BN Products SIGMA DCM 40 Operating instructions

1

SIGMA

DCM 40 MECHANICAL REBAR CUTTING

MACHINE

OPERATING AND MAINTENANCE MANUAL

Supplied by

BN Products-USA, LLC

3450 Sabin Brown Rd. Wickenburg, AZ 85390 (800) 992-3833 or (928) 684-2813

2

TABLE OF CONTENTS

Heading : Page No:

1. Machine Assembly. 4

1.1.Machine assembly. 4

1.2.Sequence of machine operating procedures. 4

2. Technical data. 6

3. Equipment to accompany the machine. 6

4. Correct and wrong cutting forms 7

5. Disallowed operations on the machine 8

6. Warranty conditions: 9

7. Protectors to be used during operation of the machine. 10

7.1. Protective clothing. 10

7.2. Work clothing. 10

8. Transportation of the machine: 10

9. Checks & adjustments on the machine and

Blade replacement. 11

9.1 .V-Belt adjustment. 11

9.2. Demounting of V-Belt. 12

9.3. Blade replacement. 12

10.Maintenance of the Machine:

10.1. Daily maintenance of the machine. 13

10.2. Weekly maintenance of the machine 13

10.3. Monthly maintenance of the machine. 14

10.4. 6-Month maintenance of the machine. 14

10.5. Annual maintenance of the machine. 14

11.Fault analyses and remedies: 15

12.Electrical diagram. 17

13.Materials list. 18

14.Earthing connection 23

3

DCM 40 MECHANICAL REBAR CUTTING MACHINE :

DCM 40 Mechanical Rebar cutting machine is manufactured only for the purposes of

cutting the Rebar. The use of the machine for other purposes is not permitted. The machine

can be easily transported within the short distances under the site conditions by the help of

the wheels.

Important warnings:

•Please read the operation and maintenance manual thoroughly.

•The machine should be operated by the trained people.

•The machine should be shut off and the electrical connection will be cut off during

maintenance and lubrication of the machine, blade replacement and belt tension

adjustments are conducted.

•The maintenance and lubrication requirements of the machine should be observed.

