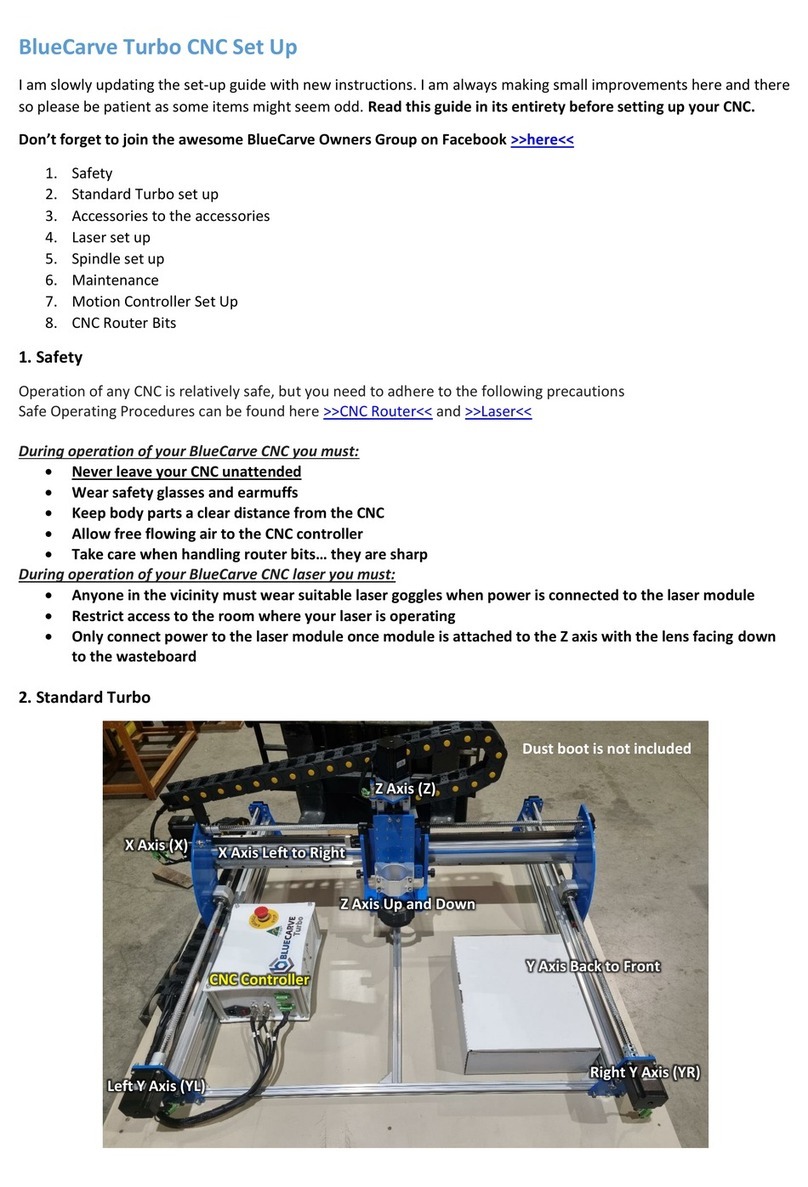

BlueCarve Spark Plasma Manual

Other BlueCarve Control System manuals

Popular Control System manuals by other brands

Certified Cirus Control Systems

Certified Cirus Control Systems Single Channel Motor Control Operation manual

Smartwares

Smartwares SHS-53000 user manual

