Bison SVH-1 User manual

Models

SUBSOILER OPERATOR’S MANUAL

Part No.

4350-2135-01

SVH

SVH

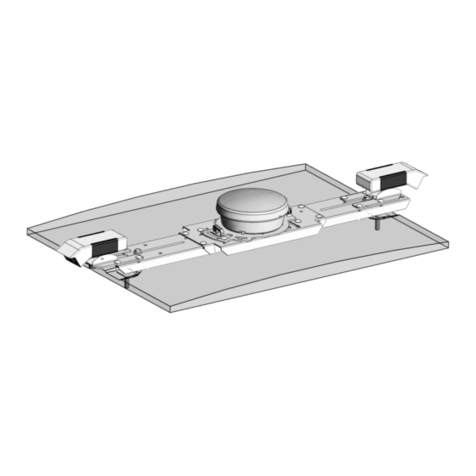

SVH-1 SVH-5/3 SVH-9/5

READ THIS MANUAL carefully to learn how to operate and service your

machine correctly. Failure to do so could result in personal injury or equipment

damage.

THIS MANUAL SHOULD BE CONSIDERED a permanent part of your

machine and should remain with the machine when you sell it.

MEASUREMENTS in this manual are given in both metric and customary U.S.

unit equivalents. Use only correct replacement parts and fasteners.

RIGHT-HAND AND LEFT-HAND sides are determined by facing in the

direction the implement will travel when going forward.

.

INTRODUCTION

4350-2135-01 (Rev. 17/10/12)

!!

TO OUR CUSTOMERS:

Congratulations for acquiring a Bison® product.

We are confident in your excellent decision to purchase Bison®equipment,

and are honored to have you as our valued customer.

Your dealership shall make the technical pre-delivery of your equipment,

and a trained technician shall provide you maintenance and operation

instructions contained in this manual. Get in contact with your dealership

representative if you have questions regarding your equipment or need

specialized help.

We recommend that you read this manual before operating the equipment.

Therefore, the time you take to learn about all maintenance features,

adjustments and recommendations will result in the long, efficient life of

your equipment.

This equipment is covered by a warranty duration provided by your Bison®

authorized dealer at the purchase or technical delivery of same.

Bison®is a Brand of Tecnomec Agrícola, S.A. de C.V., Aguascalientes,

México.

GENERAL INDEX

INTRODUCTION

GENERAL INFORMATION

SPECIFICATIONS

SAFETY RULES

OPERATION

MAINTENANCE

TROUBLESHOOTING

ASSEMBLY

PARTS INDEX

BOLT TORQUE CHART

WARRANTY

!!

01

06

07

11

14

16

17

26

36

39

OPERATOR’S MANUAL

If this manual is lost or destroyed

a new copy can be requested to:

TECNOMEC AGRICOLA S.A. DE C.V.

Carr. a Paso Blanco, Km 2 No. 400

Col. Vista Hermosa, Jesús María

Aguascalientes, México. C.P. 20905

Tel. 01 (449) 922 47 66, 922 47 60

Fax 01 (449) 922 47 67

SVH Subsoilers are designed to work safely, however, please note the

following considerations:

Read this manual thoroughly for information on the proper operation and maintenance of your

Subsoiler.

Note the serial number at the end of the warranty section to aid in the recovery of the machine

in the event of theft. Keep this manual in a safe place. It should not be kept on the machine.

The cautious operator is the best guarantee against any accident, as improper operation of

these machines can cause serious injury or even death.

Make sure that there are no people near the equipment before starting the subsoiling work.

Be cautious when making adjustments and avoid accidents when handling Subsoiler

components.

To achieve a more efficient and higher quality subsoiling, it is important to read and follow the

adjustment and operation instructions of your Subsoiler, since a properly adjusted implement

saves time, labor and fuel.

After each day, clean and inspect your Subsoiler for possible faults.

GENERAL INFORMATION

01

Tecnomec Agricola offers original spare parts, thru authorized

dealers.

Our trained personnel, is well versed on methods to service to

your equipment. If you need additional information or custom

assistance please contact your Bison authorized dealership

or directly to TECNOMECAGRÍCOLA S.A. DE C.V.

YOUR AUTHORIZED DISTRIBUTOR

TECNOMEC AGRÍCOLA, S.A. DE C.V.

IT IS THE POLICY OF TECNOMEC AGRICOLA TO

CONTINUOUSLY IMPROVE ITS PRODUCTS AND

RESERVES THE RIGHT TO MAKE CHANGES TO ITS

SPECIFICATIONS OR DESIGN WITHOUT INCURRING

IN THE OBLIGATION TO APPLY THEM TO UNITS

ALREADY SOLD.

CURRENT MODELS MAY VARY IN SOME DETAILS

GIVEN CONTINUOUS IMPROVEMENT TO WHICH OUR

PRODUCTS ARE SUBMITTED.

*Some pictures show equipment that is not necessarily

included as part of the standard machine.

02

GENERAL INFORMATION

LISTS OF INSPECTION

PRE-DELIVERY INSPECTION MADE BY BISON DEALERSHIP

After the Subsoiler has been completely adjusted, check it and make sure it is ready for proper

operation before delivering it to the customer. The following list is a reminder of the items to

inspect. Check each item if it has been found satisfactory or after the proper adjustments have

been made.

■ Make sure that the Subsoiler has been properly assembled.

■Verify that the bolts, nut and set screws are tight.

■Verify that the shanks have been installed to the customer's desired rotation width.

■Clean the Subsoiler and touch up any places where the paint is lifted or scratched.

■Make sure all decals are properly positioned and undamaged.

■Ensure that the machine carries the options that the customer requires.

