Black Diamond Equipment BDPM-60 User manual

INSTRUCTION MANUAL

BDPM-60

60 Qt. Planetary Mixer

This manual contains important information regarding your Black Diamond unit. Please read this

manual thoroughly prior to equipment set-up, operation and maintenance. Failure to comply

with regular maintenance guidelines outlined in this manual may void the warranty.

March 2019

WARNINGS

•

Do not immerse unit, cord or plug in liquid at any time

•

Unplug cord from outlet when not in use and before cleaning

•

Plug only into a 3-hole grounded electrical outlet of appropriate voltage

•

Do not operate unattended

•

Do not use this unit for anything other than intended use

•

Do not use outdoors

•

Always use on a firm, dry and level surface at least 12” from walls or any other obstruction

•

Do not use if unit has a damaged cord or plug, in the event the appliance malfunctions, or has been damaged in any

manner

•

Keep children and animals away from unit

•

Any incorrect installation, alterations, adjustments and/or improper maintenance can lead to property loss and

injury. All repairs should be done by authorized professionals only

•

Ensure that the designated power supply is adequate for continual usage

•

Do not hose down mixer

•

Do not operate with wet hands

•

Unplug from the electrical supply prior to any maintenance or repairs

TO INSTALL:

1. Remove unit from box and make sure all plastic, tape and packing materials are removed.

2. Place the unit on a flat, secure surface with at least 12” of open space around all sides.

3. Check to make sure the outlet of the correct voltage for this item (220V) is near. Do not use an extension cord, this

item must be plugged directly into an outlet.

STANDARD ACCESSORIES - This mixer comes with one of each of the following accessories:

When mixing always use the correct agitator for the job. To install agitator raise into the mixing axle and rotate

clockwise on the shaft until it locks into place. To remove an agitator, raise it on the shaft until it clears the lock and

rotate counterclockwise and lower. All of the accessories are fitted to the mixing bowl for precise use.

Flat Beater - Used for mixing dry ingredients and can work on all speeds. Do not run for more than 15 minutes.

Dough Hook - Used for mixing dough and can work in low and medium speeds only. Do not use on high speed. Do

not run for more than 20 minutes.

Wire Whip - Used for mixing liquids and soft ingredients and can work in all speeds. Do not run for more than

15 minutes.

NOTE: Always stop the machine first before changing speeds in order to avoid damage to the unit’s gears. Always

ensure that the bowl is fully lifted and the wire guard is closed when in use.

•

Slow speed is the middle setting (Dough hook setting with the knob facing forward)

•

Medium speed is the bottom setting (Flat beater setting with the knob facing down)

•

High speed is the top setting (Wire Whip setting with the knob facing up)

