BN Products DBR-25WH User manual

Page 1

BN Products-USA, LLC.

3450 Sabin Brown Road • Wickenburg, AZ 85390

(800) 992-3833 • (928) 684-2813 • mail@bnproducts.com

DBR – 25WH

REBAR STRAIGHTENER

HANDLING INSTRUCTIONS

READ THESE INSTRUCTIONS CAREFULLY BEFORE

ATTEMPTING TO USE REBAR STRAIGHTENER

Not following proper operating procedures can lead to accidents.

If in doubt of any procedure, contact your local authorized agent.

The DBR-25WH is a portable heavy-duty electric/hydraulic rebar bender

and straightener. It helps save valuable man-hours by cleanly and e-

ciently bending or straightening bent rebar. It functions as a simple 90-de-

gree portable electric rebar bender. The interchangeable bending hook

covers rebar diameters from #4 to #8 grade 60. Maximum pressure for

bending and straightening ranges from 8.5 to 11 tons. It’s portable and

versatile enough to bend or straighten rebar in-place with its push/pull hy-

draulic capabilities. It will bend a 90-degree angle in only (4) seconds.

The bending head also rotates 360 degrees. Ships complete in a plastic

carrying case with hydraulic oil, a tool kit and two additional bending dies.

This tool solves bending applications other tools can’t even attempt.

DBR-25WH_Product_Manual-2018

Page 2

BN Products-USA, LLC.

3450 Sabin Brown Road • Wickenburg, AZ 85390

(800) 992-3833 • (928) 684-2813 • mail@bnproducts.com

GENERAL SAFTEY PRECAUTIONS

Application: Use DBR-25WH on concrete re-enforcing

bars only.

RESTRICT USE TO DESIGNATE MATERIALS

There is always a chance that the end of material may

break and shoot out, especially if the material is harder

than those specied. Exceeding designated material

specications greatly increase this risk and will also

damage the tool. Do not attempt to use the tool for

rebar harder, thicker, or thinner than those specied.

USE EYE PROTECTION

Wear safety goggles, safety glasses with side shields or a

face shield when using the rebar straightener.

KEEP HANDS AWAY

Do not touch rebar, housing, hook, rollers, and/or the

piston while rebar straightener is being operated.

GUARD AGAINST ELECTRIC SHOCK

To avoid possible electric shock, do not handle the DBR-

25WH with wet hands, or use in the rain or other damp

places. Be aware of all power lines, electric circuit and

other hazards that may be contacted, especially those

that are below the surface or otherwise hidden from

view.

UNPLUG TOOL

Disconnect the tool from outlet when not in use and be-

fore cleaning, adjusting, or servicing. Do not disconnect

plug from outlet by pulling on the cord. Always check

that the switch lock is OFF before plugging your tool in.

BEWARE OF YOUR ENVIRONMENT

Do not use rebar straightener in the presence of amma-

ble materials (e.g., paint, thinner, petroleum products,

and adhesives.) Do not use rebar straightener in a pos-

sibly explosive environment, (e.g., fumes, gas, or dust)

or in areas that are poorly ventilated.

KEEP WORK AREA TIDY AND WELL LIT

Make sure that work area is properly lighted and clear of

obstructions. Operator should at all times have an unob-

structed view of their rebar straightener, rebar, and the

surrounding area.

WEAR PROPER APPAREL

Do not wear loose clothes, dangling objects, or jewelry.

Restrain long hair. The use of a safety helmet and rubber

soled boots are strongly recommended. If safety gloves

are worn, be especially careful that gloves do not get

caught in the moving parts.

KEEP VISITORS AWAY

Keep all visitors at a safe distance from the work area for

their own protection and to prevent distraction of the

operator.

