Bison 170-101-0212 User manual

SS2 SS2

S3

MIN-SPEED-MAX IR COMP

S3

L2

L

A+/B

A-/B

A-/AA+/A

ACC/DEC CUR LIM

A -- INHIBIT -- B

A B

A-B

1

J501

C4

C506

C505

C503

U3

U2

D501

J2

J

QC502

QC501

D502

R502

U

C502

R503

R501

R26

C15

Q504

Q503

Q502

R38

MOV502

R25

C501

0.74 [19]

1.75 [44]

3.58 [91]

4.30 [109]

0.96 [24]

1.41 [36] 1.53 [39]

0.19 [5]

6 PLACES

C6

J5

J4

J3

TORQUE

SPEED

INDEP.

RATIO

DECEL

COAST

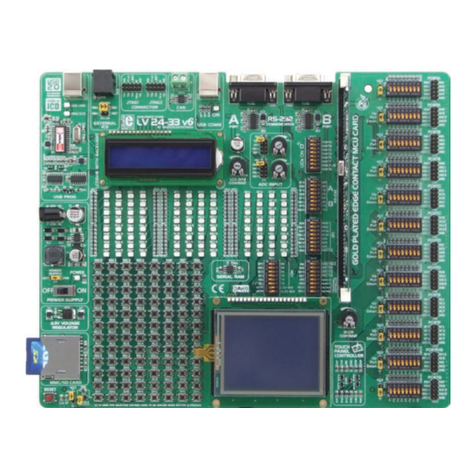

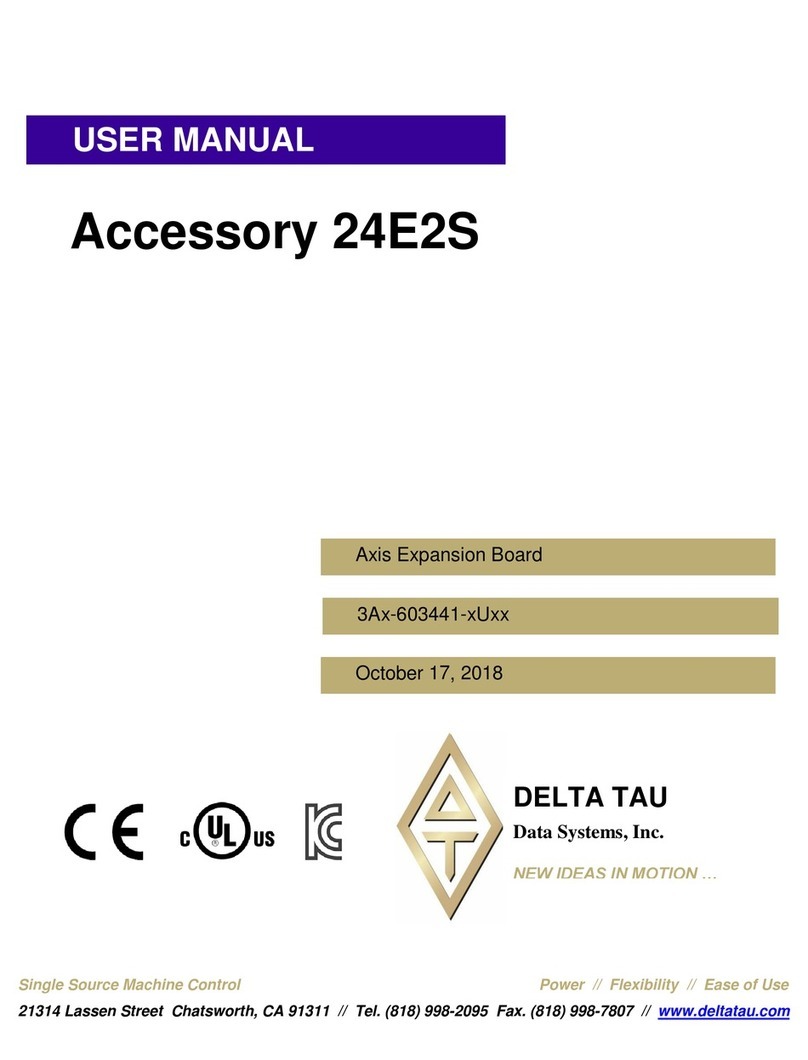

QUICK START GUIDE

170-101-0212

DIMENSIONS

SPECIFICATIONS

* Heatsink (part number 170-990-0100) is required if one side provides more than 5A or the total output of

both sides is more than 6.5A.

Dual Motor Control SCR DC Drive

CONNECTIONS

S1S2 S1S2S3

MIN-SPEED-MAX

IR COMP

S3

L2

L1

A+/B

A-/B

A-/AA+/A

1

ACC/DEC CUR LIM

A -- INHIBIT -- B

SPEED A

POTENTIOMETER

RATIO OR SPEED B

POTENTIOMETER

A B

A-B

C6

C4

C506

C505

C503

U3

U2

D501

D502

J2

J1

R502

U1

C502

R503

R501

C15

Q504

Q503

Q502

R38

MOV502

R25

C501

J501

CLOSE TO INHIBIT DRIVE

M

LINE

VOLTAGE

INPUT

115 VAC

MASTER

POWER

SWITCH

FUSE

MOTOR A MOTOR B

J5

J4

J3

TORQUE

SPEED

INDEP.

