on request

4.2.2 FTA-2i:

- FTA-2i, aspirator with flask trap........................................................................1 pce.

- MA-U, universal adapter ..................................................................................1 pce.

- Hydrophobic filter set .........................................................................................1 set

- Aspiration tips, 200 µL....................................................................................50 pcs.

- Aspiration tips, 1000 µL..................................................................................10 pcs.

- Holder tubes (2 ml) ..........................................................................................5 pcs.

- Spare hydrophobic filter ...................................................................................1 pce.

- External power supply .....................................................................................1 pce.

- Operating instructions, certificate ...................................................................1 copy

- Extended tubing (2 m), with fittings and MA-U adapter.............................on request

- MA-8, 8-channel aspiration tip with holder................................................on request

- HAS-1, hand operator set with SH-6 stand...............................................on request

Figure 1. Assembled FTA-1 Figure 2. Installation of MA-8 aspiration tip

8 Edition 1.-4.03

Figure 3. FTA-2i front view Figure 4. FTA-2i lid with sensor and tubing

Figure 5. MA-U, universal adapter

Figure 6. FTA-2i filter setup Figure 7. FTA-2i rear panel

4.3 FTA-1 setup.

- Place the unit on horizontal even working surface.

- Install the trapping flask (fig. 1/5) on the unit.

- Assemble the lid, aspiration tubing and filter set (fig. 1/2). Attach aspiration tip (fig.

1/6) to the tubing.

Caution!

Position the filter with the IN marking pointing towards the unit (fig. 1/2).

- Screw on the lid with the filter set and aspiration tubing to trap flask. Ensure that the

filter set is tightly inserted.

- Connect the filter tubing to the pump (fig. 1/1) located at the top of the base behind

the trap flask, by turning the fitting clockwise.

- Place the microtubes for aspiration tip into the holder (fig. 1/4).

- Connect the external power supply unit into the socket at the rear side of the unit

and position the unit for an easy access to the external power supply and the power

switch.

Edition 1.-4.03 9

4.3.1 Optional MA-8 aspiration tip installation. Remove microtubes and aspiration tip

from the holder (fig. 1/4). Place MA-8 storing holder (fig. 2/1) into the holder. Remove

aspiration tip (fig. 1/6) from the aspiration tubing and connect the MA-8 aspiration tip

(fig. 2/2). Store the aspiration tip in the new holder.

4.4 FTA-2i setup.

- Place the unit on horizontal even working surface.

- Install the trapping flask (fig. 3/2) on the unit.

- Screw on the lid with the sensor needles and valves for tubing (fig. 3/1) to trapping

flask.

- Assemble the filter set (figure 6) and connect it to the port on the rear panel of the

unit (fig. 7/1).

Caution!

Position the filter with the IN marking pointing away from the unit (fig. 6/1).

- Attach the fitting (fig. 4/1) of the tubing to the filter (fig. 4/2) to the valve with white

ring on the lid.

- Ensure that the filter set is tightly fixed in the slot (fig. 7/1).

- Assemble the MA-U aspiration tip set (figure 5).

- Attach the fitting (fig. 4/3) of the tubing for liquids (fig. 4/4 and 5/3) to the valve with

the blue ring on the lid.

- Connect the sensor cable (fig. 4/5) to the lid of the unit and to the port on the rear

panel of the unit (fig. 7/4).

- Place the microtubes for aspiration tip into the holder (fig. 3/3).

- Connect the external power supply unit into the socket at the rear side of the unit

(fig. 7/5) and position the unit for an easy access to the external power supply and

the power switch.

4.4.1 Optional MA-8 aspiration tip installation. Remove microtubes and aspiration tip

from the holder (fig. 3/3). Remove the aspiration tip (fig. 5/1) from the MA-U adapter

and connect the MA-8 aspiration tip (fig. 8/1A).

