Blue Point Engineering Wizard - 11 User manual

Wizard - 11 Board Controller

Instruction I

Blue Point

Pointing the Way to Solutions!

Engineering Inc.

Page 1

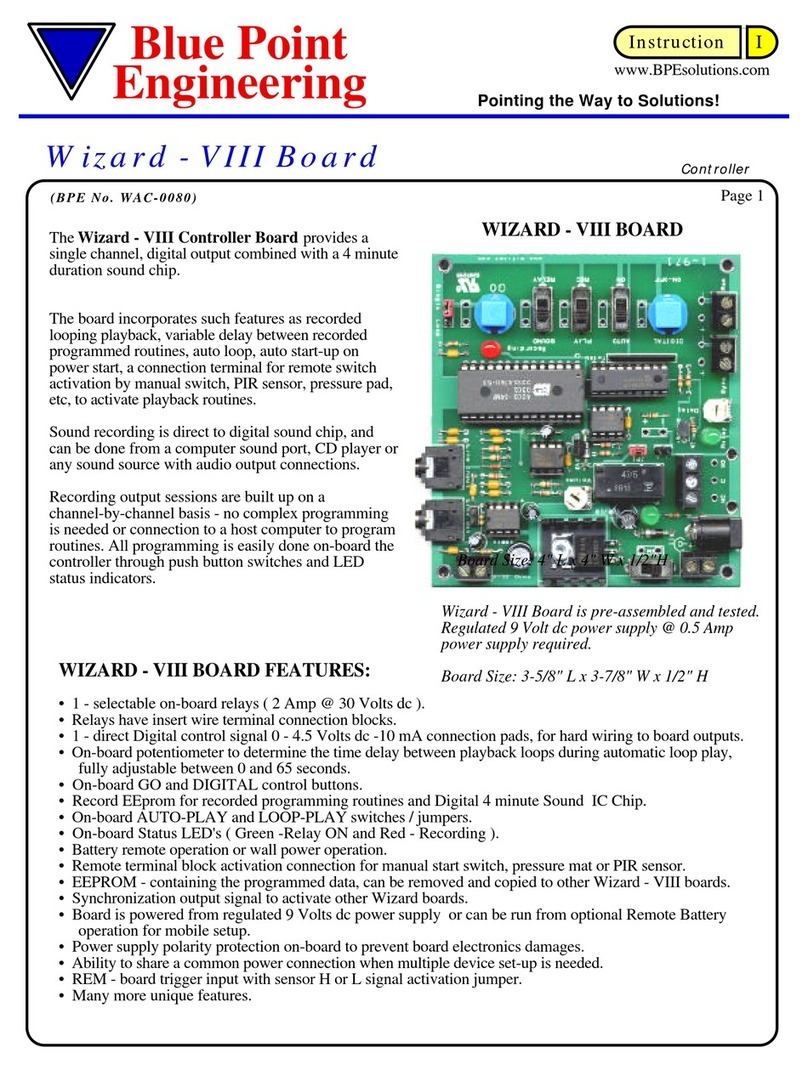

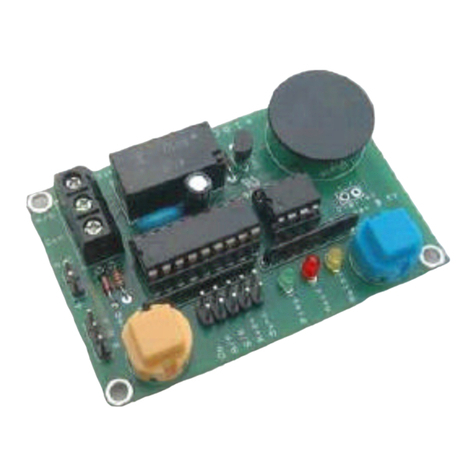

Wizard - 11 Board is pre-assembled and tested.

Regulated 9 Volt dc power supply @ 2 Amp and

Regulated 6 Volt dc power supply @ 5 Amp

power supply required

WIZARD - 11 BOARD

www.BPEsolutions.com

Board Size: 7-3/8" L x 4-1/8" W x 1/2"H

The Wizard 11 Board will record and playback up to

6 minutes of motion for up to 6 servos and On and

Off relay action for 2 digital outputs. It also

incorporates a 4-minute audio recording and playback

IC sound chip with the option to control one servo

channel from recorded moves, from an input audio

signal or directly from the on-board sound IC chip.

The board includes features such as looping action with

variable delay between loops, auto start-up on

power up and a connection terminal for a PIR, remote

switch or sensor to initiate playback start.

Recording sessions are built up on a simple channel

-by- channel method using on-board switches and

potentiometer control. No computer or complex

programming is required to operate board.

During recording, all previously recorded channels are

re-played to aid synchronization.

• 2 Digital channels - either 0 / 4.5 Volts @ 10mA outputs or change over relay rated 30V @ 2 Amp.

• 6 Servo channels – one channel (ch2) may be automatically controlled from an audio signal either from

the line input or from the on-board sound chip.

