Bison NVH-150-T User manual

NVH-240-T ...harvesting better implements!

O P E R A T O R ’ S

M A N U A L

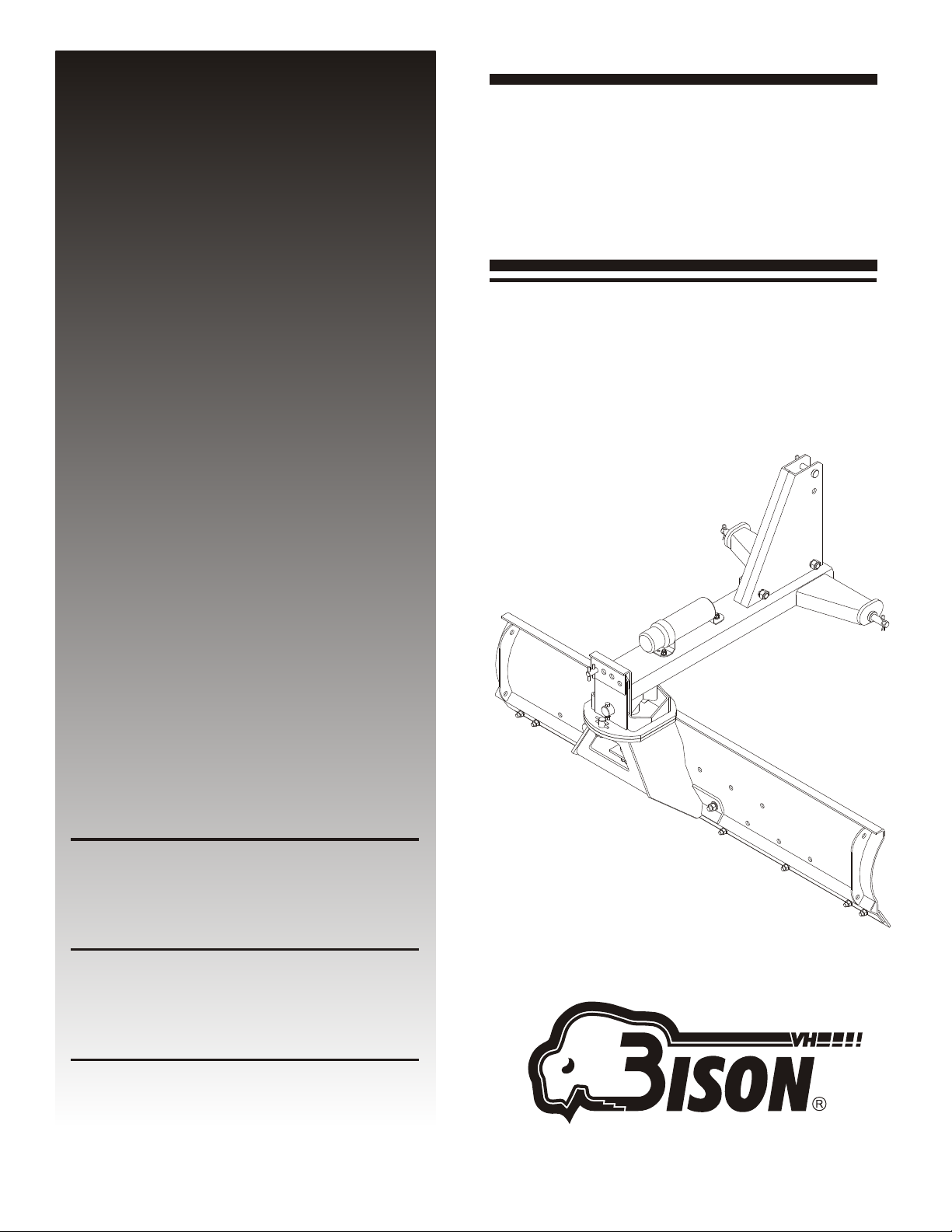

REAR

BLADES

REAR

BLADES

4350-2113-00 (Rev. 09/06/04)

NVH-210-T

NVH-180-T

NVH-150-T

This Safety-alert Symbol indicates a hazard and means

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Indicates an imminently hazardous situation that, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury, and includes hazards that are

exposed when guards are removed.

