Table of contents page

1. IDENTIFYING THE MACHINE .....................................................................................................................5

2. INTRODUCTION ........................................................................................................................................6

3. INTENDED USE .........................................................................................................................................6

3.1. Technical data.....................................................................................................................................7

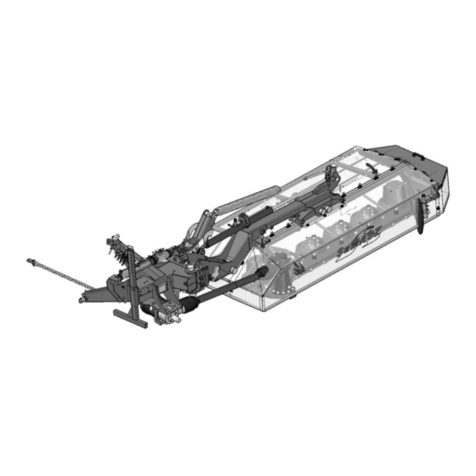

3.2. Design and working principle..............................................................................................................11

3.2.1. Extension arm...............................................................................................................................11

3.2.2. Mowing head................................................................................................................................16

3.2.3. Mounting mowing heads ...............................................................................................................19

3.3. Characteristics of hydraulics of extension arm....................................................................................20

3.4. Standard equipment and spare parts ..................................................................................................22

3.4.1. Flails applied in mowing heads......................................................................................................22

4. SAFETY PRECAUTIONS ...........................................................................................................................24

4.1. Safety rules and regulations...............................................................................................................24

4.2. Operator's qualifications ....................................................................................................................26

4.3. Conditions of mounting machine on tractor ........................................................................................26

4.4. Transport ..........................................................................................................................................26

4.4.1. Putting the machine onto another vehicle for transport...................................................................26

4.5. Working parts ....................................................................................................................................28

4.6. PTO shaft ..........................................................................................................................................28

4.7. Hydraulic assembly............................................................................................................................28

4.8. Residual risk......................................................................................................................................29

4.8.1. Residual risk assessment..............................................................................................................30

4.9. Safety decals and their meaning.........................................................................................................31

5. OPERATION............................................................................................................................................34

5.1. Mounting arm on tractor ....................................................................................................................34

5.1.1. Connecting the articulated telescopic shaft (PTO)..........................................................................34

5.2. Preparing machine for transport.........................................................................................................35

5.3. Preparing the extension arm with mowing head for work .....................................................................38

5.4. Operation ..........................................................................................................................................38

5.4.1. General information about mowing................................................................................................38

5.4.2. Operating positions.......................................................................................................................39

5.4.3. Operating control panel.................................................................................................................40

6. MOUNTING AND ADJUSTMENTS.............................................................................................................46

6.1. Mounting and dismounting flail head ..................................................................................................46

6.2. Mounting flail heads ..........................................................................................................................46

6.3. Adjusting flail head mowing height .....................................................................................................49

6.4. Replacing knives in mowing adapter...................................................................................................49

6.5. Operating hydraulics ..........................................................................................................................50

6.5.1. Oil tank with equipment.................................................................................................................50

6.5.2. Oil shut-off valve...........................................................................................................................51

6.5.3. Multiplier with pump set................................................................................................................51

6.5.4. Suction filter CCA 302 CD1............................................................................................................52

6.5.5. Control distributors.......................................................................................................................52

6.5.6. Initial regulations..........................................................................................................................53

6.5.7. Safety valves ................................................................................................................................54

6.5.8. Hydraulic engine...........................................................................................................................54

6.6. Manual control of electrical and electrical-proportional distributor.......................................................55