Biotix xPipette User manual

This manual suits for next models

1

Table of contents

Popular Laboratory Equipment manuals by other brands

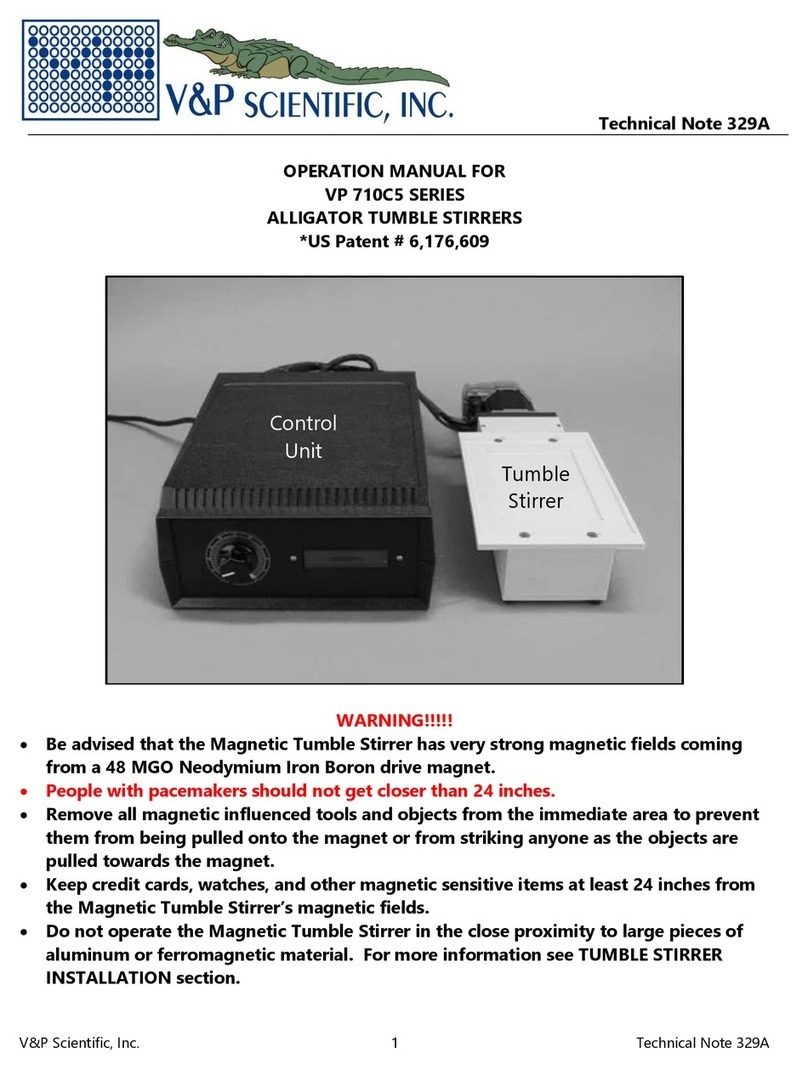

V&P Scientific

V&P Scientific VP 710C5 Series Operation manual

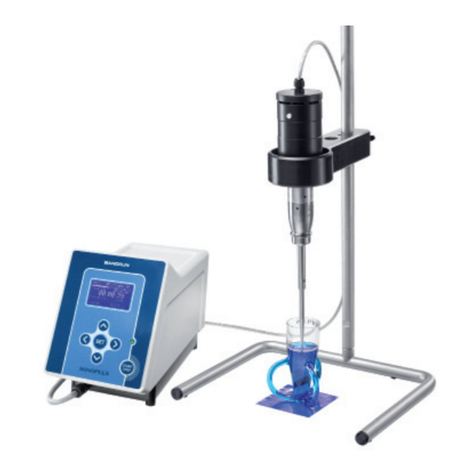

BANDELIN

BANDELIN Sonopuls HD 4050 operating instructions

Dr. Brown's

Dr. Brown's Natural Flow Microwave Steam Sterilizer manual

OHAUS

OHAUS Frontier FC5706 instruction manual

EP Lighting

EP Lighting TransportAirKleen Series Installation and maintenance manual

THORLABS

THORLABS M780L3-C1 operating instructions

Palas

Palas Promo 2000 Operation manual

IKA

