BMC PS2000TL+ User manual

V1.31

TableofContents

1. Features --------------1

--------------2

2. How to Install Roll Paper

2-1 Specification of thermal roll paper --------------1

2-2 Step of changing --------------1

2-3 How to removing paper after paper jamming --------------2

2-5 How to adjust paper near-end sensor --------------2

3. How to change the memory back-up battery --------------1

4. Operation for maintenance

4-1 System reset --------------1

4-2.Cancel password of the control lock mode

4-3 Display program version --------------1

4-4 All RAM memory clear --------------1

4-5 Communication port loop-back test --------------2

4-6. E-PROM CHECK-SUM Printing --------------3

5. Logic Circuit

5-1 Connection Diagram --------------1

5-2 Block Diagram --------------2

5-3 Primary power circuit --------------3

5-4 Power circuit --------------4

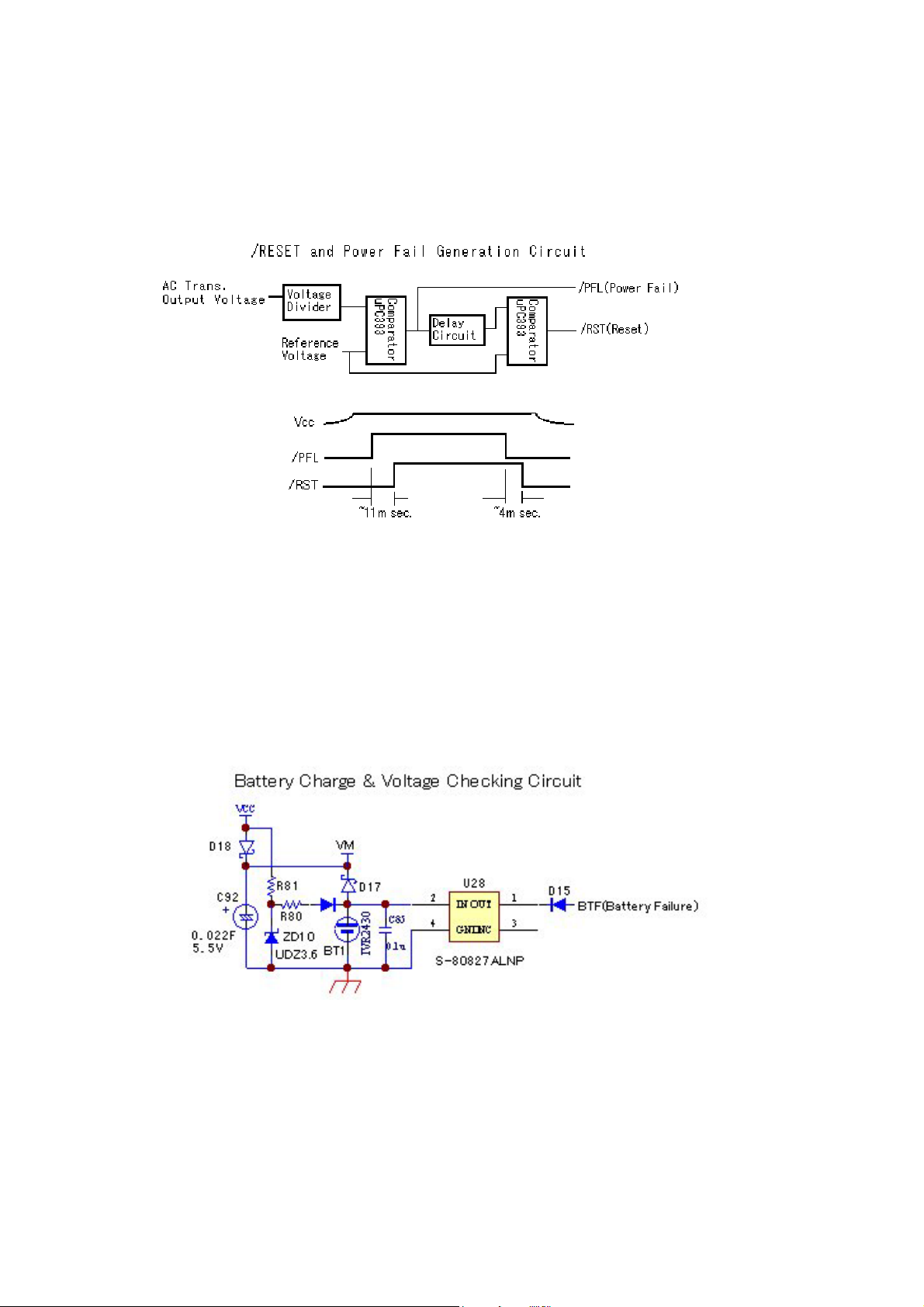

5-5 Power failure & Reset signal generation circuit--------------5

5-6 Battery charge & Voltage checking circuit --------------5

5-7 Memory selection circuit --------------6

5-8 I/O selection circuit --------------7

5-9 Real-Time clock circuit --------------8

5-10 Buzzer circuit --------------8

5-11 Drawer circuit --------------9

5-12 Key scan circuit --------------10

5-13 Keyboard physical position & Matrix

