BMS 3000-OBC Quick start guide

2

1General Description.............................................................................................................................................3

2Testing Principles.................................................................................................................................................3

3Range of Application ...........................................................................................................................................3

4Technical Parameters ...........................................................................................................................................4

5Descriptions of Mechanism Parts ........................................................................................................................5

6Preparation...........................................................................................................................................................6

7Package Opening .................................................................................................................................................6

8Cautions of Transportation...................................................................................................................................7

9Installation and Commissioning ..........................................................................................................................7

10 Preparation prior to normal operation..............................................................................................................8

11 Operation of micrometer....................................................................................................................................12

12 Testing procedures.........................................................................................................................................13

13 Cleaning and Lubrication...............................................................................................................................14

14 Cautions for operation....................................................................................................................................14

15 Troubleshooting.............................................................................................................................................14

3

1General Description

Hardness is an important parameter of mechanical performances for metallic and alloy materials. It usually refers

to the resistance capacity of a material against the indentation of the other harder material with certain shape which

is pressed into its surface without residual deformation by itself.

Model 210HBS-3000 Brinell Hardness Tester can be used to measure the Brinell hardness of

unquenched steels, cast irons, non-ferrous metals and other softer bearing alloys in the laboratories of factories,

research institutions and colleges.

2Testing Principles

Brinell hardness testing is to apply specified test forces onto the surface of test specimen through a tungsten

carbide ball of certain diameter (Figure 1), retain it for a specified period of time, and then remove it and measure

the diameter of indentation on the surface of specimen. The Brinell hardness is shown by the average pressure

(kgf/mm2) on the surface area of ball impression on the specimen (Table 1) and calculated as per the following

formulation (1):

Brinell hardness=0.102* ……………… (1)

Table 1 Symbols and Descriptions

Symbols

Descriptions

Unit

D

Diameter of tungsten carbide ball

mm

F

Test forces

N

d

Average diameter of indentation

mm

d1, d2

Diameters of indentations along two perpendicular directions

mm

h

Depth of indentation

mm

HBW

Brinell hardness

HBW

Fig-1 Testing Principle diagram of Brinell hardness

To apply specified test forces onto the surface of test specimen through a tungsten carbide ball of certain diameter,

retain test force for a specified period of time, then remove it and measure the diameter of indentation on the

surface of specimen, referring to Fig-1.

For example, 350HBW5/750 means that the hardness is 350 measured with a tungsten carbide ball of diameter

5mm, under a test force of 750 kgf which is retained for 10 to 15 seconds.

*For details, please refer to GB/T 231.1-2002: 《Metallic Brinell Hardness Test》.

3Range of Application

The standard terms and conditions of Brinell Hardness Test often uses tungsten carbide ball indenter with a

diameter of 10mm and test force of 3,000 Kgf (Fig-2), which fully symbolizes the characteristics of Brinell

hardness. However, due to the fact that the specimens vary in hardness and size, one test force and one kind of ball

indenter can’t meet all the different requirements. Only when the ratio of test force divided by the square mean of

)(

2

22 dDDD

F

4

steel ball diameter is a constant, can the same hardness of the same specimen with steel ball of different diameters

and different test forces be obtained. For details, please refer to Table 2.

Fig-2 Tungsten carbide ball indenter

Table 2 Selection of carbide ball diameters and test forces in Brinell Hardness Test

Test force

Diameter

F/D2

Diameter D of tungsten carbide ball

Range of

hardness

Range of applications

10

5

2.5

1.25

1

30

3000

750

187.5

46.9

30.0

140-(945)

Steel, aluminum and gray cast iron

10

1000

250

62.5

15.6

10.0

48-315

5

500

125

31.2

7.8

5.0

23.8-158

Annealed aluminum

2.5

250

62.5

15.6

3.9

2.5

11.9-79

Bearing alloy

1.25

125

31.2

7.8

2.0

1.2

6.0-39

Conductor wires

0.5

50

12.5

3.1

0.8

0.5

2.4-15.8

Soft materials

4Technical Parameters

Main Technical Parameters are included in Fig-3 and Table 3:

Table 3 Main Technical Parameters

Item (code)

Content

Measuring range

8-650HBW

Height (H)

910 mm

Width (W)

330 mm

Length (L)

722 mm

Maximum height of specimen (without sleeve) (B)

280 mm

Depth of throat (A)

150 mm

Net weight

230 kg

Power supply

220V / 110V, 50 / 60 Hz

Unit

Grades of test force (kgf)

Tungsten carbide ball indenter (mm)

Brinell

187.5

250

500

750

1000

3000

2.5

5

10

5

5Descriptions of Mechanism Parts

This tester is of lever structure, which features compact structure and easy operation. So it is widely used in the

workshops. For the structure of this tester, please refer to Fig-3. The tester is composed of loading and unloading

parts, main shaft parts, lever system, worktable parts and electronic control system.

For normal operation, the specimen is placed on the worktable and the tungsten carbide ball indenter is fitted at the

low end of main shaft. The test forces are amplified by the lever system and applied onto the tungsten carbide ball.

The test force presses the ball indenter into the surface of specimen. After the test forces are removed, the diameter

of indentation shall be measured, by which the hardness value is obtained.

In the front of cast-iron machine body (1), the screw rod seating (2) is fitted, inside which screw rod (5) is fitted.

Over the screw rod, there is replaceable work table (7). The elevation of work table relies on the elevation of screw

rod, which is enabled by hand wheel (4) and nut (3). Lever mechanism is composed of larger lever components

(12), smaller lever components (17) and hoist ring (22), etc.

Test force is applied onto the specimen via lever system. Replaceable weights (24) are hanged on the hoist ring

along the longer arm of larger lever. The composition of weights makes up the following test forces: 1839, 2452,

7355, 9807 and 29420 N (187.5, 250, 750, 1000, 3000Kgf). The application of test forces is carried out

automatically by the loading and unloading parts which are fitted inside the machine body. The rotation of motor is

transferred to the screw rod. When the screw rod descends, the test force is passed onto the indenter via larger lever

(12), smaller lever (17) and main shaft.

Main shaft parts are composed of main shaft bench, main shaft, indenter seating, rotary parts seating, rotary part,

connection nut and connection seating, etc. At idle conditions, the spring limits the connection nut on the

supporting frame so that the main shaft is pressed closely against the knife support in the center of smaller lever,

maintaining the precise position of main shaft.

Electronic control system is consisted of wiring board of front display screen and photoelectric switches, etc. When

the “START”button is pressed, the motor starts to rotate and the screw rod will descend, test force being applied

and retained. After the test force is retained for a certain time (12s, 30s, 60s), the motor rotates in reverse direction,

screw rod will rise up to remove the test force. Herein, the larger lever will be reset under the action of spring.

When bumper iron chip touches the travel switch, the motor will stop running and the test force is unloaded.

Optical measuring System is composed of micrometer, objective lens, ocular lens and prism. After the indentation

is obtained, turn hand wheel to shift away the indenter, pinpoint the objective lens to the indentation (1x leftwards

and 2x rightwards). Herein, the press shaft of locator parts will be located on the pit groove of locator bumper iron

chip, and then a round indentation pit can be observed within the field of view.

Fig-3 Schematic diagram of mechanism

6

6Preparation

The hardness tester should be placed in a clean and dry room without

any corrosive gases.

A room with no foreign mechanical vibrations recommended

The ambient temperature should be kept around 10-30ºC.

The work table should be made of cement or metal with enough

strength and stiffness to carry the tester and its auxiliaries. As shown in

Fig-4 (the dimensions are for your reference only), a hole of φ70mm is

made for the screw rod to pass through. The levelness of work table should

be within 0.2/1000.

Enough space should be reserved around the tester for the

convenience of installation, repair and commissioning. Fig-4 Schematic diagram of platform

7Package Opening

1. Remove the packing belts A& B wrapping the outer box with tools if necessary, as shown in Fig-5.

2. Remove the wood screw fastening the packing box and the bottom with pliers, and lift up the packing box.

3. Take out the document bag and verify that it is complete with Operation Instruction, Packing List and

Certificate of Quality.

4. Loosen the nuts of hooks fastening the accessory box with a spanner, and remove the pressure plate &

accessory box. Check the parts in accordance with the Packing List.

5. Remove the nuts of hook fastening the weights box and take off the hook;

6. Remove the dust cover on the tester;

7. Remove the 4 foundation bolts fastening the tester to the bottom of packing box.

1. Machine body

14. Micrometer

2. Screw rod seating

15. Connection seating

3. Nut

16. Bolt

4. Hand wheel

17. Smaller lever

5. Screw rod

18. Spring

6. Loading and unloading parts

19. Front panel

7. Work table

20. Support frame

8. Indenter

21. Smaller hoist ring

9. Locator parts

22. Hoist ring

10. Optical Measurement parts

23. Hoist rod

11. Sensor seating

24 Weights

12. Larger lever

25. Coder socket

13. Electric parts

7

Fig-5 Schematic diagram of Box Opening

8Cautions of Transportation

Don’t try to move the tester by yourself. Or it may damage the tester and bring about personnel injury.

Therefore, the tester shall be moved by two or more skilled personals.

During transportation, the axial line between the indenter and the screw rod shall not be more than 15ºslanted.

During transportation, it is prohibited to contact all the other parts and faces except the outer surface so as not

to affect the accuracy.

The tester should be gently handled to prevent any collision or impact.

9Installation and Commissioning

Before installation, get ready the spanner, level meter and larger anvil.

1. Place the tester on the prefabricated work table in the way that the screw rod falls into the hole.

2. Remove cushion block of indenter (Fig-6).

3. Removing wood cushion of the indenter: Turn the hand wheel anticlockwise so that the screw rod descends

and the wood cushion can be removed therein. Should the screw rod fail to descend when the hand wheel

is turned, to the contrary that the hand wheel rises up with screw rod and the wood cushion can’t be

removed, it is because the screw rod and its seating are bonded together during transportation. In this case,

turn hand wheel anticlockwise to rise around 20mm, press the handle by force to disengage the screw rod

from its seating.

4. Remove the wood wedges on the larger lever (Fig-7).

8

5. Remove the protective sleeve around the screw rod, clean away the antirust grease on the screw rod and

hand wheel with kerosene, fill some lubricants to the contacts between screw rod and hand wheel, and then

resume the protective sleeve.

6. The larger anvil is put into the hole at the top of screw rod, and then places the level meter onto the larger

anvil. Metallic pads may be put under the bottom of the tester so as to adjust the levelness to be within

0.2/1000.

7. Insert the micrometer into the hole reserved for it.

8. Insert the plug in the coder socket (25)

9. Take out power cable and plug it properly.

Note: As the power cable is three-corded, three-foot power socket is necessary and it should be well

grounded.

Take out the printer and data lines, and plug properly.

Take out the weights and hang them onto the larger lever.

Fig-7 Removing wood wedge of larger lever

Fig-6 Removing wood cushion of the indente

10Preparation prior to normal operation

1) Prefabrication of specimen: the specimen shall be polished with smooth and flat surface, free from layers of

oxide skins, electroplated layers oil dirt and any defects. In addition, the surface roughness Ra should not be more

than 0.016mm. Its hardness should not be changed due to heating or processing. Also the parallelism should be

guaranteed.

2) The requirements for selection of indenter, fitting of indenter and specimens

A. Selection of indenter (Table 4)

Table 4: Correlation Table of tungsten carbide ball diameters and test forces for Brinell Hardness Test

9

Materials

Range of

hardness

(HBW)

Specimen

thickness

(mm)

F/D2

Ball diameter

(mm)

Test force F

(Kgf)

Test force

retaining time (s)

Ferrous metals

140-650

>6

F/D2=30

10

3000

12

6-3

5

750

<3

2.5

187.5

Ferrous metals

<140

>6

F/D2=30

10

3000

30

6-3

5

750

<3

2.5

187.5

Non-ferrous metal and alloys

(copper, bronze and others)

31.8-140

>6

F/D2=10

10

1000

30

6-3

5

250

<3

2.5

62.5

Nonferrous metals and alloys

(aluminum bearing alloy)

8-35

>6

F/D2=2.5

10

250

60

6-3

5

62.5

<3

2.5

15.6

It can be understood from the above table that the tungsten carbide balls and test forces can be selected randomly

for Brinell Hardness Test. However, if you adopts different tungsten carbide balls with different diameters and

apply different test forces to the same specimen, only when the ratio of test force against the square of ball

diameter is a constant, is it possible to obtain the same hardness or comparable results

Cleaning: Remove the antirust grease with acid-free gasoline and clean it with cotton or soft gauze.