Date of Assembly___________Name and Signature of Technician_______________

03

DELIVERY BY BISON DEALERSHIP

The following list is an important information reminder to be transmitted directly to the

Client at the moment of the delivery of the Subsoiler.

Check that each point was duly explained to the client.

■Point out to the Client that useful life of this or any other machine is dependant of proper

lubrication as described on its Operator's Manual. Hand your Client the Operator's Manual

and fully explain all operations, lubrication and maintenance adjustments.

■Explain the importance of a proper and safe operation of the machine. Stress the

importance of labels as those prevent the operator from hazards due to unsafe operation

procedures and conditions.

■Notify the client of accessories or options available.

■When Subsoiler is transported on roads or highways during the day or the night, adjust

lights or safety devices to alert operators of other vehicles. Recommend your client to

check local official transit regulations.

■Show the client how to mount the machine.

■Notify your client of serial number of its Subsoiler on the space provided at the end of

this operator's Manual.

■Complete Delivery and warranty forms, listing serial number of machine.

■Give details on the warranty. Make a format for execution by the Client and dealership.

■Machinery is being delivered ready to use and the Client has been informed about its

operation and care.

Date of Delivery___________Name and Signature____________________

OWNER REGISTRATION

Name

City

State

Serial number

Model number

Purchase date

LISTS OF INSPECTION

04

LISTS OF INSPECTION

POST-SALES INSPECTION

It’s advised that the following items are constantly checked during first hours of operation.

■Fully check the machinery and certify there are no damaged parts.

Repair or change if necessary. AII guards shall be in place.

■Check there are no loose or missing screws. lf possible, operate Subsoiler to check proper

operation.

■Check during Subsoiler operation that there is no interference between hoses and mobile

parts that can be damaged.

■Check the operator's manual in full with your client and highlight importance of a regular and

proper lubrication as well as safety precautions.

Inspection Date____________ Name and Signature___________________________

MORNING OPERATION INSPECTION

Lube all points in need of daily lubrication and those that require lubrication at a recommended

time.

■Ensure all screws are complete and parts tight.

■ Check that mounting components are safe.

SEASONAL INSPECTION

■Check general state of Subsoiler (normal wear and tear, no bumps, no leaks in ducts, etc.)

■ Ensure that proper lubrication has been made.

■ Ensure that the proper operating adjustments are made.

05

06

* Tecnomec Agricola, S.A. de C.V. reserves the right to make any changes deemed necessary to the specifications

without prior notice.

* Some pictures may include options that are not a part of the standard equipment.