for Conversion key type --------------11

5-14 Keyboard physical position & Matrix

for Flat key type --------------12

5-15 LCD display circuit --------------13

5-16 VFD display circuit --------------14

5-17 Thermal printer circuit --------------15

6. Printer Maintenance

6-1 Cleaning --------------1

6-2 Inspection --------------1

6-3 Lubrication --------------2

6-3-1 Type of Lubricant --------------2

6-3-2 Lubrication standards --------------2

6-4 Tools & Jigs

6-4-1 List of Tools --------------2

6-5 Troubleshooting of printer

6-5-1 Repair Levels --------------3

6-5-3 Repair Procedure --------------3

6-6 Head Connector --------------8

TableofContents

7. Parts List

7-1 M-T245 Printer --------------1

7-2 Main board Assy --------------4

7-3 Front Display board Assy --------------7

7-4 Rear Display board Assy --------------8

7-5 AC Line Noise Filter board Assy --------------8

7-7 Keyboard Assy --------------9

7-8 Housing Assy -------------12

7-9 Printer Assy -------------14

7-10 Others --------------14

8 Circuit Diagram

8-1 Main board 1/4

8-2 Main board 2/4

8-3 Main board 3/4

8-4 Main board 4/4

8-5 Front display board

8-6 AC Line Noise Filter board

8-7 Back Display board

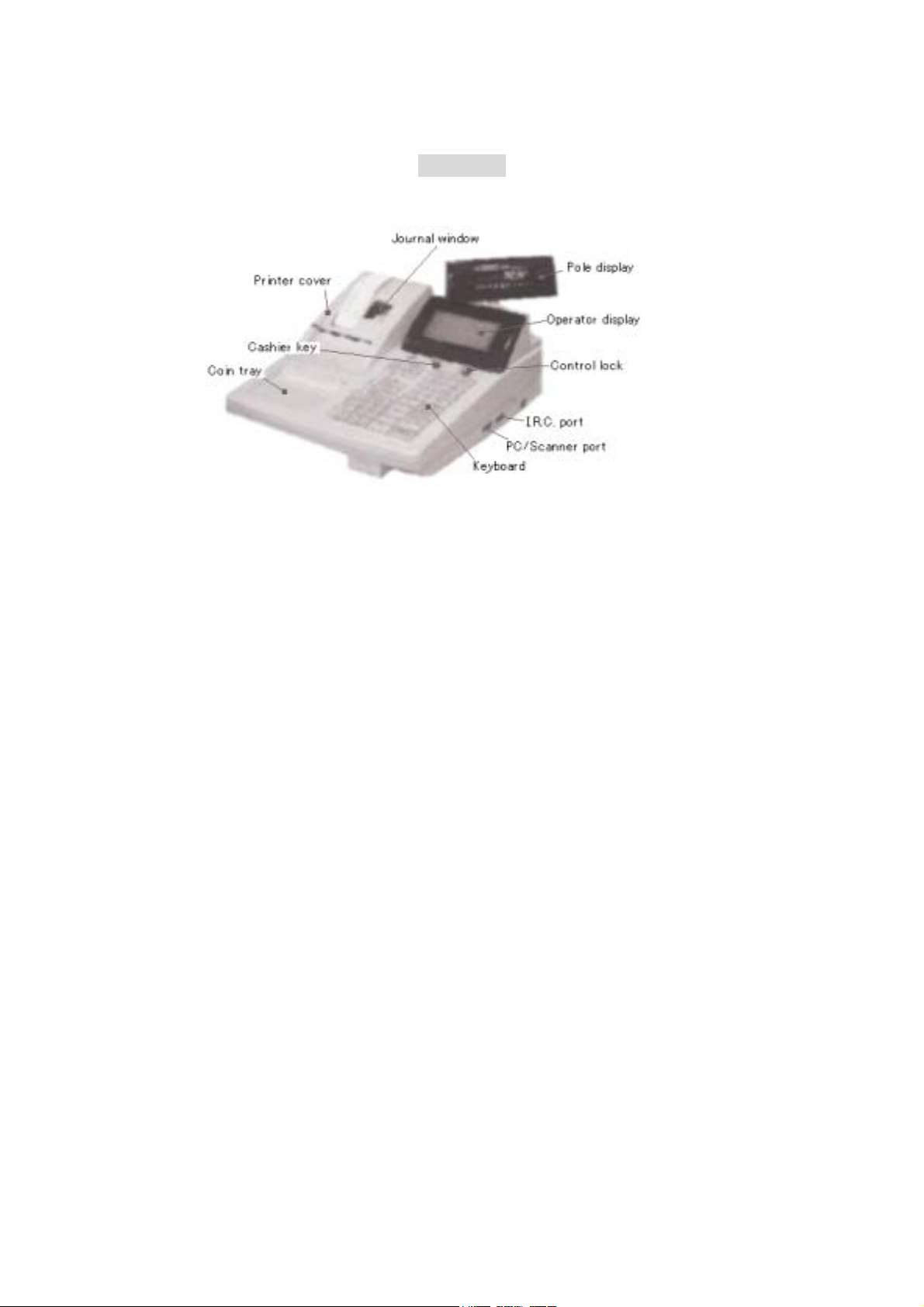

1. Features

The PS2000TL+ is an excellent electric cash register that is equal to a P.O.S. system.