• 4 minute (240 sec) high quality sound chip - digital recording from line input.

( Computer sound card, CD player, wav files, etc.).

• Digital ON-OFF, NEXT, PLAY and RECORD on-board buttons.

• Servo action reversing option on the audio channel servo - 2

• Maximum and minimum servo travel set points for the audio servo channel - 2

• 2 - selectable on-board relays ( 2 Amp @ 30 Volts dc ).

• Relays have insert wire terminal connection blocks.

• 2 - direct Digital control signal 0 / 4.5 Volts dc -10 mA connection pads, for hard wiring to board outputs.

• On-board potentiometer to determine the time delay between playback loops during automatic loop play,

fully adjustable between 0 and 65 seconds.

• Record enable / disable jumper to protect recorded programming routine.

• On-board AUTO-PLAY and LOOP-PLAY switches.

• Maximum and Minimum set points to the audio servo channel (ch-2) and optional reversing servo action.

• Remote terminal block activation connection for manual start switch, pressure mat or PIR sensor.

• Programming and operation Green and Red status LED's.

• EEPROM - containing the programmed data, can easily be removed and copied to other Wizard - 11 boards.

• Synchronization output signal to activate other Wizard boards linked together.

• Board is powered from regulated 9 Volt dc power supply and 6 Volt dc power supply.

• REMote - board trigger input from remote sensor with H or L signal activation jumper.

• Many more unique features.

Position Potentiometer - Servo motion, Time delays

Adjusts the position of the currently selected servo travel ( Channel -1 through Channel - 6 )

Sets the audio channel end stops.

Sets the time delay between playback in loop-play, adjustable to between 0 to 65 seconds.

Board Functions: - CONTROL

WIZARD - 11 BOARD FEATURES:

Page 2

Digital - Key - On / Off -button

Pressing the Digital key will activate the current channel selected (ch -7 and 8) output relay as ON or OFF.

This is a momentary switch. Press and hold the Digital key, when you want the relay to be ON, release OFF.

Relay - N.C, C, N.O connections.

N.C = Normally Closed position of the relay contacts ( Circuit is ON- will open circuit (OFF) when activated )

C = Common connection to relay contacts.

N.O = Normally Open position of the relay contacts ( Circuit is OFF- will close circuit (ON) when activated )

Relay / Pin Output Jumpers. When this jumper is in place, the board will control the on-board relays. The

relays are rated at 30 V @ 2 Amp. When the jumper is removed, the relay is de-activated and the output pins

may be used as voltage drivers ( 0 Vdc or 4.9 Vdc @ 100mA when on). The pins are marked with Plus (+)

and Minus (-) for correct polarity connection. Use caution when connecting to the pins to observe correct

polarity (+ / - )

Play - key

Replays a set of recorded relay actions.

During play back the channel LED’s will form a bar-graph indicating the amount of time used.

When the recorded routine has finished playing the bar-graph-LED’s will go out.

A switch, sensor may be connected to the REM connection and this will function in the same way as the

Play-key.

Next - channel key (servo ch 1-6, Relay ch 7-8, sound IC chip)

Changes the current active channel to the next channel.

Each key-press selects the next channel - servos 1 and 2, digital 3 and 4 and the sound chip.

Record - key (Servos, Relays and Sound IC)

The record - key has no effect unless enabled by the record-enable E/D Jumper. (see drawings for details)

Press and release the record key to start recording a routine. Press and release the Record-key to stop

recording. If the Record-key is held down when power is applied to the board, all memory will be erased.

(Takes approximately 20 seconds, LED will form a bar-graph indicating EEprom erasing is occurring.).

During the recording of a channel the LED’s will form a bar-graph indicating the amount of time being used.

When the action has finished playing the bar-graph-LED’s will turn off.

RECORD NOTE:

The recording on channel -1 will set the maximum available recording time for all other channels.

Always record channel -1 first, then the other channels ( 2-4 ). Recording periods for channels 2-4 cannot

be longer than for channel -1.

Record D / E Jumper - EEprom Protect.

The Record / Enable jumper protects the programmed routine in the EEprom. If the jumper is set at the "E"

enable position then recording will be permitted. Move the jumper to "D" disable recording to prevent

recording to the EEprom. The Record button E/D jumper will enable or disable button from operating.

SYNC Terminal - Output

Synchronizing connection for multiple board to be linked together. On-board terminal connection delivers a

pulse signal (50 msec) at the start of playback and record event which may be used to trigger other Wizard

boards connected in a chain or master module - slave module setup. SYNC output to REM input of other

boards.

REMote Terminal

Used to trigger Wizard board by remote switch, sensor. Can also be wired together for no-stop playback.

REM Jumper - H and L positions. ( Sensor N.O. or N.C. relay input option)

To begin playback when the input line drops from + to ground, set the REM jumper to the L position. To

begin playback when the action input goes from ground to + (sync pulse) set to the H position

LOOP -slide switch.