4

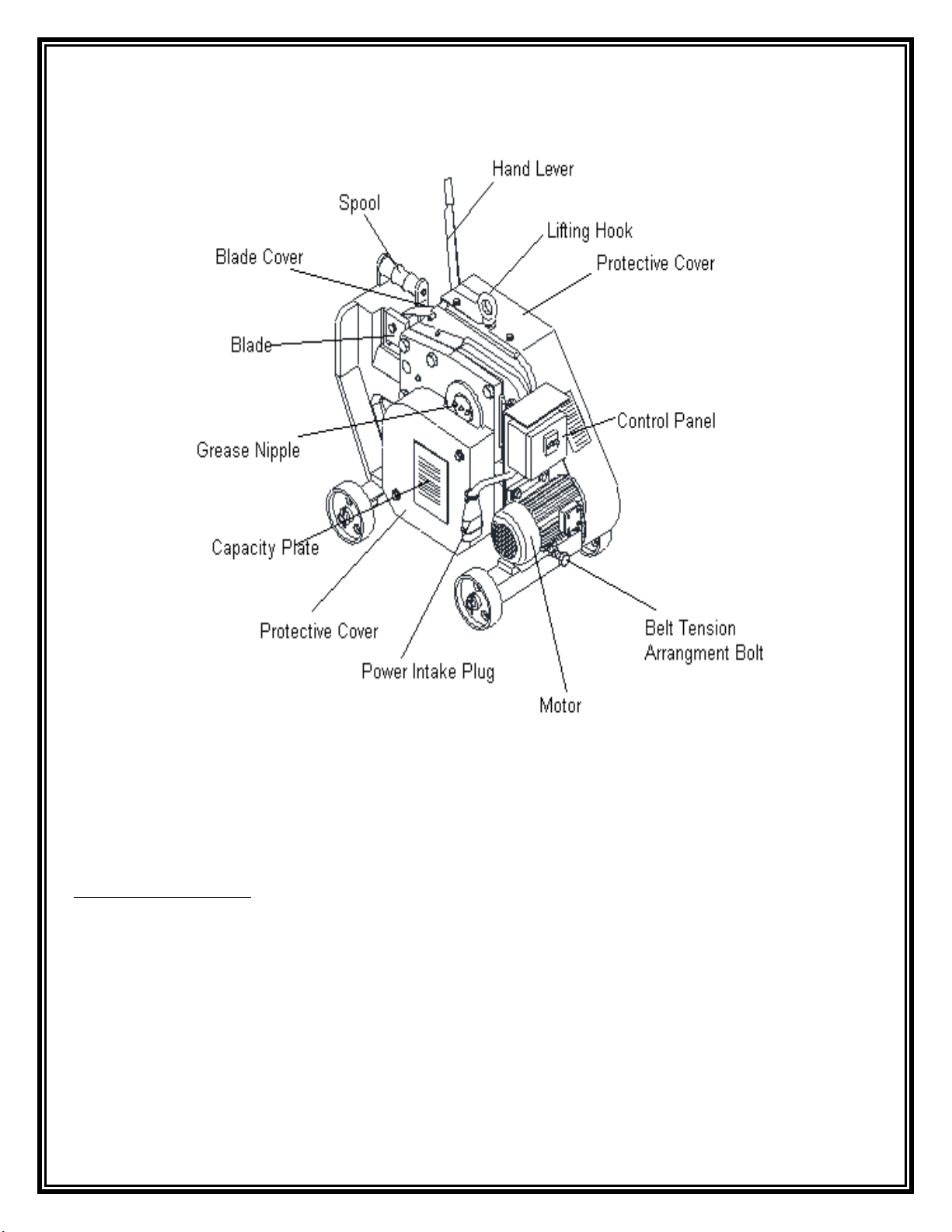

1.1 Machine Assembly:

•The machine is to be balanced by feeding with wedges underneath in a manner to

disconnect the wheels from the ground on a smooth surface. (see Figure 1)

•The electrical connection of the machine should be installed by the authorized people.

Operating voltage should be 415 V. See page 23.

•The earthing should be provided for the safety purposes. The machine cannot be

operated without the earthing connection. See page 23.

1.2 Sequence of machine operating procedures :

•Make sure that the machine is installed in accordance with the assembly rules.

•Plug on the power supply cord (4 X 4 sqmm) the feeding line of main power.

•Grounding is made for safety. Do not operate machine without grounded power.

•Switch on the machine and check if the direction of rotation is as per indicated arrow. If

not you have to change the terminal of phases by means of qualified Electrician.

•Please study the Capacity Plate of machine which indicates no of rebar’s corresponding

to dia of rebar.

•Lift the protective shield of the machine & place the rebar to be cut close the protective

shield. Adjust the retainer position so that rebar to be cut is held between fixed &

Movable blade.

•In Case the rebar are more than one. Place one bar above the other. (Indicated In Fig 4)

•Press the foot pedal once and cutting will take place.

5

Start- Stop Buttons :

Figure : 2

Machine cutting capacity :

Diameter Of Rebar

650 N/mm2

850 N/mm2

Ø40(#11) X 1

Ø32(#10) X 1

Ø32(#10) X 1

Ø25(#8) X 1

Ø25(#8) X 1

Ø16(#5) X 1

Ø12(#4) X 4

Ø12(#4) X 3

Ø10(#3) X 4

Ø10(#3) X 3

Ø6(#2) X 6

Ø6(#2) X 5

6

2. TECHNICAL DATA

•Machine Type: DCM 40

•Machine Designation: Mechanical Rebar Cutting Machine

Blade Size:

Width: 85 mm

Length: 85 mm

Thickness: 20 mm

Belt Used:

V-belt: A-49

Machine Dimensions:

Width: 560 mm

Length: 1020 mm

Height: 750 mm

Weight: 350 kg

Motor specifications:

Motor power: 5.5 Kw

Motor Revolution: 1730 rpm

Motor Supply: 220/460 V

Frequency: 60 Hz

3. EQUIPMENT TO ACCOMPANY THE MACHINE

•Allen Key 14mm 1 Piece

•500 cm grease pump 1 Piece

•Cutting Blade 2 Piece

7

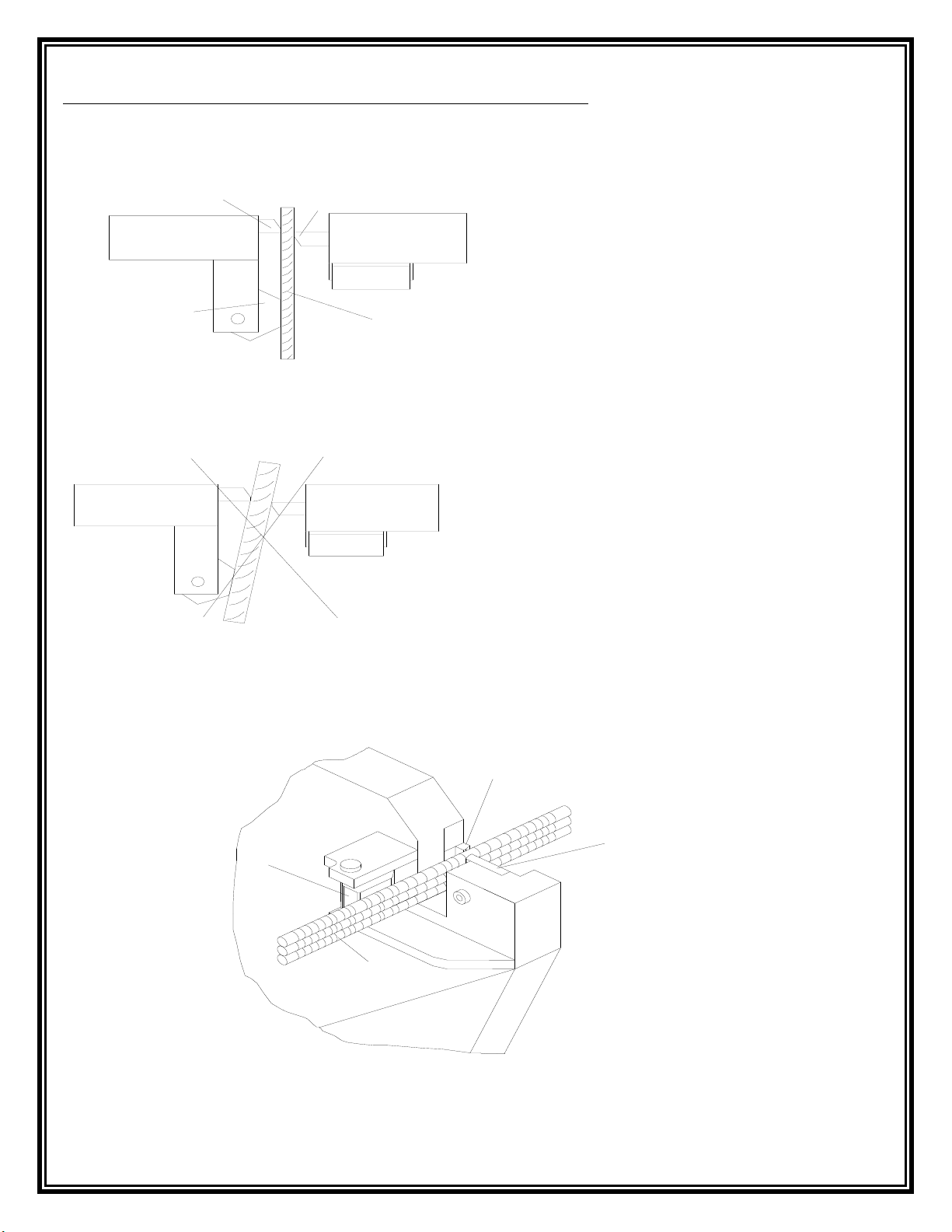

4. Correct placement of the steel between the blades:

Figure: 3

CORRECT CUTTING

Wrong placement of the steel between the blades:

WRONG CUTTING

For multi-cutting operations, place one steel on the top of the other in an amount indicated

in the capacity plate. Figure: 4

SHIELD

STEEL

MOVABLE

BLADE

FIXED

BLADE

MOVABLE BLADE

FIXED BLADE

SHIELD

STEEL

8

5. DISALLOWED OPERATIONS ON THE MACHINE:

▼No cutting work should be conducted without closing the Protective Shield.

▼The machine will be powered off and the electrical system will be switched off

during a blade replacement or maintenance work.

▼No one should be allowed to stand in front of the machine during a cutting

work.

▼The limbs should be kept away from the cutting blades.

▼At any given time the hammer, meter, compass, lever and similar construction apparatus

should not be inserted in between the blades when the machine is running.

▼The machine should not be started up if it is wet.

▼The Rebar Dia and corresponding numbers of rebar as indicated in the capacity plate of

the machine should be strictly observed for cutting purposes.

▼The Rebar to be cut should be held against the fixed blade and retainer.

▼In case of rebar to be cut are more than one always put them one on the top of other

▼The machine should not be started up when the cover of the switch box is open.

▼The default settings of the thermal current adjustment field as provided by the

machine manufacturer should not be tempered with.

▼The machine should not be operated without the earthing connection.

▼The machine should not be started when the protective covers are in

disassembled position.

▼The unauthorized and untrained people should not be permitted to work on the

machine.

▼The machine should not be operated without lubricants.

▼The warning labels affixed on the machine should not be torn down.

▼No cutting should be applied by using blunt and cracked blades.

▼ The machine should not be cleaned by applying air.

9

6. WARRANTY CONDITIONS:

The manufacturer accepts the warranty and liability only if the following conditions are

observed

▼The Guards fitted on the machine are never removed.

▼The warning signals are observed.

▼The machine is not operated without lubricants.