It’s loaded a two-station heavy-duty thermal printer with auto cutter and four lines big

size LCD display with back-light for operator. The general hardware specifications

are as follows.

1-1. Printer Head 2 Station Line Thermal EPSON M-T245

MCBF : 500Mil Lines

Paper Width Receipt 45mm /Journal 45mm x 80φ(Max)

Thermal Head 8 dots /mm

Printing Speed About 17 Line/Sec

Auto Cutter Standard ( Full & Partial Cut)

MCBF:330,000Cut

Paper End Sensor Receipt & Journal

Paper Near End Sensor Receipt & Journal

Paper Auto Loading Available

1-2. Display

1-2-1 Operator Display 20 x 4 Line LCD with Back-light

View Area 123.0 (W) x 42.5(H)

Character Size 4.84 x 9.22 mm

1-2-2 Customer Display Numeric VFD

2-3 External Display (Option) 20 Alpha x2 Line LCD/VFD

1-3. Keyboard

Conventional Keyboard Type 80 keys Matrix

Flat Keyboard Type 173 keys Matrix

1-4. Operation Key

Control Lock 6 positions

Cashier Key 4 Kinds

1

1-5. Memory

C-MOS RAM( on Main Board) 4 M bits x 1 ( 512K Bytes) Standard

C-MOS RAM(on Option Board) +4Mbits x 1 (512k Bytes)

Total 1M Bytes max.

Program Memory 2 M bits(256K Bytes Max.)

1-6. Memory Back-up battery Chargeable & Changeable

Lithium Ion Battery 3.0V 60mAh ( 50 days)

1-7. Interface

TYPE-I TYPE-II

Serial Port 1( on Main Board) RS232C ( 9 pin D-SUB)

PC / Barcode Scanner/ Slip Printer/ Modem

Serial Port 2( on Main Board) RS485( 9 pin D-SUB)

(available to change to RS232C by jumper modification)

I.R.C network

Serial Port 3( on Option Board) RS232C (9 pin D-SUB)

PC / Barcode Scanner + Ext. Display / Slip Printer

Serial Port 4( on Option Board)

Type-I RS232C(9pin D-SUB)

Type-II RS232C(DIN connector)

ARC. Net(RJ45) only on Option Board-TypeII

1-8. Optional Peripheral Device

Slip Printer EPSON TM295

Barcode Scanner

Kitchen Printer

Kitchen Printer Control Box( 4 suitable Terminal Printer Connection are available )

External Display( for Customer)

Credit Card Reader(Extension)

Scale

1-9. Power Consumption AC120V 60Hz 48W(max.)

AC230V 50Hz 48W(max.)