To make the Wizard - 11 board play the recorded moves repeatedly, move the switch to the "Y" position. The

recorded moves will start to play when the PLAY-key is first pressed. There will be a pause at the end of

playing (determine by the position of the Loop Delay control) after which the recorded action will start again.

Note: To record new program routines, the LOOP switch must be set to the "N" position.

LOOP -delay.

Pause between playback loop option.

When the Wizard - 11 board is set to the LOOP "Y"position, the length of the pause between repeated

playbacks may be set by the on-board Loop Delay control potentiometer.

Turn theLoop Delay control counter clockwise (CCW) for the minimum delay (approximately 2 seconds and

clockwise for the maximum delay (approximately 65 seconds).

AUTO - slide switch.

To make the Wizard - 11 board play the recorded moves repeatedly on power - ON or reset, move the switch to

the "Y" position. The recorded actions will start to play on any power-up.

Note: to record new program moves, the AUTO switch must be set to the "N" position.

Servo 2 - Options (Programmed movement or Auto - Sound to Motion)

Set the jumper (Servo - 2) to theEEprom position to record and playback moves in a similar manner to Servo

Channel 1. (Programmed motion)

Set the jumper to Audio to control the movement of Servo - 2 from an audio signal (line in or from sound chip)

When set to audio, the audio signal generated by either the on-board sound chip or a suitable line input signal is

sampled and used to control the servo movement. This feature is particular useful for "Mouth" servo operation

as it requires no special user programming synchronization needed with a sound source. Use the Audio Source

jumper to select from the on-board sound Chip or the Line input jack.

Using Servo - 2 with an Audio Control Signal (sound IC or line input source)

Setting Servo - 2 travel end points

Select the required audio source (On-board chip or line input jumper)

Set the servo travel end points for servo - 2. Press and hold the NEXT key and apply power to the board.

LED -S will start to flash and servo - 2 can be controlled by the Position potentiometer. Move the servo to one

end point of the required servo travel range. Press the Digital button.

LED -R will now flash - adjust the servo position to the other end of the servo limit and press the Digital button.

LED -R will now turn off and the control board will return to a normal operation mode ( LED-1 will turn on).

The two servo limit travel points have been stored in memory and will limit the travel of Servo -2 when

responding to an audio signal.

The degree of Servo - 2 movement is governed by the combination of the sound source volume and the Gain

presets. Rotate the Gain potentiometer on-board, clockwise for maximum signal gain and maximum servo

movements.

Audio Channel - Reverse / Normal Jumper

Setting the jumper to the Reverse position will cause the motion of Servo - 2 to be reversed (operate in the

opposite direction currently moving)

Audio Setting

INPUTS - ( 150 mVolts P-P Level )

Line Input - audio source going into the Wizard - 11 board (CD player, computer, stereo, etc.),usually to be

recorded to the Sound IC chip, or to drive Servo - 2 directly.

OUTPUTS - ( 2.5 Volts P-P Level )

Line Output - audio from the on-board sound chip going out to a remote external powered speaker or amp

system. The audio from the sound IC chip is slightly amplified to operate an 8 Ohm speaker directly only for

playback audio review. In normal use the audio output should be connected to a remote external powered

speaker or amp for best sound results and volume.

Page 3

Clearing Memory to start a new program.

The Enable jumper must be set at the (E) position and the Record-key jumper also set to the (E) position.

The LOOP switch and the AUTO switch must be in the "N" position.

The RECORD - key is held down during Power Up, and released after power is applied.

The LED's "1-4" will form a count down bar-graph indicating that current programmed

EEPROM memory is being cleared. (This will take approximately about 20 seconds).

After the initial 20 seconds all green LED’s will turn OFF and the current selected

channel LED will turn ON, indicating the board is now ready for new programming.

Power Connection Solder Pads:

When powering the board from a regulated supply, the supply wires can also be soldered to the holes directly

for a more permanent connection. Observe polarity + and - to prevent damaging the board.

Page 4

Examples

1. Recording - Servo Motion and Relay Action On and Off - New program start

Make sure that the EEprom E/D jumper is set at the (E) position and that the Record key -E/D jumper is also

set to the (E) position. The LOOP and the AUTO switch must be in the "N" position.

Power down the Wizard -11 controller and then hold down the record key and apply power back to the board,

all memory will be erased (LED's will count down, approximately 20 sec.)

Select Servo Channel -1 by pressing NEXT-channel-key until the green number 1 - LED is ON.

Press and release the RECORD-key. (The red LED will turn ON, record mode is now active)

Adjust the Position Potentiometer, moving Servo - 1 as needed. ( approx. 2 minutes)

Press and release the RECORD-key to end recording session and set total record time (5 Min Max).

Select Relay - 1 Channel by pressing NEXT-channel-key until the green number 3 - LED is ON.

Press and release the RECORD-key to start recording session for relay.

Press and hold the Digital - key for approximately 1 minute, then release the Digital key switch.

Relay - 1 will turn On and Off, as you press and release Digital key.

