Page 1

PrimeTec

User Manual

Introduction

IJK

H

O

G

LN

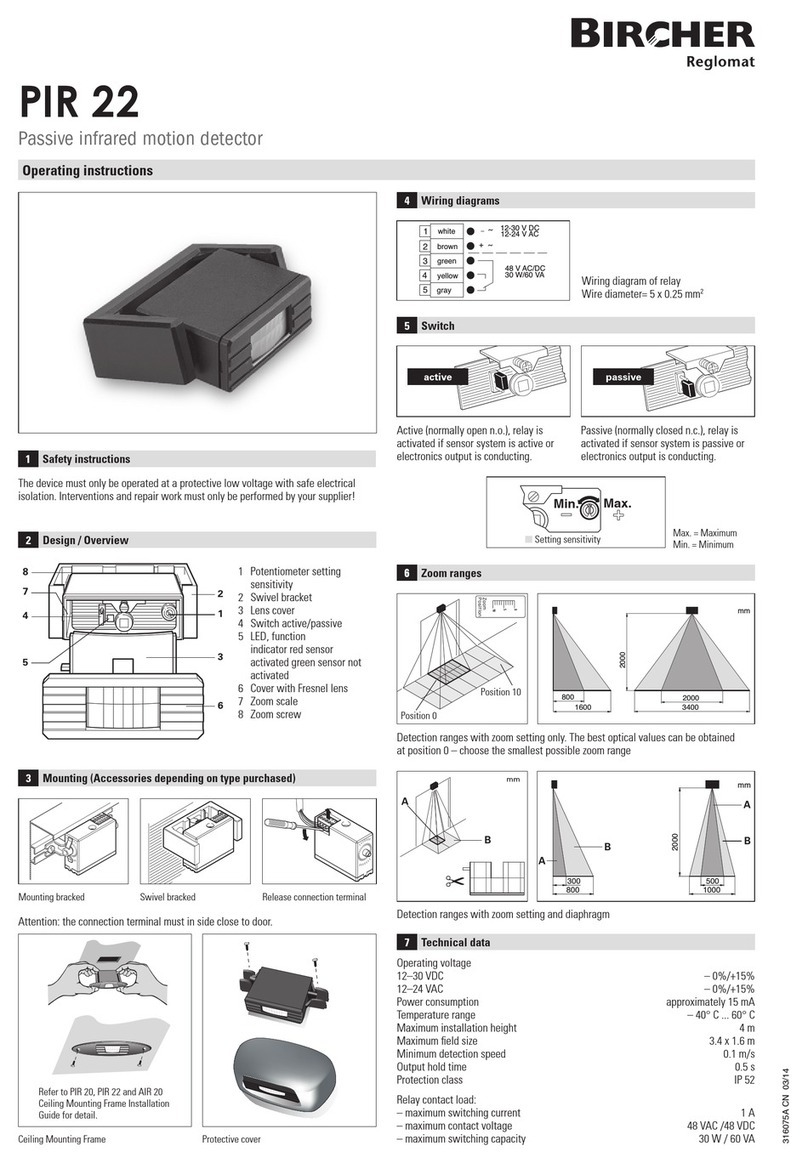

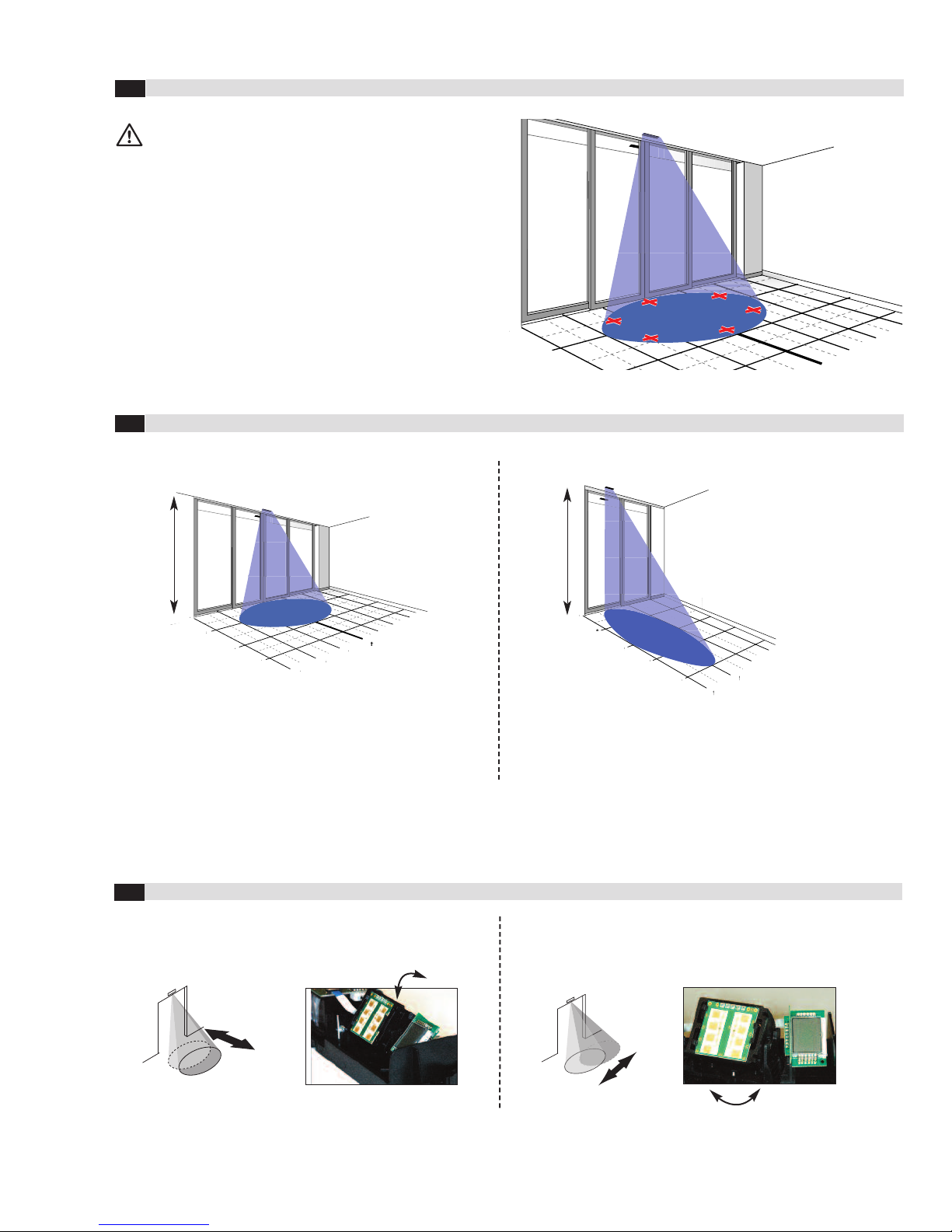

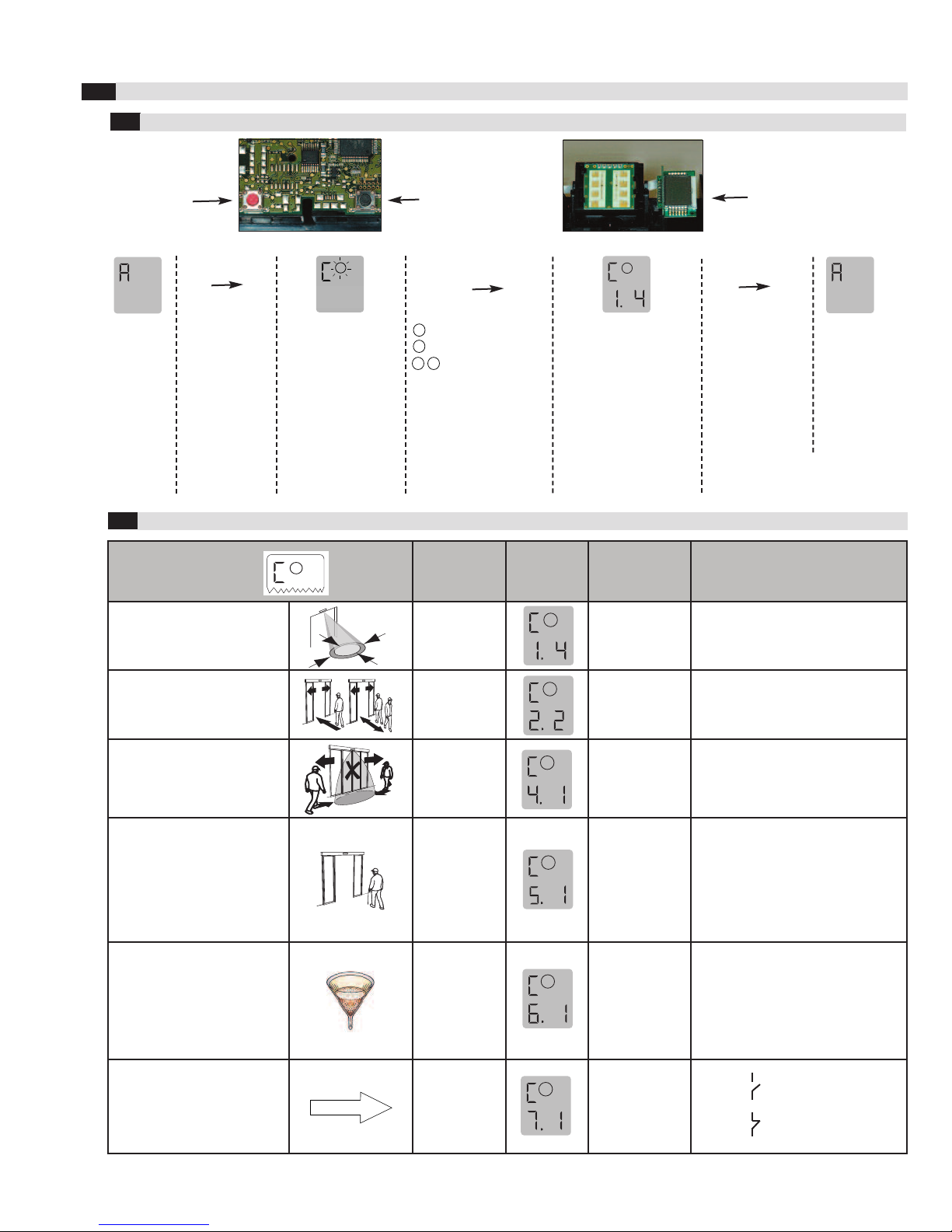

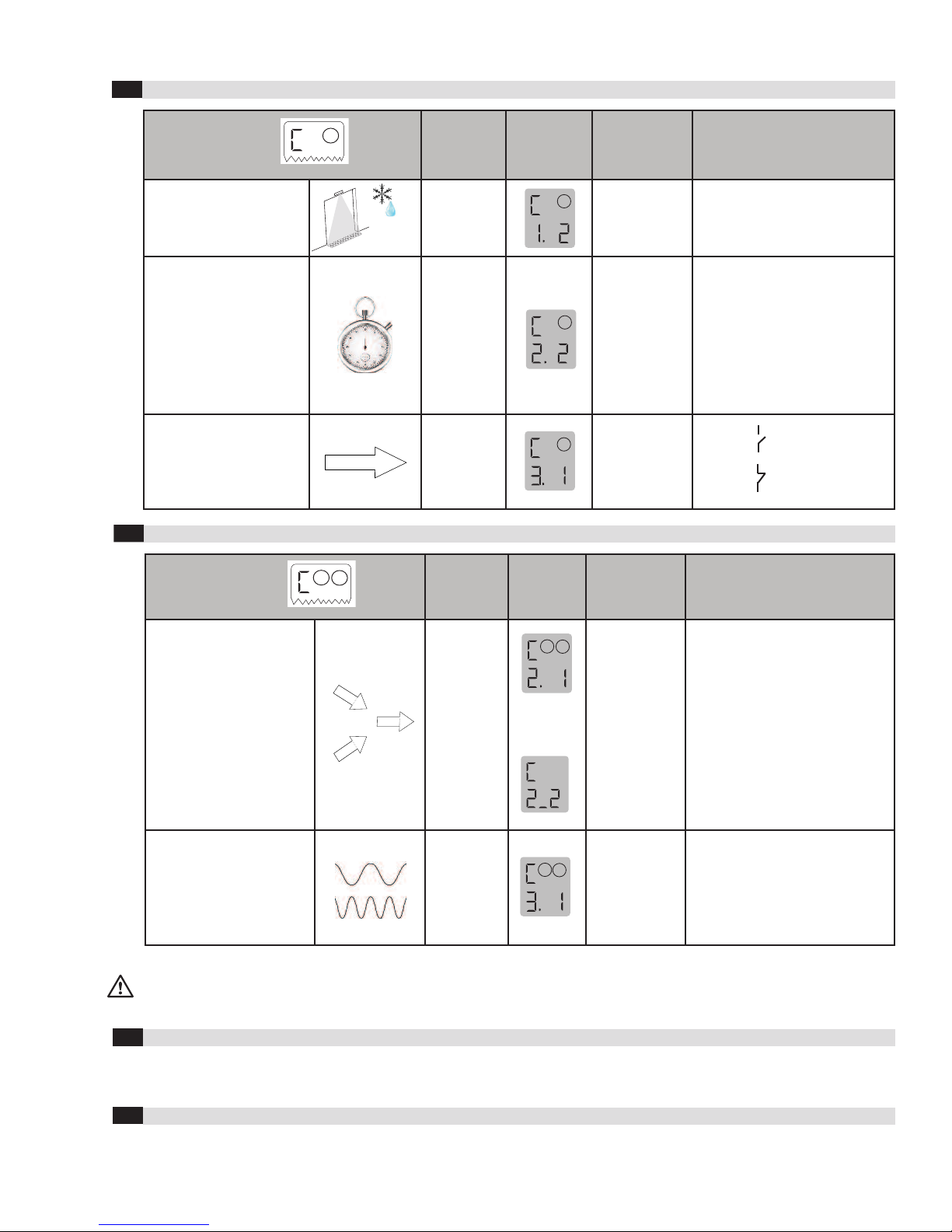

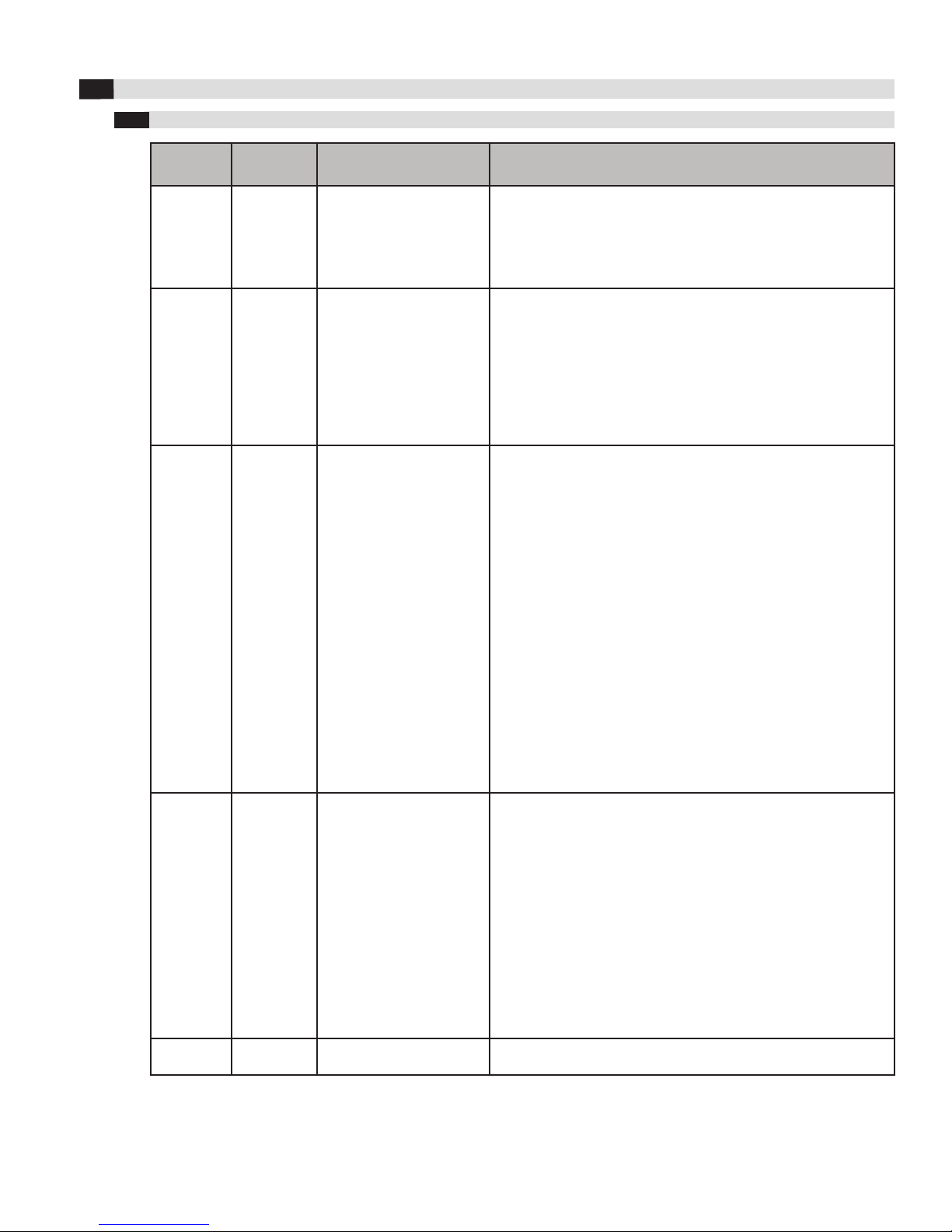