2

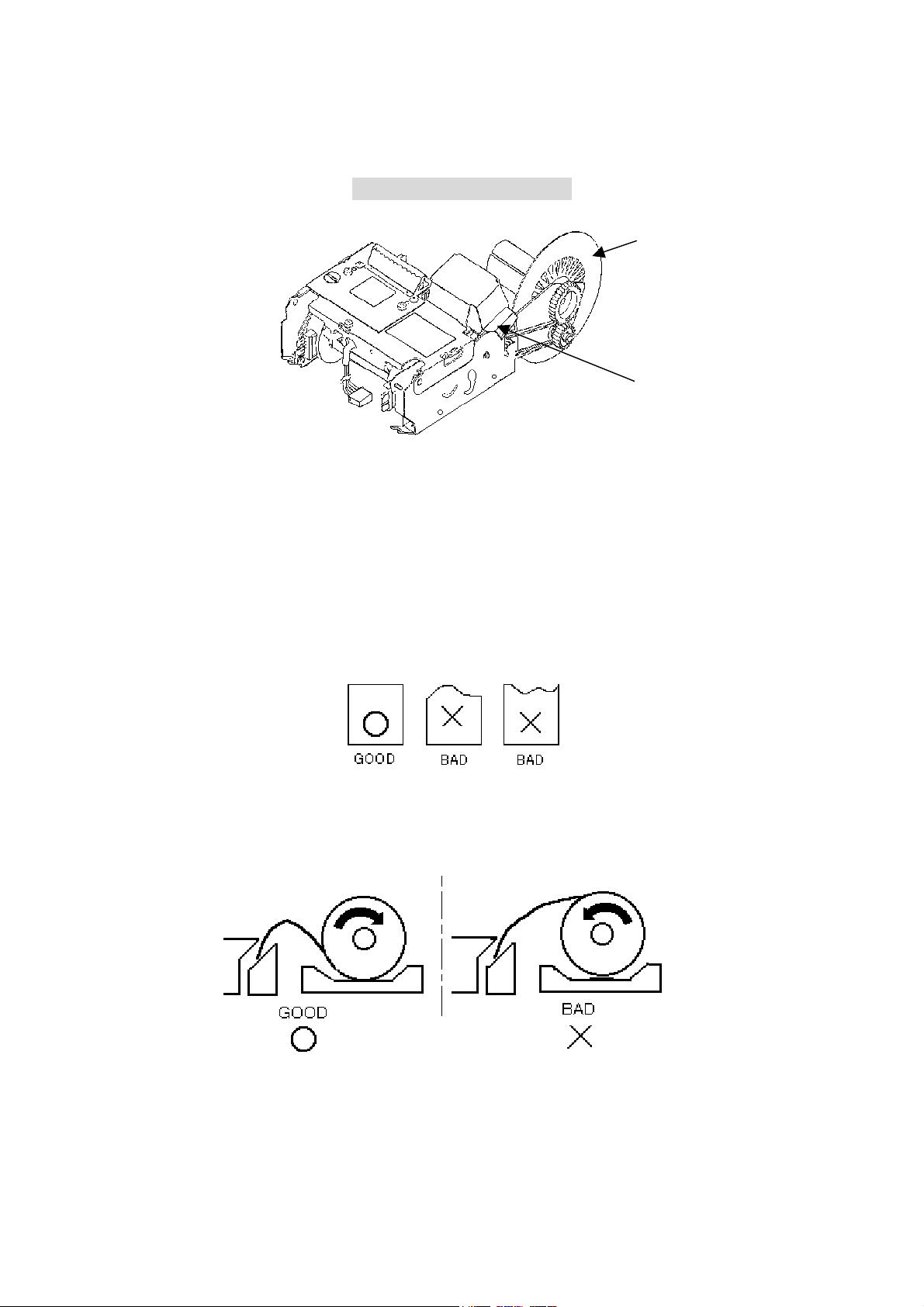

2. How to Install Roll Paper

Head-up lever

Take-up reel

2-1 Specification of thermal roll paper

The loaded printer is thermal head printer. Please use following thermal roll paper to change.

TF50KS-E by Jujyo Seishi ( recommendation)

Size: 44.5mm(width) x φ83mm(max.)

2-2 Step of changing

1) Cut the end of the roll paper correctly.

2) Put on a roll paper correct way and insert paper to the printer.

If power is on and the head-up lever is down, paper is inserted automatically

after inserting to the internal sensor position.

1

2-3 How to removing paper after paper jamming

If paper jamming occurs, follow the procedure below.

Cover frame screw

Cover frame

Head-up lever

1) Remove the cover frame screw. Then open the cover frame.

2) Release the head-up lever.

3) Remove all jammed paper and paper chips.

4) Return the cover frame until touching the portion.

5) Fix it with the cover frame screw.

2-5 How to adjust paper near-end sensor

If you want to adjust the near-end sensor timing, follows the procedure below.

1) Loosen the adjustment screw.

2) Move up or down the frame corresponding measure scale.

2

3. How To Change The Memory Back-Up Battery

3-1 How to change the memory back-up battery.

When needing to change the memory back-up battery, follow the procedure below.

1)Remove the printer cover from the cabinet.

2)Open the upper case by removing three screws which fix it.

3)Remove the battery from the holder by hand.

The supper capacitor installed on the main board will keep memory

for few minutes during change it.

Please use new battery as same as original type(IVR2430)

We can’t guarantee if you use any other kind of battery to change.

1

4. Operation for Maintenance

4-1 System Reset

This operation should be done immediately after changing program E-PROM or

repairing. All programmed data and report data will be kept after the system

reset operation.

DEPRESS

POWER OFF ‑‑‑‑> ‑‑‑‑‑‑‑> [RF] ‑‑‑‑‑‑‑> POWER ON

[JF]

P2 position [VOID]

4-2 Cancel password of the control lock mode

Even if P2 or P1 mode password is programmed, you can cancel it by a special

password “2001”. This password is also effective when losing original password.

4-3 Display Program version

Select "VERSION No. DISPLAY" in P2 mode main menu and press [CASH] key.

VERSION No.xxxx

Current ROM version is indicated to the last line.

4-4 ALL RAM Memory Clear

This operation should be done immediately after changing program E-PROM

version and install the extension memory board.

OPERATION SEQUENCE

SELECT PROGRAM ITEM

DETAIL SLIP FORMAT

VERSION NO. DISPLAY

RAM CLEAR OPERATION

Select "RAM CLEAR OPERATION" in P2 mode main menu and press [CASH] key.

Select “All RAM CLEAR”and then press [CASH] key. If you want to exit, press [TOTAL] key.

1

RAM CLEAR OPERATION

ENTER PASSWORD

0

Enter system password (2001) and enter [CASH] key.

