i Table of Contents

Table of Contents

01 Snowplow Operation

02 Warning!

Assembly Instructions

03 Unpacking & Inspection

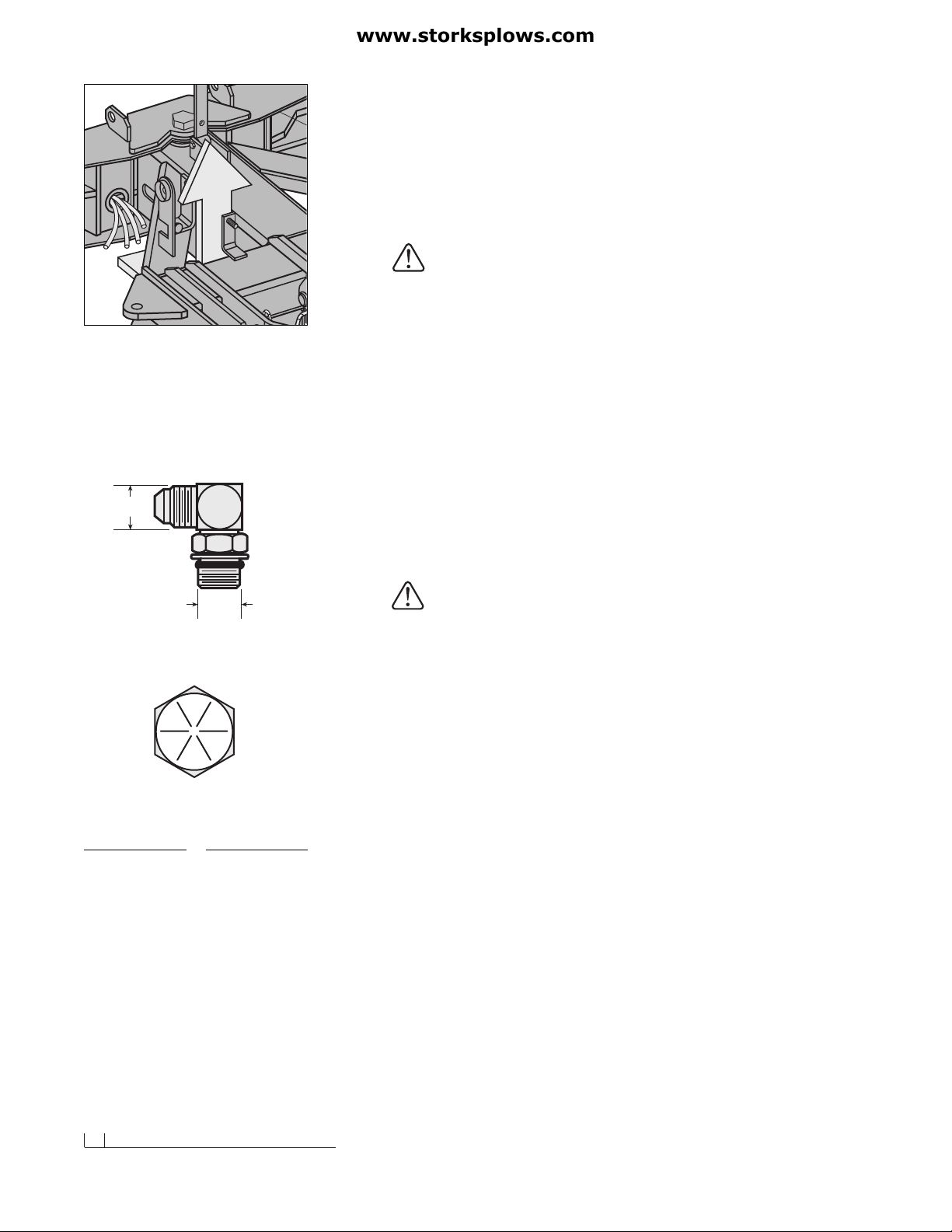

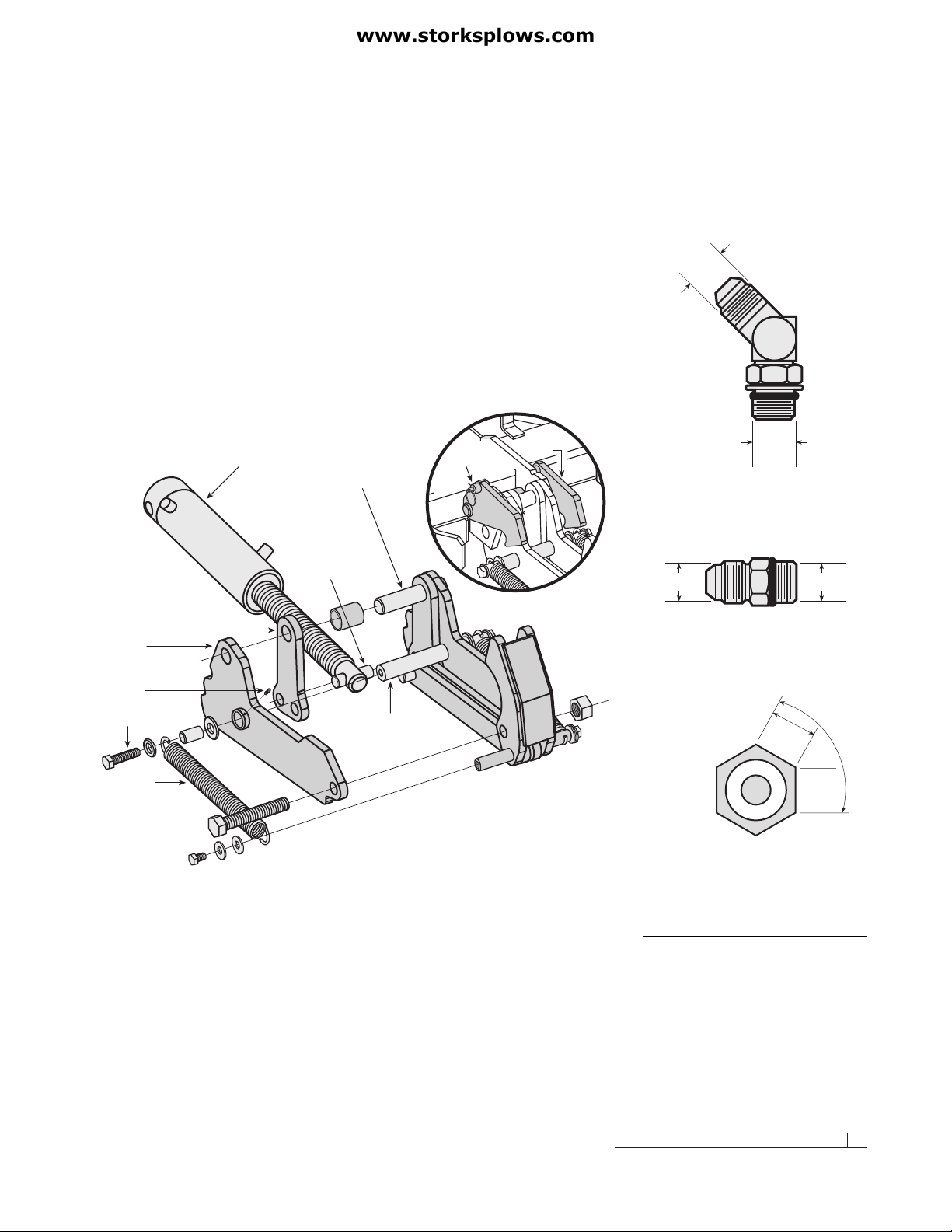

04 Moldboard & A-frame Assembly

08 Electrical Assembly - Plow Harness

09 Electrical Assembly - Vehicle Harness

12 Testing The Snowplow

13 Mounting & Dismounting Instructions

Maintenance & Plow Specifications

14 Regular Maintenance

15 Storing Your Snowplow

16 Plow Specifications

Plow Diagrams & Part Lists

17 Model 810 Parts List

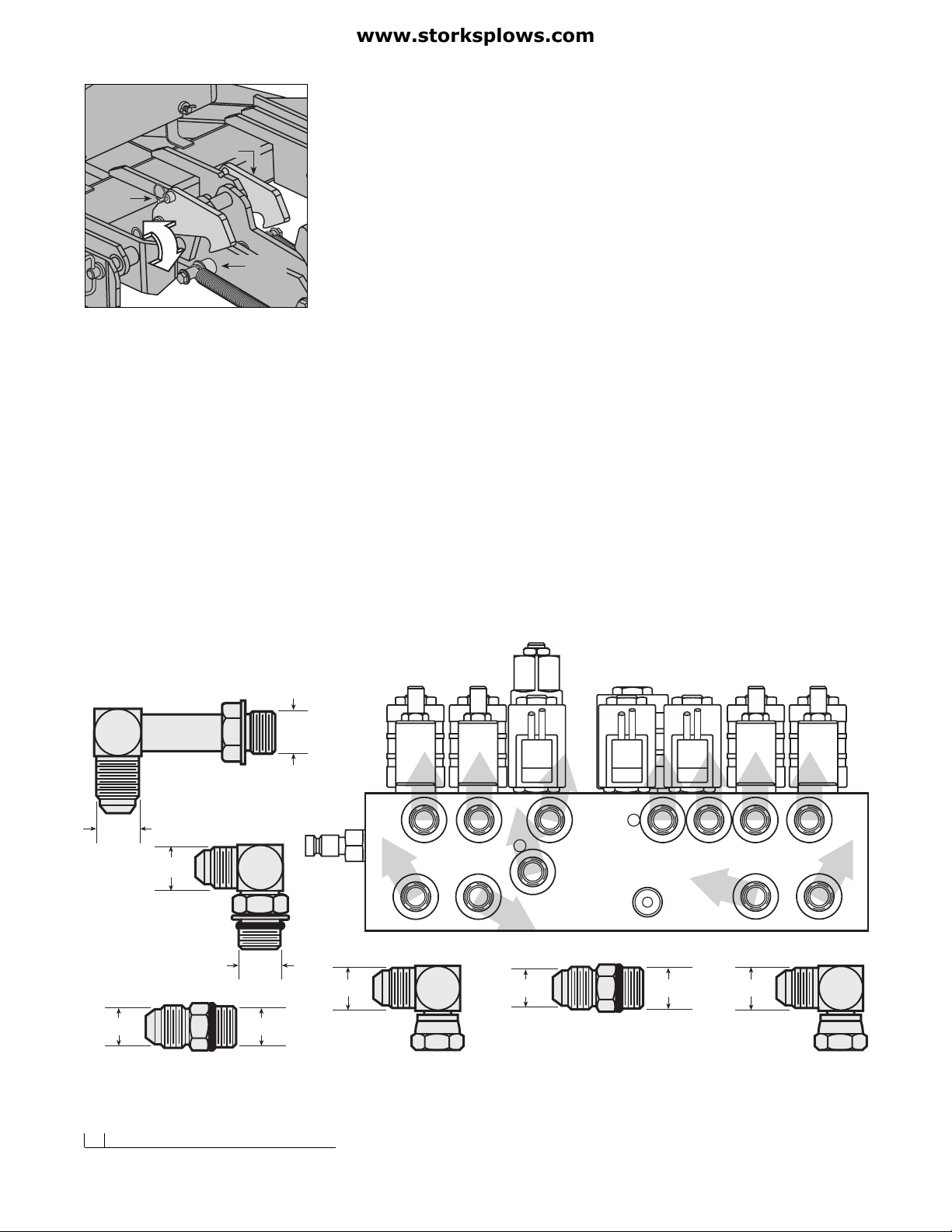

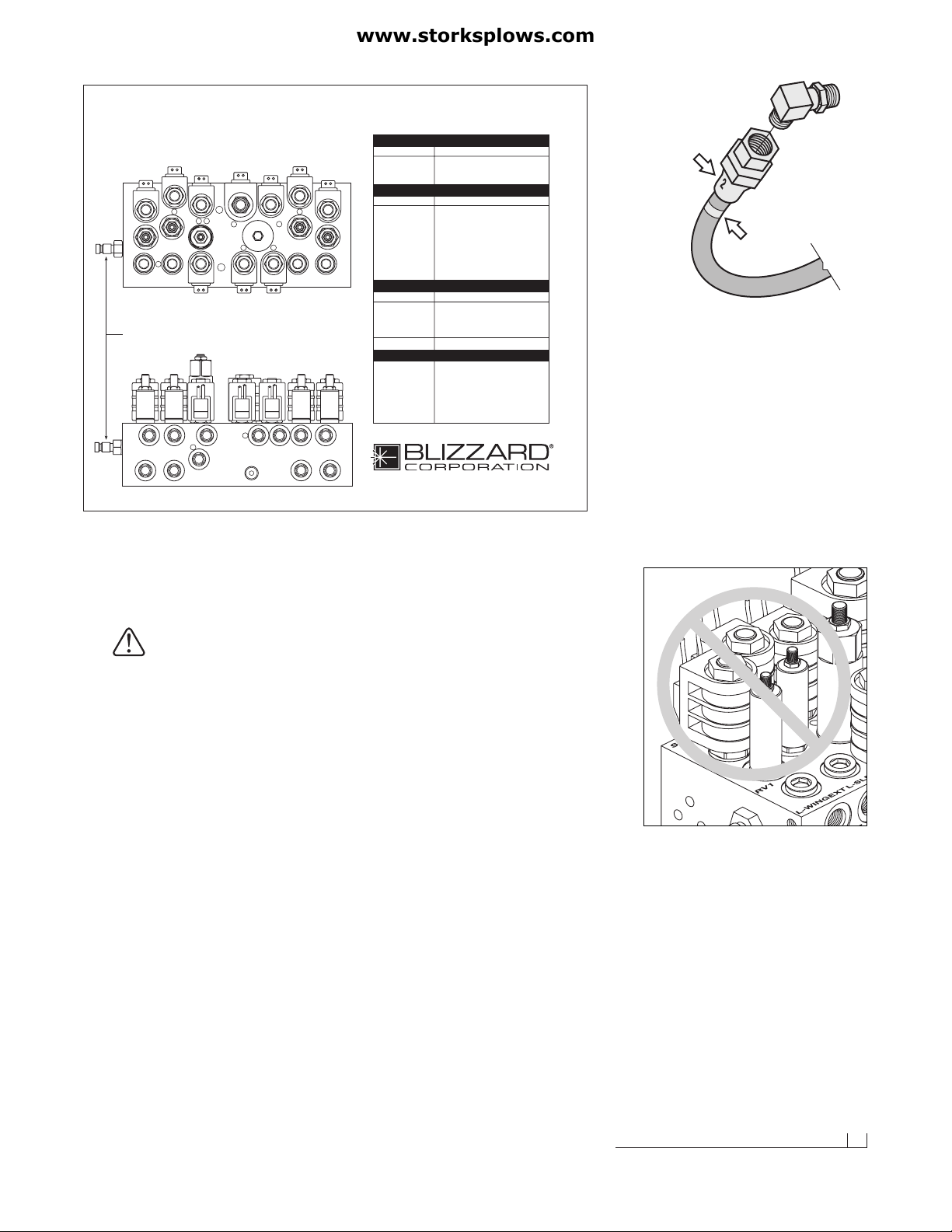

21 Hydraulic Manifold Detail

22 Model 810 Assembly Schematic