4.4.2 Optional HAS-1 hand operator installation. Unscrew the MA-U adapter from the

aspiration tube (fig. 5/3) and connect the HAS-1 hand operator (fig. 8/5) by screwing

it to the fitting.

10 Edition 1.-4.03

5. Operation

5.1 Connect the external power supply to the mains.

5.2 Turn the Power switch (fig. 1/3 or 7/2) to the position I(on). The pump starts working.

5.3 (For model FTA-2i) Regulate the aspiration intensity with the regulator knob on the

front panel of the unit (fig. 3/4). Clockwise turning direction increases power, counter

clockwise –decreases. Current intensity is indicated by a light ring around the regu-

lator knob.

5.4 Touch the surface of the liquid with the aspiration tip (fig. 1/6, 5/1 or MA-8) to remove

the liquid.

Caution!

During operation, do not allow the collectedliquid to exceed the maximum

level. Empty the trapping flask when the liquid level reaches maximum

allowed level, according to 5.6.

Note.

In model FTA-2i, when collected liquid exceeds the maximum level, the

sensor turns off the pump and produces sound and light warning sig-

nals.

5.4.1 (For model FTA-2i) When using the optional HAS-1 hand regulator, touch the liquid

with the aspiration tip, then press and hold the blue button on the regulator to collect.

5.5 After finishing the operation, switch off the Power switch and disconnect the external

power supply from the mains.

5.6 Emptying the trapping flask. Turn off the unit. Remove the tubings and cables from

the lid. Remove the closed flask from its place. Unscrew the lid and empty the trap-

ping flask. Screw the lid back on and return the trapping flask on the unit. Replace

the tubings and the cables.

Caution!

Take necessary precautions in utilizing waste liquid in accordance with

general laboratory standards. For information regarding autoclaving pro-

cedures, see 9.2.4.

Edition 1.-4.03 11

6. Specifications

The unit is designed for operation in cold rooms, incubators (except CO2incubators)

and closed laboratory rooms at ambient temperature from +4°C to +40°C in a non-condens-

ing atmosphere and maximum relative humidity 80% for temperatures up to 31°C decreasing

linearly to 50% relative humidity at 40°C. Operating altitude above sea level is up to 2000 m.

Biosan is committed to a continuous programme of improvement and reserves the

right to alter design and specifications of the equipment without additional notice.

Model

FTA-1

FTA-2i

Aspiration speed

up to 1.7 mL/s

up to 27.8 mL/s

Vacuum regulation

–

Yes

Working vacuum pressure (at sea level)

-500 mbar

-200 … -800 mbar

Overflow protection sensor

–

Yes, invasive

Overflow protection actions

–

Pump stop, sound and light signals

Trapping flask

1 L, glass

2 L, polypropylene (PP)

Air filtration

Hydrophobic microbiologic air filter 2200/021

Filter pore diameter

0.027 μm

Operating voltage

12 V=

Operating current

300 mA

1 A

Power consumption

3.6 W

10.8 W

External power supply

input 100–240 V~, 50/60 Hz; output 12 V=

Dimensions

160x210x340 mm

185x290x390 mm

Weight, accurate within ±10%

1.7 kg

1.85 kg

1

Eliminates risk of contamination from the trapping flask with bacteria, viruses, and infected particles

12 Edition 1.-4.03

7. Ordering information

7.1 Models and versions available:

Model

Version

Catalogue number

FTA-1, aspirator with trap flask

V.4AW

BS-040108-AAG

FTA-2i, aspirator with trap flask

V.1A01

BS-040120-A02

7.2 To inquire about or order the optional accessories or the replacement parts, contact

Biosan or your local Biosan representative.