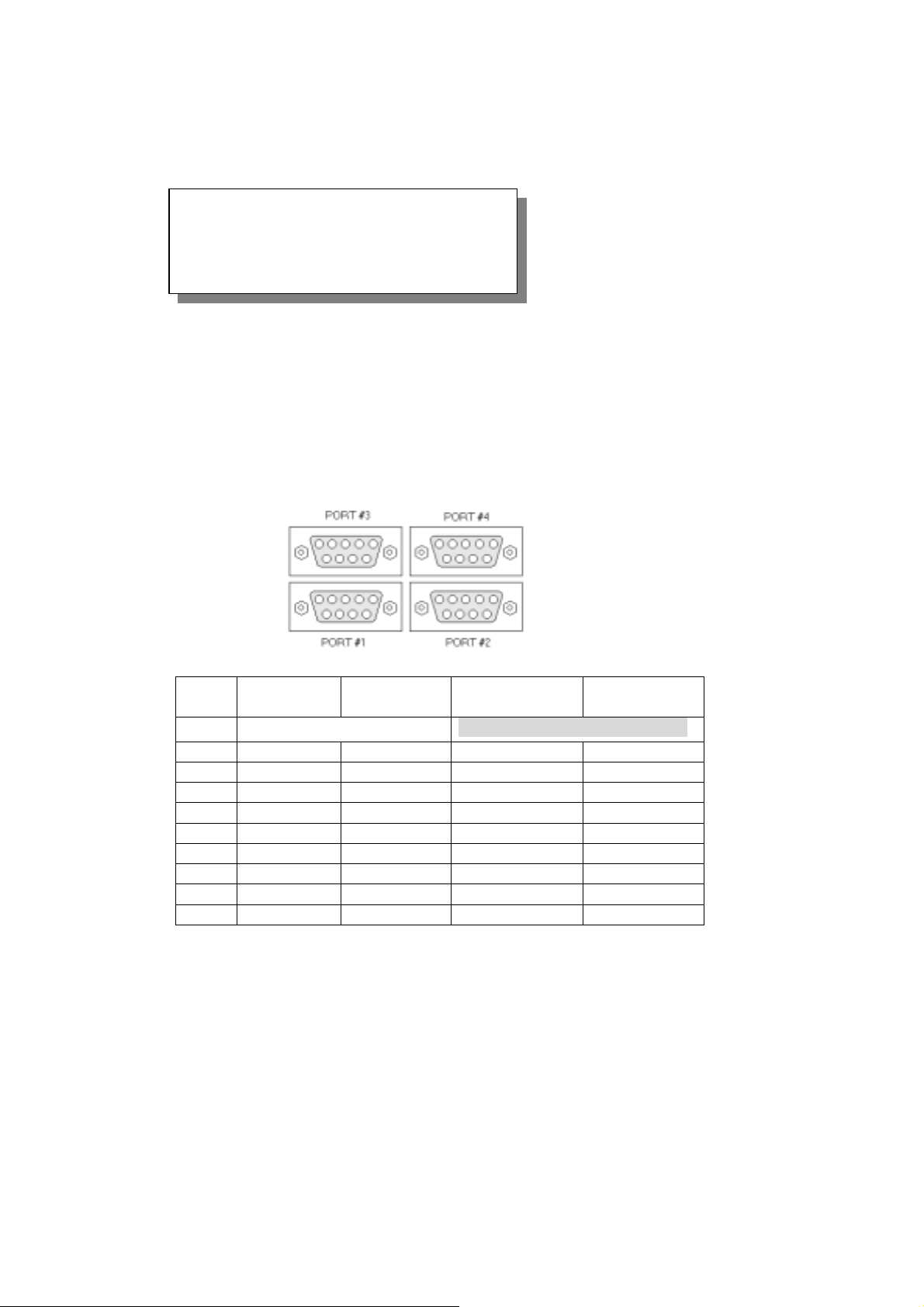

4-5 Communication Port Loop Back Test

This test checks if serial port circuit works by loop back sequence.

Before starting this test, loop‑back connector should be connected to a D‑SUB connector without

port #2 that you want to check. This loop‑back connector should be shorted 2nd pin and 3rd,4th

and 8th .

PIN Assignment

PIN# #1 PORTA #2 PORT B #3 PORT C #4 PORT D

with IF. cable

On the Main Board Extension Memory I/O Borad

1 NC NC NC NC

2 RXD (RXD) RXD RXD

3 TXD (TXD) TXD TXD

4 DTR (DTR) DTR DTR

5 SG SG SG SG

6 DSR TX- NC NC

7 RTS TX+ NC NC

8 CTS (CTS) CTS CTS

9 +5V +5V (+5V) (+5V)

2

Connect the LOOP‑BACK connector to the port that you want to check.

Select "SYSTEM TEST" in P2 mode main menu and press [CASH] key.

SELECT PROGRAM ITEM

RAM CLEAR OPERATION

IRC RAM COPY

SYSTEM TEST

Enter target port number and press [CASH] key.