( Note: Servo Channel -1 will playback previously recorded action to help in synchronization of the new

channels being recorded )

The recording will end automatically after approximately 2 minutes ( established by channel - 1 recording

time used )

Playback of Recorded Program Servo Channel -1 and Relay -1

Press and release the PLAY-key to review the recorded sequences.

Relay -1 and Servo Channel -1 will playback recorded actions, then wait for PLAY-key to be pressed again.

Programming Servo - 2 as a Recorded Routine.

Make sure that the EEprom / Audio jumper is set at the (EEprom) position and that the EEPROM E/D jumper

and the Record key jumper is also set to the (E) position. The LOOP and the AUTO switch must be in the "N"

position.

Select Channel -2 by pressing NEXT-channel-key until the green number 2 - LED is ON.

Press and release the RECORD-key. (The red LED will turn ON, record mode is now active)

Adjust the Position Potentiometer, moving Servo - 2 as needed.

( Note: Relay -1 and Channel -1 will playback previously recorded action to help in synchronization of the new

channels being recorded )

The recording will end automatically after approximately 2 minutes ( established by channel - 1 recording

time first set).

NOTE: The recording on channel - 1 will always set the maximumavailable recording time for all other

channels. Always record channel - 1 first, then the other channels. Recording periods for channels 2 cannot

be longer than for channel - 1. ( Maximum recording time for servos and relays is 5 minutes).

Examples

2. Editing a Servo Channel (channel -2 example)

You can re-program Servo channels 2, by pressing the NEXT-channel-key until Channel -2 green LED is ON.

Press and release the RECORD-key. (The red LED will turn ON, record mode is now active)

Adjust the Position Potentiometer, moving Servo - 2 as needed.

The recording will end automatically based on Channel -1 recorded time.

Remember that Channel -1 sets the maximum time for all the channels. if you re-program Channel -1 with less

time then previously recorded, all the other channels will also be adjusted to meet the length of Channel -1

record time if longer times were originally recorded for them.

If re-programming Channel -1, then you will need to always press and release the RECORD-key, a second

time, after re-programming Channel - 1 to end the programming sequence, and set record time line.

3. Editing Relay Channel - 1

You can re-program Relay Channel - 1 by selecting the NEXT-channel-key until Channel -3 green LED is

ON. Press and release theRECORD-key. (The red LED will turn ON, record mode is now active)

Press and release the Digital - key as needed. The recording will end automatically after approximately 2

minutes ( established by Channel - 1 recording time first set)

Page 5

Make sure that the EEprom E/D jumper is set at the (E) position and that the RECORD-key -E/D jumper is

also set to the (E) position. The LOOP and the AUTO switch must be in the "N" position.

Make sure that the Audio Source Jumper is set to the Chip position.

Connect a audio cable from a sound source (CD player, Computer sound port, Stereo, etc.) to the Line Input

Jack on-board the Wizard - 11 board. ( need 150 mV P-P input from sound source to operate Wizard - 11

board sound system)

Select Sound Chip by pressing NEXT-channel-key until the green S- LED is ON.

Press and release the RECORD-key at the same time that you start sound source. (CD player, Computer

sound port, Stereo, etc.), The red LED will turn ON, record mode is now active. The sound source is now

being digitized into the sound IC chip. The sound recording will end automatically after 4 minutes, or you can

Press and release the RECORD-key to stop recording sound.

Playback of Recorded Program Servo Channel - 1, Relay - 1 and Sound.

Connect an audio cable from the Line Output Jack on-board the Wizard - 11 to a remote amplified speaker

unit. Make sure that the amplified speaker is turned on, and volume set below the mid level point to start.

Press and release the PLAY-key to review the recorded servo, relay and sound..

Servo Channel -1, Relay -1 and Sound will playback recorded actions and end.

Press the PLAY-key to be start again.

LOOP -slide switch.

To make the Wizard - 11 board play the recorded moves repeatedly, move the switch to the "Y" position. The

recorded moves will start to play when the PLAY-key is first pressed. There will be a pause at the end of

playing (determine by the Loop Delay control from Position potentiometer) after which the recorded action

will start again. Note: To record new program routines, the LOOP switch must be set to the "N" position.

LOOP -delay (Position potentiometer)

Pause between playback loop option.

When the Wizard - 11 board is set to the LOOP "Y"position, the length of the pause between repeated

playbacks may be set by the on-board Loop Delay control (Position potentiometer).

Turn theLoop Delay control counter clockwise (CCW) for the minimum delay (approximately 2 seconds

and clockwise (CW) for the maximum delay (approximately 65 seconds +/-).

AUTO - slide switch.

To make the Wizard - V board play the recorded moves repeatedly on power-up or reset, move the slide switch

to the"Y" position. The recorded actions will start to play on any power-up.

Note: to record new program moves, the AUTO switch must be set to the "N" position.

Examples

5. Operating Servo Channel - 2 in Auto Sound to Motion Mode

Using on-board Recorded Sound IC Chip to Operate Servo - 2

Make sure that the sound IC Chip has been recorded with needed audio.

