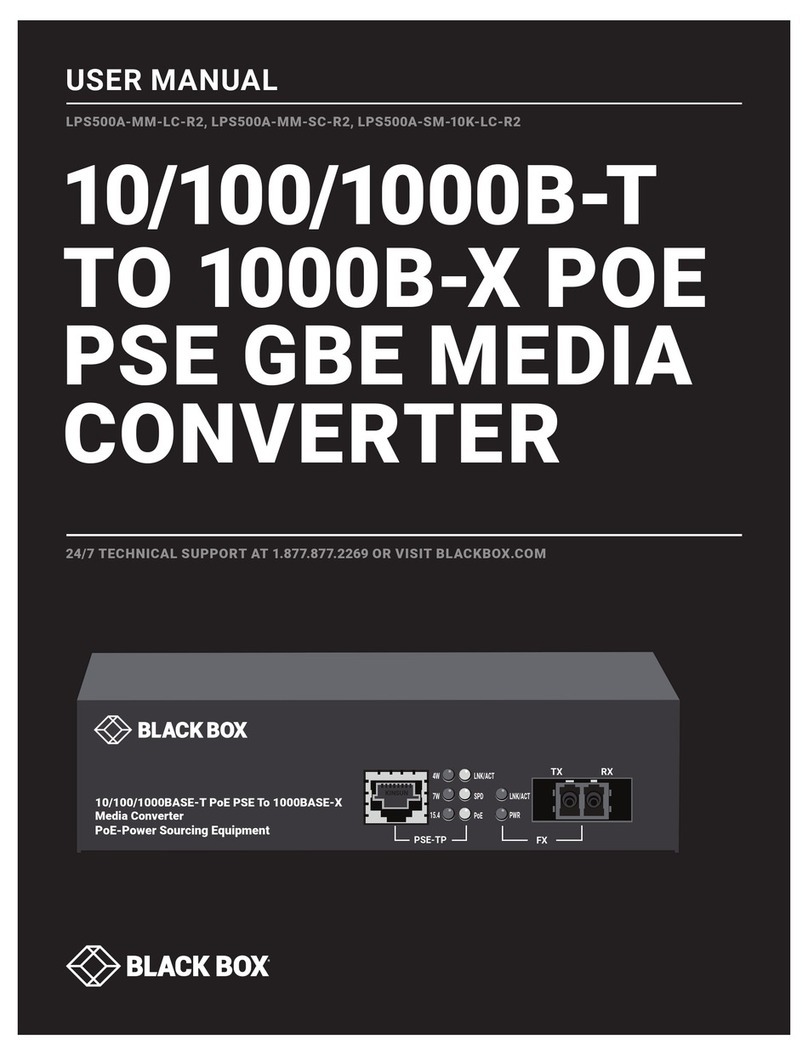

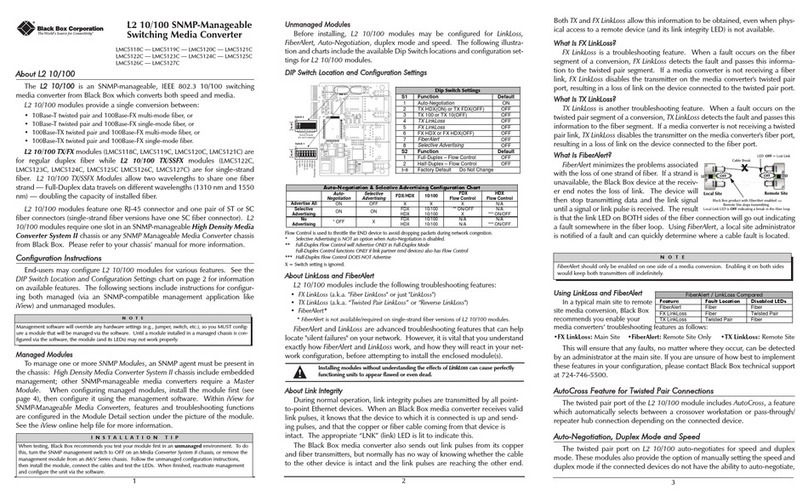

LED Indicators

L1 Gigabit features several diagnostic LEDs.