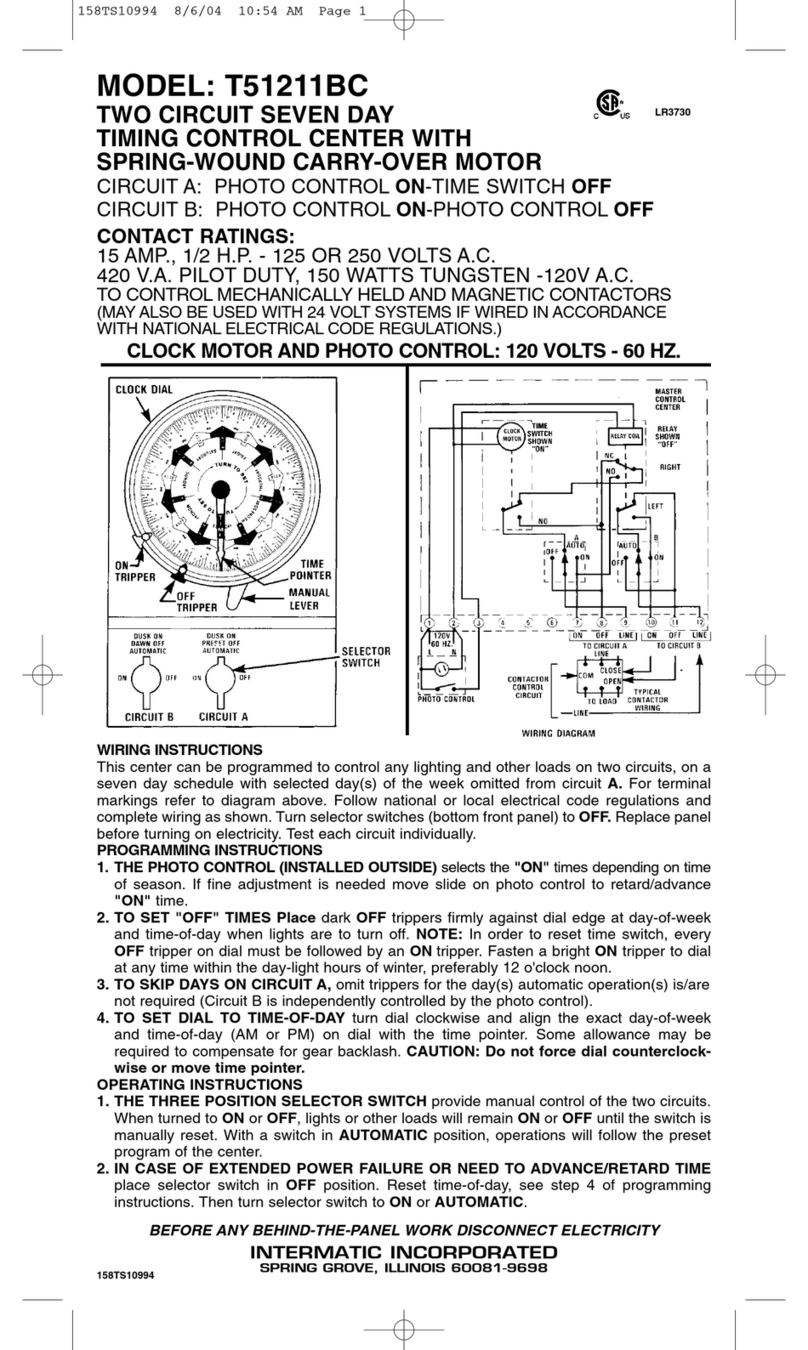

Intermatic

Intermatic T51211BC supplementary guide

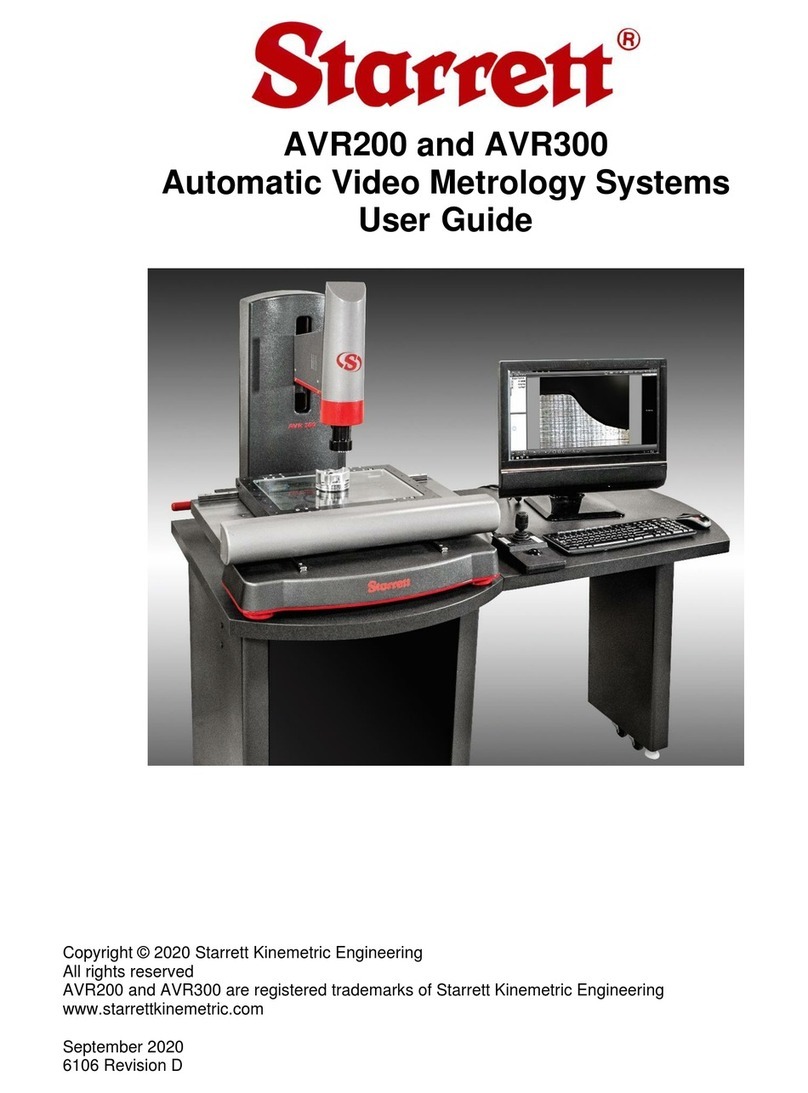

Starrett

Starrett AVR200 user guide

Siemens

Siemens SINUMERIK 840D Operator's guide

ADB

ADB AGLAS user manual

OPTO 22

OPTO 22 B3000-B user guide

John Crane

John Crane API PLAN 74 STEAM Installation, operation & maintenance instructions