▼The machine is not started without installing the earthing connection.

▼Only the genuine spare parts from manufacture should be used for the

replacement of the malfunctioned parts of the machine.

▼The conditions specified as the safety measures are observed.

▼The disallowed operations are avoided.

▼The machine is installed in accordance with the assembly conditions.

▼The machine is operated by the trained and authorized people.

▼No of rebars corresponding to rebar dia as indicated in capacity plate are

observed.

▼The electrical connection is installed by the authorized and competent people.

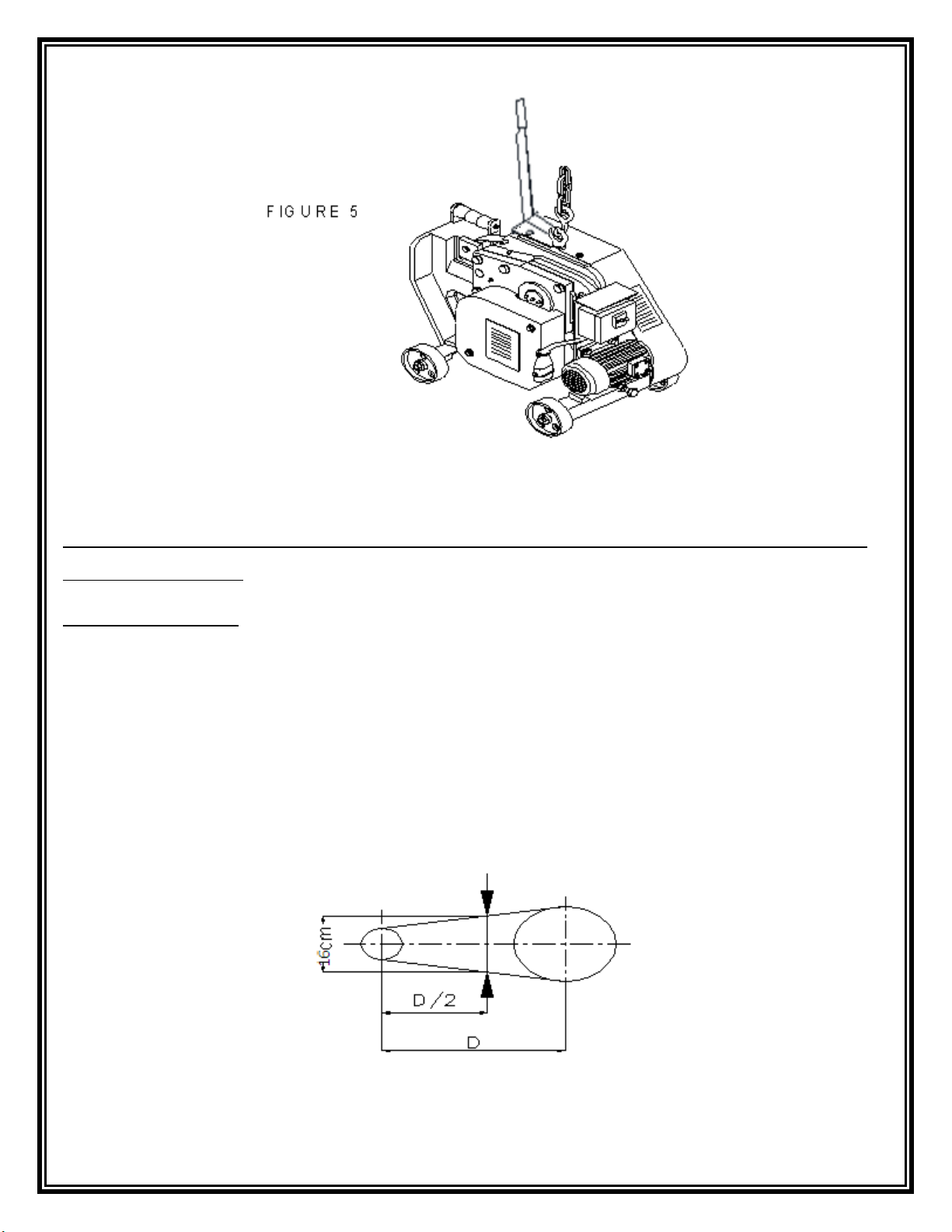

▼The machine is carried in accordance with the handling conditions (See Figure 5

▼ For multi-cutting purposes, bars are put one on the top of the other.

▼The machine is serviced in accordance with the maintenance conditions.

.

10

7. PROTECTORS TO BE USED DURING OPERATION OF THE MACHINE

7.1The protective clothing:

•Hard hat

•Glasses

•Safety Shoes

•Gloves

The above mentioned protectors are to be used. Otherwise, there is a risk of injury and body

harm.