SYSTEM TEST

ENTER TEST PORT No.

0

The loop-back test will be done and results will be printed on the receipt.

4-6 E-PROM CHECK-SUM Printing

You can print the check-sum value of the main E-PROM by following operation.

Turn to the S-position by using the S-key.

Enter system PASSWORD (2001) and enter [CASH] key.

3

5 LOGIC CIRCUIT

CN10, CN11

CN1

CN3

CN4

Auto Cutter

Thermal Head

Feed Motor J

Feed Motor R

CN2

MT245 Thermal

Printer

Fiscal Memory

CN12

CN9

CN8

Drawer A

Drawer B

Line Noise

Filter Board

Front Display Board

VFD. Back Display

Control

Lock

Cashier

Key

CN7 CN4

CN9,CN10

KEY Board

Unit

CN5

CN6

LCD 20 x 4 Display Module

CN11 CN12

Main Board Unit

Paper Near‑End R

Paper Near‑End J

CN15

CN14

CN16

Connection Diagram

CN5

CN6

RS485 for I.R.C.

RS232C

Extension

Memory I/O

Board

CN7

CN1

CN5

CN5

RS232C

RS232C

POWER

TRANSFORMER

5-1 Connection Diagram

1

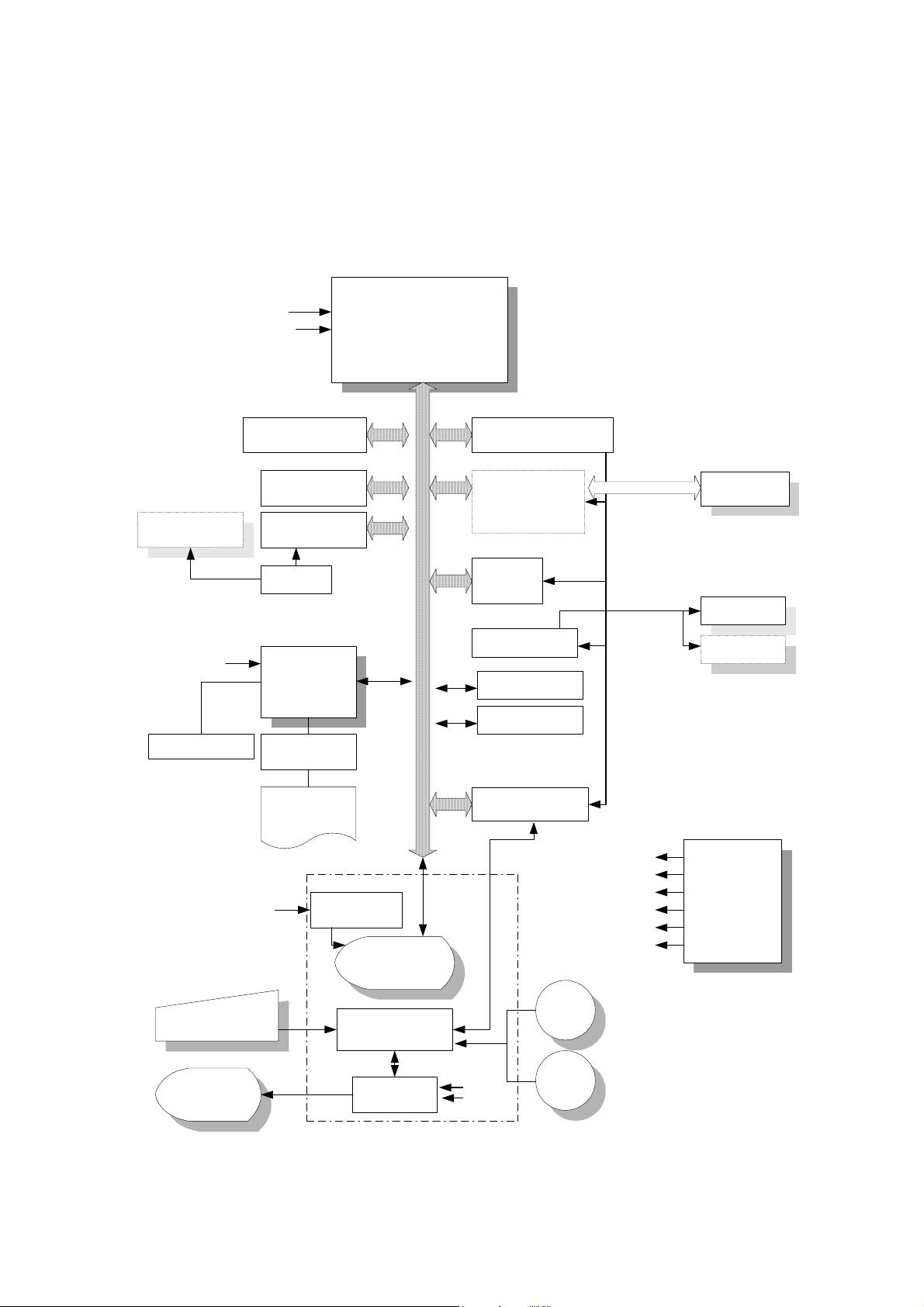

5-2 Block Diagram

CPU HD64180Z

ROM 256K bytes

27C2001

RAM 512K bytes

TC54001CF

RAM 512K bytes

Drawer Drive &

Sensor Circuit

Back‑Up

Battery

Power Circuit

+24V,+5V,VFD

/RESET

/POWER FAIL

/RESET

/POWER FAIL

Real‑Time

Clock

RTC72423

Printer

Controller

M37732SAFP

ROM 32K bytes

Printer Driver

Circuit

MT245

Thermal R/J

Printer

4x20 LCD DOT

Display Module

VFD Numeric

Back Display

SCANNING

Multiplex

Circuit

DC/DC for

Back‑Light

VFD Driver

uPA80GR x 3

Control

Lock

Chashier

Key

Keyboard Unit

+24V

Vf

Vgrid

Fiscal Memory

Control Circuit

82C55 & HC273

Fiscal Memory

27C1001

I/O ADDRESS

DECODER GAL

MEMORY ADDRESS

DECODER GAL

Sync

Serial

RS485 Driver

MAX491

RS232C Driver

MAX238

PORT0

PORT1

KEY & DISPLAY

SCANNING Circuit

Sync.

Port

Drawer A

Drawer B

Vf

Vgrid

+24V

VCC

/RESET

/POWER FAIL

/RESET

2

5-3 Primary Power Circuit

1)Filter Circuit

AC power is supplied to the transformer through a fuse and the filter circuit.

The filter circuit is constructed three capacitors and a choke coil as a common mode

filter.

2)AC Power Transformer

This power transformer has two primary taps ( brown and red). The brown is for 115V

and red is for 230V range. By both taps,32V(AC) voltage is output to the secondary

side.

3

5-4 Power Circuit

5-4-1 VP(+24V) Generation Circuit

The AC power from the secondary of transformer undergoes full wave rectification by

diode bridge DB1 and smoothed by capacitor C4. After smoothing DC power is

supplied to DCDC converter U1(STK733). The main power VP is supplied to each

part after regulating to 24V by this DCDC converter.

