The release valve

has not been

fully closed.

Turn the

release valve

clockwise until it

can no longer be

turned.

The oil level

is low.

See refilling

instructions.

The hydraulic

system has

become blocked

by dirt particles.

Manually pull the

piston up. Turn

the release valve

anti-clockwise

and push the

piston down

quickly.

Air has entered

the hydraulics.

See bleeding the

hydraulic system

instructions.

The hydraulic

system will not

fully extend.

The jack will not

lift the

rated load.

The jack lowers

under load.

The hydraulic

system will

not lower.

The handle

raises or

springs back

under load.

ll

ll

lll

l

l

COMMON FAULTS

fault

finder

SOLUTIONS

23

Mo el Max Loa Min Height Max Height Weight Or er Co e

Number (Kg/Tonne) (mm) (mm) (Kg) KEN-503

B5048 50,000/50 300 480 34kg -5790K

CAPACITIES

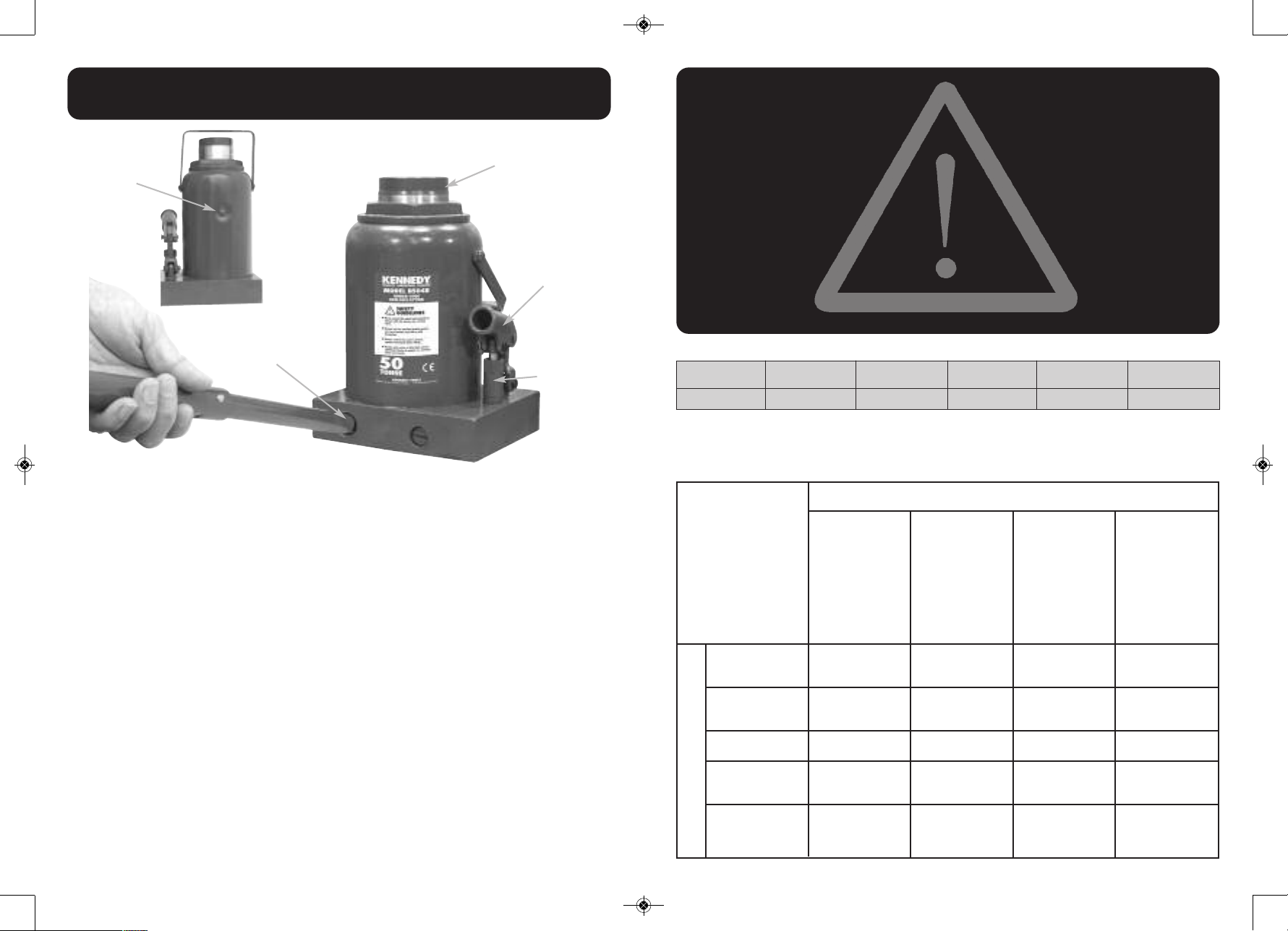

Rubber

Stopper

OPERATINg INSTRUCTIONS

Load

Plate

Release

Valve

Piston

Assembly

Pump

Handle

Socket

SAFETY gUIDELINES

lAlways use on specifie jacking points, on a level surface an with a soli

foun ation.

lAlways check that jacking points are not corro e before use.

lAlways ensure the loa is secure against movement before lifting.

lAlways work un er a lifte loa with an a itional means of support i.e.

correctly rate axle stan s.

lNever excee the rate loa capacity or tamper with the factory set overloa

valve.

lNever lean against the raise vehicle.

lNever mo ify the jack, it is not esigne to support extensions or cra les an

coul become unsafe.

KENNEDY

Bottle Jacks are esigne to help you work safely an efficiently. Lifting

equipment can be angerous if the correct operating an maintenance proce ures are not

followe . Operating instructions an basic safety proce ures are as follows:

1. Assemble the pump han le by fitting the smaller

tubes into the larger tube using the bolts provi e .

2. To engage the pressure piston use the slotte en