Max Rebar Diameter 25 mm

Straightening Max yield point 345N/mm2

Bending Max yield point 295N/mm2

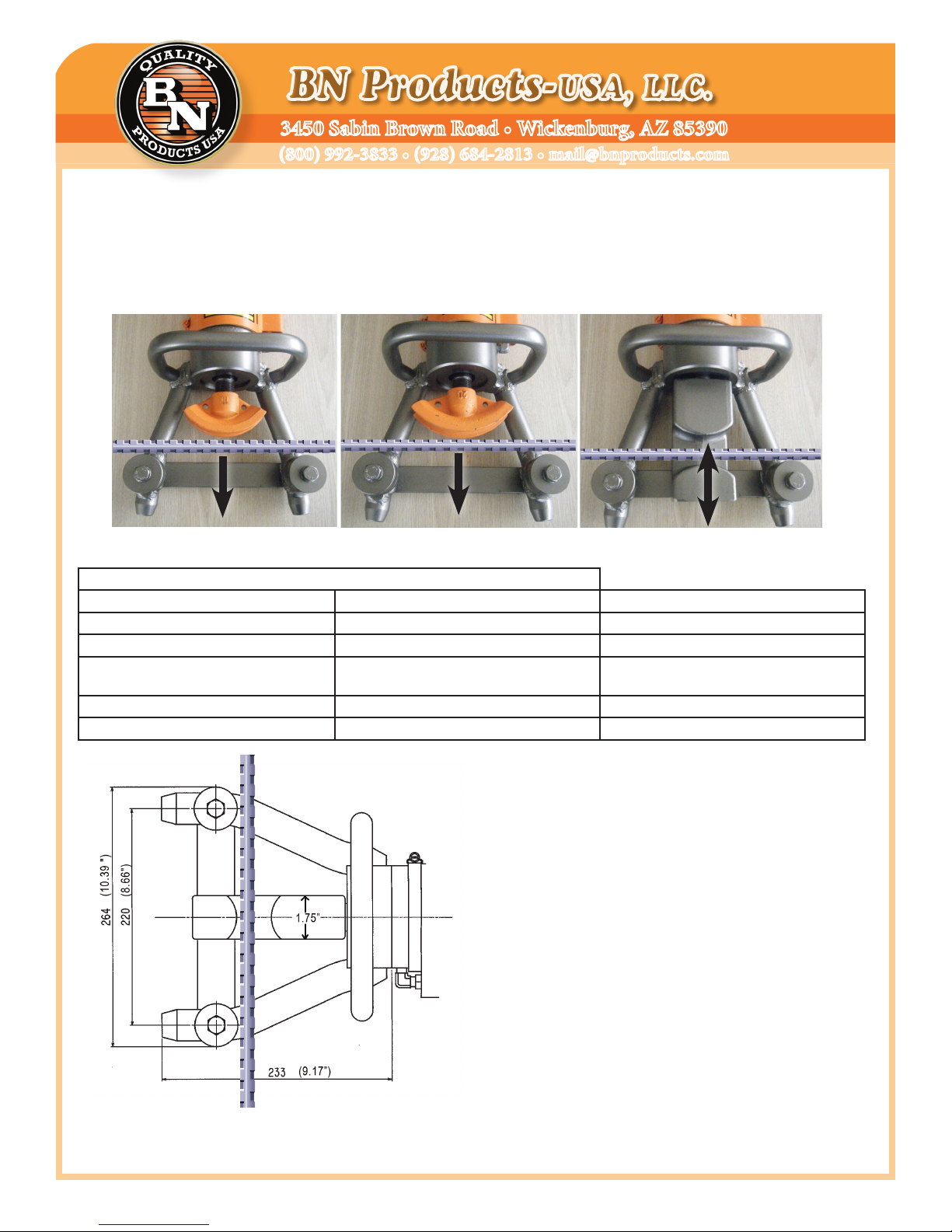

Rebar Diameter Straightening Capacity Bending Capacity

Push Pull Push Pull

13 mm up to 125° up to 121° up to 94° up to 92°

16 mm 128 124 90 90

20 mm 130 126 90 90

25 mm 132 124 90 90

Max pressure 11 Tons 8.5 tons 11 tons 8.5 tons

Output 1.5 HP

Weight 22.5 Kg

Dimension 660x270x200mm (LxWxH)

Page 3

BN Products-USA, LLC.

3450 Sabin Brown Road • Wickenburg, AZ 85390

(800) 992-3833 • (928) 684-2813 • mail@bnproducts.com

MAINTAIN REBAR STRAIGHTENER WITH CARE

Inspect rebar straightener before each use. Faulty or

loose bending hook could possibly result in personal

injury. Keep handle dry, clean and free from oil and/or

grease. Keep housing and piston free of dirt and iron l-

ings. Check that no screws or bolts are loose or missing.