7.2.1 Optional accessories:

Description

Catalogue number

МА-8, 8-channel aspiration tip (fig. 8/1A) with holder (fig. 8/1B)

BS-040108-BK

HAS-1, hand operator set (only for FTA-2i). Set includes:

Handheld vacuum controller with adapter (fig. 8/5),

8-channel adapter (with ejector) for 200 µL tips (fig. 8/6),

1-channel adapter with 125 mm stainless steel pin (fig. 8/7),

1-channel adapter with 40 mm stainless steel pin (fig. 8/8),

8-channel adapter with 35 mm stainless steel pin (fig. 8/9),

1-channel adapter (with ejector) for 200 µL tips (fig. 8/10C),

Stand SH-6 for hand operator parts (fig. 8/10)

BS-040118-PK

Extended tubing (2 m), with fittings and MA-U adapter

BS-040120-DK

7.2.2 Replacement parts for FTA-1.

Description

Catalogue number

Hydrophobic filter

BS-040108-S25

Aspiration tip, 200 µL, 1000 pcs. (fig. 8/2)

BS-000001-S04

Aspiration tip, 8 channels, for MA-8 (fig. 8/1A)

BS-040108-S24

Trapping flask, 1 L, glass, with lid, inserts and sealing ring

BS-040108-S11

Tubing and fitting set

BS-040108-S22

7.2.3 Replacement parts for FTA-2i.

Description

Catalogue number

MA-U, universal adapter for 200/1000 µL single use tips (fig. 8/4)

BS-040118-AK

Hydrophobic filter

BS-040108-S25

Aspiration tip, 200 µL, 1000 pcs. (fig. 8/2)

BS-000001-S04

Aspiration tip, 1000 µL, 1000 pcs. (fig. 8/3)

BS-000001-S05

Aspiration tip, 8 channels, for MA-8 (fig. 8/1A)

BS-040108-S24

Trapping flask, 2 L, polypropylene, with lid, inserts and sealing ring

BS-040120-S11

Tubing and fitting set

BS-040120-S14

Sensor cable

BS-040120-S12

Edition 1.-4.03 13

1

2

3

4

5

6 7 8 9 10

Figure 8. Optional accessories and replacement parts

14 Edition 1.-4.03

8. Chemical compatibility

8.1 Different aerosols and vapours from volatile and hazardous agents can have a dam-

aging effect on the specific parts of the units. Please see below for FTA-1 and FTA-

2i material compatibility tables 1 and 2 with different common laboratory chemicals.

It is required to use the FTA-2i pump’s exhaust (fig. 7/3) by connecting it to the means

of required filtration through a tube or, alternatively, by placing the unit in a fume hood

when working with volatile and hazardous agents. FTA-1 does not have pump ex-

haust connector available; therefore, it is obligatory to place the unit in a fume hood.

It is suggested to test the compatibility of related parts to a specific chemical prior to

extensive use. Biosan does not warrant that the data in the tables is correct or com-

prehensive and that any material is fit for any purpose.

8.2 Resistance grades used in tables:

•1(Excellent) –at ambient temperature and pressure, the material should not be affected.

•2(Good) –the material is slightly affected but not to the point of being unsuitable.

•3(Fair) –a degree of reaction that is generally considered unsuitable and should not

be used.

•4(Severe) indicates that the material should not be used under any circumstances.