of the pump han le, turn the release valve

clockwise until tight.

3. Position the Jack un er the vehicle so that the loa

plate will be centre un er a specifie jacking point.

4. Insert the pump han le into the piston assembly &

pump the han le to raise the loa .

5. Once the loa has been raise to the require

height, use an a itional support (i.e. correctly

rate axle stan s) before continuing work.

6. To lower the vehicle, raise the jack in or er to

remove the a itional supports. Insert the slotte

en of the pump han le into the release valve &

turn it anti-clockwise no more than one complete

turn. The spee at which the vehicle is lowere can

be controlle by how far the release valve is turne .

REFILLINg ThE OIL RESERVOIR

1. Only refill the oil with the jack in an upright position.

2. The Jack's piston shoul be in the lowest position.

3. Remove the rubber stopper from the cylin er housing.

4. Using hy raulic oil ISO VG.22/32, fill to the lower rim of

the stopper hole.

5. Replace the rubber stopper an blee the hy raulic

system of air.

BLEEDINg ThE SYSTEM

1. Using the slotte en of the pump han le turn the

release valve anti-clockwise no more than one

complete turn.

2. Remove the rubber oil stopper from the cylin er

housing.

3. Insert the pump han le into the piston assembly &

pump the han le several times to force out any air.

4. Turn the release valve clockwise until it can no

longer be turne .

5. Replace the rubber stopper.

STORAgE & MAINTENANCE

1. All moving parts shoul be regularly oile

2. Keep upright. The jack is not suitable for horizontal or

upsi e own use.

3. Keep the piston in the lowere position to protect the

hy raulics from corrosion.

4. If the jack comes into contact with moisture, wipe ry

an grease all moving parts.

5. The hy raulic pump unit is teste an seale at the time

of manufacture. It contains no serviceable parts.

KEN-503-5790K_Inst uctions:KEN-503-5790K_Inst uctions.qxd 15/05/2012 09:40 Page 2