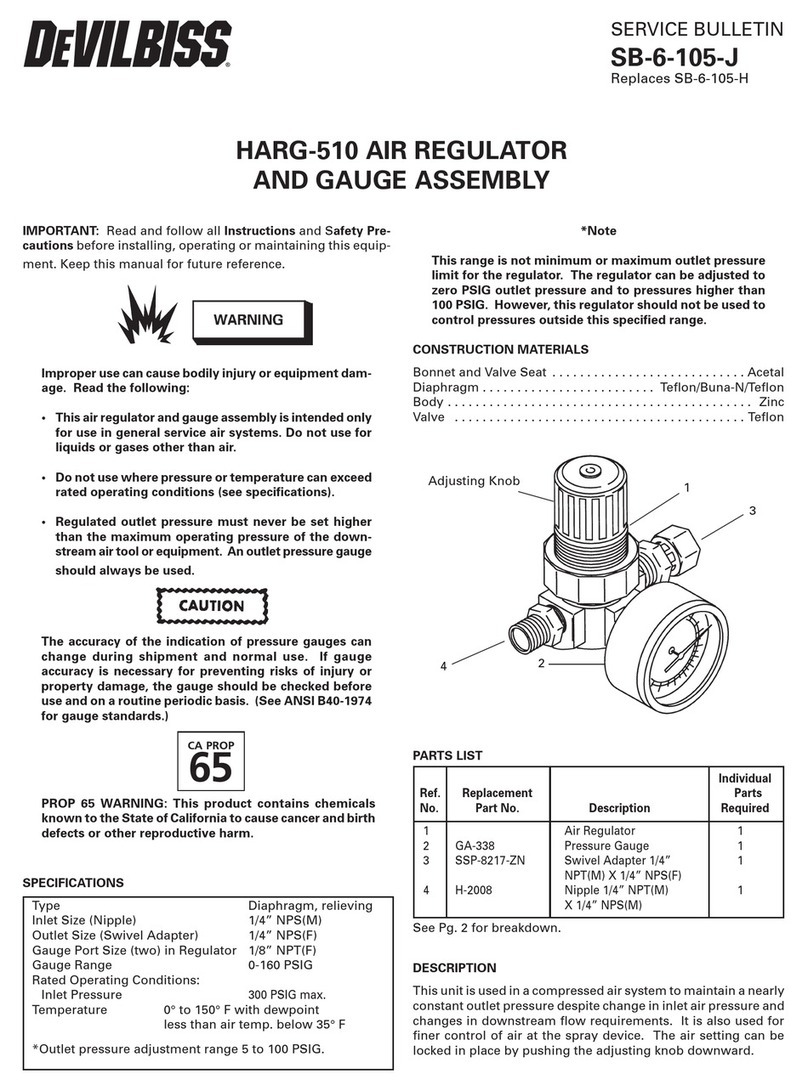

PARTS LIST

Individual

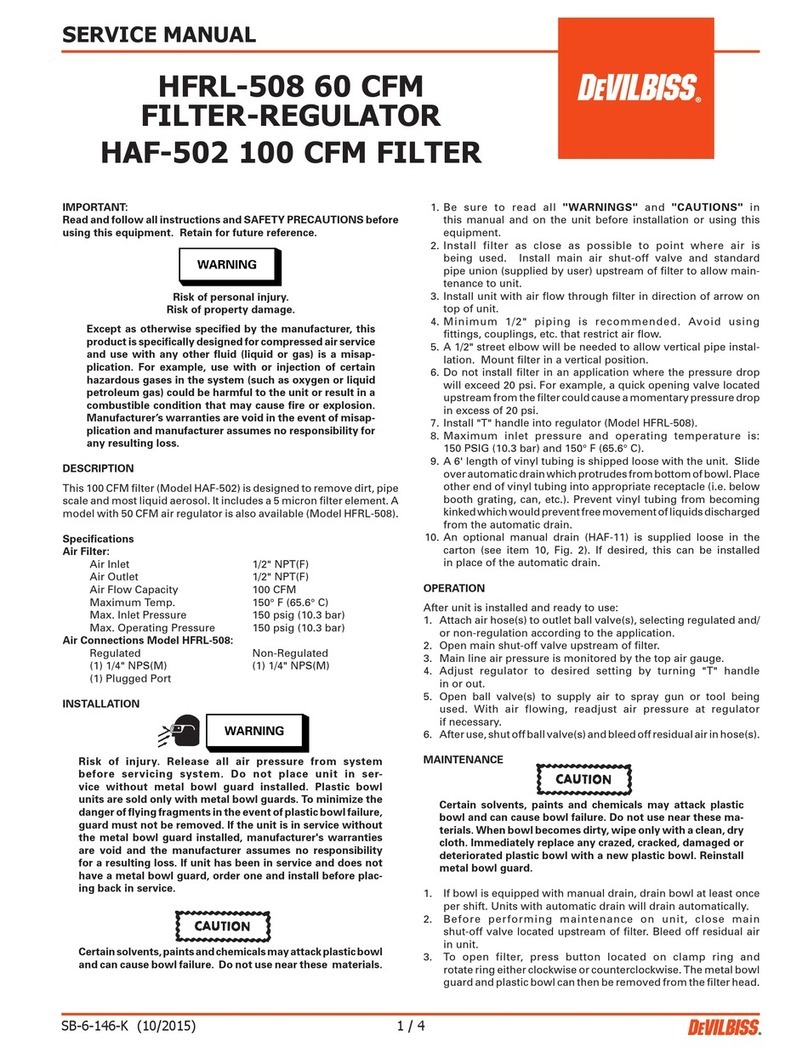

Ref. Replacement Parts

No. Part No. Description Required

1 Air Regulator 1

2 GA-338 Pressure Gauge 1

3 SSP-8217-ZN Swivel Adapter 1/4” 1

NPT(M) X 1/4” NPS(F)

4 H-2008 Nipple 1/4” NPT(M) 1

X 1/4” NPS(M)

See Pg. 2 for breakdown.

IMPORTANT: Read and follow all Instructions and Safety

Precautions before installing, operating or maintaining this

equipment. Keep this manual for future reference.

Improper use can cause bodily injury or equipment

damage. Read the following:

• This air regulator and gauge assembly is intended only

for use in general service air systems. Do not use for

liquids or gases other than air.

• Do not use where pressure or temperature can exceed

rated operating conditions (see specifications).

• Regulated outlet pressure must never be set higher

than the maximum operating pressure of the down-

stream air tool or equipment. An outlet pressure gauge

should always be used.

The accuracy of the indication of pressure gauges can

change during shipment and normal use. If gauge

accuracy is necessary for preventing risks of injury or

property damage, the gauge should be checked before

use and on a routine periodic basis. (See ANSI B40-1974

for gauge standards.)

SPECIFICATIONS

Type Diaphragm, relieving

Inlet Size (Nipple) 1/4” NPS(M)

Outlet Size (Swivel Adapter) 1/4” NPS(F)

Gauge Port Size (two) in Regulator 1/8” NPT(F)

Gauge Range 0-160 PSIG

