BN Products DIGITAL DISPLAY Series User manual

Page | 1

3450 Sabin Brown Road • Wickenburg, AZ 85390

BNT-Tiger Tier-Operations Manual - 2021

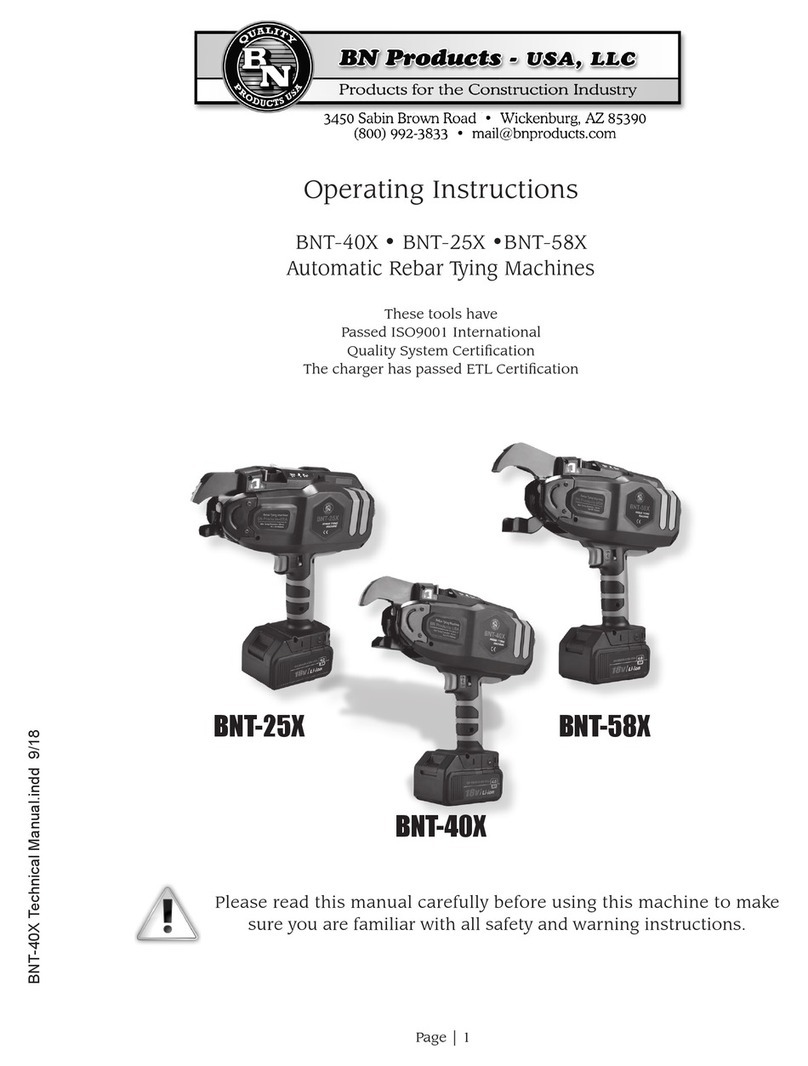

BNT-25X • BNT-40X • BNT-58X

Operating Manual

This tool has

passed ISO9001

International Quality System Certication

The charger has passed ETL Certication

Please read this manual carefully before using these

machines to make sure you are familiar with all safety and

warning instructions.

DIGITAL DISPLAY SERIES

Page | 2

BNT-Series Tiger Tier™

Callouts

Please read this manual carefully before using these

machines to make sure you are familiar with all safety and

warning instructions.

Battery Charger

Page | 3

Safety First

• This machine is a high-performance battery-operated tool. Failure to follow the

warnings and instructions may result in an electric shock, re, or serious injuries.

• Always operate the tool with personal protection equipment (including eye protec-

tion, etc.). Using the appropriate safety equipment at all times will avoid injury.

• Keep children and bystanders away while operating this tool. Distractions may

cause serious accidents. Do not aim the tool at those standing around your work

area. Serious accidents can happen if you mishandle this tool.

• Do not place your hand or position the machine near your body. Doing this could

cause serious injury.