7.2 Work clothing:

The objects having the risk of getting caught and seized up while working on the machine are

listed below, which may cause injury if not observed.

Long hair, dress with long sleeves, jewelry on arm, aprons with long bottoms, jewelry

protruding from the body.

8. TRANSPORTATION OF THE MACHINE

The machine should be carried and transported by means of the forklift, traveling crane or

EOT cranes. The forklift may only be used when the machine is enclosed in the box. To carry

the machine in the boxed situation, a wedge should be inserted underneath the machine in a

manner not allowing the wheels of the machine to contact with the box surface or the wheels

will be pulled out. The steel rope chain and polyester sling shot should be used for lifting the

machine. The lifting from the box ring on the machine should be used for lifting without a

box. The experienced expert people and subcontractors should be employed in the lifting

works.

WARNING!!!

The machine should be moved without vibration. The machine should not be carried in the

wet places. Any parts lost or damaged during the transportation process should be notified to

the manufacturer in the form of a report

•When using the lifting and handling equipment, the maximum carrying capacity of

these equipments will be taken into consideration.

•The weight gravity center of the equipment should be taken into consideration during

the lifting.

•The warning signals on all of the handling equipments should be observed.

11

9. CHECKS & ADJUSTMENTS ON THE MACHINE AND BLADE

REPLACEMENT

9.1 Belt adjustment:

The V-belts placed on the machine are loosened over time. Also the belt adjustment is

necessary as it will be misadjusted after the belt replacements. If the belt is loose, it causes

noise during the running of the machine and shortens the life time of the belt. The machine

fails to cut if the belt is too loose. However, it may cause the roller bearings on the motor

and body to warm up if the belt is set very tightly. The tightness of the belt should be

adjusted from the motor adjustment bolt, so that the distance between the two sides of the

belt should be 9 cm when it is pressed at the middle of both of the pulley centers.

12

9.2 Sequence of demounting of the V-belt from the machine:

1. Demount the protective cover at the pulley side of the machine.

2. Loosen the motor connection bolt.

3. Unscrew the nut of the motor adjustment bolt.

4. Make the pulleys close to each other by turning the motor adjustment bolt.

5. Remove the V-belt firstly from the small pulley and then from the bigger one.

6. To fit the belt in position, fit it firstly to the big pulley and then to the smaller one.

7.Set the tension of the belt by means of the motor tension bolt.

8. Tighten the motor connection bolt.

9. Complete the belt replacement process by fastening the protective cover.

Şekil : 8

9.3. Blade replacement

Remove first the movable blade and then the stationery blade while replacing the blades.

Ensure that the cutting edges are matching each other while fitting the blades.

FIGURE 9

:

Figure 8:

V- BELT

MOTOR ADJUSTMENT BOLT

PULLEYS

13

10. MAINTENANCE OF THE MACHINE:

It is of great importance that the maintenance is performed properly in order to increase the

service life of the machine and ensure a safe cutting work. We recommend that each user

installs a reliable system for the control and maintenance of the machine. The following

instructions are provided only for reference purposes. The machine should always be

lubricated with grease.

10.1 Daily Maintenance of the Machine:

•Check the machine for the noise when running.

•If the machine is operated in open air conditions, protect from rain when it is

rainy.

•Clean the blade spaces with a brush.

•Check the blades for bluntness and cracks, and replace if necessary.

10.2 Weekly Maintenance of the Machine:

•Replace the broken grease nipples fitted on the machine with the new ones.

•Lubricate the machine with the grease pump using the grease nipples fitted on the

machine.

•Check the blade bolts for tightness.

•Check the machine belts for their tensions

10.3 Monthly Maintenance of the Machine:

•Check the bolt connections on the machine for their tightness.

•Demount the protective covers of the machine and lubricate the movable

sections of the gear parts, engagement parts and foot pedal.

•Demount the protective cover and clean the steel shaving if any accumulated

between the movable sections.

10.4 6- Month Maintenance of the Machine:

14

•Demount the protective covers of the machine and remove the

contaminated oil on the movable parts and re-lubricate them.

•Check the movable running gears, engagers and carriers, machine bodies

and machine components for bluntness, breaks and cracks.

•Check if cavities are formed due to wear on the bronze bearings of the

machine, and replace the bronze bearings if so.

•Check the roller bearings of the machine for proper functioning

•For the proper functioning of machine it is necessary to change all the

roller & Bronze bearing every six month.

10.5. Annual Maintenance of the Machine:

•Check if cavities are formed due to wear on the bronze bearings of the

machine, and replace the bronze bearings if so.

•Check the roller bearings of the machine for proper functioning and replace if

necessary.