Flat Beater Dough Hook

Wire Whip

Mixing Bowl

March 2019

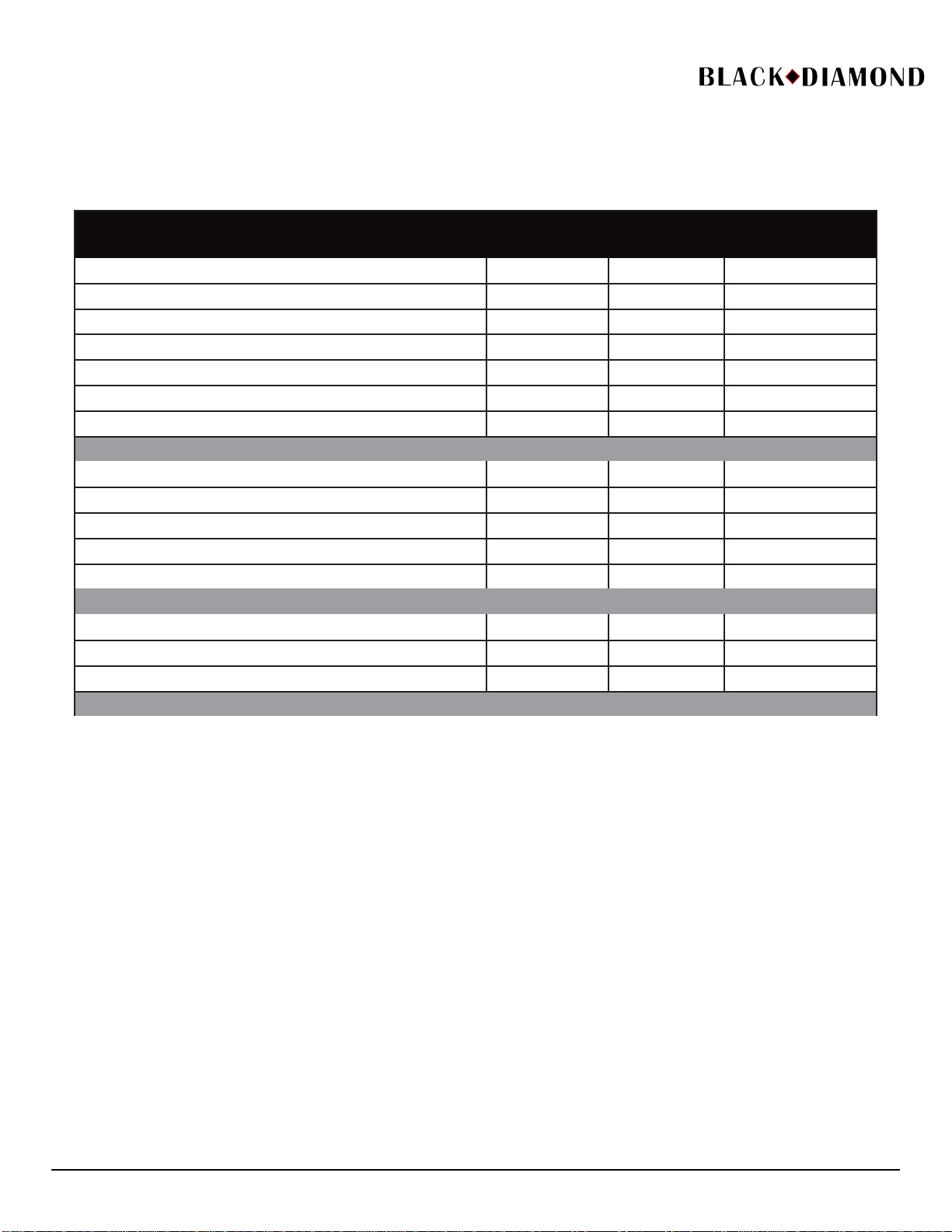

MIXER CAPACITY CHART

Product

Agitator

Speed

Max Bowl

Capacity (60 qt)

Bread and roll dough - 60% AR *•◊

Dough hook

1st only

80 lbs

Heavy bread dough - 55% AR *•◊

Dough hook

1st only

70 lbs

Pasta Basic Egg Noodle

Dough hook

40 lbs

Pizza dough, thin - 40% AR *X•◊□

Dough hook

1st only

40 lbs

Pizza dough, medium - 50% AR *•◊□

Dough hook

1st only

70 lbs (1st)/35lbs (2nd)

Pizza dough, thick - 60% AR *•◊

Dough hook

1st only

70 lbs

Raised donut dough - 65% AR *◊

Dough hook

1st and 2nd

60 lbs

Mashed potatoes

Flat beater

40 lbs

Waffle or Hotcake batter

Flat beater

24 qts

Egg whites

Wire whip

2 qts

Meringue (Qty. of water)

Wire whip

1

3/4

qts

Whipped cream

Wire whip

12 qts

Fondant Icing

Flat Beater

36 lbs

Cake

Flat beater

60 lbs

Pie Dough

Flat beater

50 lbs

* NOTE: The mixer capacity depends on the moisture content of the dough. When mixing doughs (pizza, bread, or bagels)

remember to check your AR%!

%AR (% Absorption Ration) = Water weight divided by flour weight. The capacities listed in the cart above are based on flour

at room temperature and 70˚F water temperature

XMaximum Mixing Time – 7 minutes

• If high gluten flour is used, reduce the batch size by 10%

◊If using chilled flour, water below 70˚F, or ice, reduce batch size by 10%

□ 2nd speed should never be used on 60% AR or lower with the exception of the BDPM-60. BDPM-60 requires a 50% reduction

in batch size to mix in speed 2 with 50% AR doughs.

Helpful measurements for calculating the correct size mixer for your application

8.3 lbs = 1 gallon of water - 2.08 lbs = 1 Quart

NOTES:

•

Do not use attachments on the #12 hub while mixing

March 2019

TO USE:

1. Plug the unit into an outlet of the appropriate voltage.

2. With unit turned off insert the mixing bowl into the holder in the down position and align on the pins. Once bowl is

securely aligned on pins, lock into place with the side clips.

3. Insert the desired agitator onto the mixing axle and turn to lock into place as directed on page 2.

4. Once the bowl and agitator are locked into place, add ingredients to the bowl and raise the bowl by pulling the bowl

lift handle towards you until it hits its full raised position.

5. Adjust your speed setting for the correct application by turning the knob to the correct position as described on

page 2.

6. Set the timer for the desired mixing time. The timer has two settings; turn the dial to the left for manual run or you

can turn the dial to the right to a desired set time for mixing. Once the timer goes off the machine will shut down.

The timer must be set to one of these settings or the machine will not operate.

7. With bowl in the fully raised position, the agitator locked into place and the correct speed setting selected, close the

wire guard over the bowl, set the timer and press the green power button to start mixing. The wire guard must be

closed fully for machine to operate.

8. Once mixing is completed, press the red stop button to stop the agitator.

9. Open the wire guard and lower the bowl to its lowest setting. If more mixing is needed repeat step 7.

NOTE: Always stop the machine before changing speeds.

Meat Grinder Attachment:

•

The Meat Grinder should only be used for purposes intended

•

Please remove bones, skins and any other foreign materials before grinding

•

Meats and other food should be defrosted and not used when frozen

•

For best results, cut the meat into smaller size pieces to fit easily through the feed tube

•

If not in use, please remove the meat grinder attachment from the unit

•

Do not run the grinder for longer periods of time then necessary

CLEANING - NOTE: To maintain cleanliness and increase service life, this item should be cleaned daily. Do not immerse the

unit in water or any other liquid, if liquid enters the electrical compartment it may cause a short circuit or electrical shock.

1. Before cleaning or attempting to move this item always turn off and unplug.

2. Wipe the entire unit with a clean soft cloth until it is completely dry.

3. To avoid damage to the unit, do not use abrasive cleaners or scouring pads.

4. If soap or chemical cleaners are used, be sure they are completely rinsed away with clean water immediately after

cleaning. Chemical residue could damage or corrode the surfaces of the unit.

5. After using of the machine, please remove the flat beater, dough hook, wire whip and meat grinder from the machine

and wash these parts thoroughly in hot, soapy water to prevent the growth of bacteria.

6. When clean and maintain the inside of the protective cover and swivel mount, please loosen the screw around the

protective cover and take off the protective cover. If there is no sign of oil leak, no need to take off the swivel mount.

Clean the swivel mount with a wet cloth, the protective cover can be cleaned by detergent and washed under the wa-

ter supply tap. After washing by clean water, use dry cloth to wipe out the water and make it dry.

To avoid serious injury or damage, never attempt to repair or replace a damaged power cord yourself. Contact a professional repair

service.

TO REMOVE GUIDE RAIL DUST GUARD PLATE FOR REGULAR CLEANING:

1. Rotate wheel to release bowl to the lowest position

2. Loosen screws on both sides of the guide rail dust guard plate

3. Remove the guide rail dust guard plate to clean, and ensure to clean inside the hole.

(Note: If screws are loosened manually, it is not necessary to remove the handwheel. If a power tool is used, the handwheel

must be removed first)

Net Weight: 661.5 lbs (300 KGS)

Dimensions: 30.5”x 26” x 52” (770 x 660 x 1315 mm)

March 2019

TROUBLESHOOTING

Problem

Possible Causes

Solution

The axles don’t work when

operating the machine

Electrical connection is not

good Check the plug in the outlet

Leaking oil

Oil gaskets are worn

out or damaged Replace the oil gasket(s)

Difficult to raise or lower the

bowl

Either the slideway is

corroded, or the lead screw,

bevel gear or hand wheel

shaft is dried out

Clean and oil the dried out

parts

Motor is overheating and

speed has decreased

The voltage is not enough,

incorrect speed is set or there

is too much food in the bowl

Check the voltage or adjust

the speed to a better setting.

If the bowl is overloaded,

remove some of the food to

lighten the load

Item is making too much

noise and overheating Poor lubrication Add or replace oil

Agitator touches bowl

Either the bowl or agitator

is deformed

Repair or replace deformed

part

Mixing bowl is out of position

Moving direction is not

correct Adjust position

March 2019

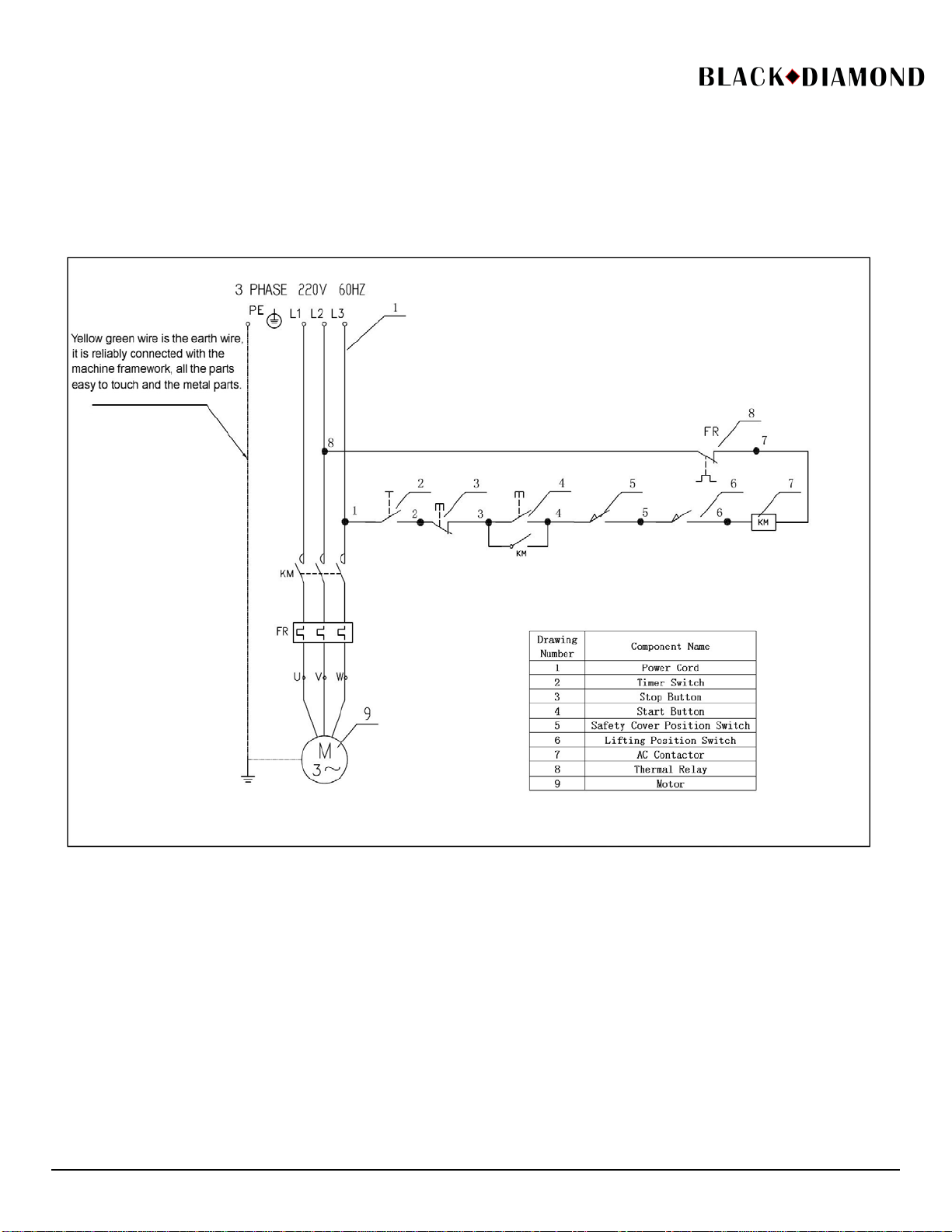

Wiring Diagram for the Planetary Mixer

March 2019

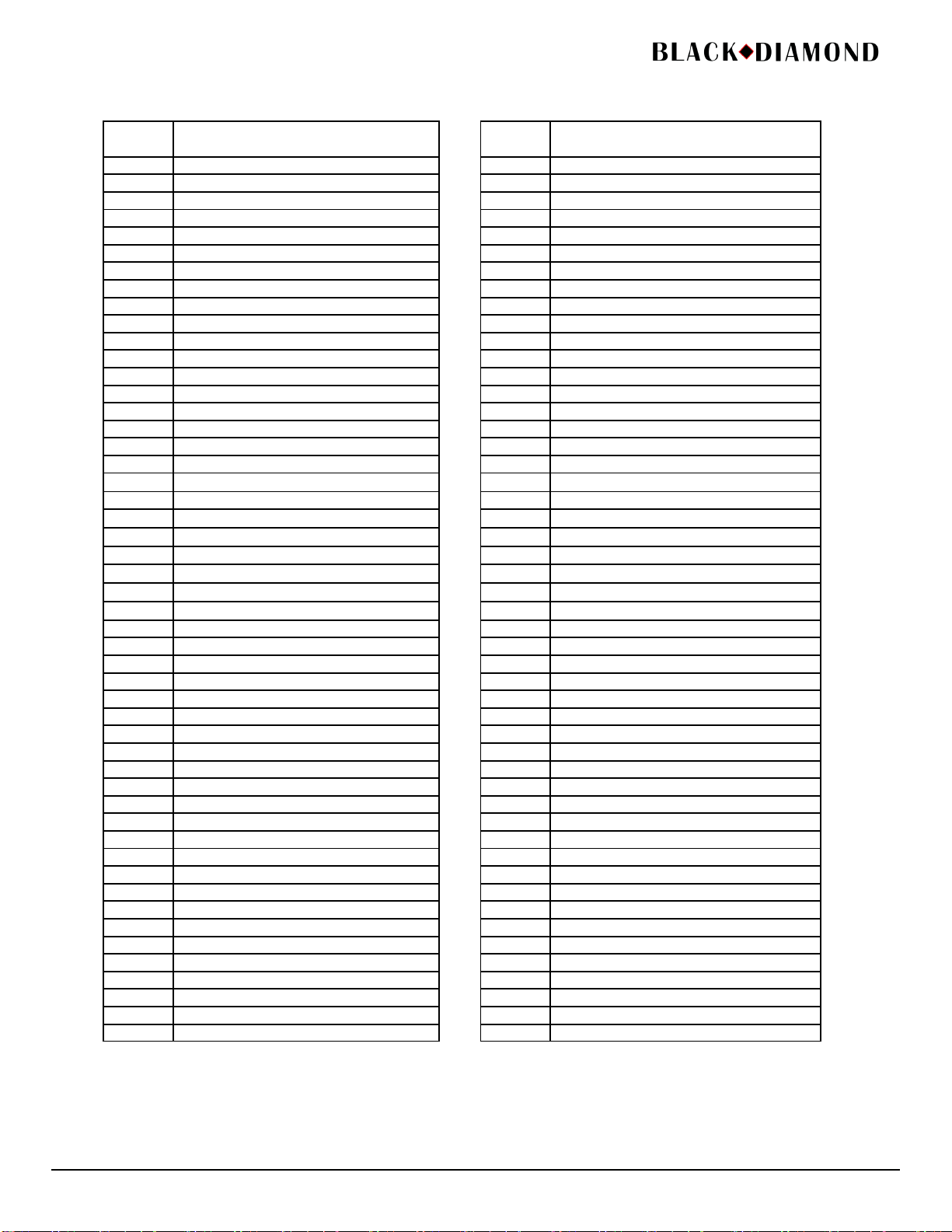

Parts Diagram and Replacement Parts for the Planetary Mixer

March 2019

Replacement Parts for the Planetary Mixer

Drawing

Number

Part Description

1

Timer

2 Start Button

3

Stop Button

4

Switch Panel

5 Convex Upper Cover

6

Large Flat Washer

7

Hex Bolt

8

Electrical Base Board

9

Cross Recessed Pan Head Screw

10 Hex Nut

11

Hex Nut

12

Spring Washer

13 Flat Washer

14

Electrical Base Board Fixed Rod

15

Thermal Relay

16 AC Contactor

17

Power Line Sheath

18

Power Line Sheath

19

Power Line Sheath

20 Synchronous Belt

21

Inner Hexagon Screw

22

Loose Rib

23

Hex Bolt

24

Motor Adjusting Base

25

Hex Bolt

26 Spring Washer

27

Motor Shaft Circlip

28

Motor Pulley

29

Flat Key

30

Hex Bolt

31

Spring Washer

32

Large Flat Washer

33 Motor

34

Casing

35

Data Plate

36

Hex Bolt

37

Power Line Sheath

38

Hex Bolt

39

Rear Cover Plate

40

Hex Bolt

41

Spring Washer

42

Bevel Gear Circlip

43 Lifting Bevel Gear

44

Rolling Bearing

45

Flat Key

46 Lifting Screw Arbor

47

Hex Bolt

48

Spring Washer

49

Bevel Gear Circlip

50 Lifting Bevel Gear

Drawing

Number

Part Description

51

Flat Key

52 Handwheel Shaft

53

Flat Key

54

Handwheel Shaft Fixing Base

55 Spring Washer

56

Inner Hexagon Screw

57

Elevating Handwheel

58

Shaft Circlip

59

Cross Recessed Countersunk Head Screw

60 Support Pillar

61

Base

62

Podotheca

63

Hex Bolt

64

Guide Rail Dust Guard Plate

65

Annular Gear

66 Inner Hexagon Screw

67

Front Cover

68

Inner Hexagon Screw

69

Locking Screw

70 Bevel Gear Base

71

O Ring

72

Oil Seal

73

Needle Roller Bearing Without Inner Ring

74

Plane Bearing

75

Passive Bevel Gear

76 Bearing Base Oil Hole Cover

77

Inner Hexagon Screw

78

