bluelab IntelliDose User manual

IntelliDose Controller

User Manual

English

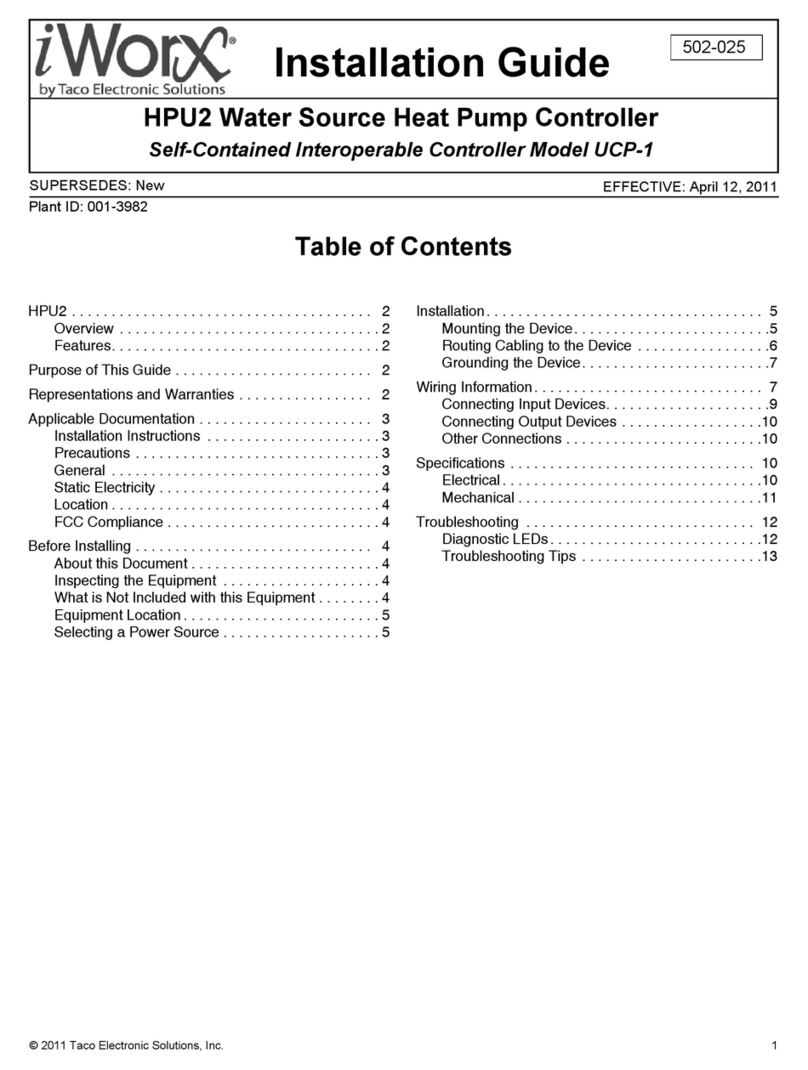

Contents

1.0 Introduction & Overview .............. 3

1.1 Features ........................................... 3

1.2 What’s in the box? .......................... 3

1.3 Key functionality ............................. 4

1.4 Edenic Software .............................. 5

2.0 Understanding your device .......... 6

2.1 The controller ................................. 6

2.2 The display ...................................... 6

2.3 Terminal block ................................ 7

2.4 Menu ................................................ 8

3.0 Initial Configuration ...................... 9

3.1 Configuration menu ....................... 9

3.2 Selection of units ............................ 9

3.3 Powered Outputs ......................... 10

3.4 Other settings ............................... 10

4.0 Installation .................................... 11

4.1 Mounting ....................................... 11

4.2 Configure Outputs ........................ 11

4.3 Wiring probes ............................... 11

4.4 Connecting pumps and solenoids

.......................................................... 12

4.5 Typical installation diagrams ...... 13

4.6 Controlling 110/240 VAC.............. 15

4.7 Peristaltic Pumps .......................... 16

4.8 Placement of the probes ............. 17

4.9 Set up inlet dosing tube ............... 17

5.0 Dosing setup ................................. 18

5.1 Dosing Menu ................................. 18

5.2 Set Point ........................................ 19

5.3 Dose time ...................................... 19

5.4 Dose interval ................................. 19

5.5 pH Raise or Lower ........................ 19

5.6 Multi-part dosing .......................... 20

5.7 Advanced Dosing .......................... 21

5.7.1 Water top up ........................... 21

5.7.2 Proportional Dosing ............... 21

5.7.3 Sequential Dosing ................... 21

5.7.4 Day/Night EC............................ 22

5.7.5 Scheduling ............................... 22

5.8 Dosing Lockout ............................. 22

6.0 Irrigation ....................................... 23

6.1 Irrigation Menu ............................. 23

6.2 Station settings ............................. 24

6.3 Separate Pump ............................. 24

7.0 Alarms ........................................... 25

7.1 Alarm Menu .................................. 25

7.2 Parameter Alarms ........................ 25

7.3 External Output ............................ 25

8.0 Calibration .................................... 26

8.1 How to perform a pH calibration 26

8.2 Conductivity Calibration .............. 28

8.3 Calibration Tips ............................. 29

9.0 Cleaning & Maintenance ............ 30

9.1 Bluelab pH Probe care ................. 30

9.2 Cleaning the Bluelab pH Probe .. 31

9.3 Hydrating the pH probe .............. 32

9.4 Peristaltic Pumps .......................... 32

10.0 Troubleshooting & FAQ ............. 33

10.1 Troubleshooting guide .............. 33

10.2 Frequently asked questions...... 34

10.3 Controller Menu ......................... 35

11.0 Specifications ............................. 36

11.1 Technical specifications ............. 36

11.2 pH adjuster compatibility for