Table 1. FTA-1 chemical resistance chart

Parts

Material

Formalde-

hyde CH2O

Acetic acid

C2H4O2

Hydrochloric

acid HCl

Sodium

hydroxide

NaOH

Ethanol

C2H5OH

Acetone

(CH3)2CO

Tubing

Silicone

2

2

3

3

1

3

Bottle 1L

Glass

1

1

1

1

1

1

Lid

Polypropylene

1

1

1

1

1

1

Lid seal

NBR

2

3

2

2

2

4

Fittings

Polypropylene

1

1

1

1

1

1

Quick couplings

Ertacetal POM

1

1

3

1

1

1

Housing

Polystyrene

4

3

2

1

2

3

Pump head housing

Polycarbonate

1

2

4

4

2

4

Pump head membrane

EPDM

2

1

2

1

1

1

Pump valve

EPDM

2

1

2

1

1

1

Filter membrane

PTFE

1

1

1

1

1

1

Edition 1.-4.03 15

Table 2. FTA-2i chemical resistance chart

Parts

Material

Formalde-

hyde CH2O

Acetic acid

C2H4O2

Hydrochloric

acid HCl

Sodium

hydroxide

NaOH

Ethanol

C2H5OH

Acetone

(CH3)2CO

Tubing

Silicone

2

2

3

3

1

3

Bottle 2L

Polypropylene

1

1

1

1

1

1

Lid

Polypropylene

1

1

1

1

1

1

Lid seal

TPE

1

3

1

1

1

1

Level detection pins

Stainless steel

3

3

3

2

1

1

Fittings

Polypropylene

1

1

1

1

1

1

Quick couplings

POM

1

1

3

1

1

1

Housing

ABS

2

4

1

1

2

4

Pump head housing

Nylon

4

4

4

3

1

1

Pump head membrane

EPDM

2

1

2

1

1

1

Pump valve

EPDM

2

1

2

1

1

1

Filter membrane

PTFE

1

1

1

1

1

1

16 Edition 1.-4.03

9. Care and maintenance

9.1 Service.

9.1.1 If the unit is disabled (e.g., no aspiration, no reaction to key presses, etc.) or requires

maintenance, consult the troubleshooting table in 9.5. If the problem is not covered,

disconnect the unit from the mains and contact Biosan or your local Biosan repre-

sentative.

9.1.2 All maintenance and repair operations (except listed below) must be performed only

by qualified and specially trained personnel.

9.1.3 Operating integrity check. If the unit follows the procedure described in section Op-

eration, then no additional checks are required.

9.2 Cleaning and disinfection.

9.2.1 Use mild soap and water with a soft cloth or sponge for cleaning the exterior. Rinse

remaining washing solution with distilled water. Wipe dry the excess water with clean,

soft cloth or sponge.

9.2.2 To disinfect the plastic and glass parts, use 75% ethanol or DNA/RNA removing so-

lution (e.g., Biosan PDS-250). After disinfecting, wipe the surfaces dry.

9.2.3 Silicone and fittings. Detach and disassemble the tubing. Use only distilled water, no

less than 0.5 L, and air dry after rinsing.

9.2.4 Autoclaving procedures.

Lid, fittings, tubing

Flask

Hydrophobic filter, cables,

base pump

FTA-1

121°C and 1 atm.,

15 min.

121°C and 1 atm., 55 min.

Do not autoclave

FTA-2i

121°C and 1 atm., 15 min.

Caution!

Do not put a closed flask in the autoclave, as it might irreversibly deform.

Completely disengage the thread on the cap.

Note.

Hydrophobic filter and sensor cable are sensitive to moisture and are

not autoclavable. Tubing is made of silicone and deteriorate after fre-

quent autoclaving and should be replaced.

9.3 Tubing replacement. Change the silicone tubing every 6 months.

9.4 Filter replacement. Replace the filter as soon as it accumulates visible traces of dirt,

or when the liquid is sucked into it. Maximum working time for the filter is 30 days.

When working with infected materials, replace the filter immediately after finishing the

procedure to prevent the spread of infection.

9.4.1 Changing procedure. Remove the filter (fig. 1/2 or 6/1) by detaching it from adapters.

Insert a new filter and reconnect the adapters.

Caution!

Observe the orientation of the filter:

•For model FTA-1, the IN marking should be facing towards the unit (figure 1).

•For model FTA-2i, the IN marking should be facing away from the unit (figure 6).

Edition 1.-4.03 17

9.5 Troubleshooting.

Problem

Possible reason

Troubleshooting

Unit not working

No power

Check external power supply and con-

nector

(FTA-2i) Trapping flask full

Sensor shut down the motor. Empty the

trapping flask according to 5.6.