IKA RW 16 basic operating instructions

Ocean Optics

Ocean Optics HPX-2000 Installation and operation

Omni International

Omni International Bead Ruptor 12 user manual

Thermo Scientific

Thermo Scientific Cryofuge 16 instruction manual

Omega Bio-Tek

Omega Bio-Tek Mag-Bind RXNPure Plus product manual

TE Connectivity

TE Connectivity 2234800-1 Customer's manual

SPEX SamplePrep

SPEX SamplePrep ShatterBox 8550 manual

Watts

Watts PURE WATER PWUV Series Installation, operation and maintenance manual

Tuttnauer

Tuttnauer T-Edge 11 quick guide

MRC

MRC SPC-60 Operating instruction

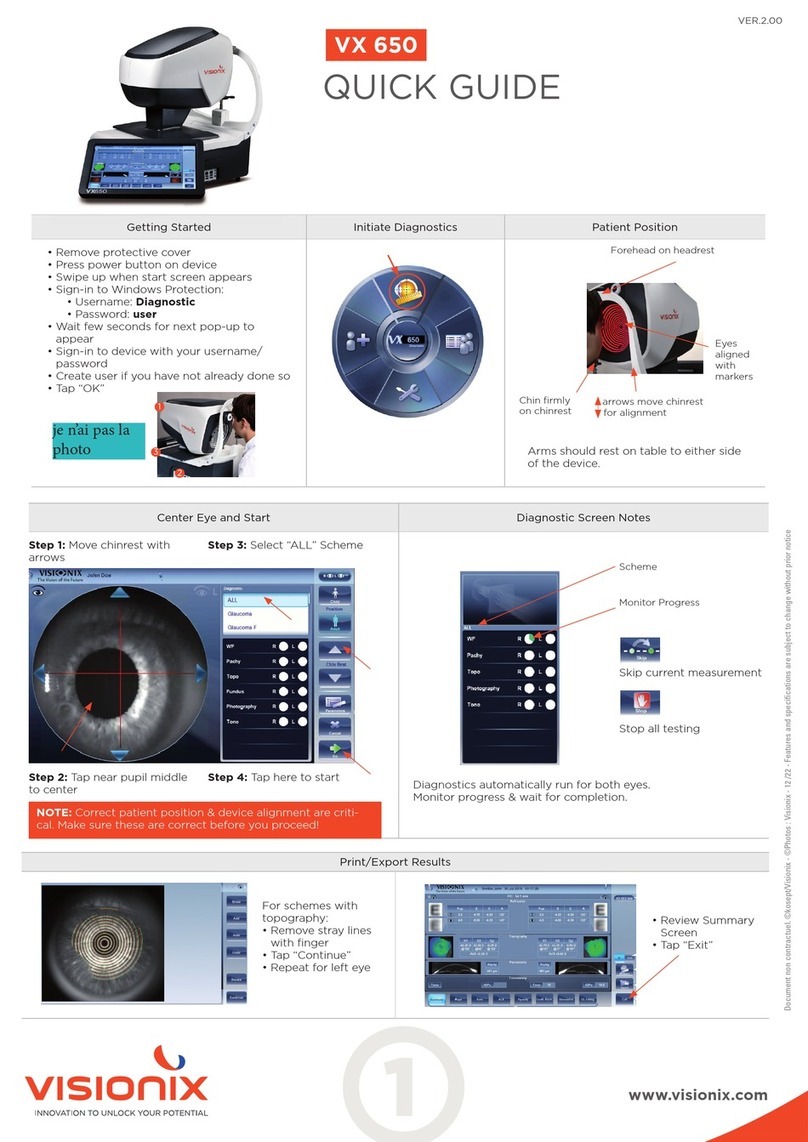

Visionix

Visionix VX 650 quick guide