Fig. Item No. Description

1 57154 Product mixer safety cover, tri directional,

#63592 on

1A 53547 Lid with chute opening

1B 53543 Conveyor chute

2 56072 Safety cover latch

3 56073 Safety cover latch mounting bracket, L.H.

4 56074 Safety cover latch mounting bracket, R.H.

5 AN20S Acorn nut, 38-16 (2 req.)

6 RHS24S Round head screw, 14-20 ´12(2 req.)

HNNL15S Hex nut, nylok, 14-20 (2 req.)

7 RHS31S Round head screw, 14-20 ´1

HNNL15S Hex nut, nylok, 14-20

8A 53456 Mixer paddle assembly, 1st grind, optional

8B 53918 Mixer paddle assembly, 2nd grind,

standard

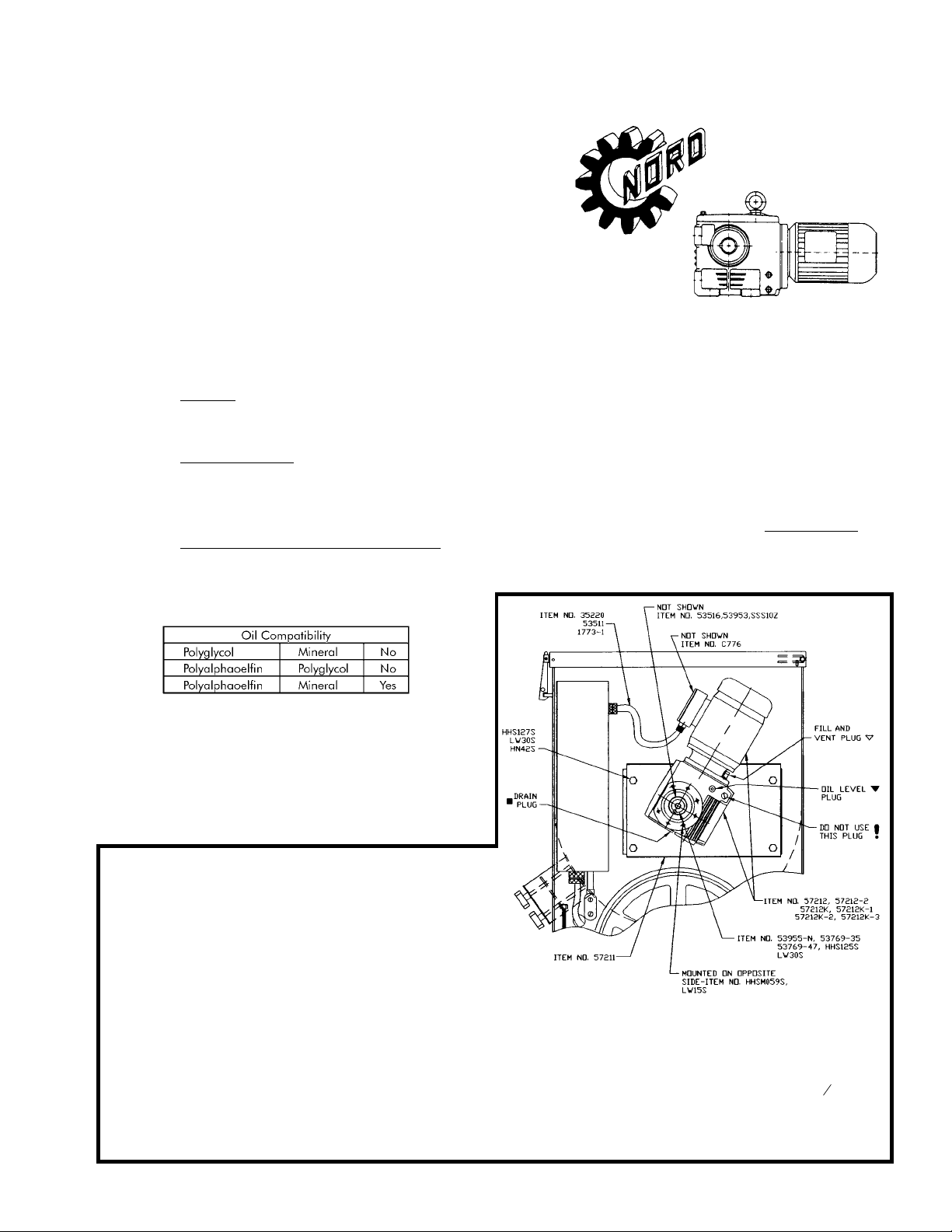

9 53953 Mixer drive shaft seal

10 53516 Mixer paddle drive pin

11 SSS10Z Drive pin set screw

12 53594 Bearing for 53520 assembly

13 53517-1 Thrust bearing

14 53852 Lock arm assembly w/brgs.