Check to see that the Servo - 2 EEprom / Audio jumper is set at the (Audio) position.

Check to see that the Audio Source jumper is set at the (Chip) position.

Set the servo travel end points for servo - 2 ( see above - Setting Servo - 2 travel end points )

Press and release the PLAY-key to playback the recorded servo, relay and sound..

Servo Channel -1, Relay -1 and Sound will playback recorded actions and Servo - 2 will operate in response

to the Audio from the Sound IC Chip. (You may need to adjust Gain control to get servo - 2 moving).

Press the PLAY-key to be start again, or set the Loop and Auto slide switches to optional modes.

Using External Remote Audio Source to Operate Servo - 2

Check to see that the Servo - 2 EEprom / Audio jumper is set at the (Audio) position.

Check to see that the Audio Source jumper is set at the (Line) position.

Connect a audio cable from the remote sound source (CD player, Computer sound port, Stereo, etc.) to the

Line Input Jack on-board the Wizard - 11 ( need 150 mV P-P input from sound source to operate)

Set the servo travel end points for Servo - 2 ( see above - Setting Servo - 2 travel end points )

Start the external sound source, and adjust the Gain control on the Wizard - 11 board to get Servo - 2 moving.

Press the PLAY-key to start playback, of Servo - 1 and Relay - 1 or set the Loop and Auto slide switches to

optional modes.

Examples

4. Recording - To Sound IC Chip

IMPORTANT NOTE: Clearing Memory

When clearing memory, only the servo and digital output recorded actions are erased.

The sound IC chip can only be cleared by re-recording over the current sound.

You must re-set Servo - 2 travel end point after clearing memory each time, if using AutoTalk

Feature. Servo - 2 will not respond under sound activation if you have not re-set the travel points,

after doing a clear memory.

Clearing Memory

The Enable jumper must be set at the (E) position and the Record-key jumper also set to the (E) position.

The LOOP switch and the AUTO switch must be in the "N" position.

Remove Power to the Wizard - 11 Board.

Hold down the RECORD - key and re-apply power back to the board, released after power is applied.

LED's "1-4" will form a count down bar-graph indicating that current programmed

EEPROM memory is being cleared. (This will take approximately about 20 seconds).

After the initial 20 seconds all green LED’s will turn OFF and the current selected

channel LED will turn ON, indicating the board is now ready for new programming.

The servo and digital

Reset of Servo - 2 Travel End Points.

Setting Servo - 2 travel end points

Select the required audio source (On-board chip or line input jumper)

Set the servo travel end points for servo - 2. Press and hold the NEXT key and apply power to the board.

LED -1 will start to flash and servo - 2 can be controlled by the Position potentiometer. Move the servo to one

end point of the required servo travel range. Press the Digital button.

LED -2 will now flash - adjust the servo position to the other end of the servo limit and press the Digital

button.

LED -2 will now turn off and the control board will return to a normal operation mode ( LED-1 will turn on).

The two servo limit travel points have been stored in memory and will limit the travel of Servo -2 when

responding to an audio signal.

The degree of Servo - 2 movement is governed by the combination of the sound source volume and the Gain

presets. Rotate the Gain potentiometer on-board, clockwise for maximum signal gain and maximum servo

movements.

I am trying to get Servo - 2 to operate from the sound IC Chip, or from a Line Input remote audio

source, but the servo is not moving to any sound.

Check to see that the Servo - 2 EEprom / Audio jumper is set at the (Audio) position.

Check to see that the Audio Source jumper is set at Chip for playback from the on-board IC Chip or

is set to Line for a remote audio input signal.

Check to see that you have a good remote sound source for Line input.

Check the Audio cables from the sound source to the Wizard - 11 Line Input Jack.

Check to see that the Sound IC has the recorded audio needed.

The degree of Servo - 2 movement is governed by the combination of the sound source volume and

the Gain presets. Rotate the Gain potentiometer on-board, clockwise for maximum signal gain and

maximum servo movements.

Reset new travel endpoints for Servo - 2 (See Reset of Servo - 2 Travel End Points)

Problem Help Guide - Audio Servo

Q

A•

•

•

•

•

•

•

Phone (303) 651-3794

www.BPEsolutions.com

Blue Point Engineering

Custom Equipment, Unique Electronic Products

Page 6

•See Wizard - 11 Controller Troubleshooting Hint pages for additional help.

Wizard Board Three ......

VDC 3-15 VDC

240

VAC

Green

(Gnd)

White

Black

Red

Black

LOOP

AUTO

LOOP

AUTO

Copyright © 2005 Blue Point Engineering , All Rights Reserved Version 1.0

PC Board

Page 7

Power Supply

The Wizard - 11 control board works with duo power supplies;

9 Vdc @ 2 Amp.

6 Vdc @ 5 Amp. or 5 Vdc @ 6 Amp

A small 2.1 mm socket with center positive is built-on board for quick power connections.