Alutech

Alutech BV-5-868 Assembly and operation manual

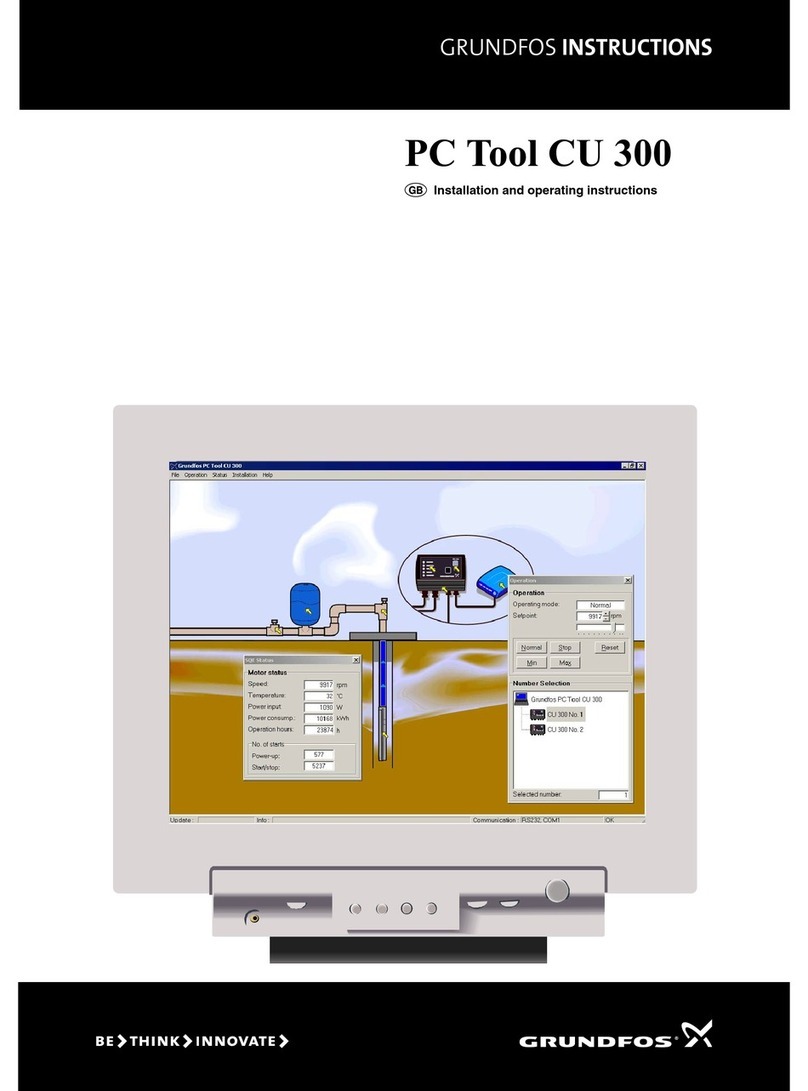

Grundfos

Grundfos PC Tool CU 300 Installation and operating instructions

Lindsay

Lindsay Universal TAU-II installation manual

Sutter Instrument

Sutter Instrument MPC-325 Series Operation manual