15 53568 Mixer paddle lock set screw

16 57047 Wireway cover, #63401 on

17 1116 Acorn nut, 10-32 (3 req.)

18 SSS45S Meatguard mounting stud

19 WN20S Wing nut

20 52392 Meat guard splash shield

21 HK48 Knife drive pin

22 HP48 Bowl plate pin (3 req.)

23 HR42/48 Bowl ring

24 52106-CTN Bowl w/plate pins

25 54278-CTN Auger assembly

25B 54278B Square drive auger adapter

25C 54278C Auger shear pin

25D FHS33S Shear pin flat head screw, 14-20 ´½

26 53413 Bowl mounting stud – short (1 req.)

HNF42S Hex flange nut, 12-13, (2 req.)

26A 53413-2 Bowl mounting stud – long (2 req.)

26B HNF42S Flange hex nut ½-13 bowl mounting nut

(3 req.)

27 57159K Auger drive shaft seal kit

27A 57160 Seal retainer, SS

27B 57159 Auger drive shaft seal, double lip

27C FHS26S Flat head screw 10-32 ´34,SS

28 53475-200 Motor, 7½HP, 200/400-60-3

53475 Motor, 712HP, 208/460-60-3

53475-50 Motor, 7½HP, 208/380-50-3

53941 Motor, 712HP, 575-60-3

53475-1 Baldor 7½HP, bearing both ends –

206KDD

53475-2 Doerr 7½HP, bearing, opp. shaft –

206KDD

53475-3 Doerr 7½HP, bearing, shaft end –

207KDD

57025-200 Motor, 10HP, 200/400-60-3

57025 Motor, 10HP, 208/460-50/60-3

57025-5 Motor, 10HP, 575-60-3

57092 Motor, 10HP, 220/380-50-3

29 53886 Journal box assembly

30 H384-CL Roller chain

31 54310 Adjusting stud

32 55092 Rear drive cover w/handles

55092-COSK Rear drive cover COS kit

55092-COS Rear drive cover w/handles & magnet

14688 4-point knob, AL

14688-COS Locking knob, AL

57219 Screw – COS rear drive cover

FW05S Flat washer ¼, SS

FW16S Flat washer 516,SS

HHS025S Hex head screw ¼-20 ´½, SS

HHS049S Hex head screw 516-18 ´½, SS

HHS050S Hex head screw 516-18 ´58,SS

Fig. Item No. Description

HHS055S Hex head screw 516-18 ´¾, SS

HN07S Hex nut 10-24, SS

HN15S Hex nut ¼-20, SS

HN20S Hex nut 516-18, SS

LW10S Lock washer ¼, SS

LWE10P Lock washer #10 ext tooth, SS

33 53478 Starter w/110V coil, Furnas size 1,

14DP32AF81, 712HP

55046 Starter w/24V coil, Furnas size 1,

14DP32AJ71, 7½HP

75DF14 Contact kit, Furnas 1 pole only (size 1)

7½HP

57027 Starter w/110V coil, Furnas size 134,

14EP32AF81, 10HP

57027CE Starter w/24V coil, Furnas size 1¾,

14EP32AJ71, 10HP

75EF14 Contact kit, Furnas 1 pole only (size 1¾)

10HP

33A 34478 Holding coil – 120V/240V

55047 Holding coil – 24V

34 53851 Fuse, FNM-1 AMP, 250V timedelay

35 53914 Transformer, 230/460 to 115V

53731 Transformer, 575 to 115V

PC141-1 Transformer replacement,

200/208/220/240/277/380 to 24V

36 See electrical diagram, page 4

37 53477 Starter w/110V coil, Furnas size 00,

14BP32AF81, 1¾HP

55045 Starter w/24V coil, Furnas size 00,

14BG32AJ71, 1HP

75BF14 Contact kit, Furnas 1 pole only (size 00)

1HP

37A 34478 Holding coil – 120V/240V

55047 Holding coil – 24V

38 53633 Starter box cover

39 53860 Starter box

40 52181-1 Magnetic switch bracket for magnet

41 52181-1 Magnet w/mounting brkt. (110 volt)

PC166 Magnetic safety switch (24 volt) old style

units only (not CE)