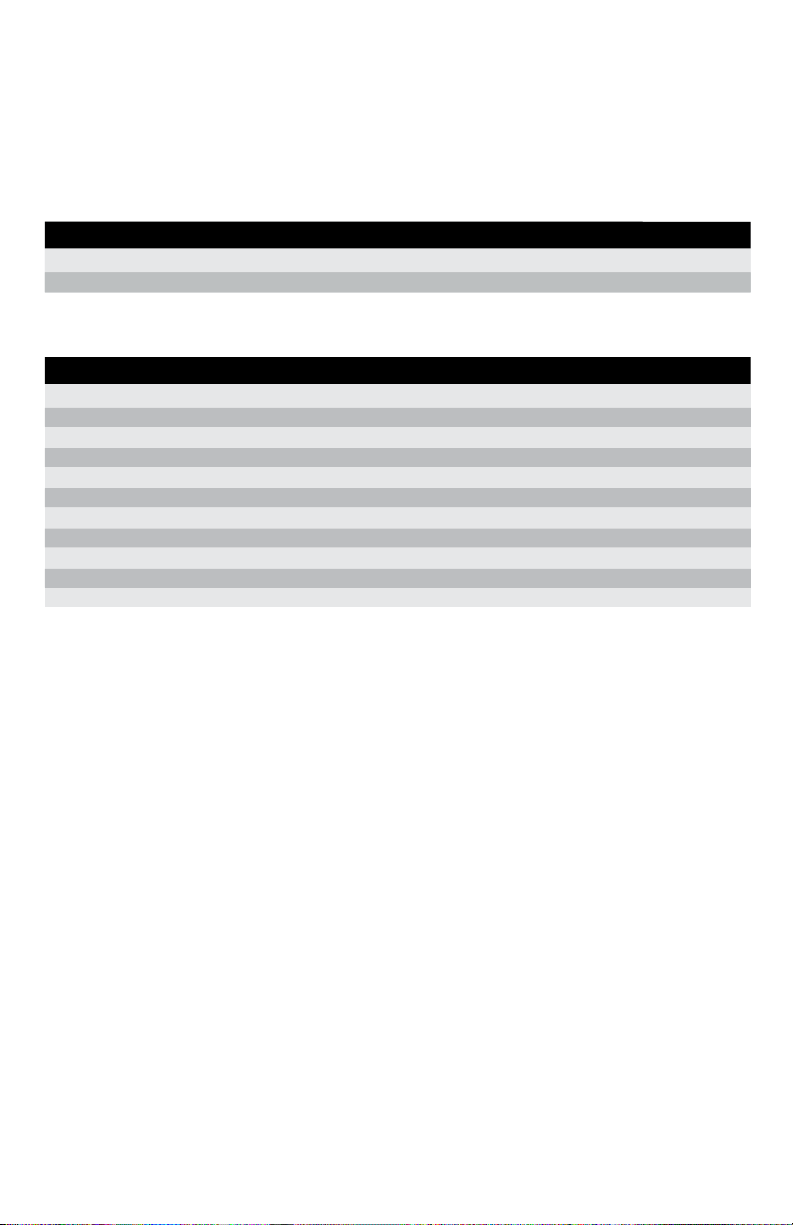

SUBSOILER SVH SERIES SPECIFICATIONS

Number of shanks

Shank width

Number of shank positions

Maximum penetration

Work depthness

Working width

Required power

Parking stand

Hitch

Approximate weight

Distance between shanks

in

in

in

in

hp

lbs

in

1

1 1/4

Fixed Position

18

14

25

25-45

Standard

3 - point cat. I & II

220

SPECIFICATIONS

Soil pulverizer

Multi-tiller points

AVAILIABLE ATTACHMENTS

1

2

SVH-1

No

No

SVH-1 SVH-5-3 SVH-9-5

5

1 1/4

9

18

14

94 1/4

100-125

Standard

3 - point cat. II

1119

15 & 18 1/2

3

1 1/4

5

18

14

73

65-90

Standard

3 - point cat. II

672

19 1/2 & 23 1/2

SVH-5-3

Yes

Yes

SVH-9-5

Yes

Yes

SAFETY RULES

This is the safety-alert symbol which means ATTEN-

TION! BE ALERT! YOUR SAFETY IS INVOLVED!

This safety alert symbol indicates important safety

messages in this manual. When you see this

symbol, carefully read the message below and be

alert to the possibility of personal injury or death.

DISTINGUISH SAFETY MESSAGES

Whenever you see the words and symbols shown

ahead and used in this manual, you MUST consider

the instructions as they are related to personal

safety.

DANGER: Indicates an imminently hazardous

situation which, if not avoided, will result in DEATH

or SERIOUS INJURY.

WARNING: Indicates a potentially dangerous

situation, if not avoided, could result in DEATH or

SERIOUS INJURY.

CAUTION: Indicates a potentially hazardous

situation which, if not avoided, could result in

MINOR INJURIES.

OBSERVE THE SAFETY MESSAGES

Before operating this equipment carefully read all

safety messages in this manual and on your

machine safety signs.

It is YOUR responsibility to read and comprehend

the safety section on this manual. Remember that

YOU are key in following safety messages. Good

safety practices not only protect you, but those who

are nearby. Study all aspects of this manual and

make them part of your safety program. Note that

this section of security is only created for this type of

equipment. Put into practice other procedures and

above all usual precautions, REMEMBER THAT

SAFETY IS YOUR RESPONSIBILITY. YOU CAN

AVOID SERIOUS INJURY OR DEATH. This security

section is meant to highlight some of the basic safety

situations that may occur during normal operation

and maintenance of this equipment, suggesting

possible ways to handle these situations. This

section does NOT replace the safety procedures that

appear in other sections of this manual.

NOTE: This handbook covers general security

practices for this equipment.

SAFETY RULES

07

DANGER

WARNING

CAUTION

SAFETY RULES

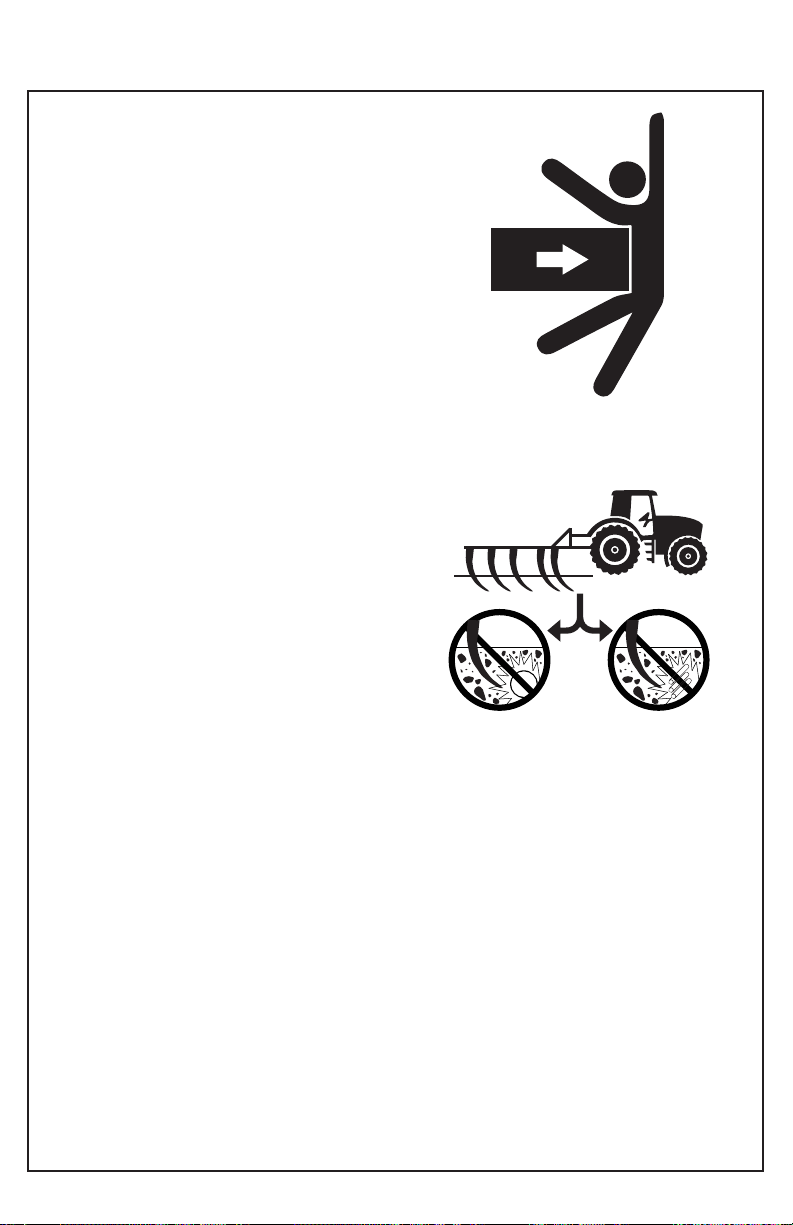

PASSENGERS ARE NOT ALLOWED IN THE

MACHINE

Only allow the operator on the machine.