5-4-2 VCC, Vf ,Vgrid Generation Circuit

The regulated VP is supplied to self-oscillator circuit made up Q1,Q2,R23,C23 and T1.

VF1&2 for heating filament of VFD,-Vgd(-29V) for grid of VFD and VCC(+5V) are

generated from the VP by this DCDC converter circuit.

4

5-5 Power Failure & Reset Signal Generation Circuit

Secondary voltage of the power transformer which is rectified by D1 and D2 is

supplied to the comparator U3 as a checking voltage after dividing properly by

R1,R2,R7,R8 and R6. This voltage is compared with reference voltage which

generated by ZD4 and power failure signal /PFL is generated. This /PFL signal

generates reset signal /RST after coming out of the delay circuit and next comparator.

5-6 Battery Charge & Voltage Checking Circuit

The VCC, which is adjusted to 3.6V by the ZD10 supplies to the battery BT1 during

power on. The VCC also charges the supper capacitor C92. When turning power off,

the battery voltage 3.0V is supplied to back-up C-MOS RAM and real-time clock IC .

And this battery voltage is always checked if voltage is less than 2.7V by a voltage

checking IC U28. If the battery voltage is less than 2.7V, the BTF signal will be

active on to inform battery voltage error.

5

5-7 Memory Selection Circuit

Address decode circuit of main memory is constituted with a programmable array

logic IC U24. This IC makes five kinds of selection signals from address

lines(A15-A19) and memory enable signal /ME.

Device Purpose of using

/M0 U25 M27C1001 Used for 512K bytes Program Area

/M1 U30 TC554001 Used for reading of 512K bytes data area

/M2 U30 TC554001 Use for writing of 512K bytes data area

/M2 EXTERNAL RAM Used for reading of 256K bytes data area

/M3 External RAM Use for writing of 256K bytes data area

6

5-8 I/O Selection Circuit

Address decode circuit of I/O is constituted with a programmable array logic IC U10.

This IC makes ten kinds of selection signals from address lines(A12-A15) and I/O

enable signal /IOE.

Device Purpose of using

/IO0 U29 Real-time Clock IC Used for selecting real-time clock IC.

IO1 U8 Latch IC HC374 Used for making segment data of VFD.

IO2 U16 Latch IC HC374 Use for making scanning selection.

IO3 U9 Latch IC HC374 Used for making LCD control signal.

/IO4 Not used

/IO5 U18A Buffer IC HC240 Used for making credit card reader interface

signal.

/IO6 U13 PPI MSM82C55 Used for making data and address bus line

of fiscal memory.

/IO7 U7 Buffer IC HC244 Used for reading key-scanning(R0-R7)

/IO8R U14B Buffer IC HC244 Used for reading printer status information.