15

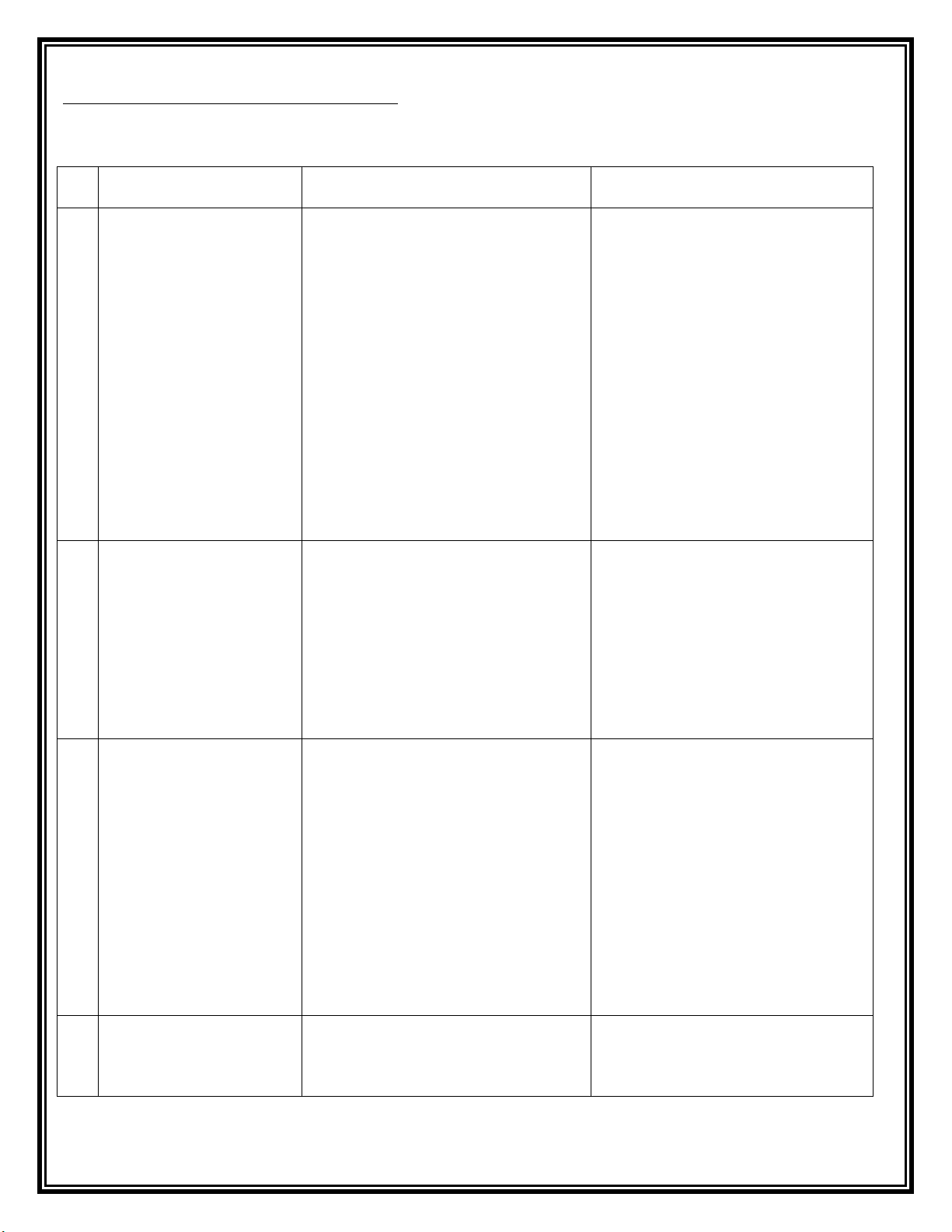

11. FAULTS AND REMEDIES:

The faults to arise during the operation of the machine and their reasons and remedies are

NO

FAULT

DESCRIPTION

REMEDY

1.

The power switch is

interrupted frequently

1. The power switch may be

interrupted due to overheating of

the motor.

2. There may be a short circuit in

the machine or installation.

3. The motor protection switch may

be malfunctioned and does not

activate the starters.

1. Check the belts for their

tightness.

2. Check if there is a short circuit.

.

3. Check the power switch.

Replace it if defective.

2.

The machine does not

start up

1. There may be an interruption in

the cabling.

2. There may be a

short circuit in

The motor.

3. The electrical network to

which the machine is connected fails

to receive phase

1. Check the cabling connections.

2. Check if there is a short circuit

by cutting off the electrical

connection of the machine.

3. Check the fuses on the

electrical panel.

3.

The machine fails to cut.

