blue photon BlueCure 4 User manual

www.BluePhotonGrip.com • 855-777-20401002 Industrial Park Dr., Shelby, MI 49455

Adhesive Workholding

Quick Start Guide | BlueCure 4

Technology & Workholding Systems LLC

®

Before you start: review all safety and design precautions

This quick start guide was written for the users of Blue Photon’s workholding technology. Before

you use, read this manual carefully. In particular, pay attention to the warnings and cautions that

appear in the safety and design sections at the front of the manual. Before you begin, you should

also read the user guide. For more information, visit our website for the most up-to-date product

and safety information: www.BluePhotonGrip.com.

Sales and Engineering Support

Blue Photon Technology & Workholding Systems LLC

1002 Industrial Park Dr., Shelby, MI 49455

CAUTION

This guide as well as additional

manuals provide a description

of the function, application and

safety considerations of the Blue Photon system.

These manuals must be read and understood

before any attempt is made to install or use this

system. Improper use could result in damage to

the product or unsafe conditions for the user.

Follow these safeguards to prevent serious

injury or property damage. Consult the factory

on turning applications.

IMPORTANT

Before using the ultraviolet

(UV) LED equipment read and

understand all manufacturer’s

documentation for proper

setup, safety and necessary maintenance.

**Caution** Do not stare directly at the light

emitted from the LED head. This may be

harmful, resulting in eye injury.

Always use UV protective eyewear.

WARNING

Do not use the Blue Photon workholding

system to hold overhead loads. The

Blue Photon workholding system is not

designed to support people. Never stand

under a lifted xture and/or part. If insufcient holding

strength to resist cutting forces; or if improperly used, a

workpiece may be ejected from the xture at a high rate of

speed. Always follow employer work instructions and Blue

Photon user guide recommendations to minimize any risk.

Always use proper guarding to protect people from injury

due to a workpiece coming dislodged from the xture.

DESIGN

CONSIDERATIONS

This guide provides general operating

procedures. Your specic application

will have special considerations in setup,

function and use. There are several design considerations

that must be addressed before implementing Blue Photon

workholding. Review these considerations with your

design and engineering teams, including the number and

position of grippers, adhesive joint temperature, adhesive

cure time, amount of adhesive, setting the part on applied

adhesive, and part and gripper cleaning.

Adhesive Workholding

Quick Start Guide

Instructions

www.BluePhotonGrip.com • 855-777-2040

2

®

1. Installing the gripper adapters to the UV LED heads

The adapters protect the UV LED heads and provide an accurate alignment to the back of the gripper.

• Small Gripper Adapter

The adapter is screwed onto the UV LED head.

• Medium Gripper Adapter

UV LED head is inserted and pushed into the adapter until the head stops, then tighten the set screw to lock

in place.*

• Large Gripper Adapter

UV LED head is inserted into the adapter until the head is ushed, then tighten the set screw to lock in

place.*

*Caution: Do not over tighten the set screw.