Connector

Regulated

+ 9 Volt DC

Wizard -11 Controller Board

Power Supply Overview

9 Vdc @ 2 Amp

+ Vdc

center

- Vdc

2.1 mm

Connector

Regulated

Power

- Vdc

outside

+ Vdc

center Red

Black

Wall Plug Power Supply

REGULATED 9 Vdc @ 2 Amp

Recommended

outside

2.1 mm

Connector

N

Y

N

Y

Wall Plug Power Supply

REGULATED 6 Vdc @ 5 Amp

2.1 mm

Connector

Connector

Regulated

+ 6 Volt DC

6 Vdc @ 5 Amp

Phone (303) 651-3794

www.BPEsolutions.com

Blue Point Engineering

Custom Equipment, Unique Electronic Products

Copyright © 2005 Blue Point Engineering , All Rights Reserved Version 1.0

Page 8

AudioTalk

Servo Motion Function

Wizard - 11 Controller Board

Jumper Overview

Servo - 2

AutoTalk

EEprom

Programmable

Control Audio Talk

Feature

Relay

Relay

De- Activated

Relay

Activated

Audio Source

Chip

Line

E D

EEPROM

Wizard Board Three ......

VDC 3-15 VDC

240

VAC

Green

(Gnd)

White

Black

Red

Black

LOOP

AUTO

LOOP

AUTO

REM Port

H L

Loop

N

Y

N

Y

Auto

Reverse Normal

Position

Potentiometer

Wheel

Wall Plug Power Supply

REGULATED 6 Vdc @ 5 Amp

2.1 mm

Connector

Protection

Page 9

Copyright © 2005 Blue Point Engineering , All Rights Reserved Version 1.0

Wizard - 11 Controller Board

Remote Activation / Auto-Playback

Playback Option Modes

REMOTE SWITCH

• Floor Mat Switch.

• PIR Sensor.

• Manual Operated Switch.

• Relay Contact Switch, etc.

To replay the recorded action repeatedly, the LOOP selection switch

must be in the "Y" position. The length of the pause between repeated

playback is set by the Delay control, CCW (5 sec.) or CW (65 sec.).

The PLAY key or REMOTE switch must be pressed once to start the

playback action or if The AUTO selection switch is set to the "Y"

position, then the recorded playback action will begin automatically

each time on power-up.

Note: For a "0" pause delay between playback, set the LOOP

selection switch to "N" and the AUTO selection switch to "Y".

Place a jumper wire across the Remote Switch connection.

Remote (Rem) Switch Connection

OR

( Output to other Wizard Boards (Multiple boards)

Sync Terminal

Jumper Wire

OR

Loop Delay

Control

CCW CW

Delay

65 sec.

Delay

5 sec.

Loop Pause Delay

(CCW/CW)

B

A

C

Wizard Board Three ......

VDC 3-15 VDC

240

VAC

Green

(Gnd)

White

Black

Red

Black

LOOP

Y

N

AUTO

Y

N

LOOP

Y

N

AUTO

Y

N

N

Y

N

Y

Wall Plug Power Supply

REGULATED 6 Vdc @ 5 Amp

2.1 mm

Connector

Position

Potentiometer

Wheel

Page 10

Remote Switch

( Rem ) Terminal

Connection

The REMOTE switch on board One (Rem) when pressed will start board One (Sync) and

Trigger board Two (Rem) and board Three ( Rem ) ..... etc, activating automatic program

playback actions for all boards connected.

REMOTE SWITCH

• Floor Mat Switch.

• PIR Sensor.

• Manual Operated Switch.

• Relay Contact Switch, etc.

( Sync )

Terminal

Connection

Wizard - 11

Board - One

Wizard - 11

Board - Two

( Rem )

Terminal

Connection

Push Buttons

(Momentary)

Remote

Switch / Sensor

(+)

(-)

Wizard Board

Connections

(+)

(+)

(-)(+)

(-)

(+)

Example:

Floor Mat Switch

( Board-2 ) ( Board-1 ) ( Board-1 )

Wizard Board Three ......

Wizard - 11 Controller Board

Multiple Board Connection

Copyright © 2005 Blue Point Engineering , All Rights Reserved Version 1.0

VDC 3-15 VDC

240

VAC

Green

(Gnd)

White

Black

Red

Black

LOOP

AUTO

LOOP

AUTO

N

Y

N

Y

Wall Plug Power Supply

REGULATED 6 Vdc @ 5 Amp

2.1 mm

Connector

Wizard - 11

Board - Three

Page 11

Wizard Board Three ......