tubing¹.............................................. 38

12.0 Accessories & Warranty ............ 39

12.1 pH Probe replacement .............. 39

12.2 Probe Care Kits ........................... 39

12.3 Peristaltic Pump .......................... 39

12.4 Acid/Alkali Resistant Dosing Tube

with Connectors ............................... 39

12.5 pH Probe KCl Storage Solution .. 39

12.6 Bluelab limited warranty ........... 40

13. Get in touch .................................. 41

1.0 Introduction & Overview

1.1 Features

Nine outputs

available for dosing

nutrients, additives and pH

Four (24 VDC) outputs available

for irrigation if not used for

nutrients.

Controls all growing methods -

NFT, DFT/DWC, soil, media, drip,

and aeroponics.

Proportional dosing rapidly

adjusts between irrigations.

Sequential pump control allows

each additive time to mix.

Displays EC, CF, TDS, ˚C, ˚F, pH

Set different Conductivity (EC) for

day and night.

Water level control – to lower EC

Adjustable alarms and dosing

lockouts prevent overdosing or

running dry.

Control 120 / 240 VAC pumps,

heaters and chillers on a timer,

when connected to a Bluelab

Power Relay.

When connected to Edenic*

Instant alarm alerts to your

phone.

Remote monitoring and

control.

History reporting to

assist

data-driven decision-making.

*Requires Bluelab IntelliLink and internet access

What are Dosing Lockouts for? They are a built-in safety feature that stops Acid or

Nutrient dosing if an error is detected in the system.

1.2 What’s in the box?

1x IntelliDose controller

1x EC probe

1x pH Probe

1x Sample pot with all fittings

6x Calibration solution sachets (to get you started)

1x 24V DC 2.5A power supply

4x IEC Power cables (Type A (US), C (EU), G (UK) and I (AU))

1x 3m USB cable

1x Mounting hardware

1x Instruction manual

1.3 Key functionality

The IntelliDose is suitable to most hydroponic applications. To keep the user interface

as simple as possible, only the readings and settings relevant to the selected features

are displayed on the controller’s LCD. For access to more advanced options connect

your IntelliDose to Edenic software via an IntelliLink (purchased separately).

We recommend using a quality handheld meter to spot-check your EC & pH on a

regular basis, ensuring your probes are reading correctly and holding calibration.

Install the IntelliDose controller to one side of the mixing tank where it will not be

exposed to splashes and vapours. Remember, the sensor leads (5m) must be able to

reach the sample pot which should be mounted just above the top of the mixing tank.

Typical installation using peristaltic pumps

TIPS:

The output terminal order is dynamic and will change based on the number

of components (pumps and solenoids) that you are driving.

Mount sample pot just above top of tank as many small pumps have low

head pressure capability.

Adjust the valve on inlet pipe to the sample pot to achieve a steady flow

without excessive turbulence or air bubbles in the sample pot.

Mount IntelliDose away from moisture, preferably just outside grow room.

Clean the Conductivity sensor and calibrate all sensors before use.

Fill stock tanks and mix tank with plain water and run for a day to check for

leaks and observe operation is correct.

IMPORTANT:

When using automatic dosing, the stock solutions and acid/alkali must be diluted.