Follow all instructions for maintenance. Inspect switch,

cord, plug and any extension cable at regular intervals.

STORE CAREFULLY

When not in use, store rebar straightener and its acces-

sories in a dry place where they cannot be accessed by

anyone but the operators.

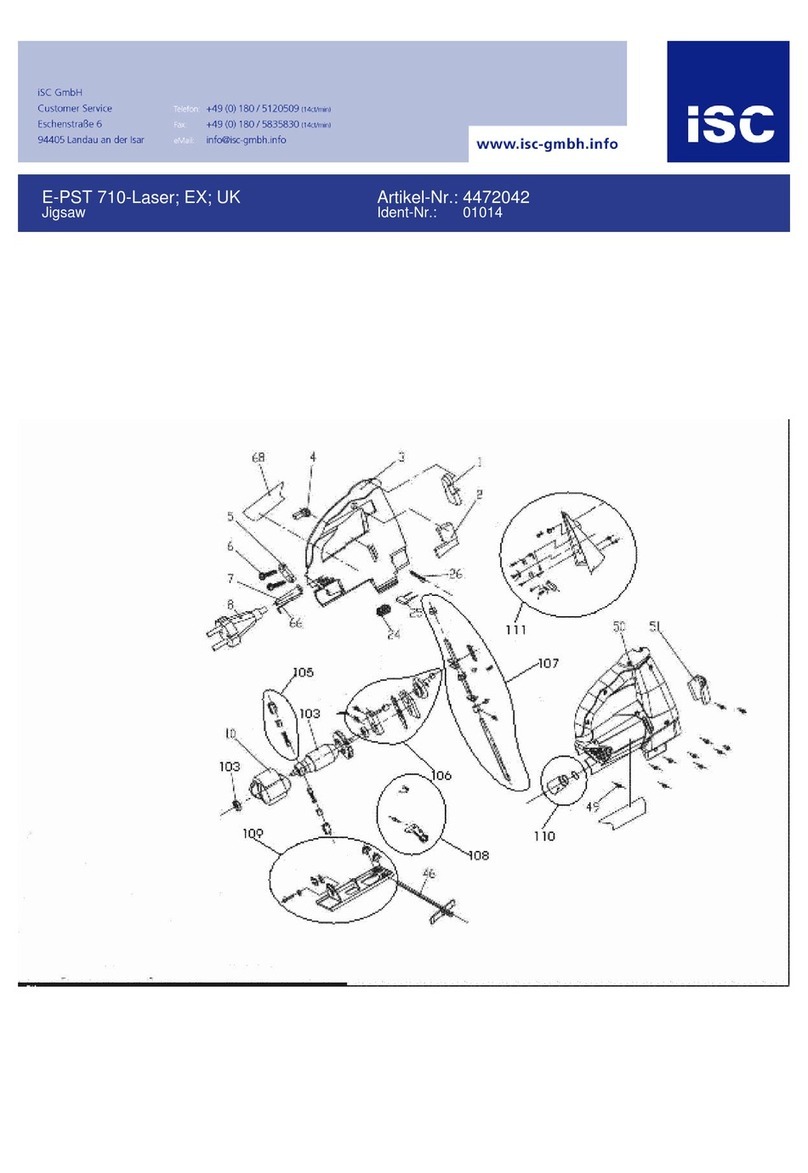

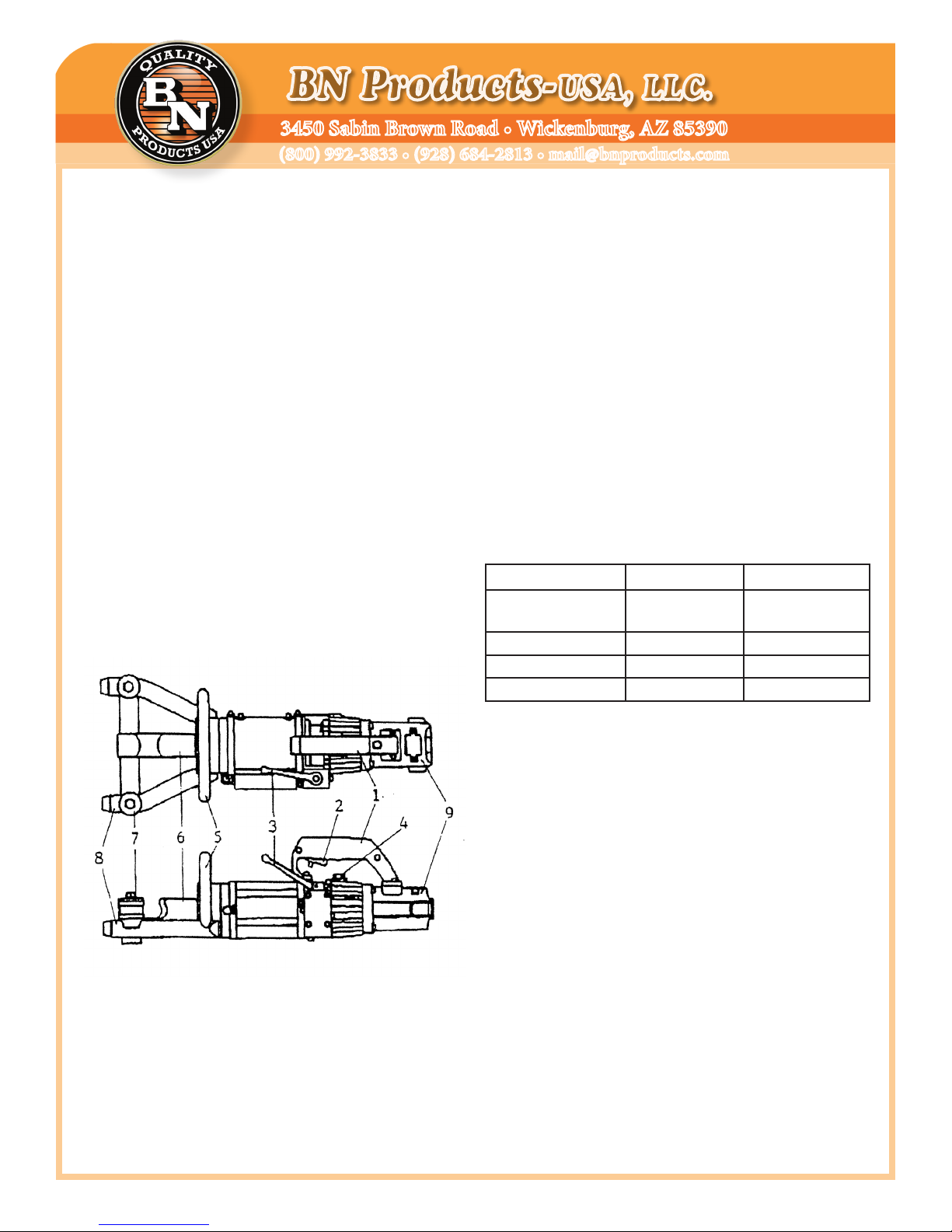

PARTS AND SPECIFICATIONS (Figure 1)

1. Handle

2. Switch

3. Mode control lever

4. Oil plug

5. Front handle

6. Hook

7. Roller

8. Housing

9. Motor

OPERATING INSTRUCTIONS

Check the oil level.

Check that the power source is appropriate to the rebar

straightener.

CARE- If voltage is too high, the motor will burn out, if

voltage is too low, insucient power will be generated.

NEVER USE DC CURRENT OR AC HIGHER THAN

110V

Check that the power supply is properly earthed.

CAUTION- Failure to properly earth the power supply

may result in a shock to the operator.

Check that the cord is undamaged and that the plug is

not loose.

CAUTION- Cut or abraded covering could result in a

short and electric shock to the operator.

If an extension cord is to be used, make sure that it is

undamaged and that it is the proper thickness for the

length. See table below.

100/115V 230V

Cable

Length

Cable Size

(AWG)

Nominal

Diameter

Up to 10m (33 ft.) 16 1.0mm2

Up to 15m (50 st.) 14 1.25mm2

Up to 30m (100ft.) 10 1.5mm2

Before plugging the tool in, make sure that the switch

lock is o.