Combined microwave (motion)/active infrared (safety) sensor

for activating and protecting automatic pedestrian sliding doors

1

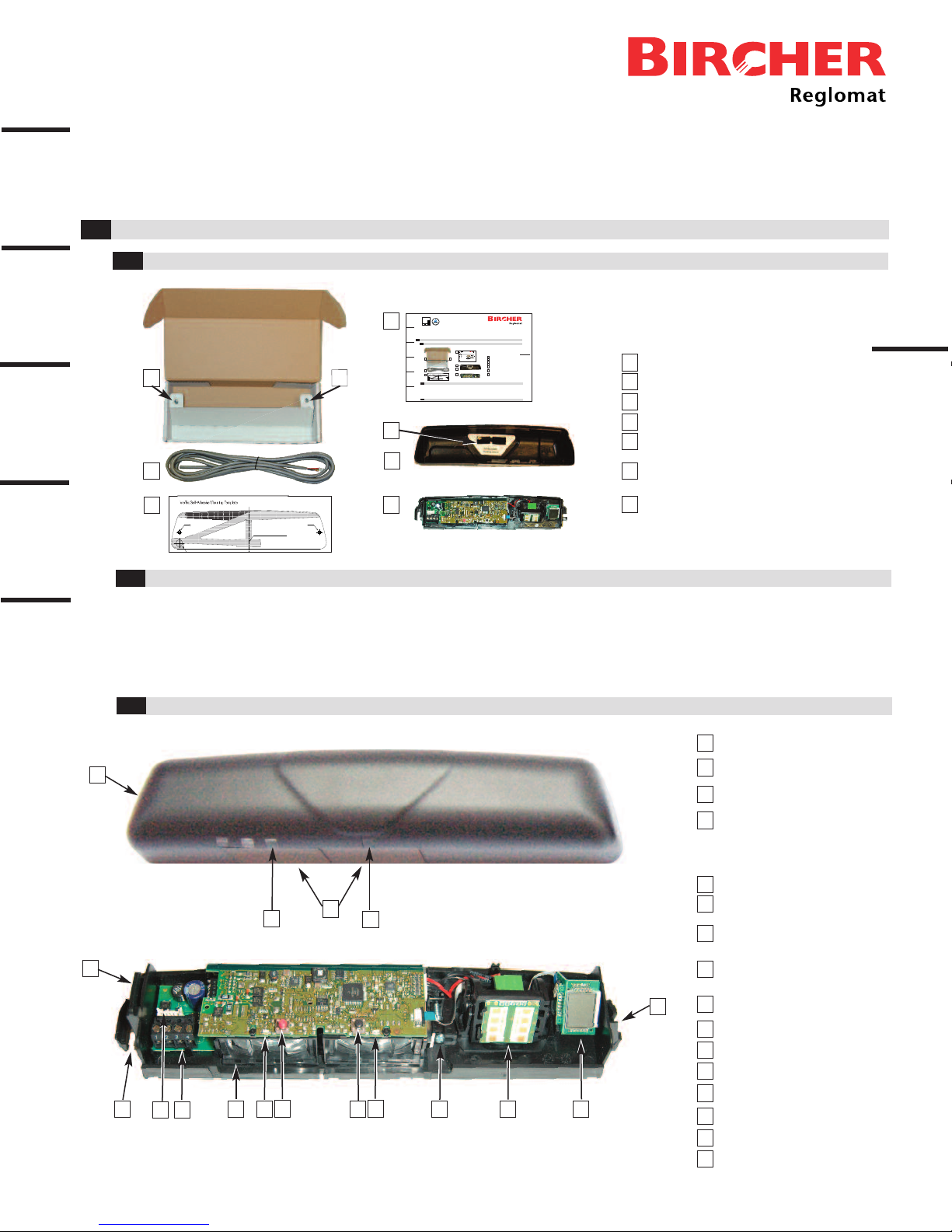

Box Contents

1.1

- Ladder

- Tape measure

- Level

- Wire cutter

- 4 gauge (5 mm dia.) wire stripper for cable sleeve

A