Riders on machine are subject to injury such as

being struck by foreign objects and being thrown off

of the machine. Riders also obstruct the operators

view resulting in the machine being operated in an

unsafe manner.

BE PREPARED IN CASE OF EMERGENCY

Due to the flammable nature of many substances,

there should be a fire extinguisher within reach of

the operator.

Have on hand a first-aid kit for minor cuts and

scratches.

Keep the local emergency numbers near you.

WEAR APPROPIATE CLOTHING

Avoid wearing loose fitting clothing, use proper

safety equipment according to the type of work. The

safe operation of the equipment requires full

attention of the operator. Do not use headphones to

listen to the radio when traveling on roads.

USE SAFETY LIGHTS AND ACCESSORIES

Slow moving vehicles, tractors, trailed or suspend-

ed equipment can pose a risk when being transport-

ed or towed on a highway because they are difficult

to see, especially at night. Avoid injury or even

death that can result from a collision with other

vehicles.

It is recommended to use safety lights and accesso-

ries when driving on public roads. To improve

visibility, use all lights available on the tractor. The

additional installation of rotating warning lights is

recommended. Check that the signaling devices are

in good condition.

Replace lost or damaged safety attachments,

warning devices immediately.

08

WARNING WARNING

SAFE MAINTENANCE

Familiarize yourself with the maintenance

procedures before performing the work. The work

area must be clean and dry.

Do not carry out any greasing, repair or adjustment

work with the engine running.

Keep hands, feet and clothing away from moving

parts at all times. Put all controls in neutral to relieve

pressure. Lower all equipment to the ground. Stop

the engine. Remove the ignition key and wait for the

engine to cool.

Carefully support all machine parts being lifted for

maintenance work.

All components must be in good condition and

correctly installed. Repair damage immediately.

Replace any worn or broken parts. Keep all

machine components clean of grease, oil and

accumulated dirt.

CORRECT USE OF SEAT BELTS

Do not use a seat belt when working with a machine

that is not equipped with a rollover protector.

Transport the Subsoiler at a maximum of 10 mph.

Reduce speed when traveling over rough terrain.

Always drive at a speed that allows you to have

adequate steering and brake control.

09

SAFETY RULES

SAFETY WHEN OPERATING UNDERGROUND

Never ride or allow others to ride on the Subsoiler.

Move anyone away from the shanks when the

equipment is in operation.

Never stand in the way of the shanks when servic-

ing, as this could cause an accident.

Always lower the Subsoiler to the ground when not

in use.

Install front counterweights for optimum tractor

stability.

AVOID OBSTRUCTING ELECTRICAL, GAS OR

WATER LINES

Contact local government companies to determine

the location of electric, gas or water lines.

10

SAFETY RULES

TRACTOR PREPARATION

REQUIRED POWER

For recommended tractor power refer to the

specifications table in the specifications section.

(page 06).

REAR COUNTERWEIGHTS

When additional weight is required or instead of

liquid weight, cast iron counterweights can be

bolted to the rear tires.

Use rear counterweights to stabilize the tractor on

uneven terrain or hillsides, and to eliminate exces-

sive tire slippage. Counterweights should not be

added to the point of completely eliminating

skidding.

Tractor tires should be inflated to the pressure

recommended in your operator's manual.

FRONT COUNTERWEIGHTS

Add weight, if necessary, to the front of the tractor

for stability.

To improve tractor handling, remove front weights

when they are not needed.

Refer to the tractor operator's manual for adding

front weight.

Observe rear wheel tracks. When the tractor is

operating at optimum load, the ground between the

tire treads should be broken or sectioned (A).

If too much counterweight has been added, the

track marks will be crisp and clear (B).

If too little counterweight has been added, the track

marks will be almost blurred (C). Refer to the tractor

operator's manual.

11

OPERATION

ABC

12

SUBSOILER HITCHING TO TRACTOR

CAUTION: To avoid personal injury or machine

damage when an implement is hitched, place the

tractor transmission in the park position and check

for interference along the hitch.

Do not stand between the tractor and implement.

The sides of the tractor and implement are the only

access for connecting and disconnecting the hitch

points.

Slowly back the tractor into the Subsoiler, making

sure that the hitch points are aligned.

2. Place the transmission in park position.

3. Shut off the tractor engine.

4. Remove the pins from the Subsoiler side and

center hitches.

5. Align the tractor lift arms with the side hitches and

install the bolts.

6. Hitch the third point arm to the hitch plates and

install the bolt.

7. Start the tractor engine.

8. Slowly move the swing axle position control lever

to raise the implement. Check that there is no

difference.

9. Lower the implement to ground level, place the

transmission in park position and proceed to level

the Subsoiler by adjusting both lift arms to the same

length.

10. Finally adjust the third point arm (lengthen or

shorten) as required to achieve longitudinal leveling

of the Subsoiler.

OPERATION

TRANSPORTING SUBSOIL SAFELY

CAUTION: The Subsoiler should not be

transported at a speed greater than 10 mph, in

order to prevent accidents.

Higher speeds may result in loss of control of the

tractor if any of the outside rudders contact any

uneven ground surface.

Always drive at a speed that allows you to have

adequate steering and brake control.

When transporting the Subsoiler on a road or

highway at night or during the day, use lights and

devices for adequate warning to operators of other

vehicles. In this regard, check your local govern-

ment regulations for proper use. A machine that is

not properly illuminated could cause an accident,

which could result in serious injury or death to you

or others.

1. To obtain more lift from the Underlayment when

transporting, shorten the lift joints and center arm to

their minimum length, or hook the lift arms into the

lower holes in the hitch plates.