• Do not attempt to dismantle, modify or perform any major maintenance on this tool.

Modications may deteriorate the tool’s performance and may cause severe injury,

and void the warranty.

• Ensure that the main switch is o when the tool is not in use or when abnormalities

occur. For example, when changing or adjusting the wire coil or when changing the

battery pack, make sure to turn o the main power switch and lock the trigger or

remove the battery.

• Do not place ngers or hands in the wire coil area. Doing so may cause injury.

• Do not operate this tool in the rain or areas where moisture is present. Doing so

may result in electrical shock or accident.

• Stay particularly alert while working in a high area. Do not operate any power tool

under the inuence of drugs, alcohol, or medication. A moment of inattention may

result in serious injury to you or someone near you.

• Do not operate this tool in a hazardous area containing ammable liquid, gas, or

powders that may ignite and cause a re.

• The charger unit uses standard AC power (100-240V ~ 50-60Hz). Do not recharge

the battery using a gas generator power supply, as this will cause the electronic

charger to malfunction.

• Our batteries charge best when the ambient temperature is between 32°F and

113°F. Therefore, Super-cooling or over-heating environments are not suitable for

charging.

• Continuous use of the charger is not advised. This will shorten the battery’s life

span and the charger’s performance. When not in the charging mode, the power

supply must be unplugged.

• Please do not carry the charger by the cord. Also, do not pull out the power cord

from the wall socket with the cord. This will damage the cord and break the wires or

cause a short circuit. A damaged cord must be repaired or replaced immediately.

• Use only the specied charger that came with your machine. Using an unauthorized

charger may result in damage to the battery components and a possible explosion.

• Avoid battery terminal contact with other metal objects. For example, trying to re-

charge the battery with an external wire could result in a short battery circuit.

• Do not throw away the protective battery cap. Use it to cover the terminal when not

in use

Page | 4

Safety Locks

Make sure that all safety features are operational before using any power tool.

DO NOT OPERATE THE TOOL IF THE SAFETY LOCKS ARE NOT FUNCTIONAL.

This tool is equipped with the following safety devices:

• The Main Switch: Please turn the main switch o when not in operation.

• The Trigger Lock: Always engage the trigger lock when not in use or when chang-

ing the wire spool.

Technical Data

Product No. > BNT-25X BNT-40X BNT-58X

Tool Only 4.15 lbs. 4.45 lbs. 4.85 lbs.

Tool + Battery 5.5 lbs. 5.8 lbs. 6.2 lbs.

Tool + Battery + Wire 6.4 lbs. 6.7 lbs. 7.1 lbs.

Height 11.81”

(300mm) 11.81”

(300mm) 12.2” (310

mm)

Width 4.29”

(109mm) 4.29”

(109mm) 4.29”

(109mm)

Length 11.06”

(281mm) 11.69” (297)

mm) 12.28”

(312mm)

Ties per spool 160-220 120-160 85+

Wraps per tie 3 Wraps 4 Wraps

Time per tie 0.6-0.8 Seconds

Max tying diameter 1” (25mm) 1.575”

(40mm) 2.283”

(58mm)

#3 x#4 #6x#6 #8x#8

Battery Li-Ion 18V, 4.0Ah, 72Wh

(BNTLI-20)

Ties per charge 4000-5000

Additional Charger (BNTLI-20C)

BNT-40-Wire

Diameter (in.) ø 0.03 (21 Gauge)

Material Q195 Galvanized

Length (in.) 3937 (approx)

BNT-40-Wire-USA

Diameter (in.) ø 0.03 (21 Gauge)

Material Q195 Black Annealed Wire

Length (in.) 3937 (approx)

Page | 5

BNT-40-Wire-P

Diameter (in.) ø 0.03 (21 Gauge)

Material Q195 Polycoated

Length (in.) 3937 (approx)

Battery and Charger Usage

Before inserting or removing the battery from this tool, please set the main switch to the

o position.

• To avoid a short circuit to the battery, always use the battery terminal cover when it

is not in use with the tool.

• When placing the battery into the tool, press the battery lock before placing it into

the battery holder. When removing the battery, press the battery lock button before

pulling it out of the battery holder.