1

7

8

9

2

3

46

5

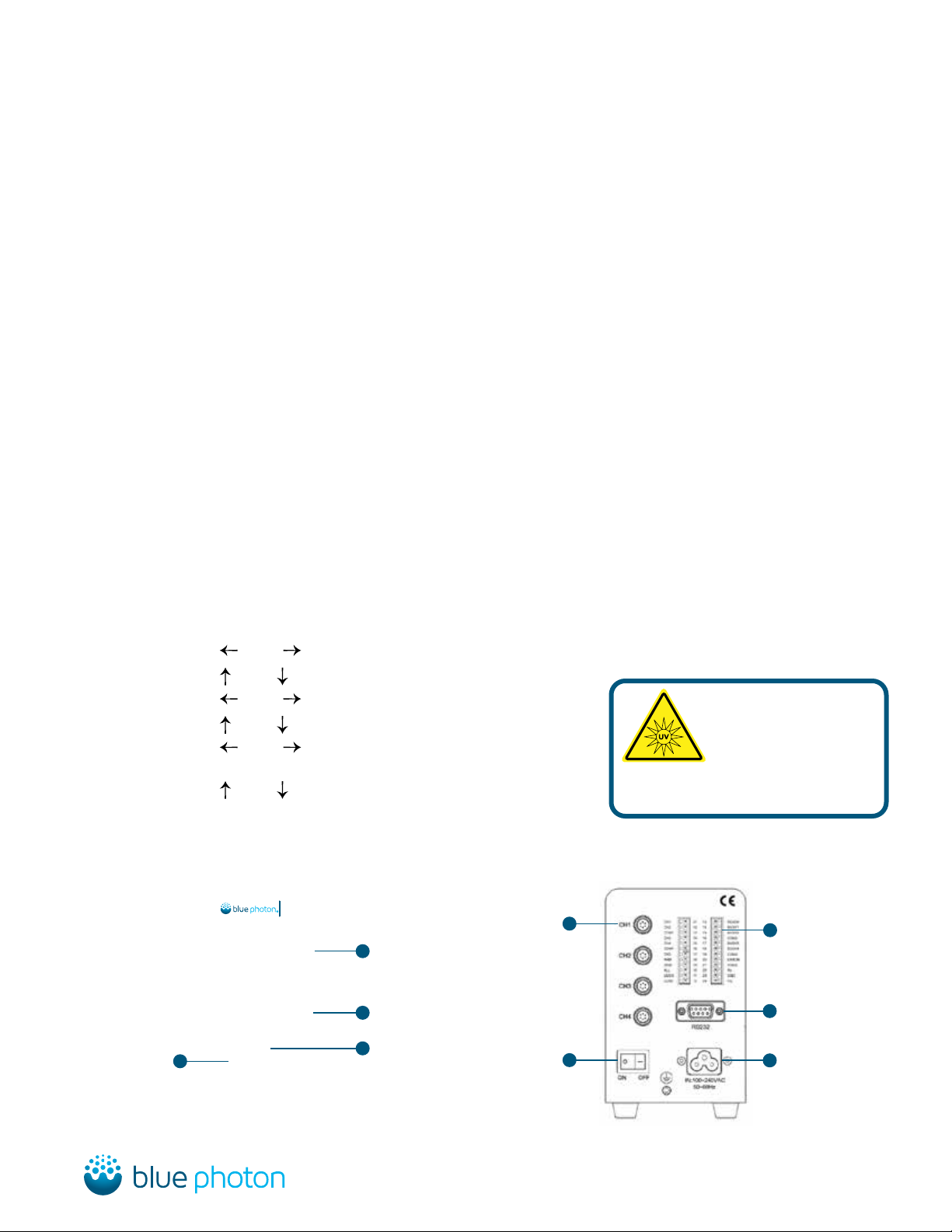

2. Setting up the UV LED head controller

Setup: A Mode: UV Power 100%

Irradiation time 060.0s

1. Turn the controller power switch on.

2. Turn the key switch on, located on front of control panel.

3. Press the “Run / Stop” button.

4. Press the “Set” button to enter into parameters setup mode.

5. Press “ ” and “ ” button to move cursor “_” to the irradiation mode.

6. Press “ ” and “ ” button to change it to A mode.

7. Press “ ” and “ ” button to move cursor “_” to the UV power.

8. Press “ ” and “ ” button to change it to 100%.

9. Press “ ” and “ ” button to move cursor “_” to the

irradiation time.

10.Press “ ” and “ ” button to change it to 060.0s.

11.Press the “Ent” button to save parameters.

12.Turn the key switch off and remove key.

13.Start the UV light source by pushing "Ent".

Front Panel Back Panel

CH1 100% A 060.0 S

CH2 100% A 060.0 S

CH3 100% A 060.0 S

CH4 100% A 060.0 S

Left: CH1~CH4 is the

UV Channel Number

Middle: UV Power /

Irradiation Mode

Right: Irradiation Time

CAUTION

Do not stare directly at

the light emitted from

the UV LED head. This

may be harmful, resulting in eye injury.

Always use UV protective eyewear.