Diluting the acid to below 2% strength ensures it does not react adversely with your

nutrient and will also increase the life of the peristaltic tubing. This is particularly

important if a small mixing tank (e.g. under 1,000L/250gal) is used.

You may need to experiment with the dilution rate of the nutrients/acid/alkalai so that

three, 3 to 8 second doses result in a change of;

Nutrients: TDS of 50ppm (0.1EC or 1CF).

pH, of 0.1pH.

It is important the tank is continually stirred while dosing and there is a continuous

gentle flow through the sample pot. If the sample pot is mounted too high there is a

danger of the flow ceasing if the pump loses pressure (head) for any reason such as

wear or a partially clogged input filter.

1.4 Edenic Software

If your IntelliDose is connected to an IntelliLink then it can send and receive data from

Edenic. Edenic by Bluelab is a cloud-based software solution that can be accessed on

your mobile device or computer. Allowing you to remotely configure and control your

parameters, schedules and set & receive alarms.

Although you can set almost everything directly on the controller, the below features

are only available in Edenic.

Wiring diagram for IntelliDose dynamic terminal

Scheduling

History reporting, exports and graphs.

For more information on Edenic please visit https://www.edenic.io/

2.0 Understanding your device

2.1 The controller

2.2 The display

Exit / Cancel

soft

button

Menu / Enter

/

Save

/

Edit soft button

Up

and

Down

buttons

Power status

Alarm status

24 VDC

Input Power

Conductivity and

temperature Probe

pH

Probe

Terminal Block

Parent menu

Parameter and

current value

Indicates the function the two

soft

buttons underneath the display

2.3 Terminal block

The IntelliDose output voltages for dosing and irrigation are dependent on the power

supply adapter used. The IntelliDose is supplied with a 24VDC power supply, but can be

run from a 12-24 V DC or AC power supply with a maximum of 2.5 A.

The IntelliDose has 9 output terminals, shown in the above diagram numbered 1-9.

These are dynamic and change depending on the confiuration of the IntelliDose. If

connected to Edenic, a wiring diagram can be automatically generated by the App.

The outputs are assigned in priority with the order being;

Nutrients (From 1 up to 9)

pH Raise

pH Lower

Irrigation Pump

Fresh Water

Alarm

Irrigation solenoids (From 1 up to 4)

Example configuration for a drip to waste system would be two nutrient parts (A and

B), pH Raise, pH Lower, Irrigation Pump, Alarm, Three irrigation stations. See the

diagram below for how the IntelliDose would configure that;

Terminal output is 24 VDC with the Bluelab supplied Power supply.

2.4 Menu

The two keys at the bottom of the display are “soft keys”. This means their function, is

shown on the screen above them. After switching on, you will see the right-hand key

has the label “menu” on the LCD above it and the left-hand key is unused at this point.

To the right of the LCD screen are two arrow keys. The arrow keys are used for moving

up or down through the menus, editing a numeric value, or to select between different

options.

DOSING

Set your targets, dosing times,

dosing intervals and enable

different

day

-

night conductivity values.

CALIBRATION

Calibrate pH or Conductivity probes using a

calibration solution.

For pH you will need pH 7 and pH 4 calibration solutions.

For Conductivity you will need EC 2.77 calibration solution.

OVERRIDES

Temporarily m

anually

override outputs to test system install or

do additional dosing when required.

IRRIGATION

Only available if irrigation is enabled in the

C

onfigure >

Advanced > Output menu.

Set irrigation run time, Irrigate at fixed times or frequency and

irrigate day only or at day and night.

ALARMS

The alarms can be enabled

to drive

a

buzzer

/siren

or to

give

mobile notifications when using Edenic. Each of these can be

silenced or enabled. Any enabled alarm will sound when a

relevant reading deviates outside set limits.

CLOCK

Set the time for day start and day end

–

required for day/night

EC settings.

Set the

current time and date.

CONFIGURE

Adjust units (Conductivity and Temperature)

and date format.

Mute the buzzer.

Adjust screen contrast and brightness.

Select what outputs you need enabled.

When you first access the menus, go to Configure > Advanced > Output and program

which features you are using (ex: pH Dosing direction and Irrigation). If you do not

install a feature, you will not have access to set it up in the previous menus.

Example, If you wish to change irrigation timings, move down to irrigation and press

“enter”. Now pressing the down and/or up arrows moves through this sub-menu,

press enter to access an item. After making any changes the soft keys will allow you

to either save the new setting or to cancel and exit out of that screen.