/IO8W U23 Latch IC HC174 Used for making DTR0,DTR1 and sub

memory bank signal MBNK.

/IO9R U17A Buffer IC HC244 Used for reading status of connection with

fiscal memory, battery voltage and paper

near end.

/IO9W U15 Latch IC HC273 Used for making fiscal memory control

signal.

7

5-9 Real-Time Clock Circuit

The RTC72423 is a bus-connection real-time clock IC built-in crystal oscillator.

Date and time data is read or written from the CPU by 4bits data line,

4bits address lines and control lines.

5-10 Buzzer Circuit

Four gates in U1 and R1,R2 and C2 constitute a self-oscillation circuit. When BUZ

signal from the main board is on, the VP synchronizes with this pulse and is supplied

to the speaker BZ1 by transistor Q1.

8

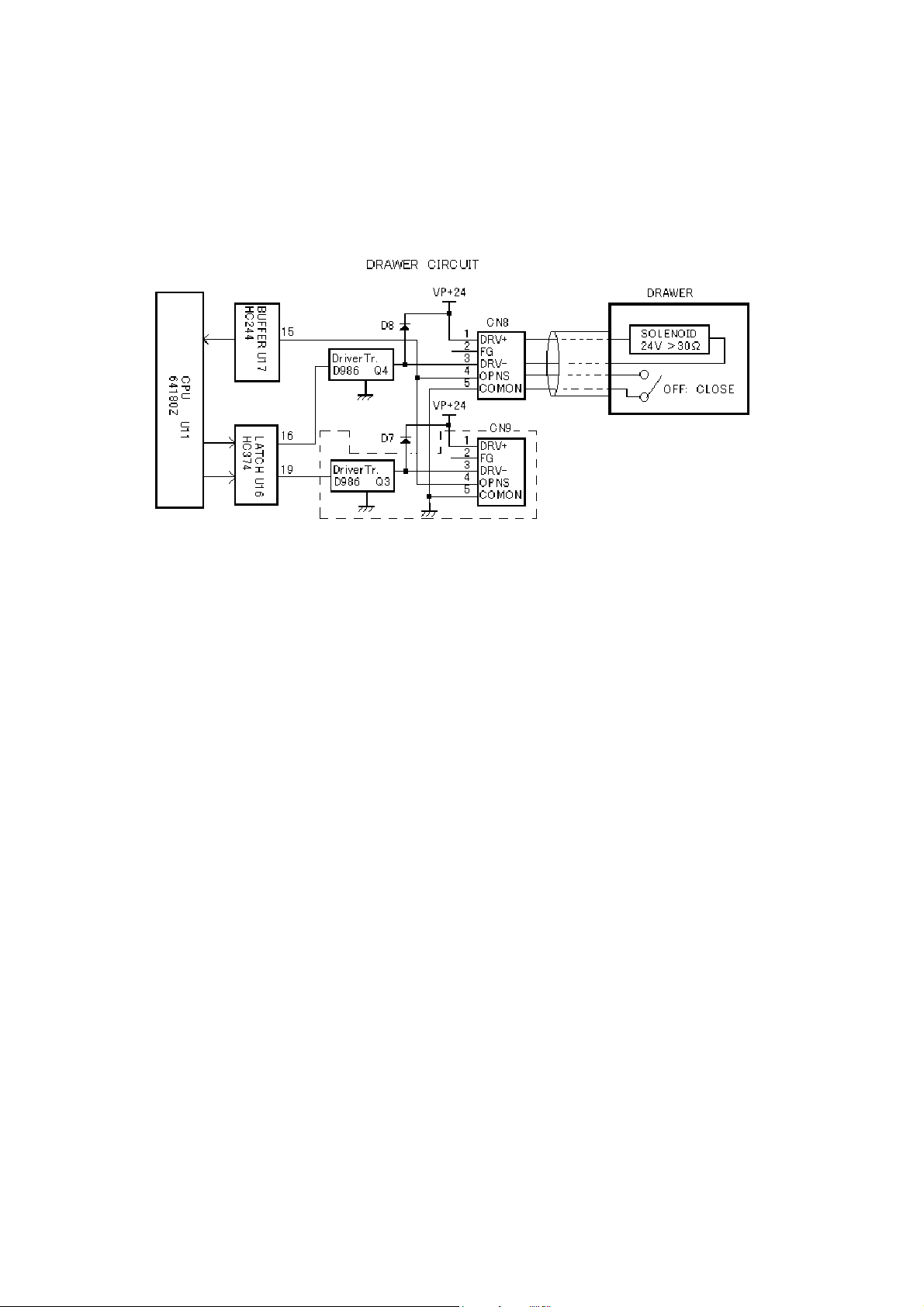

5-11 Drawer Circuit

The driving pulse signal, which is made by latch IC U16, drives a transistor D986

and drawer solenoid will be driven. The status of the drawer open sensor is read to

the main CPU through the buffer IC U17.

9

Table of contents

Other BMC Cash Register manuals