1. The belts may be loose or torn.

2. The engagement is not active.

3. The gear is broken off.

4. The eccentric axle or lever may

be broken off.

5. The cut steel is not in the

required size or strength.

1. Check the belts.

2. Replace the engagement

driving springs.

3. Check the gears.

4. Check the eccentric axle or

lever.

5.Check the cut steel acc. to the

cutting capacity plate

1. The engagement threads may be

worn.

2. The belts may be loose.

1. Replace the engagement.

2. Check the belt for its tightness.

16

4.

Machine is noisy when

running.

3. The roller bearings may be

failed.

4. The machine is not lubricated

enough.

5. The motor fan cover may be

crushed.

3. Check the roller bearings.

4. Check and lubricate the machine.

5. Check the motor fan cover.

5.

The machine frequently

causes the blade bolt to

be broken off.

1. The bearings to which the blades

are connected may be widened.

1. Check the blade connecting

points and repair if necessary.

17

12. ELECTRICAL DIAGRAM:

18

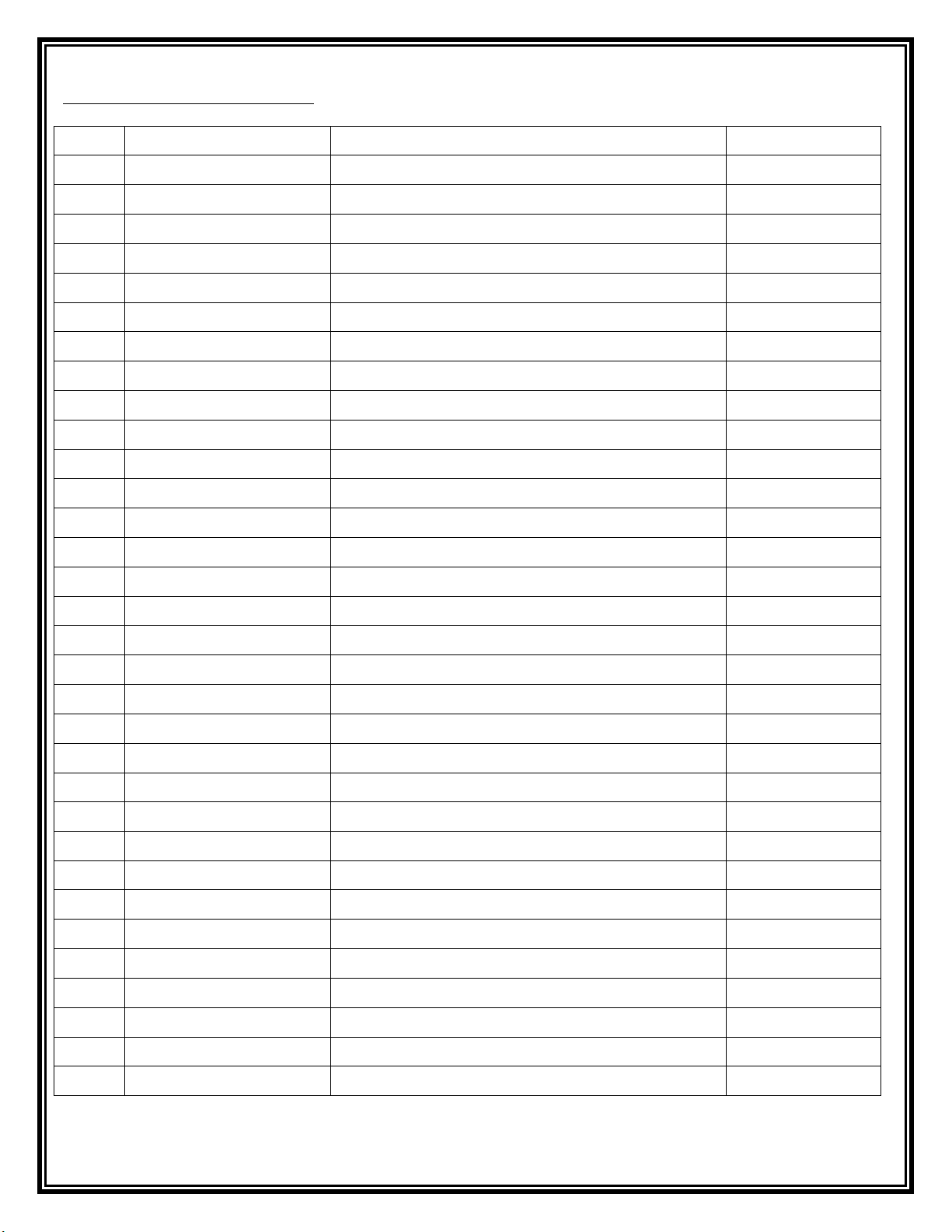

13. MATERIALS LIST:

No

Part Number

Part Name

Quantity

1

DCM40-01

Main Body

1

2

DCM40-02

Roller Bearing(6309 ZZ)