B

C

D

E

F

G

H

J

K

L

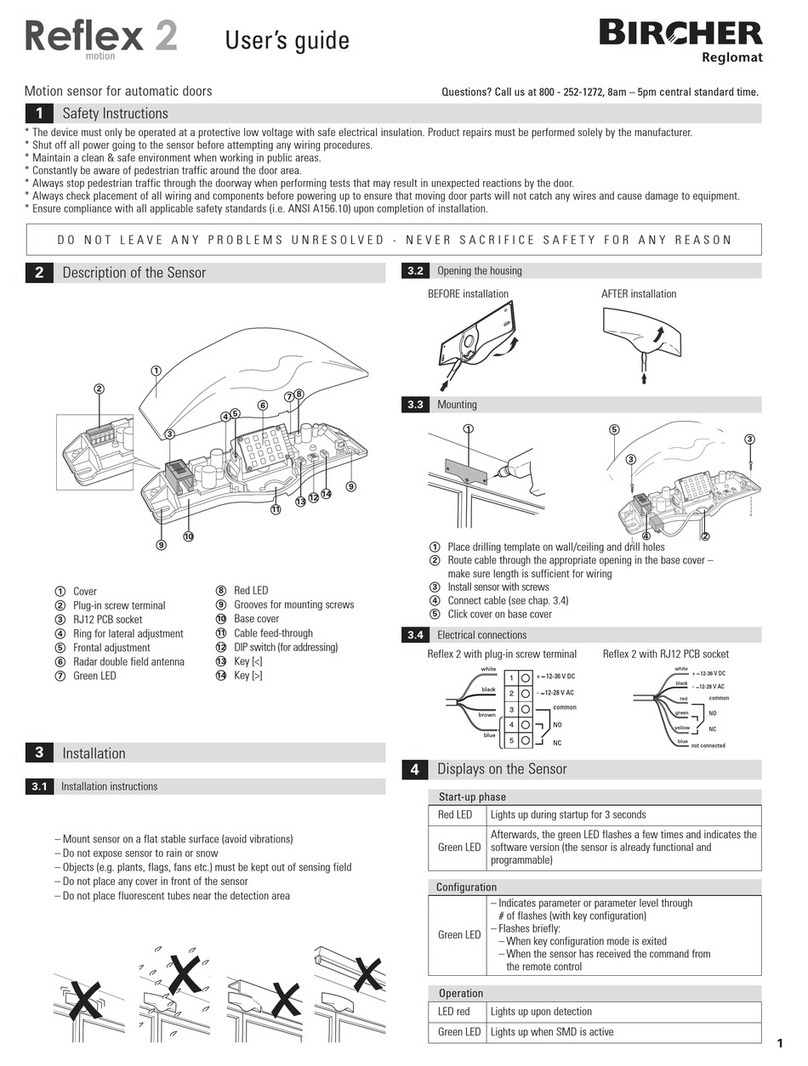

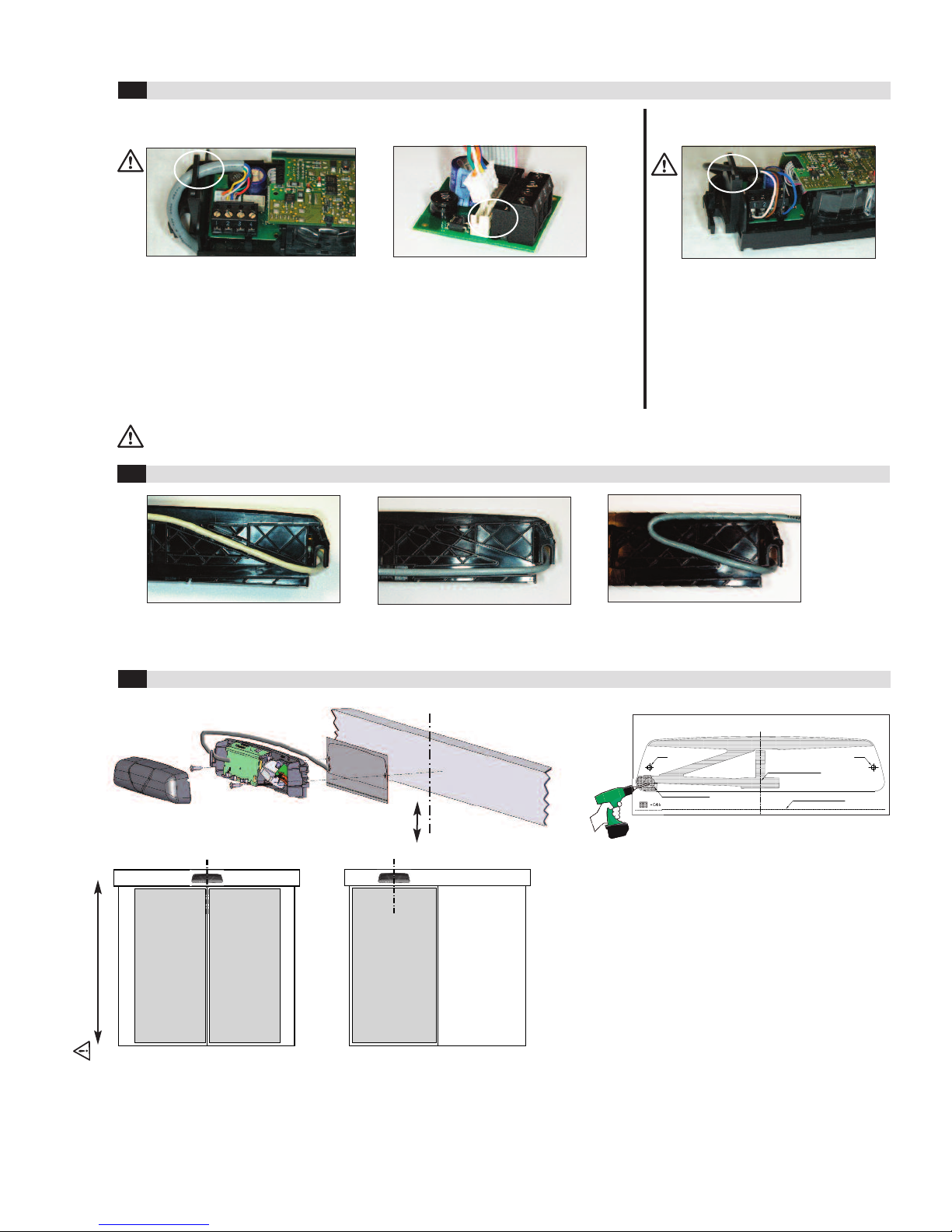

Cover

Safety curtain window

Safety sensor

indicator LED window

Cable bushing

Mounting screw holes (2x)

Cable connector

(for new installations)

Screw terminals

(for retrofit installations)

Safety sensor indicator LED (red)

Red button (function)

Black button (value)

Motion sensor indicator LED (green)

Parts of the Sensor

1.3

Motion sensor

indicator LED window

BD

C

E

M

A

F

I

M

FActive infrared safety curtain lens

(safety sensor)