2. Place in transport position (upward) the rudders.

13

LATERAL SUBSOILER LEVELING

Lateral leveling is controlled by the tractor lift arms.

Make sure that the main body of the Subsoiler is

parallel to the ground so that all tiller arms rotate to

the same depth.

After the tiller arms have penetrated the ground and

you have set the working depth, stop the tractor and

stand behind the Subsoiler to confirm that the main

body is parallel to the ground.

If the main body is not parallel to the ground, raise

the implement and adjust the tractor hitch arms until

the Subsoiler is level.

LONGITUDINAL LEVELING OF THE SUBSOILER

Longitudinal leveling is controlled by the tractor's

center hitch arm.

To determine if the Subsoiler is level longitudinally,

observe the main body while working under load.

Make sure that all rudders are at the same level.

It is more efficient to work the Subsoiler when all

shanks are level.

If the main body is not level longitudinally raise the

Subsoiler and adjust it by lengthening or shortening

the third point arm.

OPERATION

14

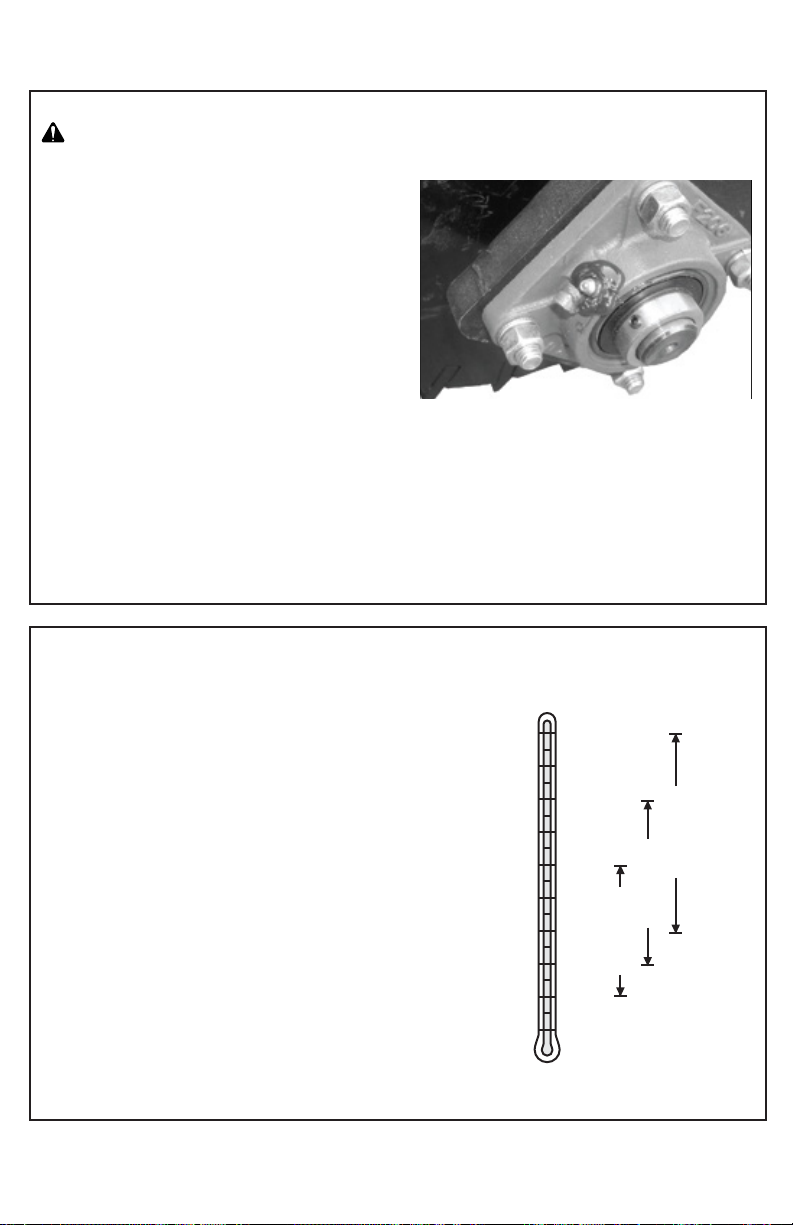

LUBRICATION

CAUTION: Do not clean, lubricate or adjust the

machine when in motion.

IMPORTANT: The recommended periods are based

on normal operating conditions. In severe or

non-normal conditions, more frequent lubrication will

be necessary.

IMPORTANT: Clean the grease fittings before using

the grease gun. Replace any missing or broken grease

fittings immediately.

Lubricate the lump braker roller bearings before each

day's work. Apply grease until it comes out of the

gasket. Rotate the roller 2 or 3 times.

This process will extend the life of the bearings.

CORRECT USE OF SEAT BELTS

Do not use a seat belt when working with a machine

that is not equipped with a rollover protector.

Transport the Subsoiler at a maximum of 10 mph.

Reduce speed when traveling over rough terrain.

Always drive at a speed that allows you to have

adequate steering and brake control.

GREASE

Choose the most suitable type of grease according to

the NLGI consistency and the temperatures that may

occur in the interval until the next grease change.

You can use greases that meet the following standard:

NLGI consistency classification GC-LB.

Alternative and synthetic lubricants

Conditions in certain geographical areas may require

the use of special lubricants or lubrication techniques

not listed in the operator's manual.

Some lubricants may not be available in the area. In

this case, consult your distributor, who will provide you

with the most up-to-date information and

recommendations.

Lubricant Storage

Your equipment can operate at maximum efficiency

only if you use clean lubricant.

Use clean containers to handle all lubricants and store

them in an area protected from dust and moisture.