Indicates a potentially hazardous situation that, if not avoided, may

result in minor or moderate injury.

Indicates that failure to observe can cause damage to equipment.

Indicates helpful information.

IMPORTANT

NOTE

DANGER

WARNING

CAUTION

TO THE DEALER:

VH

Assembly and proper installation of this product is the responsibility of the BISON dealer. Read manual instructions

and safety rules. Make sure all items on the Dealer's Pre-delivery and Delivery Check Lists in the Operator's Manual

are completed before releasing equipment to the owner.

VH

The dealer must complete the Warranty Registration, located on the BISON website. Warranty claims will be denied

if the Warranty Registration has not been completed.

TO THE OWNER:

VH

Read this manual before operating your BISON equipment. The information presented will prepare you to do a better

and safer job. Keep this manual handy for ready reference. Require all operators to read this manual carefully and

become acquainted with all the adjustment and operating procedures before attempting to operate. Replacement

manuals can be obtained from your selling dealer.

The equipment you have purchased has been carefully engineered and manufactured to provide dependable and

satisfactory use. Like all mechanical products, it will require cleaning and upkeep. Lubricate the unit as specified.

Observe all safety information in this manual and safety decals on the equipment.

VH VH

For service, your authorized BISON dealer has trained mechanics, genuine BISON service parts, and the necessary

tools and equipment to handle all your needs.

VH

Use only genuine BISON service parts. Substitute parts will void the warranty and may not meet standards required for

safe and satisfactory operation. Record the model number and serial number of your equipment in the spaces

provided:

Model: Date of Purchase:

Serial Number: (see Safety & Instructional Decals section for location)

Provide this information to your dealer to obtain correct repair parts.

Throughout this manual, the term IMPORTANT is used to indicate that failure to observe can cause damage to

equipment. The terms CAUTION, WARNING, and DANGER are used in conjunction with the Safety-alert Symbol, (a

triangle with an exclamation mark), to indicate the degree of hazard for items of personal safety.

ii

Introduction

4350-2113-00 (Rev. 09/06/04)

GENERAL INFORMATION

The purpose of this manual is to assist you in oper-

ating and maintaining your rear blade. Read it

carefully. It furnishes information and instructions

that will help you achieve years of dependable per-

formance. These instructions have been compiled

from extensive field experience and engineering

data. Some information may be general in nature,

due to unknown and varying operating conditions.

However, through experience and these instruc-

tions, you should be able to develop procedures

The illustrations and data used in this manual were

current at the time of printing. However, due to pos-

sible inline production changes, your machine may

vary slightly in detail. We reserve the right to rede-

sign and change the machines as may be neces-

Throughout this manual, references are made to

right and left direction. These are determined by

standing behind the tractor facing the direction of

forward travel.

sary without notification.

suitable to your particular situation.

TABLE OF CONTENTS

INTRODUCTION

GENERAL INFORMATION

SPECIFICATIONS

SAFETY RULES

SAFETY & INSTRUCTIONAL DECALS

OPERATION

OWNER SERVICE

ASSEMBLY

PARTS INDEX

BOLT TORQUE CHART

BOLT SIZE CHART & ABBREVIATIONS

WARRANTY

ii

1

2

3

5

7

13

15

26

31

32

33

1

General Information

4350-2113-00 (Rev. 09/06/04)

NVH-150-T / NVH-180-T / NVH-210-T / NVH-240-T

SPECIFICATIONS

NVH-150-T

Manually

adjusted angle,

tilt and offset

Cat. 1

iMatch Compatible

Formed steel

channel frame

½" x 6" reversible

360 Degrees

3, up to 53

degrees each

side

3, up to 53

degrees each

side

1/4"

60"

17"

Progressive-formed

Full bend

6" or 12" left or right

65HP (2WD)

60HP (4WD)

3, up to 22

degrees up

and down

392 lbs.

*Tecnomec Agricola, S.A. de C.V. reserves the right to make any changes deemed necessary to

the specifications without prior notice.