• Use 100-240V ~ 50-69Hz AC power supply for the charger. Fully insert the battery

into the charger slot and it will begin to charge automatically as indicated by the

charging light. It will take approximately 74 minutes to fully complete the battery

charge.

• It is recommended to charge the battery between 32°F and 113°F. Do not charge in

extreme cold or hot environments.

Machine Operation and Methods

• Before inserting or removing the wire spool turn the main power switch to o and

lock the trigger.

• When installing the wire spool in this tool only use recommended wire that is clean

and rust free.

• Only use recommended wire spools. Using non-standard wire or spool could cause

the tool to malfunction.

• Press and lock the lever.

• Push the Reel Stopper to release the Reel Stay

(door) and open.

• Cut about 2 inches of wire o the end of the coil.

• Install the wire spool with the left side facing the

tool (left is marked on the spool). Close and latch

the Reel Stay (door).

• Insert the wire into Wire Guide C. Note: the wire

must not be bent or curved.

• The wire must pass through Wire Guide C and in

between the two feeding gears until it reaches the

ared tube. Then push the wire an additional ½ inch

into the ared tube.

• Release the Release Stopper and conrm the

Release Lever has returned to its original position.

Note: the wire must be clamped in between the

feeding gears.

Page | 6

• Turn on the main power switch and unlock the

trigger. The tool is now ready for use.

How to remove the wire coil spool

• Turn o the main power switch, lock the trigger

and remove the battery.

• Press the release lever and conrm that it is

caught in the open position.

• Remove the plastic wire spool.

The Tying Procedure

• Unlock the trigger lock. Keep the mechanical arm on the rebars to be tied with a

45° angle at a vertical position to the rebars.

• Press the trigger and the tool will tie automatically.

• Remove the tool when the tying is complete.

• Do not press the trigger when the mechanical arm is not on the rebar surface.

(Note: if this should happen turn o the machine, position the trigger lock to the

“o” position and remove the trapped wire with a pair of pliers inside the machine

mouth).

• Adjust the tie tightness. There are 9 tightness levels that can be adjusted.

The Digital Display:

The left number on the LED display is the wire wraps (or

loops). The second number is the tension.

Making Wire Wrap Adjustment:

To adjust the wire wraps, hold the trigger down while

turning the tool on and it will do one less loop than the

default setting. When the tool is turned o it will reset to

the default setting. The BNT-25X and the BNT-40X de-

fault setting is three loops. The BNT-58X default setting

is four loops.

Making Tension Adjustment:

Use the up or down button to increase or decrease the tightness of the ties. 1 is the

lowest setting and 9 is the highest. Turn the tension up as much as it will tie without

breaking the twist (or pig-tail). If it breaks the pig-tail, turn down the setting until it does

not break. That is the tightest setting you can use.

Page | 7

Replacement of Gears

• Remove the screw that fastens the plastic cover over the motor.

• Remove Wire Guide “C” which is fastened to the plate.

• Remove the E-ring on Feed Gear B1. Press lever and remove feed gear.

• Release the lever and remove Comp. Spring 3. Be careful not to lose the smaller

Comp. Spring 4 on the Release Stopper.

• Take out the screw and washers from the Release Lever and remove the Release

Lever in the direction of the arrow.

• After you remove the Release Lever you can remove the E-ring and Pin to replace

Feed Gear B2.

• After you nish replacing the gears reassemble the tool in reverse order.

• First install the Release Lever and fasten it.

• Install Comp. Spring 4 on the Release Stopper and Comp. Spring 3 on the Release

Lever (press lever into locking position to hold springs in place while making sure

spring 4 stays in place).

• Install Feed Gear B1 and E-ring in sequence.

• Install Wire Guide C on the plate. Finally attach the Motor Cover with the screw.

Care and Maintenance

• Perform a daily inspection prior to using this tool.

• Please maintain this electric tool carefully, making sure that the adjustments are

correct and that it has been stored properly.

• Inspect the tool for damage and cracks in the housing and that the power supply is

in good working order.

• Make sure that the battery charger is the one that came with your machine. Using

another charger could cause damage to the battery and/or charger and could even

cause a re.