24 Coil Harness Wire Schematic / Hydraulic Manifold Schematic

Electrical Diagrams

25 Molded Plug Pin Locations (2001-2002)

26 Plow Harness (2000-2002)

27 Plow Harness Wire Schematic (2000-2002)

28 Main Lighting Harness - Relay Version (2001-2002)

29 Main Lighting Harness Wire Schematic (2001-2002)

30 Vehicle Harness - Relay Version (2001-2002)

31 Vehicle Harness Wire Schematic (2001-2002)

32 On/Off Switch Leads & Ground Lead (2001-2002)

Undercarriage Assembly Instructions

33 Technical Service Bulletin - Ford Blocker Beam™

34 1987-1991 Ford F-250 & F-350 Series

36 1992-1998 Ford F-250 & F-350 Series

38 1999-2002 Ford F-250 & F-350 Series

40 1999-2002 Ford F-450 & F-550 Series

42 1982-1987 Chevrolet/GMC C20/C30 & K20/K30

44 1988-1998 Chevrolet/GMC 2500 & 3500 Series,

1999-2000 Chevrolet/GMC 3500 Series

46 1988-2000 Chevrolet/GMC 1 Ton Heavy-Duty 2WD

48 1999-2002 Chevrolet/GMC 2500 Series

50 1979-93 Dodge 2500 & 3500 Series

52 1994-2001 Dodge 2500 & 3500 Series

Troubleshooting

54 Troubleshooting Guide

Warranties

56 Limited Consumer Warranty

57 Commercial Warranty

Introduction

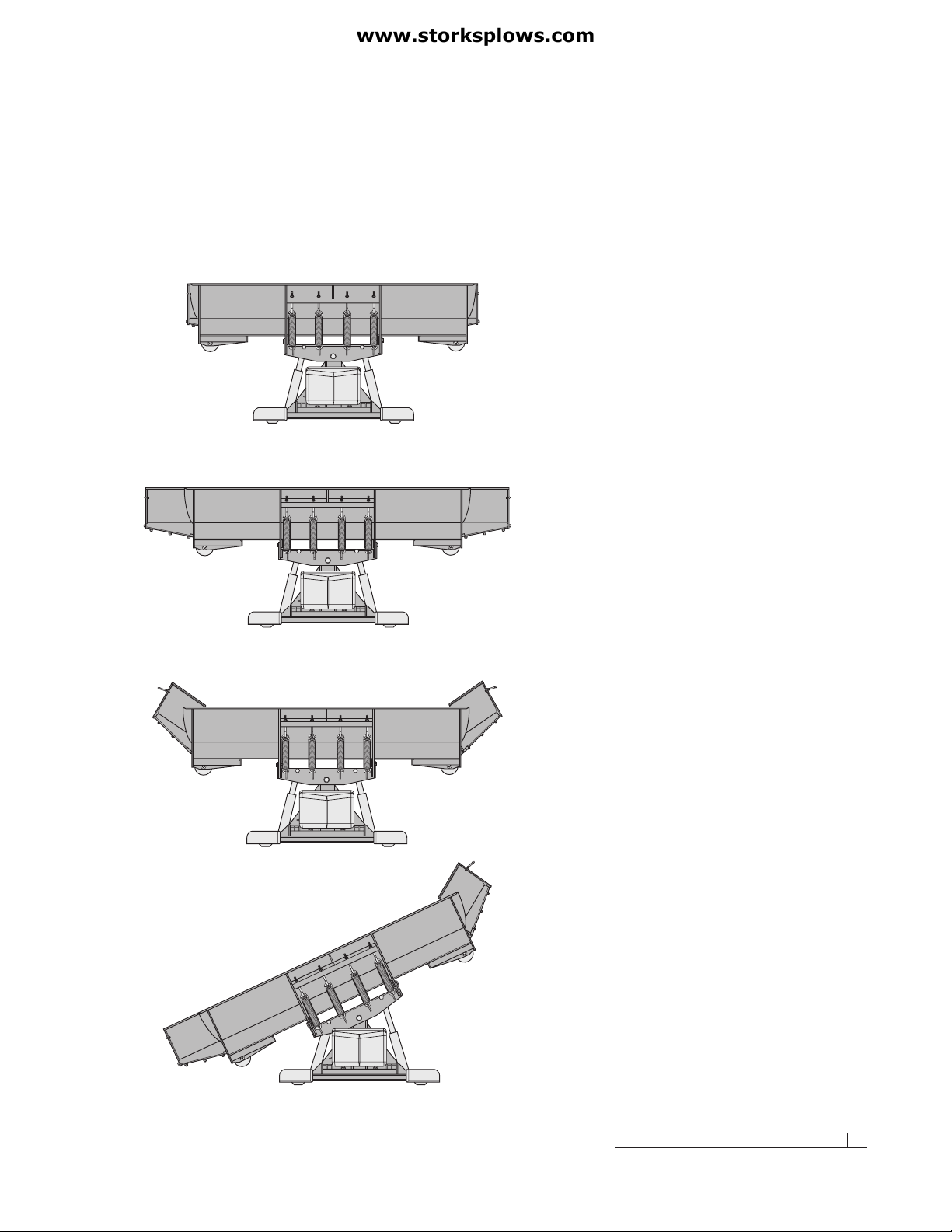

Congratulations on purchasing the

most advanced snowplow available!

The Blizzard Power Plow is clearing

new trails for innovative design,rugged

durability, quality craftsmanship and

superior performance. Our exclusive

products are manufactured and tested

in Michigan’s Upper Peninsula, the

snow capital of the Midwest. With an

annual snowfall averaging over 250,"

we couldn’t imagine building snow re-

moval products anywhere else!

Your Blizzard Power Plow is equipped

with versatile features designed for

years of dependable service. The

hydraulic draw latch mounting system

positively aligns the plow for fast

installation or removal. Twelve-inch

expanding wings automatically trans-

form a compact 8' blade into a massive

10' machine. Also, the independent

wings can pivot forward to form our

9'-3" BucketBlade™ position. Now you

can carry more snow even further.

Safety features include full moldboard

trip action, enclosed hydraulics and

automatic cylinder pressure relief.

To ensure years of optimum snowplow

performance, review the contents of

this manual. It contains assembly infor-

mation, detailed diagrams, complete

parts listings, maintenance guidelines

and troubleshooting tips.

Should you need additional information,

contact your local Blizzard Power Plow

Dealer. Their knowledgeable staff is

well informed on the latest Power Plow

information. They are also your source

for replacement parts, technical assis-

tance and all service repairs.

Comments, suggestions or concerns?

Address all correspondence to:

Blizzard Corporation

Customer Service Department

95 Airpark Boulevard

Calumet, MI 49913

(888) 680-8600

(906) 482-5555

(906) 482-5445 Fax