LCD

Arrow Buttons

Key Switch Power Switch A/C Input Socket

RS232

Signal Ports

UV Output

Channels

Set / Esc / Ent /

Stop / Run

BlueCure Mini

Blue Photon Proprietary Information 3®

Step 3a

Step 3f

Step 3b Step 3c

Step 3e

Step 3d

Clean dirt and oil from the grippers

and workpiece.

Machine the workpiece.

Apply enough adhesive to the

grippers to fully ll the gap between

the part and gripper.

Position the part onto locators.

Polymerize the adhesive by applying

UV light for 60 to 90 seconds.

Insert LED heads into xture.

3. Bond your part

1. First clean your workpiece and grippers of any dust and debris by swiping with 90% pure or greater

isopropyl alcohol or another cleaning agent. Do not use an abrasive cleaner or cloth on the grippers.

See Step 3a below.

2. Apply the required amount of BlueGrip™ workholding adhesive to the face of each of the grippers. The ideal

gap is 0.02 (0.50 mm) for small grippers and 0.04 inches (1.02 mm) for medium and large grippers. See Step

3b below.

3. Place the part onto the xture using care not to smear or scrape off the adhesive that has been applied to

the face of the grippers. See Step 3c below.

4. Insert the LED heads into xture. See Step 3d below.

5. Start the UV light source by pushing “Ent”. Consult with your design and engineering team for specic

process parameters and conguration. BlueGrip workholding adhesive cures in 60 to 90 seconds.

See Step 3e below.

6. Remove heads and repeat if more grippers need curing.

7. Your part is ready for machining. See Step 3f below.

©2023 Blue Photon Technology & Workholding Systems LLC. All Rights Reserved. Blue Photon has made every effort to ensure the accuracy

of the product information in this document; however, we are not responsible for typographical discrepancies. Actual products may vary from

those shown in photos. Refer to our website for current product and safety information. Blue Photon Quick Start Guide V2.6 10646 04.03.23

www.BluePhotonGrip.com • 855-777-2040

1002 Industrial Park Dr., Shelby, MI 49455

®

Step 5c

Step 5b

Step 5a

Remove residual adhesive with steam

or hot water spray.

Soak the part and xture with

hot water.

Loaded in CNC machine spindle

(P/N 82400) to remove cured

adhesive.

Step 4a

Separate xture from workpiece with

a 1/4 turn twist or hot water soak.

4. Release the part

The part is released from the grippers with a 1/4 turn twist of the grippers or by a hot water soak.

• Twist Debond - twist the gripper 1/4 turn counter-clockwise to shear the adhesive bond. See Step 4 below.

Retighten the grippers after debonding.

• Soak Debond - soak the part and xture in hot water (at least 180ºF (82.2°C)) for 3-5 minutes then pull the

part off the grippers. Increasing the temperature of the water decreases the required soak time.

5. Cleaning cured adhesive

• Cleaning Tool - To remove residual, cured adhesive from the grippers use our spindle mounted cleaning tool

(P/N 82400) in your CNC machine along with the included program (formatted for Haas controls).

See Step 5a below.

• Hot Water - To remove residual, cured adhesive from the part and/or gripper use hot water with a pressurized

spray to weaken and strip away the cured adhesive. See Step 5b below.

• Steam - An application of pressurized steam will soften the adhesive enough to peel it away.

See Step 5c below.

• Dry Ice Blasting - A cold jet application will remove residual cured adhesive from the part as well.

Popular Laboratory Equipment manuals by other brands

Thermo Scientific

Thermo Scientific 1267 Series operating manual

illumina

illumina Infinium LiHa operating manual

Zeiss

Zeiss TIRF 3 operating manual

REITEL

REITEL STEAMY MINI operating instructions

VWR

VWR 5600 Series Operating and maintenance manual

Gossen MetraWatt

Gossen MetraWatt SECULIFE UP operating manual

Funke Gerber

Funke Gerber CryoStar I manual

Thermo Scientific

Thermo Scientific Sorvall Legend X1R instruction manual

SP Scientific

SP Scientific VirTis BenchTop Pro Series Operator's manual

Westermo

Westermo PII-2G Quick installation guide

Hitachi

Hitachi L-2200 instruction manual

Gamry Instruments

Gamry Instruments PTC1 Operator's manual