3.0 Initial Configuration

3.1 Configuration menu

Configure

Offline Log Time

Period in which variables are logged onto the device

.

Nutrient Units

Set conductivity units as EC (Default), CF or TDS)

Date Format

Set date to be mm/dd/yy or dd/mm/yy

Temperature Units

Adjust between °F (default) and °C

Buzzer

Mute or enable (Default) the internal buzzer

Screen

Contrast

Adjust screen contrast to help with visibility

Backlight

Adjust screen brightness to suit the environment

Info

Version information for IntelliDose and connected probe.

Advanced

Dosing type

-

Simple (default) or Propotional

Dosing mode - Sequential (default) or

simultaneous

Lockouts - Stop the device from dosing if

measured values are outside accepted range.

Outputs;

Nutrient Parts (default 2)

pH Output (default Lower)

Irrigation - disable (default) / enable irrigation

Station Outputs - disable (default) / enable. Only

visible if irrigation is enabled

No. Station Outputs - Adjust from 1 to 4

depending on the number of zones.

Station Mode

Water dosing - disable (default) / enable irrigation

Alarms - disable (default) / enable external alarm

output

3.2 Selection of units

You may select either EC, CF or TDS (ppm) units for the Conductivity measure (nutrient

strength) and either °C or degrees °F for temperature. The acidity or alkalinity is always

measured in pH. In this manual, we use EC (electrical conductivity) to denote either EC,

CF or TDS. The date format is selectable between mm/dd/yy and dd/mm/yy formats.

The TDS standard used for this controller is EC x 500 but it is possible to select EC x

640 and EC x 700 when using Edenic software.

3.3 Powered Outputs

Other menus (such as irrigation) are only accessible if that function is enabled. Before

installing it is best to go through the Advanced > Outputs menu to enable functions

you require.

Note there are 9 outputs, the IntelliDose will block settings if all 9 are allocated.

Nutrient Parts

Adjustable from 1 through to 9 (default is 2 parts). Set this for how many nutrient

parts you will be mixing. If using an A and B nutrient mix then you would only

need 2 nutrient parts.

pH Output

You can have pH Lower (default, and most common for hydroponic operations),

pH Raise or both.

Irrigation

Enable irrigation pump control, this is disabled by default.

Station Outputs

Disabled by default gives one output for irrigation, enabling gives a single

irrigation station by default. This will give two irrigation outputs (one for the pump

and one for the zone solenoid valve). Only visible if irrigation (above) is enabled.

No. Station Outputs

Adjust from 1 to 4 depending on how many irrigation zones you have.

Station Mode

Set as either Independent – each irrigation zone can have it’s own trigger/timing

or Sequential – all the irrigation zones run on the same timing one-after-another.

Water dosing

Control a pump for water top-up, required in Nutrient Film Technique (NFT)

operations, to reduce conductivity. This is disabled by default, and is dependant

on different EC for day and night.

Alarms

This output is for a light/siren and will be powered whenever any alarm is raised

from the IntelliDose settings. By default it is disabled.

3.4 Other settings

Adjust the remaining settings based on your requirements.

The Date format,

Internal buzzer enabled or disabled

Screen brightness

Screen contrast

4.0 Installation

4.1 Mounting

The IntelliDose controller should be installed in a cool, dry place out of direct sunlight.

Remove the screws holding the back, fit the mounting feet, then screw to the wall. If

using the dry wall (plaster board) anchors, use the longer screws supplied. If fixing to a

plywood board, use the shorter screws.

4.2 Configure Outputs

When you first access the menus, go to Configure > Advanced > Output and program

which features you are using (ex: pH Dosing direction and Irrigation). If you do not

install a feature, the specific menus for that feature will be disabled. Refer section 3.3.

ADDITIONAL TIPS:

If an irrigation pump is used, a second small pump should be used to

circulate the solution through the sample pot and keep the tank stirred.

If the irrigation water is returned to the reservoir tank, allowance must be

made for the level to rise above the float valve level.

4.3 Wiring probes

The low voltage power from the adapter is connected to the two left connection

terminals. On the included power supply, the white wire is Live and the black wire is

Common.

The Conductivity probe (EC) connects to the far right terminal, with the red, white and

black wires connected as per the above diagram.

The pH probe connects to the BNC terminal, it needs to push in and then turn to click

into place.

4.4 Connecting pumps and solenoids

The wiring diagram for pumps and solenoids depends on your configuration of the

IntelliDose. The outputs from 1 to 9 change depending on the options selected.