(FTA-2i) Sensor not connected

properly

Check sensor cable and attachments

Aspiration slow or

absent

(FTA-2i) Aspiration intensity set to

small

Turn the regulator knob clockwise to in-

crease aspiration.

Breach in the system

Check all the tubing and fittings. Tightly

close the lid of the unit

Dirt in the tubing

Clean the tubing, see 8.3.

Liquid in the filter

Replace the filter

(FTA-2i) Sensor

activated, but the

flask is not full

Foam in the trapping flask activated

the sensor

Do not use the unit with a foaming liquid

or use antifoaming agent.

9.6 Disposal. Disposal of the appliance requires special precautions and must be carried

out at an appropriate disposal site, separate from normal household waste. To prevent

pollution of the environment, all waste resulting from the disposal of the product must

be collected and disposed of in the country of use, in accordance with the applicable

requirements for the handling of electronic waste.

10. Storage and transportation

10.1 Store and transport the unit in a horizontal position (see package label) at ambient

temperatures between -20°C and +60°C and maximum relative humidity of 80%.

10.2 After transportation or storage and before connecting it to the electric circuit, keep the

unit under room temperature for 2-3 hrs.

10.3 For extended storage, disassemble and clean according to 9.3. Empty the trap flask.

The unit does not require special procedures.

18 Edition 1.-4.03

11. Warranty

11.1 The Manufacturer guarantees the compliance of the unit with the requirements of

Specifications, provided the Customer follows the operation, storage and transporta-

tion instructions.

11.2 The warranted service life of the unit from the date of its delivery to the Customer is

24 months. For extended warranty, see 11.6.

11.3 Warranty for the unit does not cover optional accessories or replacement parts listed

in 7.2.

11.4 Warranty covers only the units transported in the original package.

11.5 If any manufacturing defects are discovered by the Customer, an unsatisfactory

equipment report shall be compiled, certified and sent to the local distributor address.

To obtain the claim form, visit Technical support page on our website at link below.

11.6 Extended warranty.

•For FTA-2i, the Premium class model, one year of extended warranty is available

free of charge after registration, during 6 months from the date of sale. Online regis-

tration form can be found in section Warranty registration on our website at the link

below.

•For FTA-1, the Basic Plus class model, extended warranty is a paid service. Contact

your local Biosan representative or our service department through the Technical

support section on our website at the link below.

11.7 Description of the classes of our products is available in the Product class descrip-

tion section on our website at the link below.

Technical support

Registration

Product class description

biosan.lv/en/support

biosan.lv/register-en

biosan.lv/classes-en

11.8 The following information will be required in the event that warranty or post-warranty

service comes necessary. Complete the table below and retain for your records.

Model

Serial number

Date of sale

FTA-1, FTA-2i,

Aspirators with trap flask

11.9 Production date. Production date is placed in the serial number, on the label of the

unit. Serial number consists of14 digits styled XXXXXXYYMMZZZZ, where XXXXXX

is model code, YY and MM –year and month of production, ZZZZ –unit number.

Edition 1.-4.03 19

12. EU Declaration of conformity

12.1 Aspirators with trap flasks FTA-1 and FTA-2i are in conformity with the following rel-

evant Union legislations:

LVD 2014/35/EU

LVS EN 61010-1:2011 Safety requirements for electrical equipment for

measurement, control, and laboratory use. General requirements.

EMC 2014/30/EU

LVS EN 61326-1:2013 Electrical equipment for measurement, control and

laboratory use. EMC requirements.

General requirements.

RoHS3 2015/863/EU

Directive on the restriction of the use of certain hazardous substances in

electrical and electronic equipment.

WEEE 2012/19/EU

Directive on waste electrical and electronic equipment.

12.2 Declaration of Conformity is available for download on the page for the relevant model

on our website by links below, in the Downloads section:

FTA-1 FTA-2i

Other manuals for FTA-1

2

This manual suits for next models

1

Table of contents

Other Biosan Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual