801-B00 Page 6/16

MOTOR DRIVEN PUMPS - INSTALLATION AND OPERATION

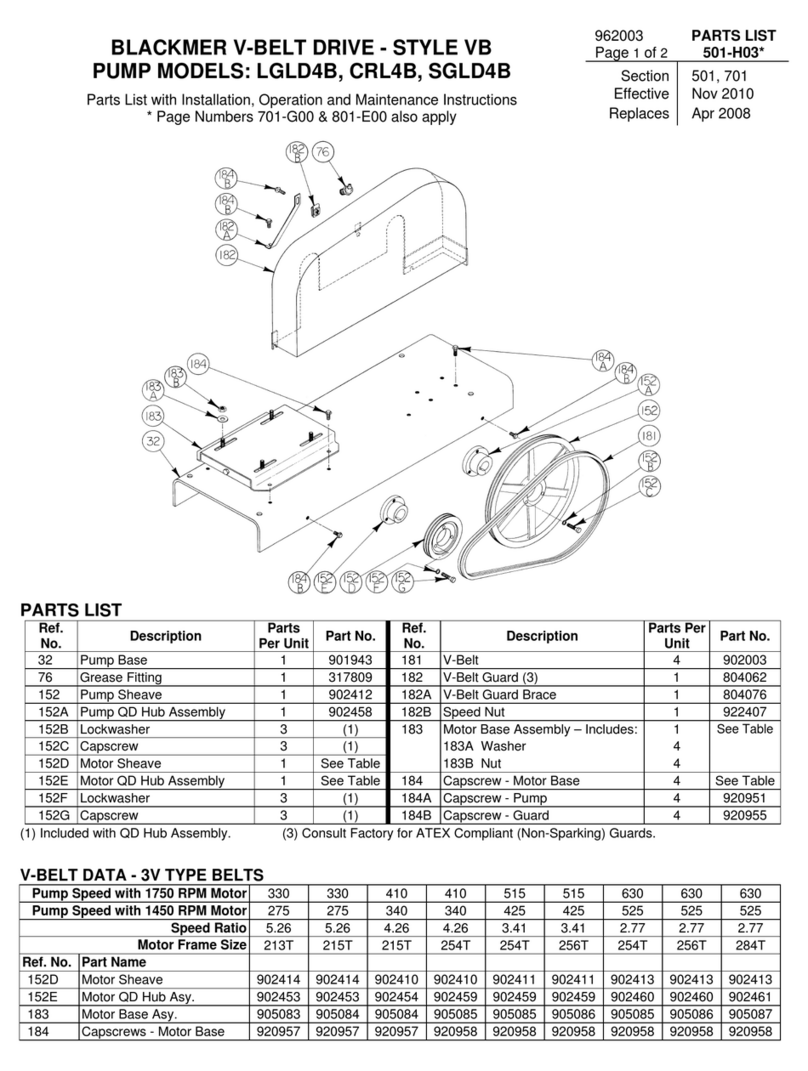

V-BELT DRIVE …. Continued

6. Adjust the motor base (183) and apply a specified force

(see Table 1) against the belt, at the center of the span,

so that the belt is deflected 1/64 inch (0.04 mm) for every

inch (25.4 mm) of span. For example, the deflection of a

20 inch (508 mm) span would be 20/64 or 5/16 inch (7.9

mm). The force required should be within the range given

in Table 1 for a properly tensioned drive. A new set of

belts should be initially tensioned to the upper limit.

BELT DEFLECTION FORCE

SMALL SHEAVE

OUTSIDE DIAMETER Minimum Maximum

2.5” to 4.5”

(63 mm to 114 mm) 3.0 lbs

(1.4 kgs) 4.75 lbs

(2.2 kgs)

4.75” to 7.0”

(121 mm to 178 mm) 4.0 lbs

(1.8 kgs) 6.0 lbs

(2.7 kgs)

Table 1 - Deflection Force Per Belt

7. Check again to ensure the sheaves (152 & 152D) are

parallel, then tighten the sheave capscrews (152C &

152G), the motor mounting nuts (183B) and the adjusting

screw locknut (183B).

8. Assemble the belt guard (182) and the belt guard brace

(182A) to the unit base (32).

Do not operate

without guard

in place

OPERATION WITHOUT GUARDS IN

PLACE CAN CAUSE SERIOUS

PERSONAL INJURY, MAJOR

PROPERTY DAMAGE, OR DEATH.

9. Check the belt tension after 24-48 hours of operating.

Recheck the tension periodically and tighten the belts as

required. DO NOT overtighten belts. Inspect belts

periodically for signs of excessive wear, and replace as

required.

V-BELT DISASSEMBLY

1. Remove the belt guard (182) and the guard base (182A).

Loosen the adjusting screw locknut (183B) on the motor

base (183) and the motor mounting nuts.

2. Ease the tension on the belts (181) by moving the motor

towards the pump to shorten the center distance of the

drive. Remove the belts by sliding them over the sheaves

(152 & 152D). DO NOT force the belts over the grooves.

3. To remove the sheave from the hub, first remove the

three sheave capscrews (152C or 152G). Then screw

two of the capscrews into the threaded holes in the

sheave hub (152A or E). If the cone grip is hard to break

loose, tap the end of the shaft or the QD hub with soft-

faced mallet while maintaining pressure on the screw.

4. The QD hub should slide smoothly off the shaft. If it is tight

on the shaft, gently pry it loose with a screwdriver or a small

wedge placed in the split part of the flange.

Refer to Blackmer V-Belt Parts List and Instructions for V-belt

drive and guard part numbers.

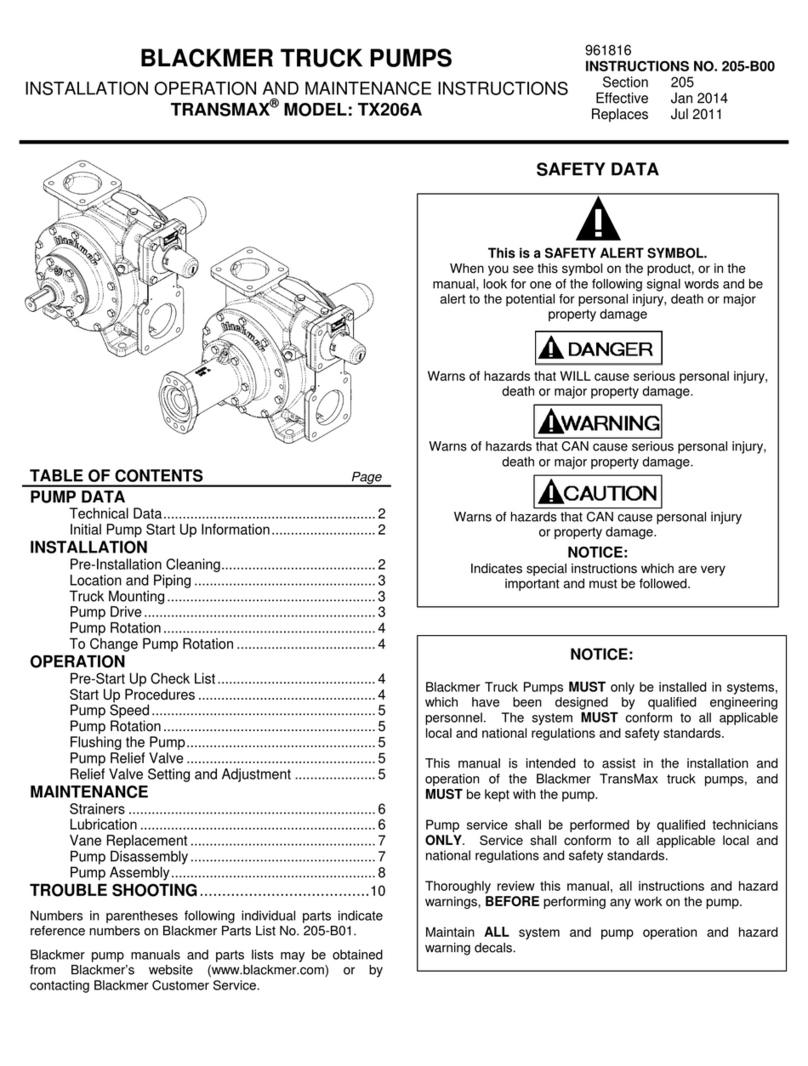

PRE-START UP CHECK LIST

1. Inspect complete piping system and supports to ensure

that no piping loads are being placed on the pump.

2. Install pressure gauges in the 1/4" NPT intake and

discharge ports located on the pump casing to check

pump performance after start-up.

3. Ensure all valves and fittings in piping system are in the

start-up or operating positions.

4. Jog the pump motor to verify proper pump rotation.

START UP PROCEDURES

NOTICE:

CONSULT THE "TROUBLESHOOTING" SECTIONS OF

THIS MANUAL IF DIFFICULTIES DURING START UP ARE

EXPERIENCED.

1. SLOWLY build pressure in the pump.

2. Start the motor.

3. Check pressure gauges to ensure the system is

operating within expected parameters. Record the gauge

readings in the "Initial Start Up Information" section of

this manual for future reference.

4. Inspect piping, fittings, and associated system equipment

for leaks, noise, vibration and overheating.

5. Check the flow rate to ensure the pump is operating

within the expected parameters. Record flow rate in the

“Initial Start Up” section of this manual.

6. Close the discharge valve and check the differential

pressure across the pump. Pressure must not exceed the

pressure setting of the external bypass valve.

7. With the discharge valve still closed, momentarily close

the manual shut-off valve in the bypass return line to

check the pump internal relief valve. The differential

pressure will be approximately 150 and 170 PSI (10.3

and 11.7 bar).

8. The external bypass valve must always be set at least 25

PSI (1.7 bar) lower than the internal pump relief valve.

NOTE: The normal operating pressure must be at least 5

- 15 PSI (0.3 -1.0 bar) less than the external bypass

valve setting. Pump speeds which result in higher

pressures (nearing the valve setting) forces the liquid to

recirculate, creating excessive wear on the pump and

equipment.

Hazardous pressure

can cause personal

injury or property

damage

PUMPS OPERATING AGAINST A

CLOSED VALVE CAN CAUSE SYSTEM

FAILURE, PERSONAL INJURY AND

PROPERTY DAMAGE