Spring Washer

79

Loose Rib

80 Bearing Base

81

Handle Sleeve

82

Variable Speed Handle

83 Variable Speed Handle Base

84

Variable Speed Mandrel

85

Elastic Cylindrical Pin

86

Hex Bolt

87

Variable Speed Base

88

O Ring

89

O Ring

90 Position Limit Spring

91

Steel Ball

92

Eccentric Bushing

93 Shifting Fork Guide Rod

94

Shifting Fork Nut

95

Shifting Fork Spring

96 Shifting Fork Top Latch

97

Shifting Fork

98

Double-screw Bolt

99

Hex Nut

100

Protective Shield Position Switch Base

March 2019

Replacement Parts for the Planetary Mixer

Drawing

Number

Part Description

101

Position Switch

102 Cross Recessed Pan Head Screw

103

Hex Nut

104

Splitpin

105

Contact Terminal

106 Carrier Rod Base

107

Carrier Rod Spring

108

Carrier Rod

109 Hex Thin Nut

110

Spring Washer

111

Loose Rib

112

Passive Belt Wheel

113

Circlip For Hole

114

Rolling Bearing

115

Rolling Bearing

116 Input Shaft

117

Flat Key

118

Rolling Bearing

119 Bridge Shaft Dust Proof Cover

120 Hex Thin Nut

121

Small Flat Washer

122

Circlip For Hole

123

Rolling Bearing

124 Bridge Shaft

125 Flat Key

126 Flat Key

127

Bridge Shaft Big Gear

128 Bridge Shaft Sleeve

129 Bridge Shaft Small Gear

130

Shaft Circlip

131

Rolling Bearing

132 Hex Thin Nut

133

Loose Rib

134

Circlip For Hole

135 Rolling Bearing

136

Ratchet Upper Cover

137

External Star Wheel

138

Roller

139

Roller Spring

140

Clutch Inner Ring

141

Driving Bevel Gear

142 Upper Coupling Gear

143

Output Shaft Gear Sleeve

144

Clutch

145 Output Shaft

146

Flat Key

147

Flat Key

148

Flat Key

149

Flat Key

150

Output Shaft Gear Sleeve

Drawing

Number

Part Description

151

Lower Coupling Gear

152 Upper Sleeve For Bearing

153

Rolling Bearing

154

Circlip For Hole

155

Lower Sleeve For Bearing

156 Oil Seal

157

Shaft Circlip

158

Planetary Gear

159 Rolling Bearing

160

Swivel Mount

161

Flat Washer

162

Spring Washer

163

Hex Nut

164

Rolling Bearing

165

Oil Seal

166 Flat Key

167

Planetary Shaft

168

Taper Pin

169

Position Limiting Seat

170 Cross Recessed Pan Head Screw

171

Position Limiting Spring

172

Position Limiting Pin

173

Movable Cover Base

174

Position Limiting Spring