MAINTENANCE

50°C

40°C

30°C

20°C

10°C

0°C

-10°C

-20°C

-30°C

-40°C

122°C

104°C

86°C

68°C

50°C

32°C

14°C

-4°C

-22°C

-40°C

NLGI Number 0

NLGI Number 1

NLGI Number 2

15

MAINTENANCE

B

A

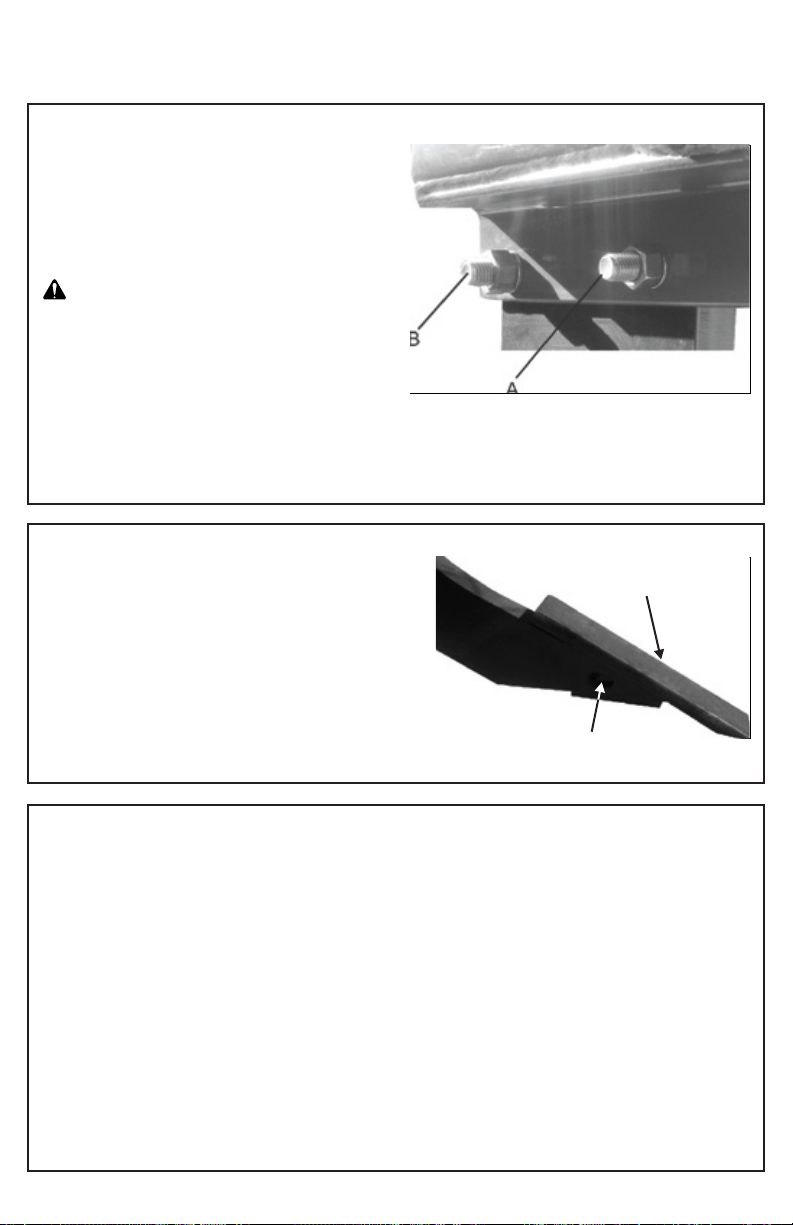

FUSIBLE SCREW

The SVH-1 Subsoiler tiller is equipped with a fusible

safety screw (A).

This bolt will break if the tiller accidentally runs into

rocks, logs, roots, etc.

This protects the Subsoil and the tractor from possible

serious damage.

CAUTION: To avoid accidents, do not attempt to

remove a broken fusible link if the tiller is in a horizontal

position (tip up). With extreme caution, place the tiller

in the vertical (normal) position before replacing the

fusible safety plug.

IMPORTANT: The fusible safety bolt (A) must be

replaced with a grade 5 fusible safety bolt, do not use

any other hardness grade. After replacing the fusible

safety bolt, retighten the rudder bolt (B) according to

the bolt tightening specifications table on page 36.