Example wiring diagram for dosing 3 nutrient parts and pH lower.

The connection diagram for more than 3-part nutrients must be mapped by Edenic

software, AFTER configuration has been complete. If you are not using Edenic, please

visit the Bluelab support knowledge base for wiring diagrams of all configurations.

As a guide, from left to right the outputs will be in the order of;

Nutrients, pH Raise, pH Lower, Irrigation Pump, Water top up, Alarm, Irrigation stations.

Example wiring diagram with 2 nutrient parts, pH Raise, pH Lower, an Irrigation Pump

– with 3 irrigation stations and an alarm output.

4.5 Typical installation diagrams

The following diagrams are illustrative of typical installations. All of these are using two

nutrient parts and pH Lower.

Reservoir control using submersible pump

Nutrient film technique (NFT)

NFT with valve to add water to dilute conductivity

Drip to waste with solenoid valves and irrigation pump controlled via a

contactor panel

4.6 Controlling 110/240 VAC

The IntelliDose outputs are 24 VDC from the supplied plug pack. If you need to drive

larger devices that are 110/240 VAC powered (i.e an Irrigation pump) you can use a

Bluelab Power Relay R4.

Please refer to the Bluelab Power Relay R4 Manual for complete details of the product.

You will need the right version for your regional socket type. The Power Relay R4 has 4

separate outputs, but the total mains current draw should not exceed the rating (refer

to product specification for more information). The input cable supplied with the

Bluelab Power Relay R4 unit has the following wiring configuration:

Wire Colour

Designation

Black

Common (GND)

Yellow

Output 1 (S1)

Green

Output 2 (S2)

White

Output 3 (S3)

Blue

Output 4 (S4)

4.7 Peristaltic Pumps

Bluelab Peristaltic pumps are rated for 12 - 24 VDC. You can run up to 9 peristaltic

pumps from an IntelliDose Controller. Peristaltic pumps should be installed above the

stock tanks and the reservoir. Place stock tanks on the ground, next to the reservoir.

Important: Peri

staltic

Pump mounting height should not exceed maximum 2.1

metres

/

7 feet measured from the bottom of the stock tank.

4.8 Placement of the probes

The tip of the Bluelab pH Probe must be submerged in the liquid.

Do not pour concentrated nutrient solution or pH adjuster directly onto probes when

in the reservoir. Strong acids, alkali and nutrients damage the probes, trigger the

alarms (if on) or cause the pump to accidentally dose or stop dosing.

Ensure the probes are in an area where the reservoir/tank solution is well mixed.

pH and conductivity probes can be fully submerged in the solution.

1.

Remove the storage cap from the pH probe by

gripping the top of the cap and gently twisting

the base one rotation to loosen. Slide the

storage cap off the pH probe.

2.

Fit

the

(optional)

pH

probe

holder

to

the

stem

of

the pH probe using a gentle twisting motion.

3. Place the pH probe into the reservoir/tank and

push the suction cup onto the side of the

reservoir but far enough down so the pH probe

tip is always in the solution. This prevents

damage to the probe from any movement in the

reservoir/tank.

4. Place the Conductivity probe alongside the pH

probe.

4.9 Set up inlet dosing tube

Ensure the inlet dosing tube will reach the

bottom of the pH stock solution container.

There also needs to be enough tube left for the

outlet dosing tube to go into the reservoir/tank.

Inlet dosing

tube

Dosing tube reaches

bottom of container

Inlet tube cap

pH stock

solution

5.0 Dosing setup

Mixing nutrients - IMPORTANT - PLEASE READ THIS CAREFULLY!

When using any automatic doser, it is important the nutrients and acid/alkali are

diluted to 2%. The instructions on many dry powdered nutrients tell you to prepare

the stock solutions to quite a concentrated level (100:1 or more). Liquid nutrients are

also very concentrated. For a small mixing tank, this will be too strong and even if very

short doses are given the system will overshoot. If using powdered nutrients, mix into

water so that for each 1 Kg (2.24 lbs) of powder you obtain at least 20 L (5 gal) of

solution. Liquid nutrients should be diluted with water to make up at least 5 times

their original volume. Acids and alkalis should be diluted to be less than 2% strength. If

using strong acids, always wear goggles, gloves and add the acid to the water then stir

well.

5.1 Dosing Menu

EC

And

pH

S

etpoint

Dosetime

Dosing Interval

E

nable (default) / disable

Day/Night EC (default is same)

Mix %

Set the % of on

time for each nutrient part.