175

Position Limiting Pin

176

Position Limiting Pin Guard

177

Cross Recessed Countersunk Head Screw

178

Movable Shield

179

Fixed Shield

180

Hex Bolt

181

Bowl

182 Bowl Trolley

183

Hex Nut

184

Bowl Tight Pressing Shaft

185 Handle Core Shaft

186

Bowl Tight Pressing Handle

187

Pin Shaft Washer

188

Decorative Sheath Bushing

189

Core Shaft Spring

190

Hex Thin Nut

191

Hex Thin Nut

192 Decorative Sheath

193

Bowl Locating Pin

194

Pin Shaft Washer

195 Spring Washer

196

Cap Nut

197

Handle Lever

198

Bowl Base

199

Hex Bolt

200

Hex Bolt

March 2019

Replacement Parts for the Planetary Mixer

Drawing

Number

Part Description

201

Position Switch

202

Shaft Circlip

203 Lifting Nut

204

Elastic Cylindrical Pin

205

Pressplate

206 Flat Washer

207

Spring Washer

208

Hex Bolt

209

Beater

210 Hook

211

Whip

ACE Equipment One Year Limited Warranty

ACE warrants its equipment against defects in materials and workmanship, subject to the following conditions:

ACE Equipment is warranted for one year, effective from the date of purchase by the original owner. A copy of the

original receipt or other proof of purchase is required to obtain warranty coverage. This warranty applies to the original

owner only, and is notassignable.

Should any product fail to function in its intended manner under normal use within the limits defined in this warranty, at

ACE’s discretion, such product will be repaired, replaced with a refurbished unit, or replaced with a new unit by ACE,

after defective unit has been inspected and defect has been confirmed. ACE does not assume any liability for extended

delays in replacing any item beyond its control. This warranty does not apply to rubber and non-metallic synthetic parts

that may need to be replaced due to normal usage, wear or lack of preventativemaintenance.

This warranty covers products shipped into the 48 contiguous United States. Warranty coverage on products used outside

the 48 contiguous United States, Hawaii, Alaska, Puerto Rico, and Canada, cover parts only.

The following conditions are not covered by warranty:

•

Equipment failure relating to improper installation, improper utility connection or supply and problems due to

