ENGLISH (Original instructions)

8

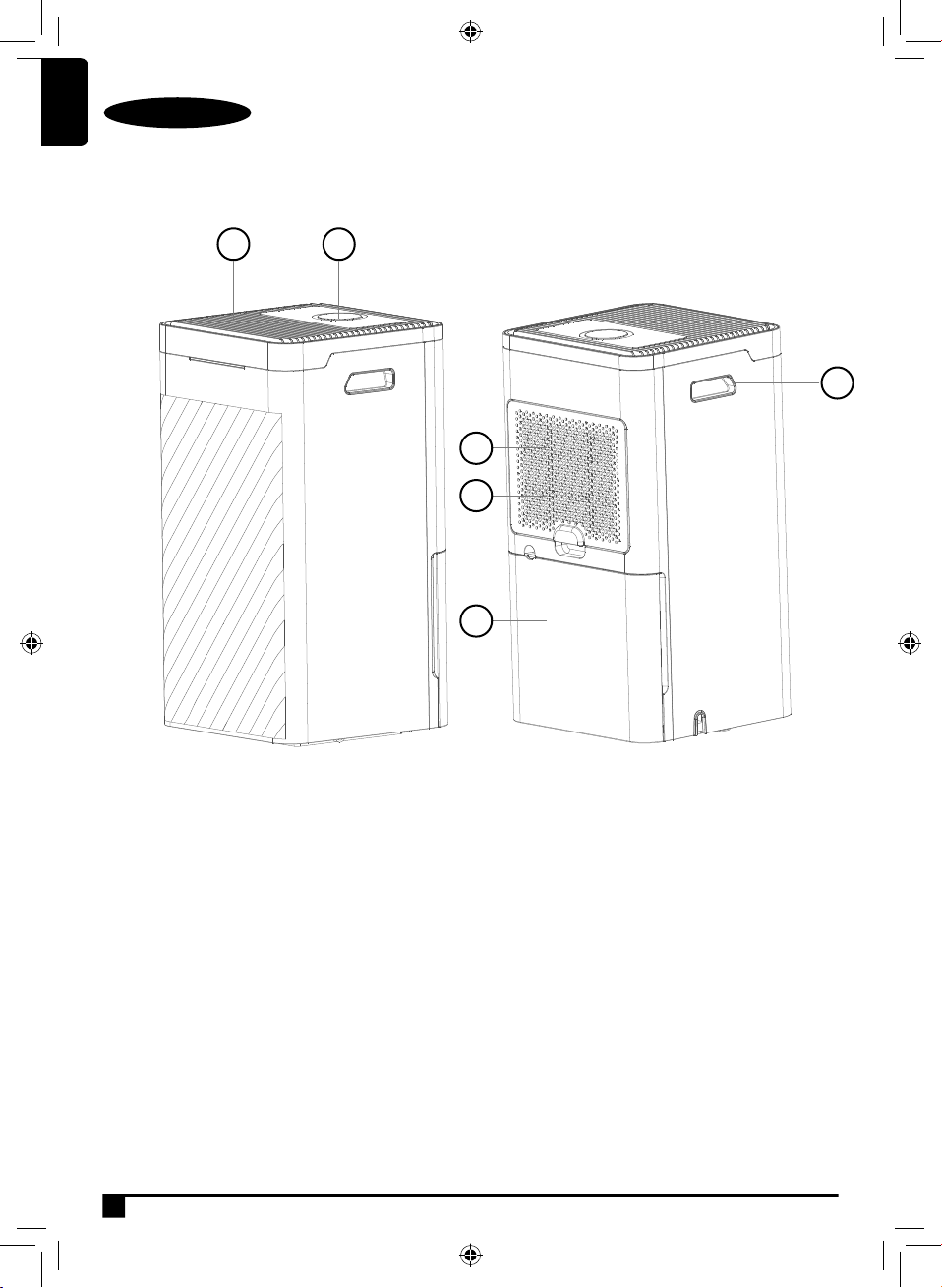

Control Panel

1. Low fan speed indicator

2. High fan speed indicator

3. Fan speed selector

4. LED display (Humidity, Timer & Modes)

5. Defrost indicator

6. Water tank full indicator

7. Sleep button

8. Timer button

9. Humidity & timer touch control slider

10. Mode button

11. ON/OFF button

Turning The Unit On Or Off

Note: To avoid damage, place the unit in an upright

position for at least 24 hours before rst use.