• Improper use of the battery could cause it to leak. If this happens it will need to be

replaced and properly recycled. Do not touch any leaking material from this battery.

If you come in contact with the battery liquid, ush with clean water and seek medi-

cal attention if necessary.

Page | 8

BNT-Series Tiger Tier™ Common Faults

*Recommended Action items that are shaded likely require professional service; Contact BN Customer Service at (800) 992-3833 for assitance

Section Use Case or

Normal

Condition

Common Fault Alert

Tone

Possible Cause Part(s) to Inspect *Recommended Action

1 Power = On >

e twister is

intialized and

the wire cutter

should operate

automatically

No LED light, no

operation occurs

None No power or bent

electrode

Check to ensure that the main

switch is in the on position.

If the unit is powered on with a charged battery,

contact BN Customer Service to assist in deter-

mining if repair is required.

No LED light, but

tool is fully func-

tional

None LED not connected

or broken wire,

bent electrode

Power off, then power on - deter-

mine if LED is lit or remains off

Service is required for LED light to be functional,

if not working

Twister assembly

fails to return to its

original position

4 beeps Twisting motor

fault

Service: Electrode wire or twisting

motor has a connection or signal

failure, or damage to the twisting

motor has occurred

(Service Required) Service is required to repair

electrode/signal wiring or repair the twisting

motor

7 beeps Twister assembly

hook is obstructed

by wire

Check for obstruction by pulling

back the curl guide

Remove obstruction or foreign bodies; cut wire if

necessary

7 beeps Electronic failure

possible, requires

Service Technician

Service: Inspect Main PWB unit,

Twister Assembly, gearbox, motor

(Service Required) Contact Technical Service for

assistance

2 Trigger is

pressed > Wire

should be fed

from the unit

No wire is fed, or a

very short segment

is released

Continu-

al single

beep

Curl guide may be

open

Inspect Curl Guide. e Guide may

not be closing completely due to

contamination or damage.

Fully close curl guide

Continu-

al single

beep

Sensor failure If curl guide is closed,

Switch lever may be broken

(Service Required) Service: Switch lever repair or

replacement may be necessary

Page | 9

Section Use Case or

Normal

Condition

Common Fault Alert

Tone

Possible Cause Part(s) to Inspect *Recommended Action

3 beeps Wire spool is

empty, or wire may

be jammed inside

the spool

Check to see if wire spool needs to

be replaced; Check spool to ensure

that wire is not loose, jammed, or

caught inside the spool

Replace wire spool, or remove slack from the wire

spool that is causing failure for wire to feed into

the machine

2 Trigger is

pressed > Wire

should be fed

from the unit

No wire is fed, or a

very short segment

is released

3 beeps Wire Spool is

blocked by Reel

Press or there is

damage to the

brake assembly

Rotate wire spool by hand, check to

ensure that the spool rotates freely.

Clean if necessary. If the spool does

not rotate freely; service is required.

(Service Required) If spool is unable to rotate or

parts appear to be damaged in the brake housing

assembly, repair may be required

Wire Feed

(check Guide A)

is blocked by a

foreign object or

buildup of dirt

Inspect wire feed channel for build-

up or obstruction from a foreign

object; see “How to Clear a Wire

Jam” in the BNT-X series Operator

Manual

Clean the wire feed (channel on Wire Guide A, or

visible obstructions) and/or remove any foreign

substances

Feed motor or

wiring to the feed

motor is damaged

If spool rotates freely and Wire

Guide A is clear, the feed motor

assembly may be damaged

(Service Required) Repair of wiring or feed motor

may be necessary

3 Binding Wire

should form a

circular pattern

(loop) and

should com-

plete a twist-tie

around bar(s)

Loop is inconsistent

and/or is deflected

from the curl guide

None Wire tie is ob-

structed by contact

with rebar during

tying

Determine if obstruction was

caused by wire colliding with rein-

forcement bars to be tied

Ensure that bars tied are within the tying range of

the tool when in-use. If the bars to be tied do not

fit within the space alotted by the tool, a proper-

ly-sized tying machine may be necessary. Refer to

the Rebar size chart in the Operator Manual for

maximum tying capacity of the tying tool

Loop is oversized /

too large

Inpsect wire guide A; also verify

that proper wire for the machine is

being used

If Wire Guide A is dirty, it should be cleaned. If a

Wire Guide A is worn, replacement may be neces-

sary - contact Customer Service for assistance.