42 42MC-Y73 Green start button

43 H442-1 Magni switch, 3 amp

53872 Safety switch mounting bracket

44 42MC-Y74 Red stop button

45 50655-1 Switch guard

H462-1 Switch guard ferrule

HN20S Hex nut 516-18 SS

LW15S Lock washer 516 SS

46 54320K Toggle switch,hand/foot, w/boot

47 54321 Toggle switch waterproof half boot

48 53869CEK Legend plate, w/int’l. symbols, int'l kit

49 53870 Legend plate gasket

50 52655 Female receptacle, 5 pole, for footswitch

51 52662 Protective cap assembly

52 53872 Safety switch bracket

53 35376 End anchor

54 35241 Mounting channel

55 35375 End barrier

56 35374 Terminal block

57 53783 Decal, rotation

58 57156 Front splash shield

HHS025S Hex head screw ¼-20 ´½, SS

HN15S Hex nut ¼-20, SS

LW10S Lock washer ¼, SS

NOT SHOWN

57073 Power cord, 10’, 8-4

54268 Power cord, 10’, 10-4

2563 Legend plate hex screw

10-32 ´12,SS

53965 Optional leg ext. kit with brace

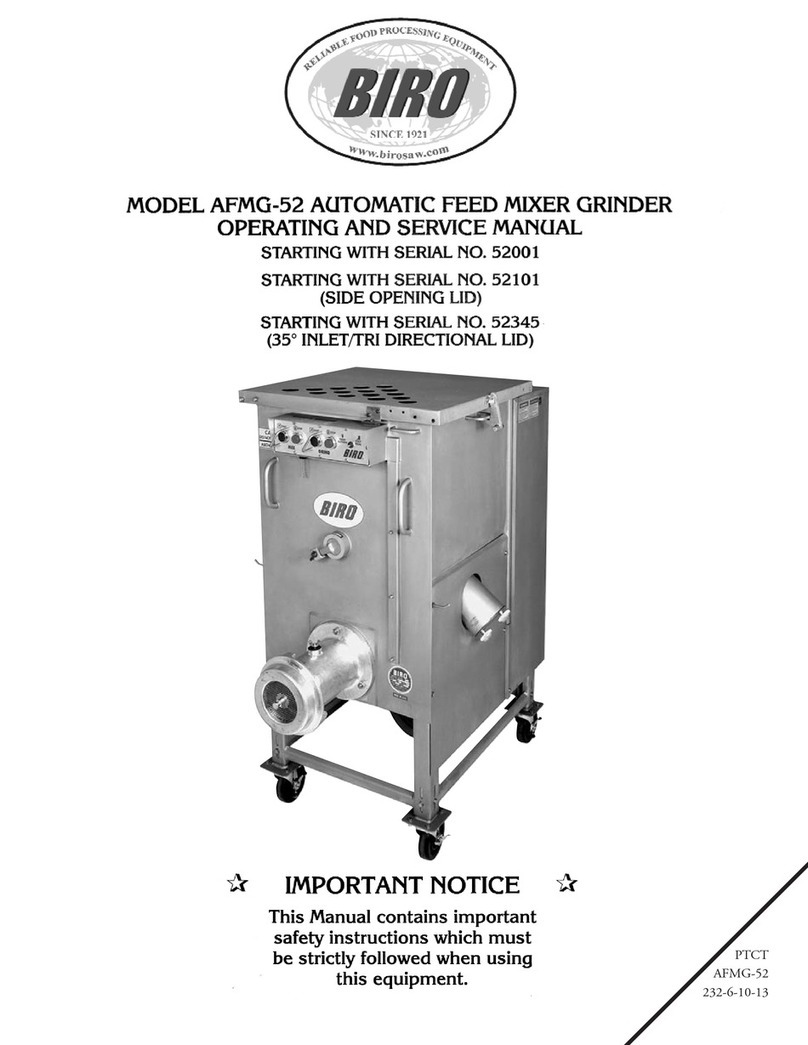

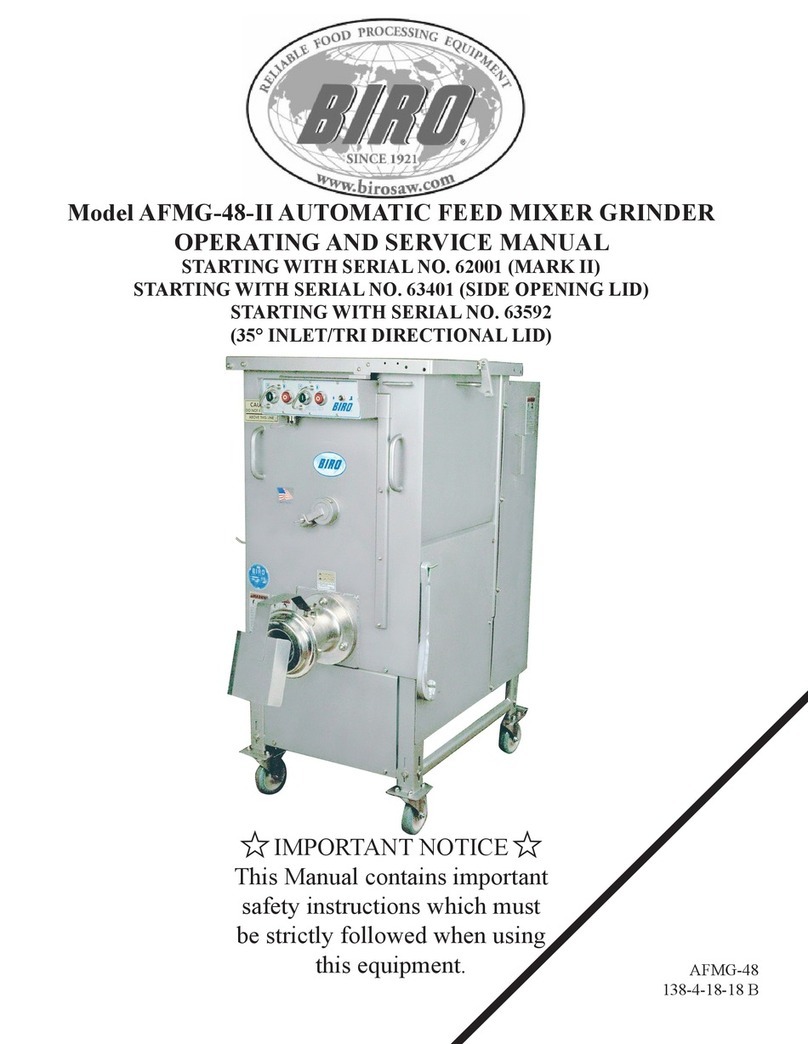

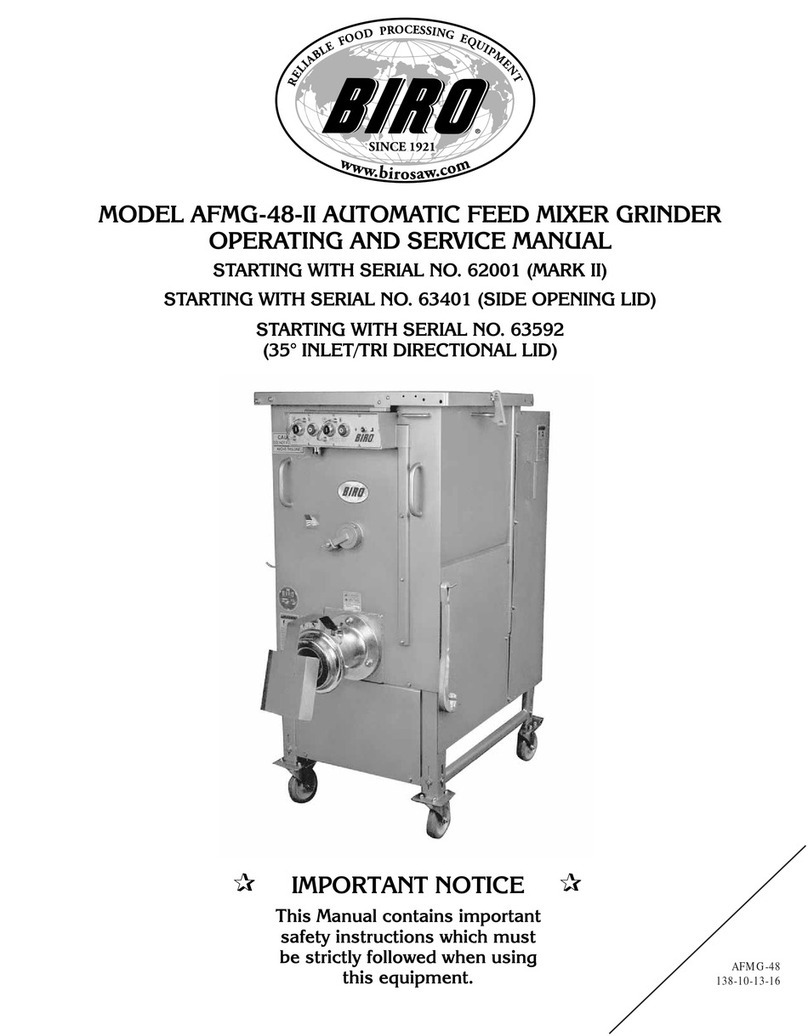

BIRO MODEL AFMG-48-II MIXER GRINDER PARTS LIST

15