2

3

DCM40-03

Helix Pinion Gear

1

4

DCM40-04

10 X 10 X 94 Wedge

1

5

DCM40-05

Roller Bearing(6211 ZZ)

1

6

DCM40-06

Helix Gear

1

7

DCM40-07

Roller Bearing (6313 ZZ)

1

8

DCM40-08

Spur Pinion

1

9

DCM40-09

12 X 12 X 38 Wedge

1

10

DCM40-10

Washer M16

1

11

DCM40-11

Allen Screw M16 X 40 Lg

1

12

DCM40-12

Eccentric Shaft

1

13

DCM40-13

Carrying Arm

1

14

DCM40-14

Carrying Arm Bush

1

15

DCM40-15

Blade Carrier

1

16

DCM40-16

Blade

2

17

DCM40-17

Allen Screw M16 X25

1

18

DCM40-18

Cover Bush

1

19

DCM42-19

Cover Plate

1

20

DCM40-20

Bush Retaining Plate

1

21

DCM40-21

Allen CSK M6 X 20Lg

4

22

DCM40-22

Hex Screw M20 X 65 Lg

6

23

DCM40-23

Protective Cover RH

1

24

DCM40-24

Hex Nut M10

14

25

DCM40-25

Housing Bush

1

26

DCM40-26

Spur Gear Bush

1

27

DCM40-27

Spur Gear

1

28

DCM40-28

Spur Gear Insert

1

29

DCM40-29

Allen Screw M8 X 50 Lg

4

30

DCM40-30

Ring

1

31

DCM40-31

External Circlip Dai 75

1

32

DCM40-32

Clutch

1

19

33

DCM40-33

Engagement Pin

1

34

DCM40-34

Clutch Spring

1

35

DCM40-35

Spring Retaining Cover

1

36

DCM40-36

Allen CSK M10 X 35

2

37

DCM40-37

Pulley A2-7”

1

38

DCM40-38

Motor Connection Stand

1

39

DCM40-39

Hex Screw M20 X 100

1

40

DCM40-40

Hex Nut M20

1

41

DCM40-41

Hex Nut M16

2

42

DCM40-42

Hex Screw M16 X 100

1

43

DCM40-43

Electric Motor 5.5Kw ,1730

Rpm,220/460V, 60 Hz

1

44

DCM40-44

8 X 10 X 36 wedge

1

45

DCM40-45

Pulley A2-5”

1

46

DCM40-46

Grub Screw M10 X 20

1

47

DCM40-47

V-Belt A49

2

48

DCM40-48

Flywheel

1

49

DCM40-49

Washer M12

1

50

DCM40-50

Allen Screw M12 X 40

1

51

DCM42-51

Axle Segment

1

52

DCM40-52

External Circlip Dia 20

3

53

DCM40-53

Allen Screw M16 X 80

1

54

DCM40-54

Wedge

1

55

DCM40-55

Spool Pin

1

56

DCM40-56

Spool Bracket

1

57

DCM40-57

Spool/Roller

1

58

DCM42-58

Blade Protective Cover

1

59

DCM40-59

Hex Screw M10 X 50

1

60

DCM40-60

Axle

1

61

DCM40-61

Retainer

1

62

DCM40-62

Lock Pin

1

63

DCM40-63

Stud M10

1

64

DCM40-64

Needle Bearing

1

20

65

DCM40-65

Hand Lever

1

66

DCM40-66

Spring

1

67

DCM40-67

Disengagement Mechanism

1

68

DCM40-68

Disengagement Pin

1

69

DCM40-69

Disengagement Spring

1

70

DCM40-70

Disengagement Block

1

71

DCM40-71

Spacer Dia 20 X 21 Lg

1

72

DCM40-72

Lever

1

73

DCM40-73

Protective Cover LH

1

74

DCM40-74

Hex Screw M10 X 15

4

75

DCM40-75

Mounting Angle

2

76

DCM40-76

Wheel

4

77

DCM40-77

Washer Dia 50

4

78

DCM40-78

Starter

1

Table of contents

Other BN Products Cutter manuals

Popular Cutter manuals by other brands

Intec

Intec ColorCut SC6500 installation instructions

Elliott

Elliott PTTC Series Operating and maintenance instructions

Hitachi

Hitachi CM5SB Handling instructions

Wacker Neuson

Wacker Neuson RCP 20 Operator's manual

Central Forge

Central Forge 41711 Assembly & operating instructions

Makita

Makita 4112HS instruction manual