Maximum Air Flow Rate 15 SCFM

Rated Operating Conditions:

Inlet Pressure

300 PSIG max.

Temperature 0° to 150° F with dewpoint

less than air temp. below 35° F

*Outlet pressure adjustment range 5 to 100 PSIG.

*Note

This range is not minimum or maximum outlet pressure

limit for the regulator. The regulator can be adjusted to

zero PSIG outlet pressure and to pressures higher than

100 PSIG. However, this regulator should not be used to

control pressures outside this specified range.

CONSTRUCTION MATERIALS

Bonnet and Valve Seat ............................Acetal

Diaphragm ........................... PTFE/Buna-N/PTFE

Body ............................................ Zinc

Valve ...........................................PTFE

2

4

3

1

Adjusting Knob

DESCRIPTION

This unit is used in a compressed air system to maintain a nearly

constant outlet pressure despite change in inlet air pressure and

changes in downstream flow requirements. It is also used for

finer control of air at the spray device. The air setting can be

locked in place by pushing the adjusting knob downward.

SB-6-105-R2 (4/2019) 1 / 4 www.carlisleft.com

IMPORTANT! DO NOT DESTROY

It is the Customer's responsibility to have all operators and service personnel read and understand this manual.

Contact your local DeVilbiss representative for additional copies of this manual.

READ ALL INSTRUCTIONS BEFORE OPERATING THIS DEVILBISS PRODUCT.

EN

SERVICE MANUAL

HARG-510 AIR REGULATOR

AND GAUGE ASSEMBLY