Curl guide or Arm

Unit is damaged

or bent

Inspect Arm Unit and curl guide for

damage

(Service Required) If Arm Unit or curl guide

are damaged, repair or replacement of parts are

necessary

Page | 10

Section Use Case or

Normal

Condition

Common Fault Alert

Tone

Possible Cause Part(s) to Inspect *Recommended Action

4 Wire feeds,

wire spool

should

dispense wire

consistently

with no excess

(slack) in wire

coil

Wire is loose on the

spool

None Brake assembly is

blocked by buildup

or blocked by for-

eign substance

Inspect brake housing for dirt and

foreign substances

Clean and/or remove buildup or foreign sub-

stances from brake housing assembly, lubricate

as needed

4 Wire feeds,

wire spool

should

dispense wire

consistently

with no excess

(slack) in wire

coil

Wire is loose on the

spool

None Wire spool is a

third-party prod-

uct not designed

for use with tool

Determine if tie-wire is designed to

work with the BNT-25X/40X/58X

tying machines

Replace spool with BNT-40-WIRE compatible

wire spool

None Damage to the

brake assembly

motor

If brake housing is clean and free

of substances, and wire spool is

compatible with machine, contact a

service representative

(Service Required) Brake motor assembly may be

damaged or require repair or replacement

5 Wire is fed and

twist-tie should

be formed

snugly around

the bar(s)

Wire loop is fed,

but machine fails to

twist wire

None Loop diameter is

too small

Check for wire jam or obstruction;

see “How to Clear a Wire Jam” in

the BNT-X series Operator Manual

Clear wire jam or obstruction

Tie is loose or

broken

None Tightness adjust-

ment is too low; or

it is possible that

Rebar tied is not

within the tying di-

ameter range (too

large or too small)

for the tool

Check to ensure that rebar being

tied fits within the tying range of the

tool; then check tighness setting on

the tying machine

Refer to the Operator Manual to check rebar (size)

tying range; use adjustment dial (on some models)

or digital display to adjust tightness of rebar ties

(tie needs to be tighter). In some instances the

loop size may be incorrect, and may require Ser-

vice (contact Customer Service for assistance)

Page | 11

BNT-25X Mesh

#1 #2 #3 #4 #5

1/8” 1/4” 3/8” 1/2” 5/8”

6mm 8mm 10mm 13mm 16mm

Mesh x x x x x x

#1 1/8” 6mm x x x x x x

#2 1/4” 8mm x x x x x

#3 3/8” 10mm x x x x x

#4 1/2” 13mm x x x x

#5 5/8” 16mm x x

BNT-40X #1 #2 #3 #4 #5 #6 #7 #8 #9 #10

1/8” 1/4” 3/8” 1/2” 5/8” 3/4” 7/8” 1” 1-1/8” 1-1/4”

6mm 8mm 10mm 13mm 16mm 20mm 22mm 25mm 29mm 32mm

#1 1/8” 6mm x x x x x x x x

#2 1/4” 8mm x x x x x x x x x

#3 3/8” 10mm x x x x x x x x x

#4 1/2” 13mm x x x x x x x x

#5 5/8” 16mm x x x x x x x

#6 3/4” 20mm x x x x x x

#7 7/8” 22mm x x x x x

#8 1” 25mm x x x x

#9 1-1/8” 29mm x x x

#10 1-1/4” 32mm x x

BNT-58X #3 #4 #5 #6 #7 #8 #9 #10 #11 #14

3/8” 1/2” 5/8” 3/4” 7/8” 1” 1-1/8” 1-1/4” 1-3/8” 1-3/4”