improper ventilation.

•

Equipment that has not properly been maintained, damage from improper cleaning, and water damage to

controls.

•

Equipment that has not been used in an appropriate manner, or has been subject to misuse, neglect, abuse,

accident, alteration, negligence, damage during transit, delivery or installation, fire, flood, riot, or act of God.

•

Equipment that has the model number or serial number removed or altered.

•

Equipment on which the security seal has been broken.

If the equipment has been changed, altered, modified, or repaired without express written permission from ACE, then the

manufacturer shall not be liable for any damages to any person or to any property, which may result from the use of this

equipment thereafter.

This equipment is intended for commercial use only and this warranty is void if equipment is used in other than a

commercial application.

For warranty and non-warranty related issues, technical support, please contact NSA at 1-877-672-7740. To purchase

replacement parts and warranty registration visit www.admiralcraft.com. Please have your model number, serial number

and proof of purchase ready. It is not necessary to contact the place where you originally purchased your product from.

“THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILTY OR FITNESS FOR PARTICULAR

PURPOSES AND CONSTITUTES THE ENTIRE LIABILITY OF ACE. IN NO EVENT DOES THE LIMITED

WARRANTY EXTEND BEYOND THE TERMS STATED HEREIN.”

WARRANTY

REGISTRATION National Service America • 230 Park Ave, 3rd Floor WEST • New York, NY • 10169

CARD

MAIL CARD

IMMEDIATELY

(Name of Business) (Dealer Purchased From)

(Address) (City) (State) (Zip Code)

(Model Number) (Serial Number)

This card must be

mailed immediately

after installation date

This is to inform that I, (Please print name of individual who owns business)

have had the above installed in my place of business (Date of Purchase)

for warranty to be in

effect. (Contact Phone Number) (Contact E-mail) (Signature of Individual Who Owns Business)

The above warranties are in effect from this installation date, or 90 days, whichever comes first.

Table of contents

Other Black Diamond Equipment Mixer manuals