NVH-180-T

Manually

adjusted angle,

tilt and offset

Cat. 1

iMatch Compatible

Formed steel

channel frame

½" x 6" reversible

360 Degrees

3, up to 53

degrees each

side

3, up to 53

degrees each

side

1/4"

72"

17"

Progressive-formed

Full bend

6" or 12" left or right

65HP (2WD)

60HP (4WD)

3, up to 22

degrees up

and down

422 lbs.

NVH-210-T

Manually

adjusted angle,

tilt and offset

Cat. 1

iMatch Compatible

Formed steel

channel frame

½" x 6" reversible

360 Degrees

3, up to 53

degrees each

side

3, up to 53

degrees each

side

1/4"

84"

17"

Progressive-formed

Full bend

6" or 12" left or right

65HP (2WD)

60HP (4WD)

3, up to 22

degrees up

and down

448 lbs.

Models

Features & Specifications

Angle, tilt, & offset

Hitch compatibility

Frame

Cutting edge

Angle/Pivot

Angle-Forward

Angle-Reverse

Moldboard thickness

Moldboard length

Moldboard height

Moldboard type

Moldboard upper edge

Offset (or swing)

Tractor max. HP

Tilt

Operating weight

NVH-240-T

Manually

adjusted angle,

tilt and offset

Cat. 1

iMatch Compatible

Formed steel

channel frame

½" x 6" reversible

360 Degrees

3, up to 53

degrees each

side

3, up to 53

degrees each

side

1/4"

96"

17"

Progressive-formed

Full bend

6" or 12" left or right

65HP (2WD)

60HP (4WD)

3, up to 22

degrees up

and down

476 lbs.

1

General Information

4350-2113-00 (Rev. 09/06/04)

TRAINING

Safety instructions are important! Read all

attachment and power unit manuals; follow all

safety rules and safety decal information.

(Replacement manuals are available from your

dealer). Failure to follow instructions or safety

rules can result in serious injury or death.

If you do not understand any part of this manual

and need assistance, see your dealer.

Know your controls and how to stop engine and

attachment quickly in an emergency.

Operators must be instructed in and be capable

of the safe operation of the equipment, its

attachments, and all controls. Do not allow anyone

to operate this equipment without proper

instructions.

Never allow children or untrained persons to

operate equipment.

PREPARATION

Check that all hardware is properly installed.

Always tighten to torque chart specifications

unless instructed otherwise in this manual.

Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head.

Make sure attachment is properly secured,

adjusted, and in good operating condition.

Power unit must be equipped with ROPS or

ROPS cab and seat belt. Keep seat belt securely

fastened. Falling off power unit can result in death

from being run over or crushed. Keep foldable

ROPS systems in “locked up” position at all times.

Make sure all safety decals are installed.

Replace if damaged. (See Safety & Instructional

Decals section for location).

A minimum 20% of tractor and equipment

weight must be on the tractor front wheels when

attachments are in transport position. Without this

weight, tractor could tip over, causing personal

injury or death. The weight may be attained with a

loader, front wheel weights, ballast in tires or front

tractor weights. Weigh the tractor and equipment.

Do not estimate.

OPERATION

Do not allow bystanders in the area when

operating, attaching, removing, assembling, or

servicing equipment.

Do not operate equipment while under the

influence of alcohol or drugs.

Operate only in daylight or good artificial light.

Keep hands, feet, hair, and clothing away from

equipment while engine is running. Stay clear of all

moving parts.

(Safety Rules continued on next page)

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Safety is a primary concern in the design and

manufacture of our products. Unfortunately, our

efforts to provide safe equipment can be wiped

out by an operator’s single careless act.

In addition to the design and configuration of

equipment, hazard control and accident prevention

are dependent upon the awareness, concern,

judgement, and proper training of personnel

involved in the operation, transport, maintenance,

and storage of equipment.

It has been said “The best safety device is an

informed, careful operator.” We ask you to be that

kind of operator.

2

Specifications

4350-2113-00 (Rev. 09/06/04)

This manual suits for next models

3

Table of contents

Other Bison Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions