TABLE OF CONTENTS

DISTRIBUTED DIGITAL FAULT RECORDER – INSTRUCTION MANUAL TOC–I

Table of Contents

1: GETTING STARTED ORDERING ........................................................................................................................................... 1

ORDERING THE RTT ............................................................................................................ 1

ABOUT YOUR NEW RTT UNIT ...................................................................................................... 2

CAUTIONS AND WARNINGS ............................................................................................... 2

CHECK THE CONTENTS OF THE BOX ................................................................................ 2

USING THIS MANUAL .......................................................................................................... 2

ABOUT THE RTT .................................................................................................................. 3

RTT UNIT SPECIFICATIONS ................................................................................................ 7

2: USING THE RTT ON SR

SERIES RELAYS

THE 469 MOTOR MANAGEMENT RELAY ................................................................................ 11

OVERVIEW ............................................................................................................................ 11

SR469 MOTOR MANAGEMENT RELAY TERMINAL LAYOUT .......................................... 12

SR469 MOTOR MANAGEMENT TERMINAL FUNCTIONS ................................................ 13

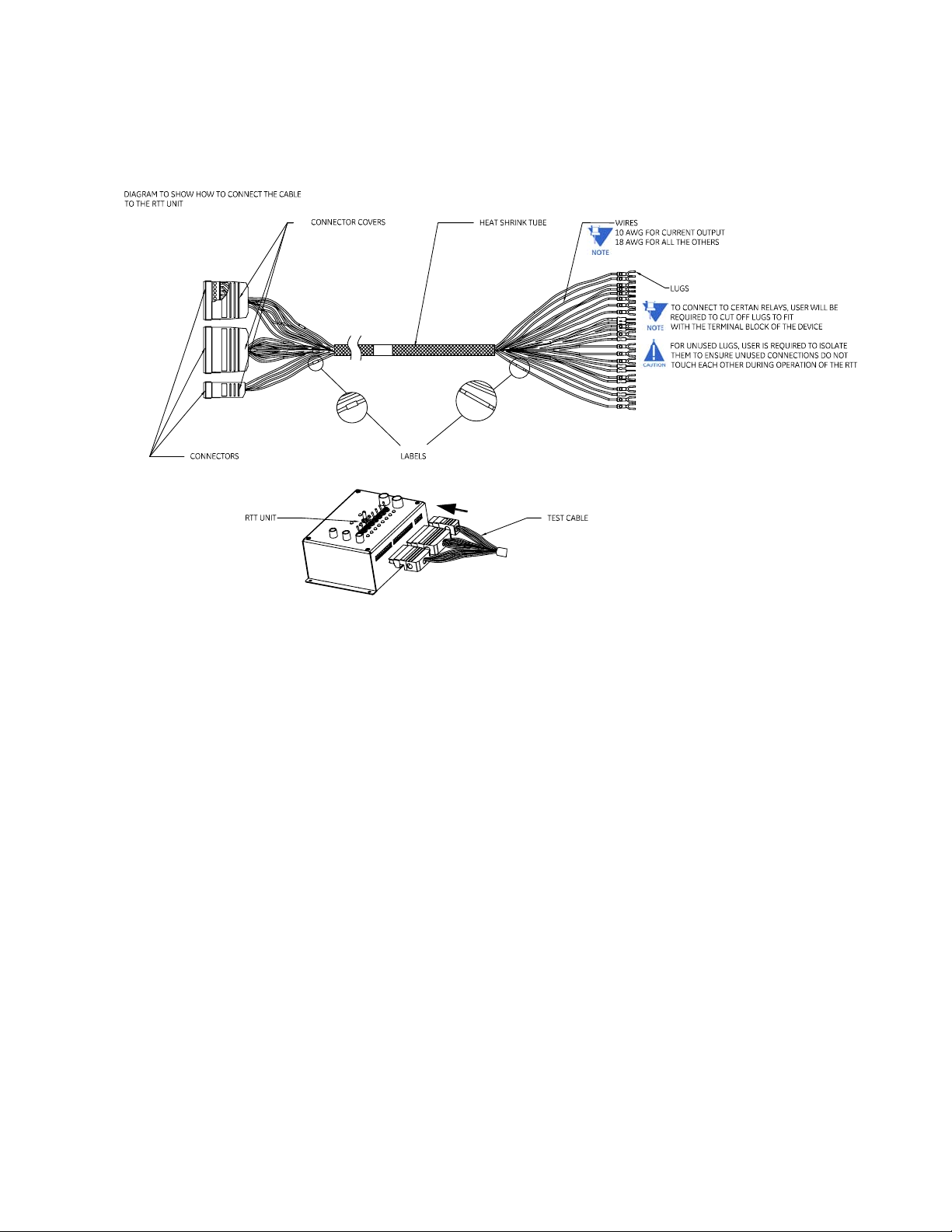

RTT TO SR469 WIRING DIAGRAM .................................................................................. 15

INTERFACING TO THE RTT THROUGH THE ENERVISTA 469 SETUP PROGRAM .......... 16

THE SR750/760 FEEDER MANAGEMENT RELAY ................................................................. 19

OVERVIEW ............................................................................................................................ 19

SR750/760 FEEDER MANAGEMENT RELAY TERMINAL LAYOUT ................................. 20

SR750/760 FEEDER MANAGEMENT RELAY TERMINAL FUNCTIONS .......................... 21

RTT TO SR750/760 WIRING DIAGRAM ........................................................................ 23

INTERFACING TO THE RTT THROUGH THE ENERVISTA 750/760 SETUP PROGRAM 24

THE SR489 GENERATOR MANAGEMENT RELAY ................................................................. 27

OVERVIEW ............................................................................................................................ 27

SR489 GENERATOR MANAGEMENT RELAY TERMINAL LAYOUT .................................. 28

SR489 GENERATOR MANAGEMENT RELAY TERMINAL FUNCTIONS ............................ 29

RTT TO SR489 WIRING DIAGRAM .................................................................................. 31

INTERFACING TO THE RTT THROUGH THE ENERVISTA 489 SETUP PROGRAM .......... 32

THE SR745 TRANSFORMER MANAGEMENT RELAY ........................................................... 35

OVERVIEW ............................................................................................................................ 35

SR745 TRANSFORMER MANAGEMENT RELAY TERMINAL LAYOUT .............................. 36

SR745 TRANSFORMER MANAGEMENT RELAY TERMINAL FUNCTIONS ....................... 37

RTT TO SR745 WIRING DIAGRAM .................................................................................. 39

INTERFACING TO THE RTT THROUGH THE ENERVISTA 745 SETUP PROGRAM .......... 40

THE SR735/737 FEEDER PROTECTION RELAY ..................................................................... 43

OVERVIEW ............................................................................................................................ 43

SR735/737 FEEDER PROTECTION RELAY TERMINAL FUNCTIONS ............................. 44

RTT TO SR735/737 WIRING DIAGRAM ........................................................................ 45

INTERFACING TO THE RTT THROUGH THE ENERVISTA 735/737 SETUP PROGRAM 46

3: USING THE RTT ON UR

SERIES RELAYS

CONFIGURATION OPTIONS ......................................................................................................... 47

OVERVIEW ............................................................................................................................ 47

UR SERIES RELAYS REAR TERMINAL LAYOUT ................................................................. 48

UR SERIES RELAYS CT/VT MODULE - TERMINAL FUNCTIONS .................................... 49

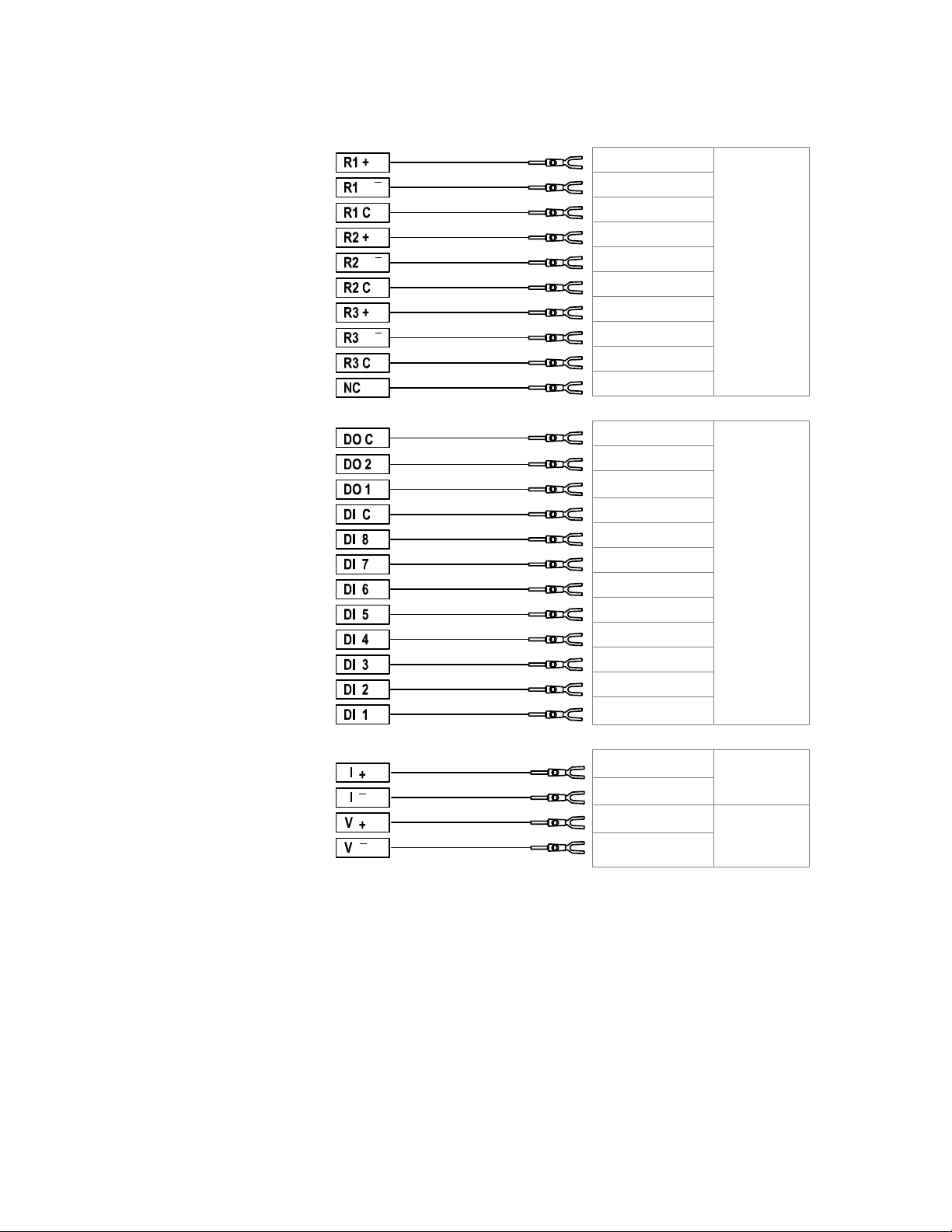

UR SERIES RELAYS TRANSDUCER & DIGITAL I/O MODULES

- TERMINAL FUNCTIONS ............................................................................................ 50

RTT TO UR RELAY WIRING DIAGRAM ............................................................................. 55

INTERFACING TO THE RTT THROUGH THE ENERVISTA UR SETUP PROGRAM ............ 56