CAUTION- If switch lock is ON; the rebar straightener

will start as soon as it is plugged in. To disengage lock,

pull the trigger switch, the lock button will pop out.

WARM UP

In cold weather, warm up the unit for 30-60 seconds

so that the hydraulic oil will reach the proper viscosity.

Pull the trigger switch to extend the piston and release

when it has reached its full stroke. Repeat this action 3-5

times.

POINTS OF ATTENTION

1. Do not cover air vents.

2. CARE- If vents are covered, the motor will overheat

and may burn out.

Page 4

BN Products-USA, LLC.

3450 Sabin Brown Road • Wickenburg, AZ 85390

(800) 992-3833 • (928) 684-2813 • mail@bnproducts.com

3. If hydraulic oil exceeds 70*C, (158*F) the power will

drop. Allow the unit to cool before resuming opera-

tion. (Be particularly careful in summer, when the

aluminum pumpcase heats up quicker.

4. If a drop in power is observed and motor is unusu-

ally hot, check the carbon brushes.

OPERATION

The DBR-25WH is primarily intended to straighten

deformed rebar. It can, or course, also be used to bend

straight rebar.

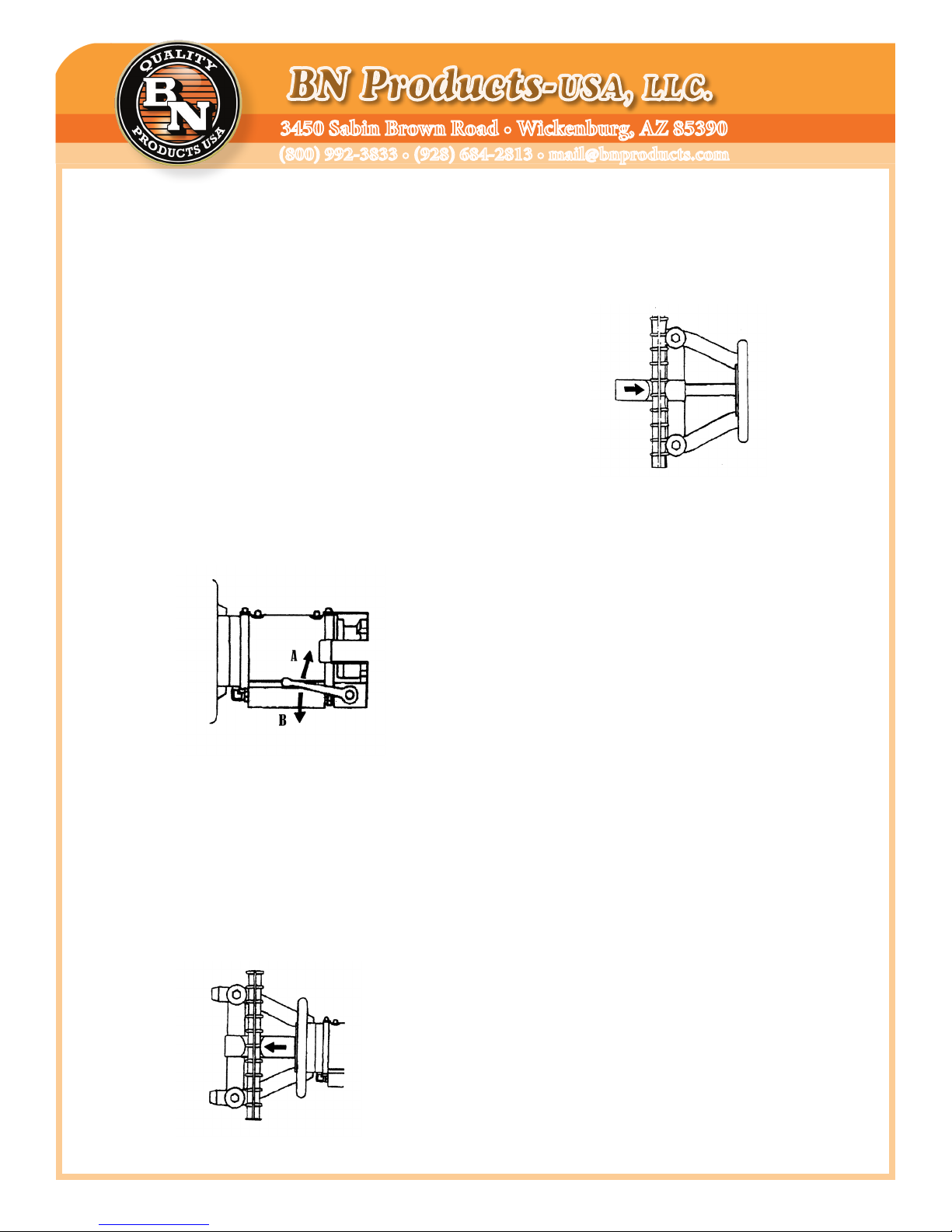

To enable the unit to be used in conned spaces, there are

twooperating modes: Push& Pull.The modeisselected by

movingthemodecontrollevertotheappropriateposition.

“A” for push (piston advances) and “B” for pull (pis-

ton retracts) In either mode, simply press the switch to

move the piston.

NB: The movement of the piston is limited by a safety

valve. To prevent overheating, release the trigger switch

when the piston has reached its travel limit.

TO PUSH

Advance or retract the piston so that the hook is in a

suitable starting position. Set the mode control lever to

“A” and t the rebar as shown at the left. Pull the trigger

switch until the rebar is at the desired angle.

TO PULL

Set the hook in the correct starting position , make sure

that the mode control lever is in the “B” position and t

the rebar as illustrated. Pull the trigger switch until the

desired angle is attained.

NB: It is important that the rebar be properly tted in

the hook and against the rollers.

INTERIOR ANGLE

Since the piston stroke is limited, interior straightening

/ bending angle will vary according to rebar diameter

and operating mode. Refer to the table below.

CLEANING