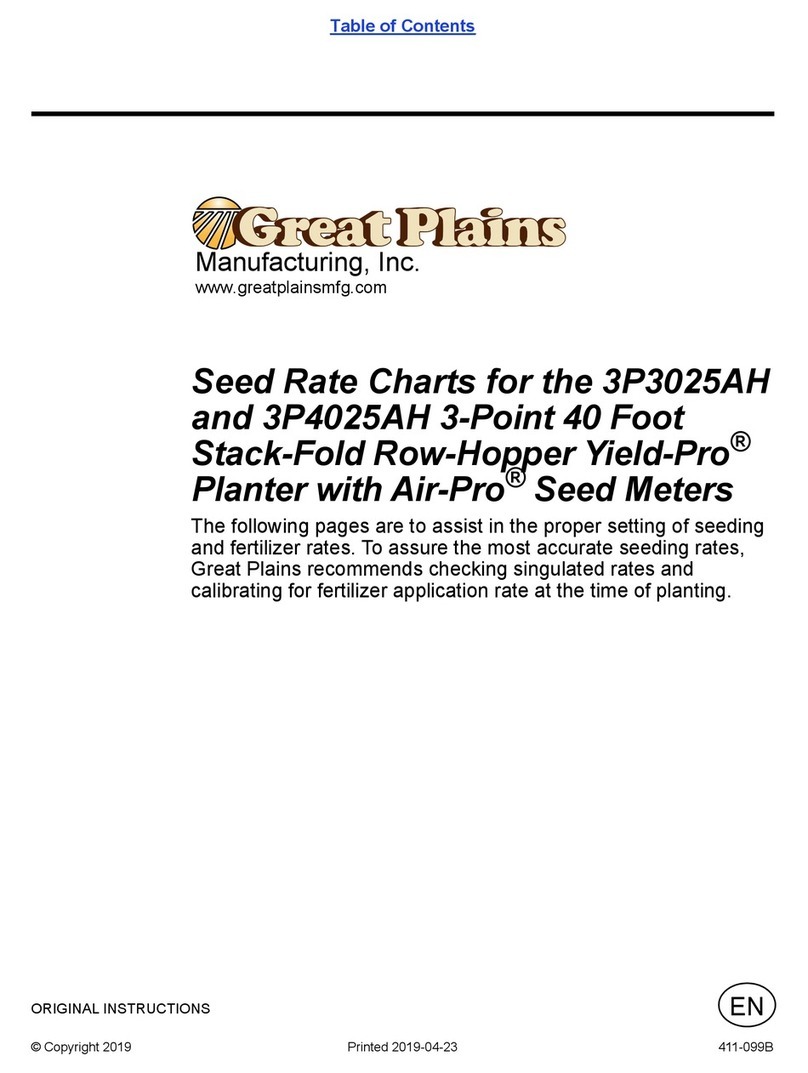

REPLACEMENT OF THE TIPS

The replaceable scarifier tip (A) on the shanks (Shoe)

allows you to replace it with a new one when a tip has

been damaged, broken or worn.

To replace a tip, drive the pinch pin (B) out from

between the tip and the rudder with a 10 mm (3/8") pin

punch. Do not use a tapered punch.

Remove the damaged tip and install a new tip on the

chisel. Place the pinch bolt through the new tip and

shank.

KEEP THE SUBSOILER AVAILABLE

Thoroughly clean the Subsoiler before storing it.

Protect shanks and scarifying tips from corrosion by

applying a light coat of oil or grease.

Apply a good anti-corrosive when storing the Suboiler

for the next season.

After storage: Clean accumulated dust from moving

parts to prevent abrasion and excessive wear.

Inspect the Subsoiler thoroughly. Check for loose parts

and adjust if necessary.