Copyright © 2005 Blue Point Engineering , All Rights Reserved Version 1.0

Wizard - 11 Controller Board

Pneumatic Output Mode

Electrical Pneumatic Valve

Relay

Wire

Terminal

Air

Compressor

Pneumatic

Cylinder

12 Vdc

Power Supply

Pneumatic

Tank

Air

Filter

Pressure

Regulator

Air Hose

Pneumatic

Valve

Air

Hose

Air Hose

Air Hose + 12 Vdc

+ 12 Vdc

- 12 Vdc

Wire

Wire

Wire

Pressure

Gauge

Quick Disconnect

Hose Connectors

Accumulator

Tank

Pressure

Gauge

Pneumatic System

Wizard - 11

Control Board

VDC 3-15 VDC

240

VAC

Green

(Gnd)

White

Black

Red

Black

LOOP

AUTO

LOOP

AUTO

N

Y

N

Y

Wall Plug Power Supply

REGULATED 6 Vdc @ 5 Amp

2.1 mm

Connector

NO - Contact Terminal

C - Contact Terminal

Page 12

Copyright © 2005 Blue Point Engineering , All Rights Reserved Version 1.0

Wizard Board Three ......

Wizard - 11 Controller Board

Relay to AC Voltage Output Mode

Power Transformer

( 6-12 VDC)

+

-

VDC 3-15 VDC

240

VAC

+

Green

(Gnd)

Back

White

Solid-State Relay

Module

Plug In

AC Voltage

Wall Plug

White

Black

Red

Black

Relay

Contacts

*Use caution when working with AC Voltage.

Touching or incorrectly wiring this circuit

could cause serious personal injury or damage

to equipment.

Caution

*

*

Wizard - 11

Control Board

*

LOOP

AUTO

LOOP

AUTO

Caution

N

Y

N

Y

Wall Plug Power Supply

REGULATED 6 Vdc @ 5 Amp

2.1 mm

Connector

NO - Contact Terminal

C - Contact Terminal

Servo

Connector

R/C Servo

Connection

B

A

C

- Black

- Red

- Yellow / White

positions

Copyright © 2005 Blue Point Engineering , All Rights Reserved Version 1.0

Page 13

Wizard - 11 Controller Board

Servo Set-up Overview

SERVO

Connection

SERVO - 1

- Yellow / White

- Black

- Red

SERVO

Connection

SERVO - 2

SERVO - 6

SERVO - 5

SERVO - 4

SERVO - 3

(-)

(+)

(S)

R/C Servo

Connection

B

A

C

positions

SERVO - 1

SERVO - 6

Copyright © 2005 Blue Point Engineering , All Rights Reserved Version 1.0

Page 14

Wizard - 11 Controller Board

Audio Record / Playback Set-up Overview

Speakers

and

Amplifier

Sound

INPUT

Audio

Cable

Sound

OUTPUT

Audio

Cable

Line Out

Line Input

Sound Source

CD Player

Computer

Sound Port

Microphone

Sound Source

Output

Mic

Amp

Audio Source

Chip

Audio Gain

Adjustment

150mv P/P Input

Copyright © 2005 Blue Point Engineering , All Rights Reserved Version 1.0

Page 15

Wizard - 11 Controller Board

Sound / Servo - 2 Set-up Overview

Speakers and

Amplifier

Sound Source

Audio Source

Line

Chip

OR

Audio Sound

IC Chip

Audio Gain

Adjustment

Direct Sound

Source

SERVO - 2

R/C Servo

Connection

BA

C

positions

- Black

- Red

- Yellow / White

SERVO - 2

Connection

Audio Servo

Control

Servo - 2

AutoTalk

EEprom

Programmable

Control Audio Talk

Feature

AudioTalk

Servo Motion Function

Reverse Normal

OR

150mv P/P Input

Copyright © 2005 Blue Point Engineering , All Rights Reserved Version 1.0

Page 16

Wizard - 11 Controller Board

Audio Playback Set-up Overview

Speakers

and

Amplifier

Sound

OUTPUT

Audio

Cable

Line Out

Audio

Cable

OR

Mini Audio Amp

Wire

Wire

Speaker

Playback OR

Audio Amp

Board

OR

2.5 V P/P Output

Wizard - 11 Controller Board

Troubleshooting Hints

Servos Channel 2-6 not programming correctly on Wizard Board - 11.

The recording on channel one will set the maximum available recording time for all other channels. Always

record servo channel one first. Recording periods for further channels two through six cannot be longer than

that set for channel one.

Servos shake, or will not operate correctly when connected to Wizard Board - 11

Use a power supply with more current. The servos may be using more amperage than the power supply can

handle. You can also split the power supply needs, by using 2 different supplies. One for the electronics and

one for the Servo Motors ( See manual on setting up board for using 2- power supplies )

How do I clear Memory to start a new program?

The Enable jumper must be set at the (E) enabled position.

The LOOP switch and the AUTO switch must be in the "N" position.

The RECORD - key is held down during Power Up, and released after power is applied.

The LED's will form a count down bar- graph indicating that current programmed

EEPROM memory is being cleared. (This will take approximately about 20 seconds).

After the initial 20 seconds all green LED’s will turn OFF and the current selected

Channel LED will turn ON, indicating the board is now ready for new programming.

How do I protect a recorded program that I like?

If the jumper is set at the “Enabled position, recording will be permitted. Remove to” Disable recordings and

protect the EEprom memory.