Clean rebar straightener everyday, preferably immedi-

ately after use.

CAUTION- Wear gloves to protect hands from metal

splinters. Do not use air guns – Blasting with air guns

can cause metal lings and/or dust to get into eyes and

respiratory system.

1. Disconnect unit.

2. Wipe or brush away all dirt and metal lings. Pay

particular attention to the lower half of the piston,

where dirt is more easily accumulated.

3. Once the piston has been retracted, pull the trigger

switch long enough to partially unplug unit. Check

the piston for accumulated dirt and iron lings that

may be jamming the piston.

OIL LEVEL CHECK

As rebar straightener is hydraulically operated, the oil

level must be checked at frequent intervals, preferably

everyday. Failure to maintain the oil at proper levels will

result in a drop in pressure and loss of the benders hy-

draulic power.

Page 5

BN Products-USA, LLC.

3450 Sabin Brown Road • Wickenburg, AZ 85390

(800) 992-3833 • (928) 684-2813 • mail@bnproducts.com

CAUTION- Hydraulic oil is highly ammable. Keep

away from sparks and naked ame. DO NOT SMOKE

WHEN NEAR OIL/BENDER.

CAUTION- Hydraulic oil may cause inammation of

the eyes and skin. If ingested, it will cause diarrhea and

vomiting.

In case of eye contact, rinse in clean water for at least 15

minutes and consult a physician immediately, as blind-

ness can occur.

In case of skin contact, wash thoroughly with soap and

water.

In case of ingestion, consult a physician immediately.

DO NOT DELIBERATELY INDUCE VOMITING.

OIL MAINTENANCE CON’T.

1. Oil should be warm, but not hot. Warm up the unit

if cold.

2. Unplug unit from the power source.

3. Remove oil plug and the seal washer (packing)

4. CAUTION- Never remove oil plug when unit is hot,

as the oil may spurt over.

5. Check that oil is level with the bottom of the plug

hole (i.e. the pump case is full to the brim) If oil level

is too low, top up with 20- weight hydraulic oil with

anti-foam and anti- abrasion properties (ISO viscos-

ity grade VG46, e.g., Shell Tellus 46, Mobil Oil DTE-

25, or Esso Uni Power SQ46)

6. After topping up, extract air from the system. Gently

tilt the unit and return it to the level position. Top

up again and tilt in the opposite direction. Repeat

this action until all air has been removed.