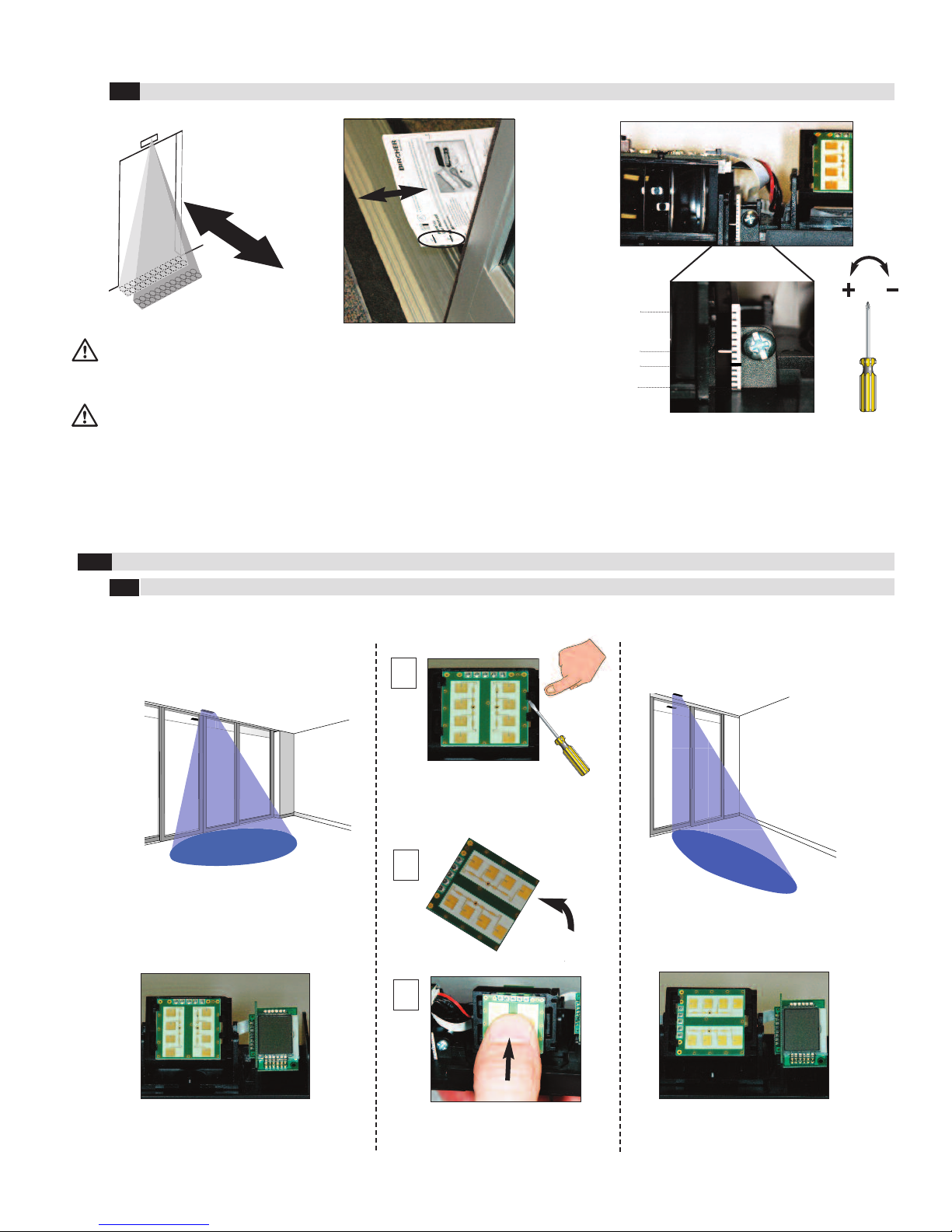

Markings for

safety curtain

adjustment

(See page 6)

3”

P

3”

2”

1”