How do I apply correct power to the Wizard - 11 board?

Separate Duo Power Supplies: ( Wall Power Supply )

Connect a stable REGULATED 5-6 Volt DC @ 5 Amp supply to thePower Plug marked +6VDC. This

power connection supplies the servos, relays and digital outputs power only.

Connect a REGULATED 9 Volt DC supply to the second Power Plug marked +9VDC. This supplies

power to the board control electronics only, via the on-board power regulator component.

•

•

•

•

•

How do I set-up the Wizard - 11 board for the different playback options.

LOOP - slide switch

To make the Wizard - 11 board play the recorded moves repeatedly, move the switch to the "Y" position.

The recorded moves will start to play when the PLAY-key is pressed. There will be a pause at the end of

playing (determine by the position of the Move control) after which the moves will start again. Turn the

MOVE control counter clockwise (CCW) for the minimum delay (5 seconds and clockwise for the

maximum delay (approx 65 seconds). The PLAY LED flashes during the pause periods set.

Note: to record new program moves, the LOOP switch must be set to the "N" position.

AUTO - slide switch

To make the Wizard - 11 board play the recorded moves repeatedly on power - ON or reset, move the switch

to the"Y" position. The recorded moves will start to play on any power-up.

Note: to record new program moves, the AUTO switch must be set to the "N" position.

Pause between play loop option

When the Wizard - 11 board is set to the LOOP "Y"position, the length of the pause between repeated

playing may be set by the MOVE-position-control.

Turn the MOVE-position-control counter clockwise for the minimum delay (5 seconds) and clockwise for

the maximum delay (approx. 65 seconds).

I am very frustrated, I can't seem to get the Wizard - 11 board to work correctly.

Check all your connections and review the jumper settings to see that everything is correctly set.

Try using a power supply with larger current (amp) to the board.

Check your servos to see that they are operating correctly, by using a servo checker; you may have a bad

servo that is drawing large currents.

Try clearing memory and start from the beginning. Keep in-mind that you need to start with channel -1 to set

the proper time for all the other channels.

Re-read the user instruction manual again.

Check the user instruction manual drawings to make sure you have things set up properly.

Try a simple program routine first, and then work toward a complex routine once you have things working.

•

•

Phone (303) 651-3794

www.BPEsolutions.com

Blue Point Engineering

Custom Equipment, Unique Electronic Products

Wizard - 11 Controller Board

Troubleshooting Hints Cont.

•

When I playback a sound recorded the audio is bad.

Adjust the sound level from the sound source, to mid range or lower Do not over drive the sound source

output sound level volume as this will cause audio distortion in recording to the sound chip.

How can I erase the sound chip?

Recording a new set of sounds, is really the only way to full erase the sound chip.

I get a hum or strange noise recorded within my sound ic chip recording?

Make sure that you have a good quality audio cable connected from the sound card to your sound source.

Check to see that your original sound source does not have the extra noise in it.

Do not over drive the sound source volume when recording to the sound chip.

Make sure that there are no power sources or signal creating sources around,. across, or near your audio

cable.

I am having trouble getting the board to trigger by a remote sensor.

Check to see that you have the sensor connected to the REM terminal and not the Sync terminal. The

Sync terminal is used to activate other Wizard Boards connected to the Wizard - 11 board.

Check out the Blue Point Engineering web site for more information.

www.BPEsolutions.com

•

•

•

Custom Equipment, Unique Electronic Products Phone (303) 651-3794

Blue Point Engineering LLC. www.BPEsolutions.com

Instruction I

Blue Point

Pointing the Way to Solutions!

Engineering www.BPEsolutions.com

Controlling Devices by Wizard-11 Relays

Relay

Output

(NO)(C)

(-)

(+)

(-)

Black Wire

Red Wire

Wall Power Supply

(12 Vdc @ 1 Amp)

LED-Bar 1 LED-Light Bars

+

-

+

-

Red Wire

LED's

LED

Resistor

- OR -

Red Wire

12 VDC 3-15 VDC

240 VAC

Green

(Gnd)

White

Black

Red

Black

Wire

Wire

N.O

COM

NC

NO

NO

C

C

NC

Relay to LED Bar,

and Single LED's

LED Resistor

Wizard - 11

Controller

Relay

Output

Wizard - 11

Controller

Air

Hose

12 VDC 3-15 VDC

240 VAC

Green

(Gnd)

White

Black

Red

Black

Copyright © 2008 Blue Point Engineering, All Rights Reserved

12 Vdc

Power Supply

Wire

Pneumatic Cylinder

(Double Acting)

Air Hose

Air Hose

Air

Supply

Wire

N.O

COM

+ 12 Vdc

- 12 Vdc

NC

NO

NO

C

C

NC

5/2 Switching

Solenoid Air Valve

Exhaust

Ports

Wire

Relay to Pneumatic Valve

Relay

Connection

Table of contents

Other Blue Point Engineering Controllers manuals