RATIO

DECEL

COAST

Motor Connections

The 170-101-0212 drive supplies motor voltage from A+ and A- terimnals. It is assumed that

when A+ is positive with respect to A-, the motor will rotate clockwise (CW) while looking at the

output of the shaft protruding from the front of the motor. If this is opposite of the desired

rotation, reverse the wiring of the A+ and A- terminals.

Power Input

Connect the AC power leads to terminals L1 and L2, or to a double-pole single-throw master

power switch (recommended).

Line Fuse

Wire an external line fuse between the stop switch (if installed) and the L1 terminal.

Speed Potentiomenter Connections

Speed adjustments are supplied by speed potentiometers connected to J1 and J2 (Factory

supplied pot kit includes two sets of potentiometer hardware).

Input Voltage +/- 10%, 50/60 Hz

Output Voltage (VDC)

Maximum Continuous Output for one motor (Amps)

Maximum Total output for combined motors (Amps)

Individual motor HP range

Maximum Total HP rating of both sides combined

Form Factor

115 VAC

0 - 90

5

6.5

1/15 - 1/2

5/8

1.37

* Without Heatsink

115 VAC

0 - 90

10

11.5

1/15 - 1

1 1/8

1.37

* With Heatsink

CALIBRATION / OPERATION

INDEPENDENT MODE (Jumper on pins 1 & 2 of J3)

There are two sets of potentiometers independently used to adjust each motor operation. Each set

consists of five on board trimmer potentiometers and one external potentiometer (commonly called

SPEED POT). To calibrate one side (A or B), use the following procedure:

1. Turn the SPEED POTENTIOMETER A (B) to full CCW. Use MIN SPEED A (B) trimmer

potentiometer to adjust minimum speed for motor A (B).

2. Turn the SPEED POTENTIOMETER A (B) to full CW. Use MAX SPEED A (B) trimmer

potentiometer to adjust maximum speed for motor A (B). Repeat steps 1 and 2 a few times due

to a level of interaction between MIN SPEED and MAX SPEED pots.

3. Set the CUR LIM A (B) to full CCW. Turn the SPEED POTENTIOMETER A (B) to full CW. Stall

the motor shaft and turn the CUR LIM A (B) CW until the desired current limit is reached.

4. Set the IR COMP A (B) to full CCW. Set the motor speed at approximately half of the rated

speed. Load motor to its full load. Keep turning the IR COMP CW until the speed equals the no

load speed.

5. Use ACC/DEC A (B) trimmer potentiometer to adjust acceleration (deceleration) ramp time.

RATIO MODE (Jumper on pins 2 & 3 of J3)

In RATIO MODE, SPEED POT A is used to adjust the speed of both motors, while SPEED POT B sets

the ratio between speeds. Turning the SPEED POT B CW will increase speed of motor B thus increasing

the ratio speed B/speed A. MIN SPEED B and MAX SPEED B are now used to adjust minimum and

maximum ratio.

TORQUE MODE (Jumper on pins 1 & 2 of J4)

TORQUE MODE regulates motor current (torque). In TORQUE MODE, the external potentiometer A (B)

sets the torque reference for Motor A (B) and the CUR LIM trimmer potentiometer A (B) sets the speed

limit for Motor A (B).

STOPPING: DECEL vs. COAST (J5)

There are two methods of stopping: DECEL and COAST.

DECEL - Placing a jumper on pins 1 and 2 of J5 and closing the inhibit terminals will cause the motor

to decelerate at a rate set by ACC/DEC pot.

COAST - Placing a jumper on pins 2 and 3 of J5 and closing the inhibit terminals will stop the

application of voltage to the motor, causing the motor to coast to a stop. This option is also

set for both motors simultaneously.

* NOTE: Deceleration time is a function of load inertia and friction. High inertia loads will decelerate

slower than high frictional loads.

Rotation: CW = Clockwise CCW = Counterclockwise

S1S2 S1S2S3

MIN-SPEED-MAX IR COMP

S3

ACC/DEC CUR LIM

A B

A-B J2

J1

U1

C15

C501

TRIMMER POTS

FOR MOTOR A

TRIMMER POTS

FOR MOTOR B

SPEED A

POTENTIOMETER

CW

RATIO OR SPEED B

POTENTIOMETER

CW

M2 POTENTIOMETER CONNECTIONS

J5

J4

J3

T

O

R

Q

U

E

S

PEED

INDEP.

RATI

O

DE

C

E

L

CO

A

ST

PINS

1

2

3

Bison Gear & Engineering Corp.

3850 Ohio Ave. -- St. Charles, IL 60174

Phone: 1-800-AT-BISON

www.bisongear.com

Document Number: 250-0415; Revision 0 -- May 2006

The Company warrants to the Buyer the products sold hereunder to be free of defects in material and workmanship under normal use and service for a

period of one (1) year from the date of shipment. The obligation of the Company under this warranty is limited to repair or replacing at its option, any part

or parts, which upon examination shall disclose to the reasonable satisfaction of the Company to have been defective in material or workmanship. Buyer

must return the products to the Company’s factory, shipping charges prepaid, and with complete information as to alleged defects and the installation,

operation and service of the products. Except as otherwise expressly stated herein the Company makes no representation of warranty of any kind, express

or implied, as to merchantability, fitness for a particular purpose, or any other matter with respect to the products sold hereunder.