A

B

C

C

D

F

GG

E

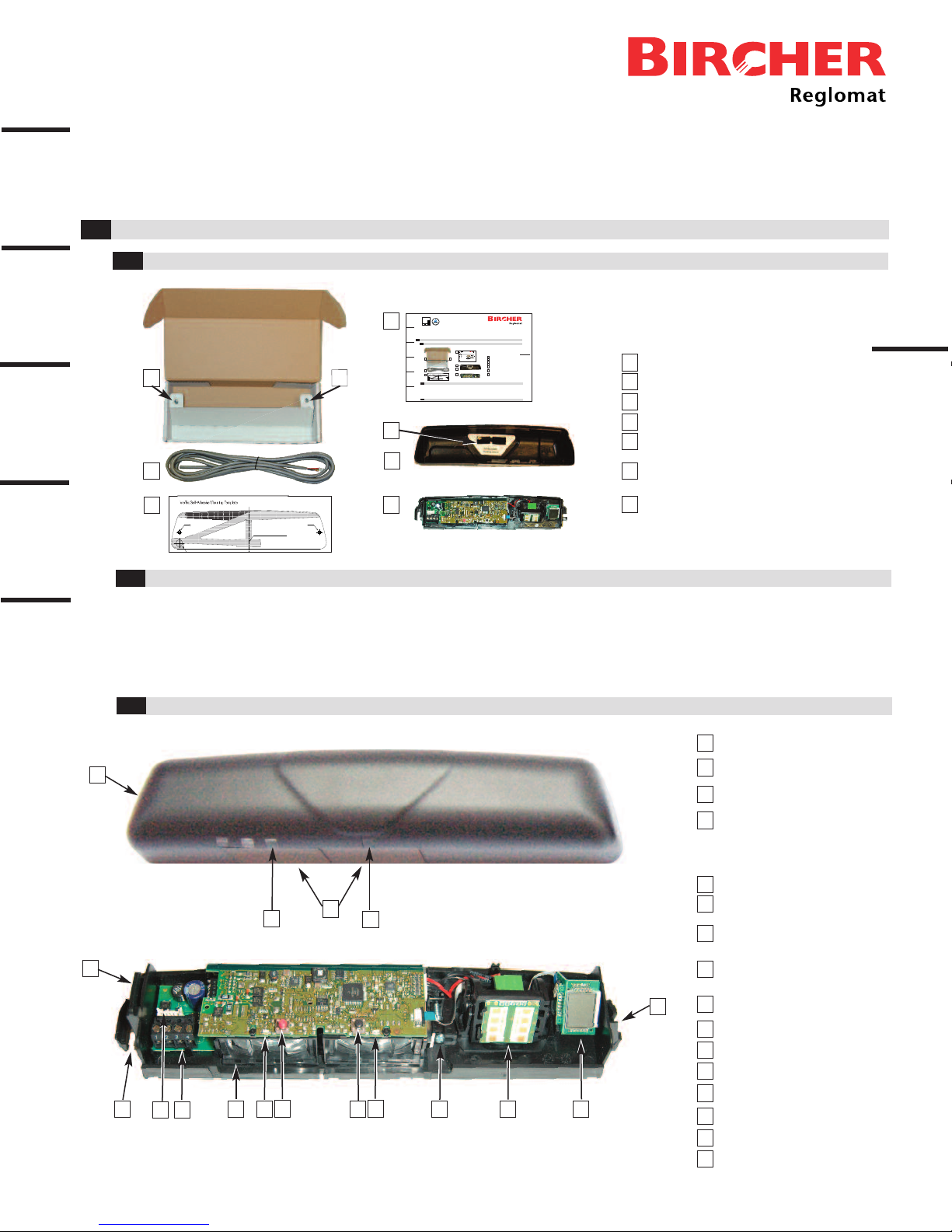

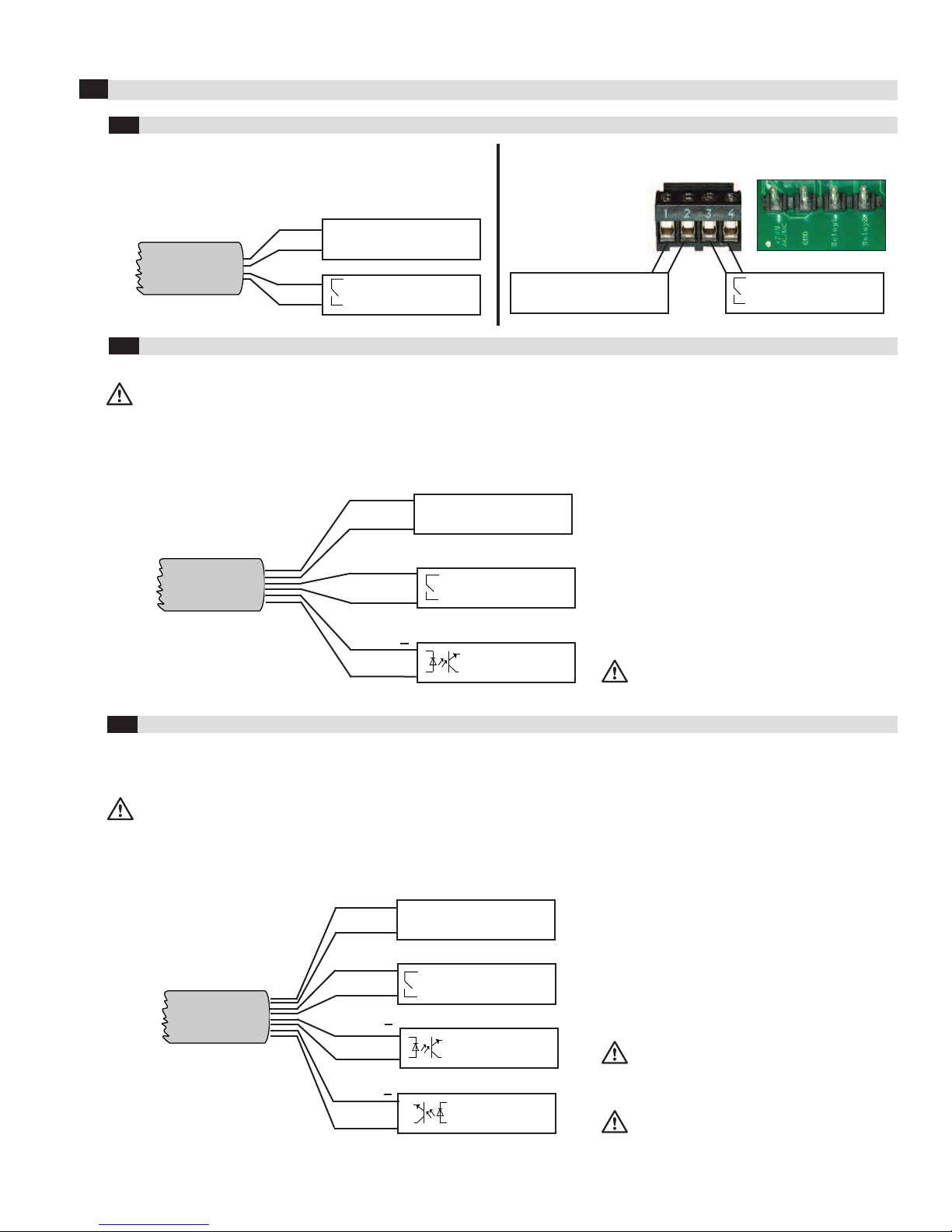

PrimeTec sensor

Sensor cover

Click-in safety curtain masking covers (2)

Instruction manual

Self-tapping mounting screws (2)

Self-adhesive mounting template

Safety curtain adjustment screw

Microwave module (motion sensor)

LCD display

N

O

P

A

B

Align with center of door header

PrimeTec Self-Adhesive Mounting Template

Screw Screw

Dia. 1/2” (12 mm) for cable exit

0641&7%6+10

Quality

international

level

EN ISO

9001

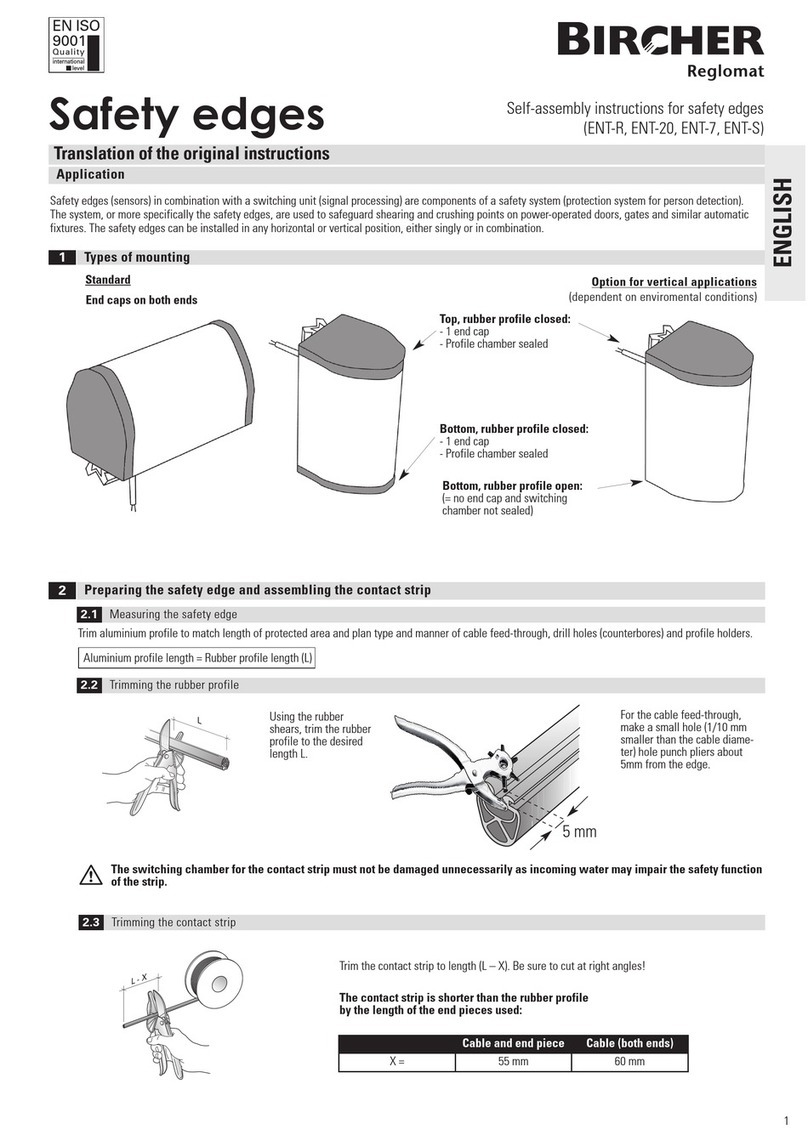

Combined microwave (motion)/active infrared (safety) sensor

for activating and protecting automatic pedestrian sliding doors

Box Contents

- Ladder

- Tape measure

- Level

- Wire cutter

- 4 gauge (5 mm dia.) wire stripper for cable sleeve

arts of the Sensor

This product meets or exceeds

ANSI standard 156.10 as independently

tested by TÜ Rheinland North America

Markings for

safety curtain

adjustment

(See page 6)

PrimeTec sensor

Sensor cover

Click-in safety curtain masking covers (2)

Instruction manual

Self-tapping mounting screws (2)