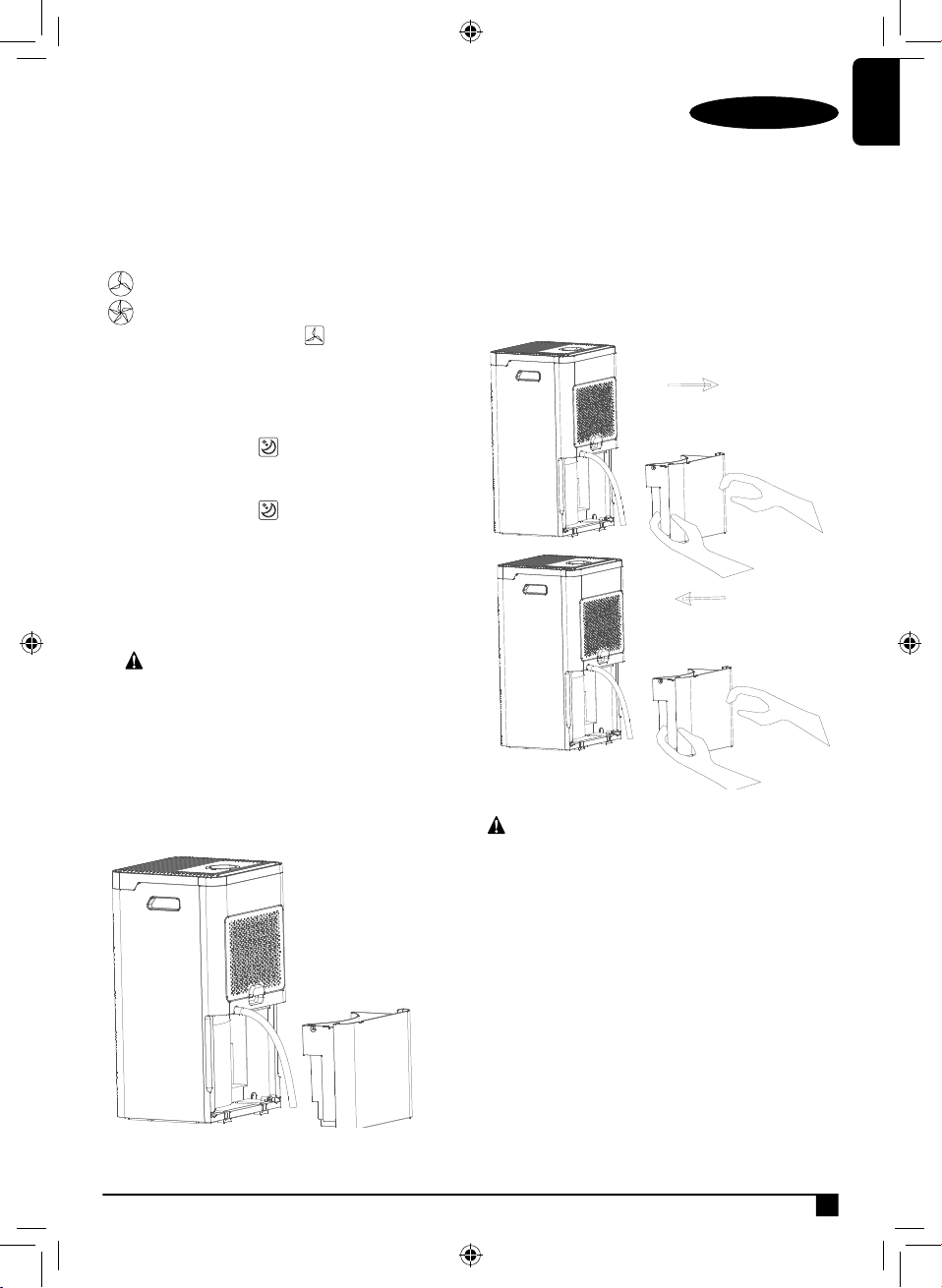

Note: Always ensure the water tank is empty and in

place before turning the unit on.

Note: During the operation, keep doors and

windows closed to save energy.

♦ To power the unit on, rst plug it into a mains

socket. A single beep will be heard. The unit will

be in stand-by mode.

♦ Press the ON/OFF button to turn the unit on.

The ON/OFF button and the fan speed light on the

unit’s control panel will illuminate and air will start

emitting from the top grille. The display screen will

show the current room humidity %.

♦ Press the ON/OFF button again to power the unit

off. Air will stop emitting from the grille to show the

unit has been powered down. All lights will go off.

♦ To shut the unit off completely, unplug it from the

mains socket.

WARNING: DO NOT store the unit immediately

after turning it off. Allow time for the unit to cool

down before storing.

Dehumidification Modes

There are 4 modes to select from:

- Normal dehumidication – adjustable fan

speed and adjustable humidity

- Continuous dehumidication – a set low fan

speed and humidity is not adjustable

- Ventilation mode – adjustable fan speed and

humidity is not adjustable

- Drying mode –a set high fan speed and set

humidity is not adjustable

Press the mode button to cycle through the

options, respective symbols will show in the display.

The mode selected will ash for 5 seconds and then

remain visible in the display.

Humidity Setting

♦ In Normal dehumidication mode, slide your nger

across the symbol horizontally to set

the humidity between 30%-80% (in increments

of 5%).

♦ The humidity selected will ash for 5 seconds in

the display.

♦ The display will then show the room’s current

humidity.

♦ To check the humidity selected at any time, press

the humidity setting symbol and it will ash in the

display for 5 seconds.

Timer Operation

♦ Whilst the unit is operating the timer is used to set

the time to turn the appliance off.

♦ Whilst the unit is in stand-by mode the timer is

used to set the time to turn the appliance on.

♦ Press the timer button to select a time

between 1-24hrs.

♦ With each press of the timer button the time will

increase by 1 hour. The time selected will ash for

5 seconds and the will illuminate in the display.

♦ To check the time selected at any time, press the

timer button and it will ash in the display for 5

seconds.

41 52 63

7 8 9 10 11