100% will be equal to the EC Dosetime.

Dosecount

Dosecount failsafe disable (default) /

enable

Max EC doses/hour

Max pH doses/hour

Hold

-

off Time

Reset EC dosecount

Reset pH dosecount

Dose times and intervals are set by trial and error. The smaller the reservoir, the

smaller the dose time needs to be. The strength or concentration of your stock

solutions will also affect the dose time setting. The stronger the stock solution, the

shorter the time the pump runs. If you are using a small reservoir tank you must

ensure your stock solutions are very dilute.

5.2 Set Point

Set your targets for pH and Conductivity (EC)

5.3 Dose time

When you have the dilution right, you should get a 0.1 change in EC with three 2 second

(minimum) dose times of A and B solutions.

In a similar way, the pH should change by about 0.1 pH with three 2 second doses of pH

adjuster solution. If it takes four or five doses to change, that is fine, but if it changes by

more than 0.1, you will need to dilute the solution further.

Best dosing accuracy is achieved with longer dose times. If any ratios of a multi-part

mix are set to a short dose time, then it is important to ensure dose time is still above

2 seconds.

5.4 Dose interval

The delay time between each dose. This gives the system time to mix the stock

solution into the reservoir thoroughly before the next dose, allowing the Bluelab

IntelliDose Controller to measure the solution accurately.

Start with a longer Dose Interval and adjust back as you go. The more thorough the

mixing in the tank, the shorter the interval can be. Larger tanks will require a longer

mixing time.

5.5 pH Raise or Lower

For most growers, pH lower is the common requirement. Depending on water source,

nutrients and plant growth, you may find you need to use pH Raise at certain growth

stages. The IntelliDose can be configured to run no pH adjuster, pH raise, pH lower or

both. If you choose to run both, you will be able to wire up separate peristaltic pumps

to the raise and lower outputs, but the system will only be able to dose in one

direction at a time.

To change direction, you need to manually switch either using the controller keypad

navigate to Menu > Configure > Advanced > pH Output Setup or via Edenic. This

manual intervention is a safety feature to prevent dosing in the wrong direction.

5.6 Multi-part dosing

For 1-part dosing, only one dosing pump is used to add nutrient to the mixing tank.

When 2-part dosing is selected then two dosing pumps will be used to add part A and

part B stock solutions. If the part A and part B do not dose at exactly the same rate (one

tank empties quicker than the other) there are a number of reasons why this may occur.

Including different pipe arrangements, filters partly blocked, tanks or dosing valves

mounted at different heights and even the difference in specific densities of the stock

solutions.

To compensate for this, you may adjust the two dose rates electronically by reducing

either A or B dose rates below 100%. For example, if you set Nutrient 1 at 100% and

Nutrient 2 at 95%, then Nutrient 2 pump will dose for a shorter Dose Time each cycle.

Always leave one at 100% and reduce the other nutrients.

Example:

If dose time is set to 5 seconds, and nutrient part 2 is set to a ratio of 10%. A ratio of

100% = 5 seconds, so a ratio of 10% be only ½ a second, an insufficient time to achieve

accurate dosing.

The solution is to increase the dose time to 20 seconds. At 20 seconds a 10% Mix ratio

nutrient will dose for 2 seconds (which will be more accurate).

If these longer nutrient doses increase the EC by more than the desired 0.1 EC

(50ppm) every 3 cycles, you will need to further dilute the stock solutions or use a

larger reservoir tank - or a combination of both.

Another approach is to dilute only the nutrient parts that require lower ratios. For

example, a recipe recommends 100:50:10. If the dose time is set to 5 seconds then

part A would dose for 5 seconds, part B for 2.5 and part C for only 1/2 second. By

diluting part C in water with 1-part C to 4-parts water, it would reduce its strength to

1/5th of the original. Then you would schedule 100:50:50 which will be more accurate.

Table of contents

Other bluelab Controllers manuals

Popular Controllers manuals by other brands

MKS

MKS 647B instruction manual

Siemens

Siemens SIMATIC ET 200SP manual

PRECISION DIGITAL

PRECISION DIGITAL Helios PD2-6310 instruction manual

TELEDYNE OLDHAM SIMTRONICS

TELEDYNE OLDHAM SIMTRONICS MX 43 user guide

Hanna Instruments

Hanna Instruments HI 8931 instruction manual

HomeMatic

HomeMatic HmIP-WUA Installation and operating manual