Self-adhesive mounting template

S

Alignwithcenterofdoorheader

PrimeTecSelf-AdhesiveMountingTemplate

Screw Screw

Dia.1/2”(12mm)forcable exit

0641&7%6+10

Quality

international

level

ENISO

9001

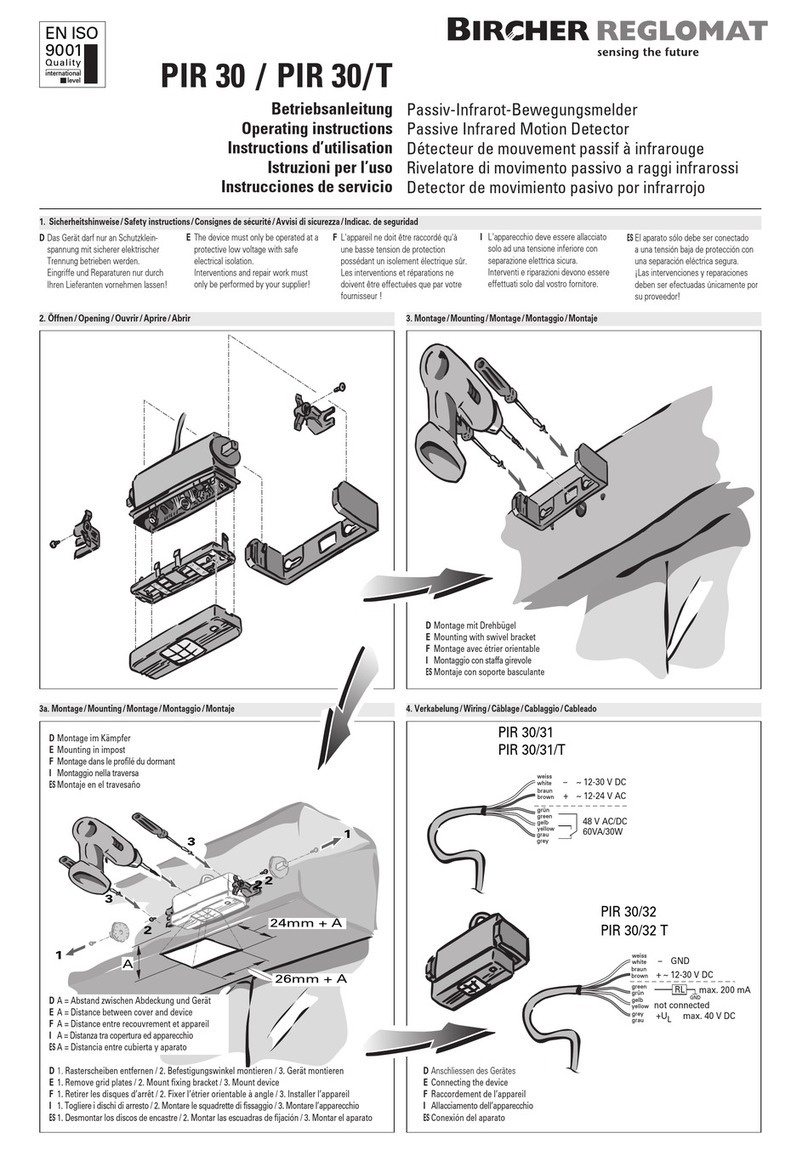

Combined microwave (motion)/active infrared (safety) sensor

for activating and protecting automatic pedestrian sliding doors

Box Contents

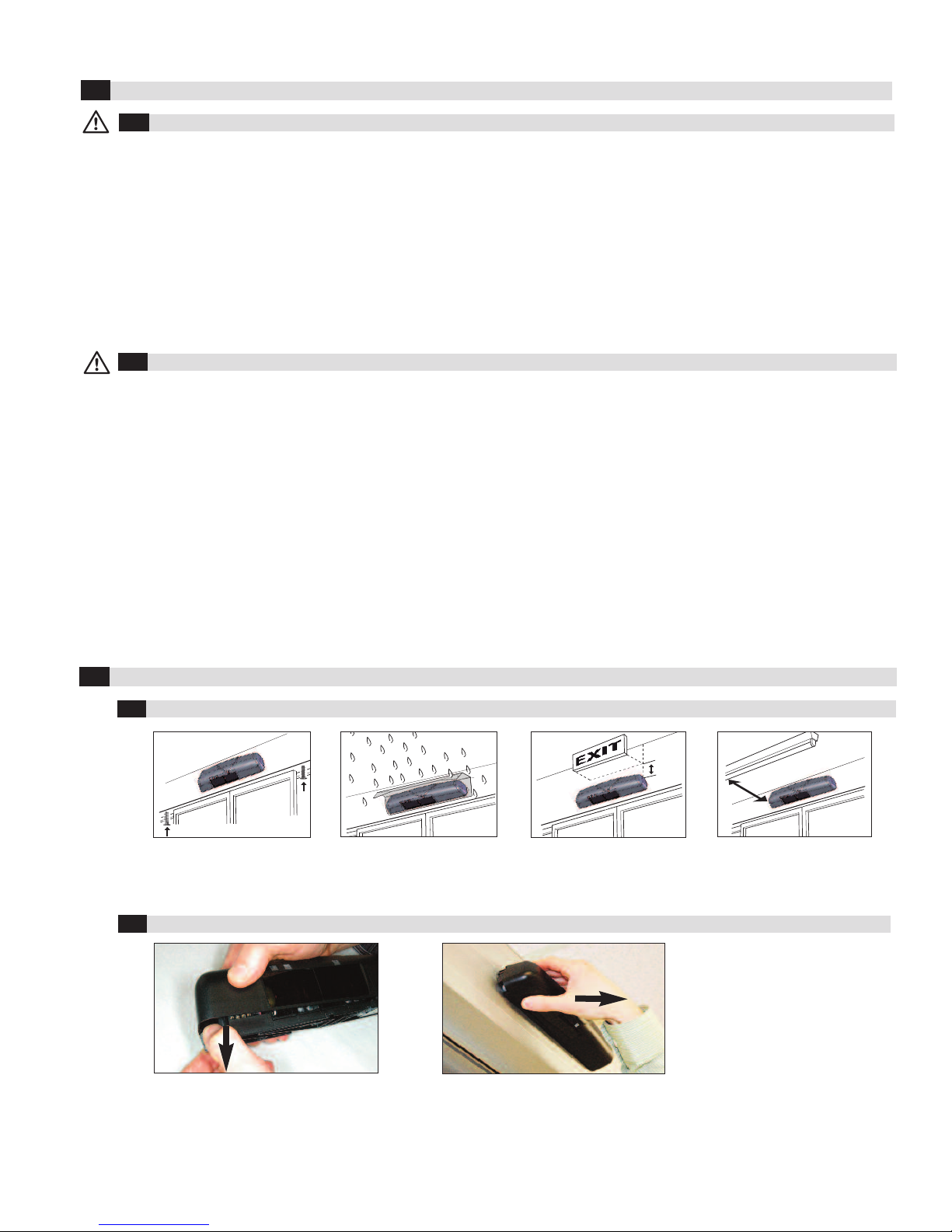

Tools required for installation:

- Ladder

- Tape measure

- Level

- Wire cutter

- 4 gauge (5 mm dia.) wire stripper for cable sleeve

- 26 gauge (0.14 mm²) wire stripper for single wires

- Phillips head screwdriver (size #1)

- Flathead screwdriver 1/8” (#1/ 3.6 mm)

- Electric drill with 1/2” (12 mm) drill bit

- Electric screwdriver with phillips head (size #2)

arts of the Sensor

This product meets or exceeds

ANSI standard 156.10 as independently

tested by TÜ Rheinland North America

Markings for

safety curtain

adjustment

(See page 6)

PrimeTec sensor

Sensor cover

Click-in safety curtain masking covers (2)

Instruction manual

Self-tapping mounting screws (2)