B. Fitting indenter

(1) Fit the indenter and tighten the screw lightly.

(2) Place the standard hardness block onto the work table.

(3) Turn hand wheel to raise up the work table until the hardness block is pressed against the indenter.

(4) Tighten the screw so that it is tightly pressed against the flat part of fixing rod.

C. Selection of test forces:

(1) Select test forces as per Table 4.

(2) Selection of test force retaining time: First turn power on, and select the retaining time as per Table 4. The

retaining time can be regulated from 4 seconds to 99 seconds.

D. The specimen shall meet the following requirements:

(1) The specimen shall be polished so that the edges of indentation are visible enough to ensure the precision of

indentation measurement. Also its surface shall be free from oxide skins, electroplated layers oil dirt and any

surface defects.

(2) The surface to be tested shall be parallel to the supporting face so that the test force is perpendicularly applied

to the specimen surface.

(3) The thickness of specimen shall be no less than 10 times to the depth of indentation. In special cases stipulated

in Technical Document, the thickness may be at least no less than 8 times to the depth of indentation. The depth of

indentation hshall be that: h = 0.102F/πD. If deformations are found at the edges of specimen and its back face,

the test shall be regarded invalid and new test shall be done with smaller ball indenter and relevant test force.

(4) The distance between the centers of indentations and edges of specimens shall be no less than 2.5 times to the

diameter of indentation. The distance between the centers of two adjacent indentations shall be more than 4 times

to the diameter of indentation. Besides, the distances shall be larger than specified herein for soft metals.

(5) After test, the diameters of indentations shall be 0.24D<d<0.6D. Otherwise, the test results are invalid and

new test shall be done with corresponding test forces.

(6) During the process of testing, the axial line of indenter must be perpendicular to the specimen or its tested

surface. The test forces shall be applied stably, without any impact or vibration.

(7) The diameter of indentation shall be measured along two directions perpendicular to each other and their

10

arithmetic means shall be accepted. The difference of two diameters shall be less than 1% of the smaller one.

3) Setup of testing parameters

Turn power on, the tester is automatically reset to unloading status and the LCD will display the interface as Fig-8

which is the default settings while exiting works. If the tester has been operated, the interface will show the

parameters set at last time.

Fig-8 Front panel & LCD display

(1) Selection of test forces: move the weights so that the selected test force conforms to the Article (8) below.

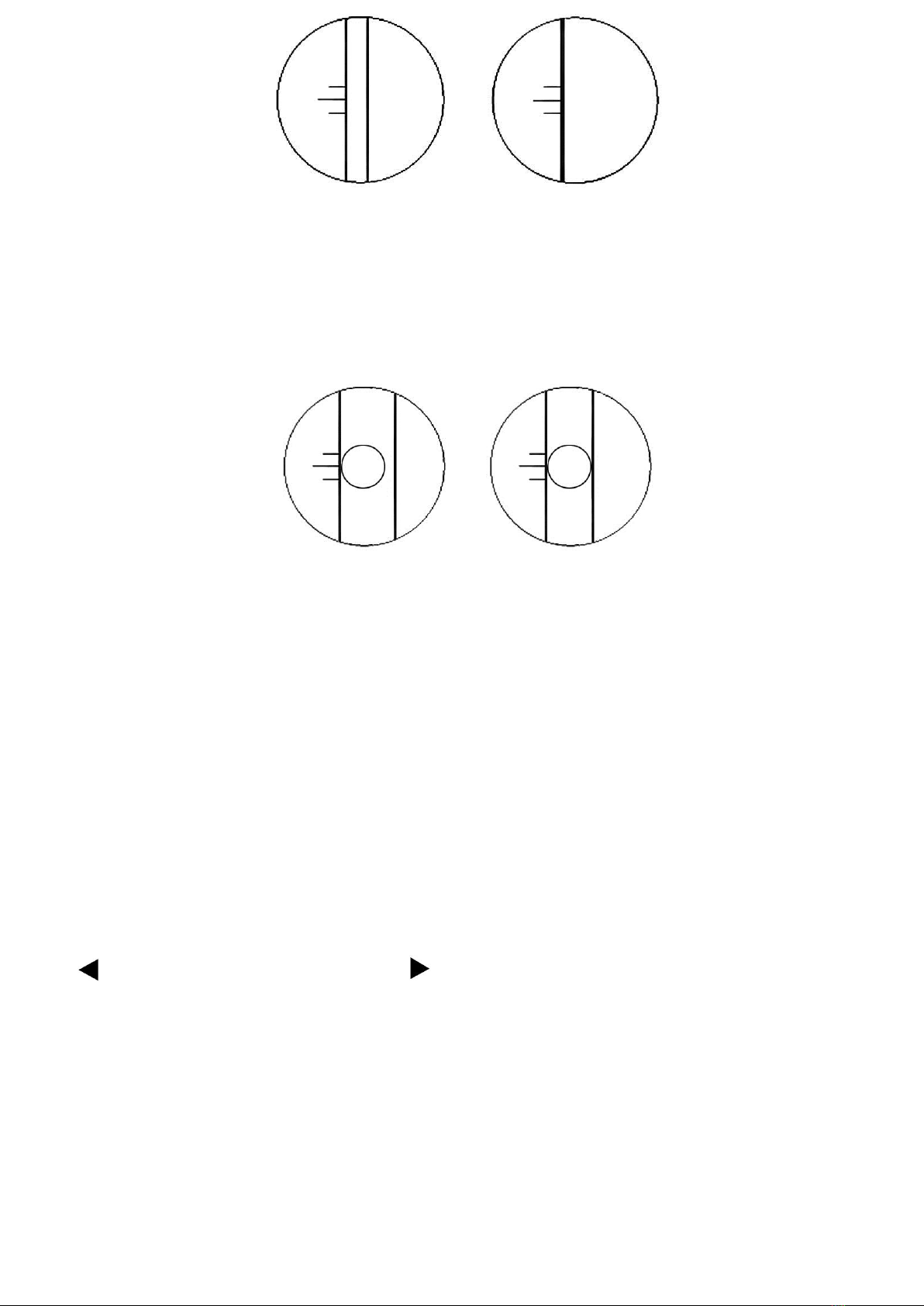

(2) Zeroing: the micrometer must be zeroed for the first time operation as follows: Turn the hand wheel and check

from the ocular lens that the two division lines are in parallel without any space between them. In case that the two

division lines are not clearly visible, turn the ocular lens until they are clear, and then press “ZERO”to make it

zero. The above operation must be repeated whenever the power is turned off and on.

(3) Display and Control panel: Press “MENU”key, then the interface will show as Fig-9.

Fig-9 Menu interface

(4) To press ▲or ▼(up and down key) to select the parameters to be set up.

(5) When the cursor comes to the item “Language”, press ENTER to change over between Chinese version and

English version.

(6) When the cursor comes to the item “Dwelling time”, press ENTER to preset the retaining time of test force

Test force: 3000Kgf Time: 12s

Magnification: 1X Print: On

HB=0.0

*d1=0.00mm

*d2=0.00mm

N=8 n=3

δ

b

= N/mm

2

HRC

▼

D=5.0mm

Tester: 88

Tester State: Allow Start 8: 18

11

which can be adjusted between 4 seconds to 99 seconds. Herein, to press ▲or ▼key to change the retaining

time and press ENTER to confirm the selected value.

(7) When the cursor comes to the item “Magnification”, press ENTER to preset the magnification ratio which can

be changed over between Auto, 1X and 2X. Herein, to press ▲or ▼key to select the expected magnification

ratio and press ENTER to confirm the selection.

If “Auto”is selected, the magnification ratio will be changed over automatically. If others are selected, the selected

magnification ratio must be the same as that actually used. Otherwise, the measured results are incorrect.