This manual suits for next models

2

Table of contents

Other Bison Farm Equipment manuals

Popular Farm Equipment manuals by other brands

GREAT PLAINS

GREAT PLAINS Yield-Pro 3P3025AH manual

Art's-Way Manufacturing

Art's-Way Manufacturing 7165 Operator's manual

Guide Gear

Guide Gear 702141 quick start guide

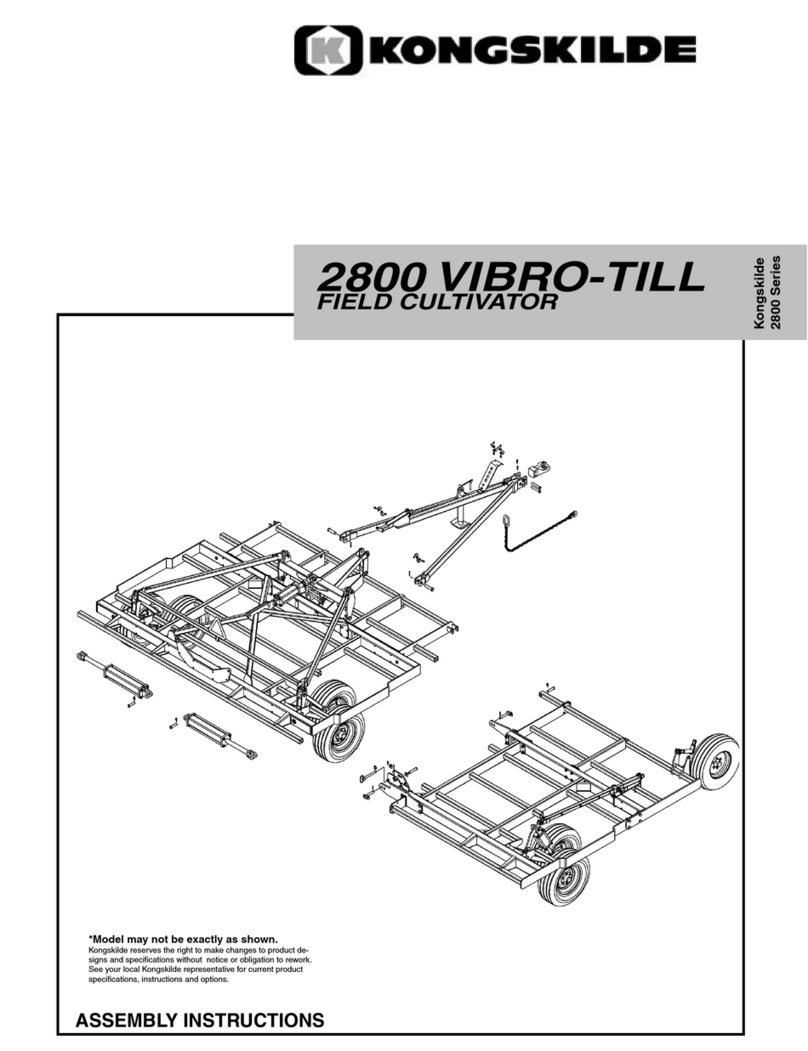

Kongskilde

Kongskilde 2800 SERIES Assembly instructions

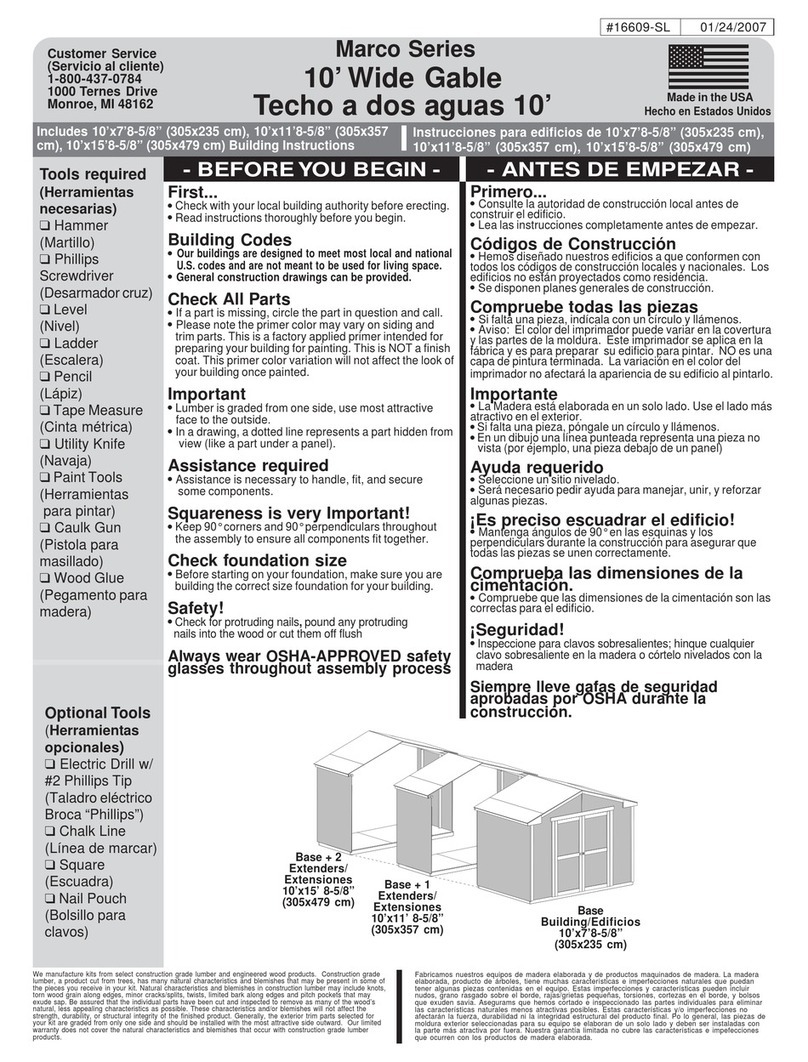

Backyard Discovery

Backyard Discovery Marco Series manual

dosatron

dosatron DosaCart Assembly instructions

Vicon

Vicon Andex 844 Assembly instructions

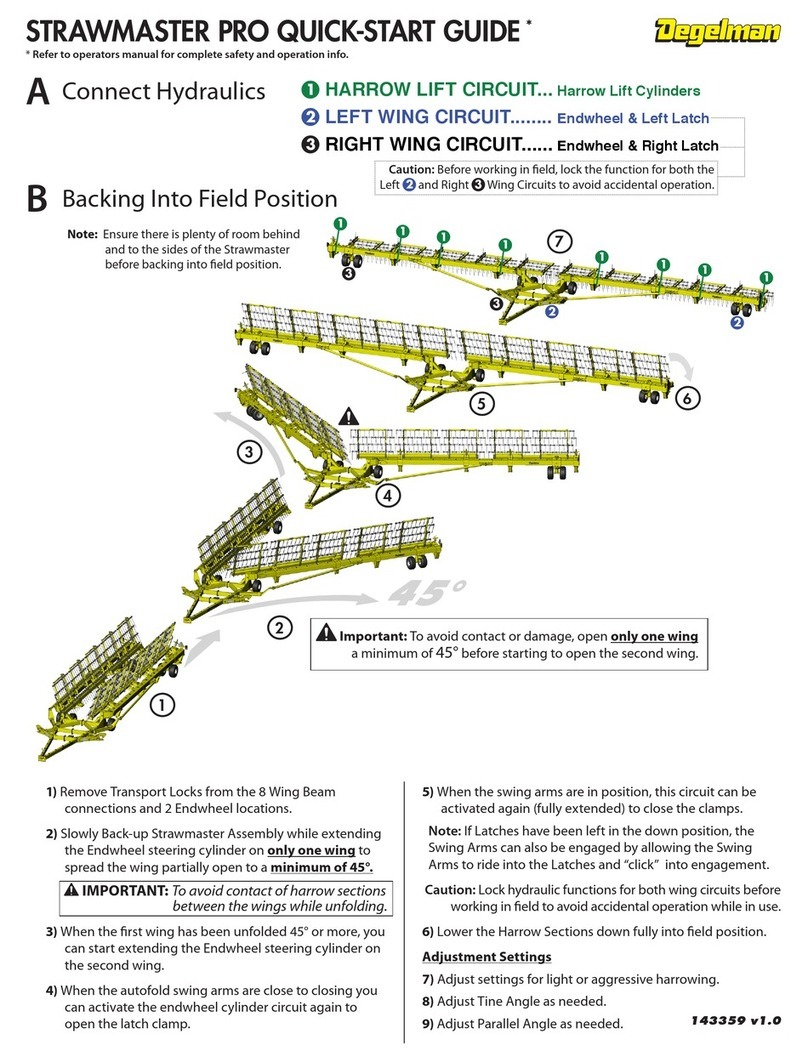

Degelman

Degelman STRAWMASTER PRO Series quick start guide

Topcon

Topcon CropSpec AGA5408 Operator's manual

Art's-Way Manufacturing

Art's-Way Manufacturing 6812 quick start guide

SaMASZ

SaMASZ KW 141 Operator's manual

GREAT PLAINS

GREAT PLAINS Terra Max HT1100-20 Operator's manual