10mm 13mm 16mm 20mm 22mm 25mm 29mm 32mm 36mm 43mm

#1 1/8” 6mm x x x x x

#2 1/4” 8mm x x x x x x

#3 3/8” 10mm x x x x x x x

#4 1/2” 13mm x x x x x x x x

#5 5/8” 16mm x x x x x x x x

#6 3/4” 20mm x x x x x x x x

#7 7/8” 22mm x x x x x x x

#8 1” 25mm x x x x x x

#9 1-1/8” 29mm x x x x x

#10 1-1/4” 32mm x x x x

#11 1-3/8” 36mm x x x

#14 1-3/4” 43mm x x

• When not in use, store this tool carefully in the supplied case. It can be

washed with a soft cloth and soapsuds after you nish work. Do not use

petroleum chemicals or alcohol to clean this tool.

• In the event that this tool malfunctions or drops in performance you can

contact our Customer Service Repair Center:

Page | 12

How To Clear A Wire Jam On

The BNT X Series Rebar Tiers

The three-beep audio error code on the BNT X Series Rebar Tier most likely signies a

wire jam in the nose of the tool. Here are the steps you can take to clear misfed wire.

1. Remove the two hex fasteners (905 & 912). A 2.5mm tool is supplied with the tier.

Remove the arm unit cover plate (101) and set it aside (see picture 1).

2. Remove the three (3) hex fasteners (908) on the wire guide (115) and remove it

(picture 2).

leave the wire cutters and the connecting rod (108) in place (see picture 3)

3. Clean the channel on the backside of the wire guide with a wire brush or small screw-

driver (see picture 4)

Page | 13

4. Reassemble the tool in reverse order. Make sure that the notch on the connecting

plate ts into the half moon cutout on the wire guide as seen in Picture 5. **Note: A tiny

bit of grease can be put on the linkage points and xed cutter but not too much as this

will attract debris.

Note: Do not over tighten any of the fasteners.

Loop Diameters and Wire Lengths

Tiger Tier Diameter Length

BNT-25X 1-13/16 to 1-15/16 in. 24-3/4 in.

BNT-40X 2-1/4 to 2 3/8 in. 31 in.

BNT-58X 3 to 3-1/8 in. 48 in.

Getting a loop sample

1. Pull the trigger while holding a screwdriver or pen in the tying position

2. Push the loops forward after pulling the trigger but before the tool twists the loops.

3. You can now measure the diameter of the loops.

The BNT-Series are hand-held battery operated tools. The tool is designed to be used

for the fast tying of rebar or steel used in construction sites for the building trades. Due

to its speed, convenience and safety, this machine can save a great deal of valuable

labor and material resources. In addition, the parts and components as well as ad-

vanced production technologies are made from well-known manufacturers both here

and abroad. This machine was developed as an economical and practical tying machine

with many international patents.

Page | 14

For additional information including:

• Product Parts List

• Product Literature

• BNT Wire Supplies

• BNEX-40X - Arm extension with electronic trigger

• BNH-40 Holster - Heavy-duty holster

• BNTLI-20 - Replacement Lithium-ion Battery (18V)

• BNTLI-20C - Replacement Charger for the BNTLI-20 Battery

Visit www.bnproducts.com or call (800) 992-3833

NOTES:

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

____________________________________________________

Page | 15

BNT Series Accessories & Supplies

This manual suits for next models

3

Table of contents

Other BN Products Power Tools manuals

Popular Power Tools manuals by other brands

Parkside

Parkside PES 200 B1 Operation and safety notes translation of original operation manual

Jet

Jet JMD-45PF operating instructions

Hitachi Koki

Hitachi Koki NV45AB2 Handling instructions

Jet

Jet JWS-18HO Operator's manual

Alpha tools

Alpha tools ASB 24 operating instructions

Urrea

Urrea 6002NM Instructive and Warranty

Milwaukee

Milwaukee 2635-20 Operator's manual

Ryobi

Ryobi AirStrike P360VN Operator's manual

BEA

BEA 380/160-400 Service instructions

Campbell Hausfeld

Campbell Hausfeld IN718303AV operating instructions

HIKOKI

HIKOKI RH 650V Handling instructions

Schneider Airsystems

Schneider Airsystems SSP-SAW 4 SYS Original operating manual