(8) When the cursor comes to the item “Test force”, to press ENTER and preset the test forces by pressing ▲or

▼key from the following: 187.5kgf, 250kgf, 500kgf, 750kgf, 1000kgf, 3000kgf. At the end, press ENTER to

confirm the selection.

(9) When the cursor comes to the item “Diameter”, to press ENTER and preset the diameter of indenter by pressing

▲or ▼to choose from φ10mm, φ5mm andφ2.5mm, and press ENTER to confirm the selection.

(10) When the cursor comes to the item “Next page”, press ENTER to enter the menu shown in Fig-10.

(11) When the cursor comes to “Quit”, to press ENTER to exit the preset menu and return to the interface of Fig-8.

Fig-10 Menu interface

(12) When the cursor comes to the item “Test points”, to press ENTER to preset whether or not to carry out data

statistics whose range is from 1 to 99. If 1 is selected, no statistics will be done, i.e. to print out the test results of

each test. If the figure more than 1 is selected, it will print out the test results of each test and the average of the test

results. The number of statistical test points can be selected by pressing ▲or ▼key.

(13) When the cursor comes to the item “Date Time”, to press ENTER to preset the date of test and a small window

will be shown as Fig-11. For details, please refer to Article (19).

(14) When the cursor comes to the item “Tester”, press ENTER to preset the code of operator by pressing ▲or

▼key to select from 1 to 99.

Fig-11 Menu interface

(15) When the cursor comes to the item “Printer state”, press ENTER to preset the printer to be On or Off.

(16) When the cursor comes to the item “Hardness type”, press ENTER to preset the type of hardness and

interchange between different hardness and tensile strength. A small window will be shown as Fig-12. For details,

please refer to Articles (20) ~ (22).

12

Fig-12 Menu interface

(17) When the cursor comes to the item “Next page”, press ENTER to return to the menu shown in Fig-9.

(18) When the cursor comes to “Quit”, press ENTER to exit the preset menu and return to the interface of Fig-8.

(19) Date of test:

At the small window in Fig-11, to press ▲or ▼key to select specific item, press ENTER and then press ▲or

▼key to change the figure. The item “Date Print” is to determine whether or not to print out the date of test.

(20) Hardness Type: The options are HBS210, HBS30C, HVS30 and HVS50. Among them, HBS210 and HBS30C

are for Brinell hardness tester while HVS30 and HVS50 are for Vickers hardness tester. This item shall be

determined as per specific model of the tester. For the model 210HBS-3000, HBS210 should be selected.

(21) Hardness conversion: It is designed as per GB1172-1999 Conversion of hardness and strength for ferrous

metals. The hardness values can be converted to HRC, HRA, HR15N, HR30N, HR45N, HV and so on.

(22) Tensile strength δb: It is designed as per GB1172-1999 Conversion of hardness and strength for ferrous

metals. The tensile strength can be converted to is including “C_St”, “Cr_St”, “CrV_St”, “CrNi-St”, “CrMo_St”,

“CrNiMo_St”, “CrMnSi_St”, “Strength_St”and “Stainless_St”.

Press ▲or ▼key to select specific item, then press ENTER and press ▲or ▼key to change the figure. At

last, press ENTER again to confirm.

11Operation of micrometer

Turn the 1X or 2X objective lens to the front and then turn elevation hand wheel so that the surface of specimen

is 15mm under the objective lens. Then turn elevation hand wheel slowly and at the same time check through the

ocular lens until the indentation can be observed clearly. Turn the ocular lens until the division lines can be seen

clearly.

Note: During process of operating, by pressing ▲or ▼key (Brightness increase / decrease) on front panel,

the brightness of illuminating source can be adjusted to obtain a better field of view.

After loading-dwelling-unloading process, turn the selected objective lens to the front and start measuring the

indentation (after the objective lens arrives in correct position, system will automatically memorize the

magnification ratio of objective lens for the purpose of hardness calculation).

Turn the hand wheels of micrometer to move the two division lines, see Fig-13. After the two lines are tangent to

each other as shown in Fig-14, press ZERO on front panel to zero the micrometer.

Fig-13 Micrometer

13

Fig-14 Zeroing of micrometer

Note: this step is not worth repeating for every measurement point. However, it must be repeated whenever

the tester is restarted.

While observing the indentation through ocular lens, in case the indentation image is not clear, turn elevation hand

wheel for micro-adjustment until the indentation can be seen clearly. Then turn micro-adjustment hand wheel so

that one division line is tangent to one side of indentation. And then turn the larger hand wheel so that the other

division line is tangent to the other side of indentation as shown in Fig-15. Then press Reading button, and the

LCD screen will display one diameter of indentation d1=x.xxx:

Fig-15 Measurement of indentation

Turn the micrometer clockwise 90°and repeat the above steps, press Reading button once again, the LCD will

display the diameter along the other direction d2=x.xxx . At the same time, the hardness value of specimen

HBW=xxx.x will also be displayed on LCD.

12Testing procedures

1) Select suitable work table as per sizes of specimen, turn power on and select right indenter, test force and

retaining time.

2) Zeroing the micrometer and calibrate the tester with standard hardness block.

3) Clean the supporting surface of specimen and put it onto the worktable. Turn the hand wheel to move the

worktable up slowly until the specimen is 0.2 mm to 0.4mm away from the indenter, or the surface of specimen can

be observed clearly from the 2X objective lens. It is recommended that 0.2mm to 0.4mm be controlled at the

beginning. After certain period of repeated operation, when the operator is able to judge the position of specimen

through the image of ocular lens, the 2X objective lens can be used.

4) In case the indenter is not aligned to the axis of worktable, press “ENTER”key and the rotation turret will rotate

automatically. No matter where the indenter is, it will make the indenter be coaxial with the worktable. Now press

key to turn to 2X objective lens, and press key to turn to 1X objective lens.

5) Press START key to apply test force and get the indentation. Only when the wordings “Allow Start”appears, can

the START key be pressed. No matter where the indenter is, it will turn to the front and start testing. The following

information will be displayed on LCD:

“LOADING”

“DWELLING”

“UNLOADING”

After the above process, it will return the interface as Fig-8.

6) Turn the objective lens to the position of indentation and measure the diameter of indentation to get Brinell

hardness value. If the diameter of indentation is more than 3mm, 1X objective lens shall be selected. Otherwise, 2X

objective lens should be selected.

14

13Cleaning and Lubrication

Protect the tester with dust-proof cover when it will not be used for a longer period of time.

Fill adequate machine oil to the contacts between lead screw and hand wheel periodically.

The friction surfaces should be lubricated regularly, 2 times per month.

The decelerator should be filled with grease #20 once every half year. (industrial Vaseline)

14Cautions for operation

Fitting Indenter: All the indenters are composed of fixing rod, fixing nut and tungsten carbide ball (Fig-2). Before

fitting indenters, the ball groove of fixing rod and the carbide must be cleaned with acid-free gasoline and make it

dry. Paint some acid-free Vaseline into the groove, fit the carbide ball and tighten the fixing nut. During the testing,

check occasionally whether the carbide ball is loose in the indenter. In case the ball is loose, the test is invalid.

During the process of loading, dwelling and unloading, never turn the rotation turret. Otherwise, the indenter may

be damaged.

Selection of power voltage: the voltage should be 220V (or 110V, 380V according to request) and must be

grounded properly.

Temperature of specimen: The temperatures of specimen shall be kept at normal atmospheric temperature during

the testing. In other special circumstances, the temperature of ferrous metals should not exceed 100℃, but that of

non-ferrous metals must be kept under ambient temperature.

The diameter of tungsten carbide ball shall be inspected regularly in case of exceeding its tolerance. When the

diameter is 2.5mm, the tolerance should not be more than ±0.003mm. When the diameter is 5mm, the tolerance

should be less than ±0.004mm. When the diameter is 10mm, the tolerance should be less than ±0.005mm the

surface finish Rz should be no more than 0.2 micron.

Distance between the surface of specimen and the indenter: It is recommended that 0.2mm to 0.4mm be controlled

at the beginning. After certain period of repeated operation, when the operator is able to judge the position of

specimen through the image of ocular lens, the 2X objective lens can be used.

15Troubleshooting

In case of breakdown, the following may be of help to find out the reason of breakdowns and recommend the

remedies. If not successful, contact our aftersales service department rather than dismantle the tester by yourself.

Table 7 Troubleshooting Guideline

Breakdowns

Reasons

Remedies

Screw rod not

elevating fluently

Rusty or chips

Remove the chips around lead screw and hand wheel, and then fill some

lubricants

Test results not

precise

Distance of indentations

The centers of two adjacent indentations are too close to each other

Indenter

Replace the indenter if damaged

Worktable

Check whether there are foreign materials at the contacts of work table and

lead screw

Check whether the selected anvil is suitable for the specimen or not

The protective sleeve of lead screw has propped up the work table

Specimen

Test force is applied to the specimen perpendicularly or not

Whether there are burrs on the back

Too thin

Surroundings

Mechanical vibration around

Ambient temperature kept at 10-30ºC

Others

Calibrate with standard hardness block

Table of contents

Other BMS Test Equipment manuals

Popular Test Equipment manuals by other brands

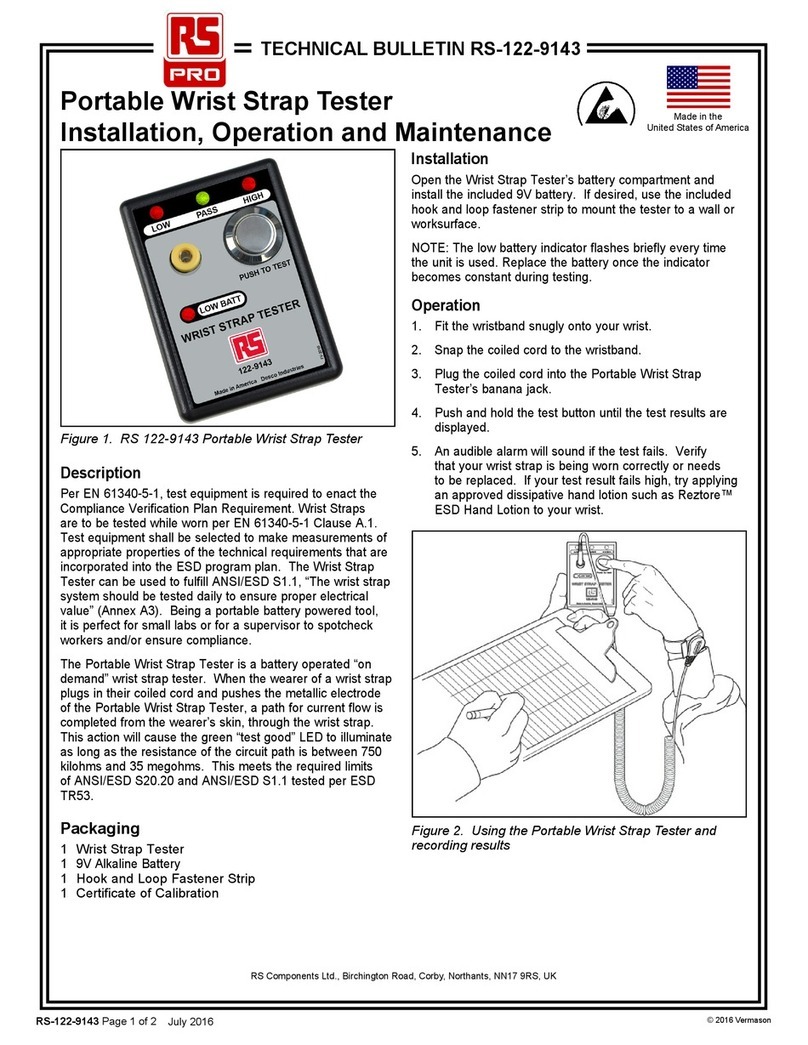

RS PRO

RS PRO 122-9143 Installation, operation and maintenance

Anritsu

Anritsu MT1000A Network Master Pro Quick reference guide

Clas Ohlson

Clas Ohlson LK-4031B quick start guide

GE

GE RTT instruction manual

ModelCraft

ModelCraft 20 69 64 operating instructions

Keithley

Keithley Interactive SourceMeter 2450 Declassification and security instructions