The LED functions are as follows:

TWISTED PAIR PORT

ACT Glows yellow when data is detected on the port.

LNK Glows green when a twisted pair link is established.

FDX Glows green when operating in Full-Duplex mode.

PWR Glows green when unit has power.

FIBER PORT

ACT Glows yellow when data is detected on the port.

LNK Glows green when a fiber link is established.

FA Glows green when FiberAlert is enabled.

Specifications

Environmental

Operating Temperature: 32°- 104°F (0°- 40°C)

Storage Temperature: 0°- 160°F (-20°- 70°C)

Humidity: 5 - 95% (non-condensing)

Power

AC Input Load: 100/240V±10% ~ 50/60 Hz, 0.2/0.1A

Heat Generated: 50 BTU/hr.

Dimensions

1.50”H x 4.65”W x 4.43”D (3.8 cm x 11.8 cm x 11.3 cm)

1.3 lbs. (0.6 kg)

Fiber Optic Specifications

For fiber optic specifications, please contact Black Box

45

Black Box Customer Service Information

CALL: (724) 746-5500 7 a.m. Monday to midnight Friday; 8 a.m. to

4 p.m. Saturday (EST)

FAX: (724) 746-0746 7 a.m. Monday to midnight Friday; 8 a.m. to

4 p.m. Saturday (EST)

Mail Order: Black Box Corporation,

1000 Park Drive, Lawrence, PA 15055-1018

Technical support, phone and fax orders 24 hours a day.

Fiber Optic Cleaning Guidelines

Fiber Optic transmitters and receivers are extremely susceptible to contamination by

particles of dirt or dust, which can obstruct the optic path and cause performance

degradation. Good system performance requires clean optics and connector ferrules.

1) Use fiber patch cords (or connectors, if you terminate your own fiber) only from a

reputable supplier; low-quality components can cause many hard-to-diagnose

problems in an installation.

2) Dust caps are installed by the manufacturer to ensure factory-clean optical

devices. These protective caps should not be removed until the moment of con-

necting the fiber cable to the device. Assure that the fiber is properly terminated,

polished and free of any dust or dirt, and that the location is as free from dust and

dirt as possible.

3) Store spare caps in a dust-free environment such as a sealed plastic bag or box so

that when reinstalled they do not introduce any contamination to the optics.

4) Should it be necessary to disconnect the fiber device, reinstall the protective dust

caps.

5) If you suspect that the optics have been contaminated, alternate between blasting

with clean, dry, compressed air and flushing with methanol to remove particles of

dirt.

Electrostatic Discharge Precautions

Electrostatic discharge (ESD) can cause damage to your add-in modules. Always

observe the following precautions when installing or handling an add-in module or any

board assembly.

1) Do not remove unit from its protective packaging until you’re ready to install it.

2) Wear an ESD wrist grounding strap before handling any module or component. If

you do not have a wrist strap, maintain grounded contact with the system unit

throughout any procedure requiring ESD protection.

WARNING! Integrated circuits and fiber optic components are extremely susceptible to electrostatic dis-

charge damage. Do not handle these components directly unless you are a qualified service technician and

use tools and techniques that conform to accepted industry practices.

3) Hold boards by the edges only; do not touch the electronic components or gold

connectors.

4) After removal, always place the boards on a grounded, static-free surface, ESD

pad or in a proper ESD bag. Do not slide the board over any surface.

Please contact Black Box for complete warranty, FCC and Safety Certification information.

6

1000 Park Drive •Lawrence, PA 15055-1018 USA

TEL: (724) 746-5500 •FAX: (724) 873-7049

© 2002 Black Box Corp. All rights reserved.

The information in this document is subject to change without notice. Black Box assumes no responsibility for any errors

that may appear in this document. Product names are trademarks of the manufacturer. Other brands or product names

may be trademarks and are the property of their respective companies.

Document Number 55-80910BB-00-A0 October 2002