Self-adhesive mounting template

Alignwithcenterofdoorheader

PrimeTecSelf-AdhesiveMountingTemplate

Screw Scew

Da.1/2”(12mm)forcableexit

0641&7%6+10

Quality

ternational

level

NISO

9001

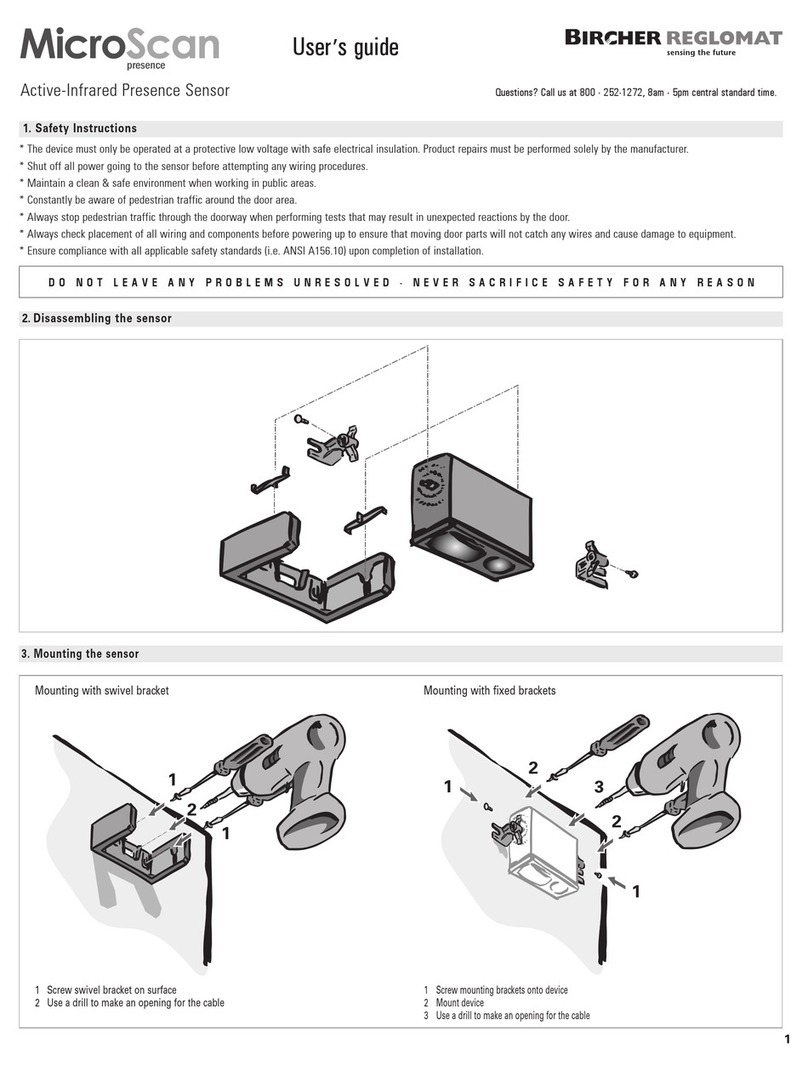

Combined microwave (motion)/active infrared (safety) sensor

for activating and protecting automatic pedestrian sliding doors

Box Contents

Tools required for installation:

- Ladder

- Tape measure

- Level

- Wire cutter

- 4 gauge (5 mm dia.) wire stripper for cable sleeve

- 26 gauge (0.14 mm²) wire stripper for single wires

- Phillips head screwdriver (size #1)

- Flathead screwdriver 1/8” (#1/ 3.6 mm)

- Electric drill with 1/2” (12 mm) drill bit

- Electric screwdriver with phillips head (size #2)

arts of the Sensor

This product meets or exceeds

ANSI stndrd 156.10 s independently

tested by TÜV Rheinlnd North Americ

Marking for

safety curtain

adjustment

(See page 6)

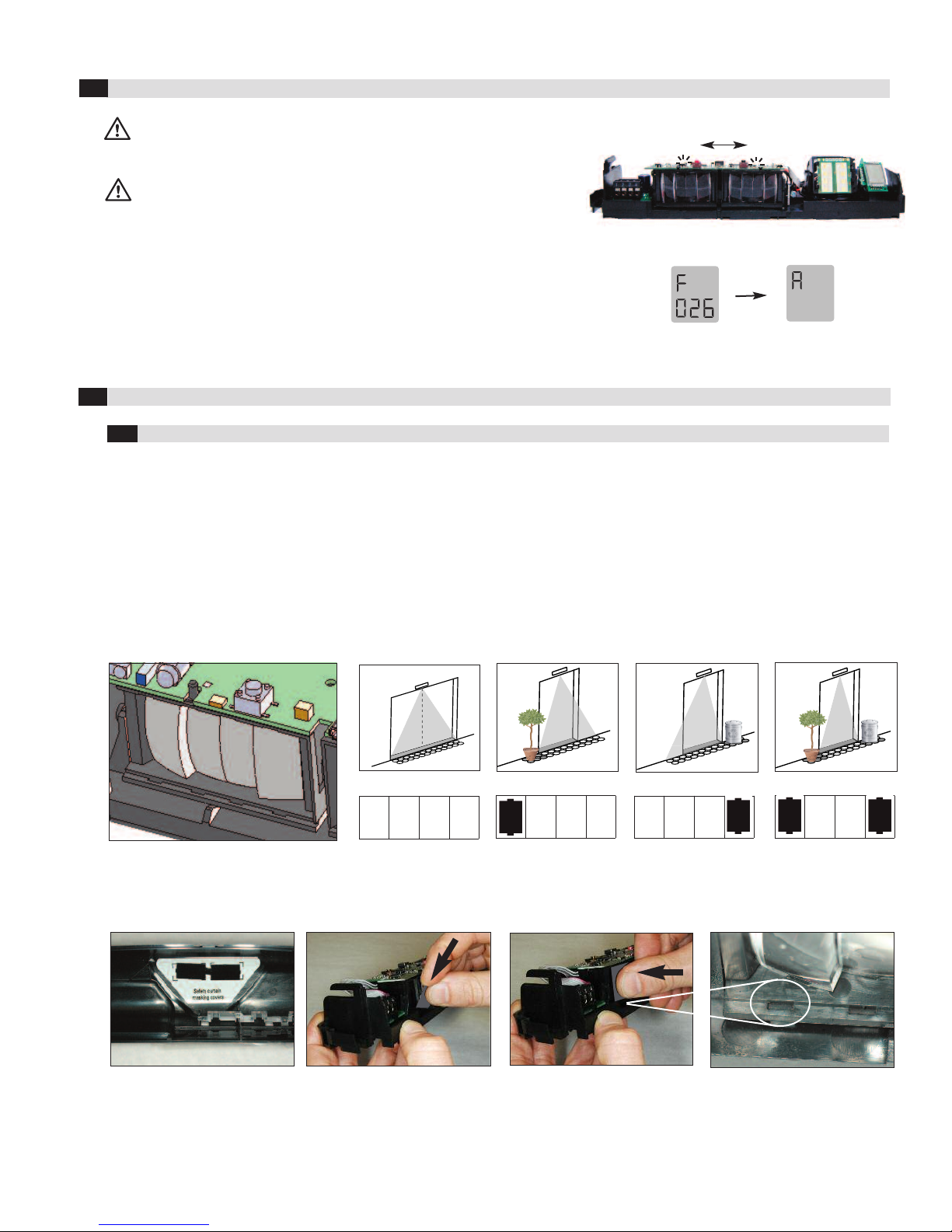

The box contains the following items:

PrimeTec sensor

Sensor cover

10’ (3 m) 8-wire electrical cable to connect

sensor to door operator

Self-adhesive mounting template

Click-in safety curtain masking covers (2)

Self-tapping mounting screws (2)

Instruction manual

10’ (3 m) 8-wire electrical cable to connect

sensor to door operator

The box contains the following items:

10’ (3 m) 8-wire electrical cable to connect

sensor to door operator

- 26 gauge (0.14 mm²) wire stripper for single wires

- Phillips head screwdriver (size #1)

- Flathead screwdriver 1/8” (#1/ 3.6 mm)

- Electric drill with 1/2” (12 mm) drill bit

- Electric screwdriver with phillips head (size #2)

Tools Required for Installation

D

E

10’ (3 m) 8-wire electrical cable to connect

sensor to door operator

4”

5”

E

F

- 26 gauge (0.14 mm²) wire stripper for single wires

- Phillips head screwdriver (size #1)

- Flathead screwdriver 1/8” (#1/ 3.6 mm)

- Electric drill with 1/2” (12 mm) drill bit

- Electric screwdriver with phillips head (size #2)

Tools Required for Installation

1.2