7. CARE- Rebar straightener cannot function properly

if oil contains air bubbles.

8. Replace seal washer and plug. Extend to its full

stroke, and remove oil plug and seal washer. Then

repeat the procedure of above

9. Replace the oil plug and seal washer.

OIL CHANGE

The hydraulic oil should be changed at least once a year,

sooner if it appears to be dirty.

1. Unplug the unit from the power source. Remove the

oil plug and packing. Turn the unit over and drain

oil into an appropriate receptacle.

2. With drain hole uppermost, slowly ll the unit with

fresh oil. Replace plug and lightly tighten. Connect

the unit to power source and advance piston two

or three times. Unplug the unit and remove the oil

plug. Top up the oil level and replace plug.

3. Finally, follow procedure for oil level check.

Please dispose of any hydraulic oil in accordance with

local regulations. Do not pour into sea, a river, lake or

drains.

BOLT TIGHTNESS

Once a week, or after every 30 times use, check the tight-

ness of all bolts, especially those securing the housing to

the cylinder.

CARBON BRUSHES

Inspect the two carbon brushes at least every two

months. (Normal brush life is around 200 hours.

CARE- Warn carbon brushes will result in power loss,

cause the motor to run hot and irreparably damaging

the armature’s commutator.

1. Disconnect unit.

2. Unscrew both brush caps and pull out the carbon

brushes.

3. Replace the brushes if less than 6MM in length.

OVERHAUL

Return the unit to an authorized agent for overhaul at

least once every two years, sooner if subject to heavy us-

age.

BN Products-USA, LLC.

3450 Sabin Brown Road • Wickenburg, AZ 85390

(800) 992-3833 • (928) 684-2813

Fax: (928) 684-7041• mail@bnproducts.com

WWW.bnrebartools.com

Maximum Bending Diameter 1” #8 Rebar (25mm) Grade 60

Bending Angle Up to 94 degrees (1/2”) - up to

90 degrees ( 1”)

Voltage/ Amperage 115V 50/60Hz / 12 amps

Tool Weight 57.3 lbs (26 kg)

Dimensions L x W x H 25.75” (660mm) x 10.5”

(270mm) x 7.8” (200mm)

Page 6

BN Products-USA, LLC.

3450 Sabin Brown Road • Wickenburg, AZ 85390

(800) 992-3833 • (928) 684-2813 • mail@bnproducts.com

DBR-25WH Portable #8 Rebar Bender

NO Part No. Part Name Qty

18 1C1922 VALVE END SPRING 1

19 7ORP14 O RING P14 1

20 1DBR83 BACK-UP RING 1

21 7SB08015 DISC SCREW M8X15 3

22 7BRP55 BACK-UP RING P55 2

23 7ORP55 O RING P55 1

24 1DBR20B HOSE BAND Ø120 2

25 1DBR66 COVER A 1

26 1DBR67 COVER B 1

27 1DBR68 PIPE COVER (1DBR682) 1

28 1DBR20A HOSE BAND Ø100 2

29 1DBR79 BAND PACKING 2

30 1DBR64 AIR BAG 1

31 7ORG70 O RING G70 2

32 7BRG70E BACK-UP RING G70 2

33 1DBR55 PIPE CYLINDER 1

34 1DBR54 STOPPER 1

35 7CB06030 CAP BOLT M6X30 2

NO Part No. Part Name Qty

1 1DBR205790 HOUSING 1

2 1DBR72 ROLLER 2

3 1BL5402000 ROLLER CLAMP (1DBR73) 2

4 7B812025 HEX. BOLT M12X15 2

5 7SW012 SPRING WASHER

M12(7SW0012)

2

6 1DBR80 HOOK 1

7 1DBR711 PACKING 2

8 1DBR309550 HOLDING WIRE 2

9 7MB3025DU DRY BUSH 1

10 7BRP30 BACK-UP RING P30 1

11 7ORP30 O RING P30 1

12 1DBR309540 HOUSING GUIDE 1

13 7PT1/8 PLUG PT1/8 4

14 3DS2359 ELBOW NIPPLE 1

15 1DBR562 PISTON 1

16 1DBR581 VALVE COVER 1

17 1DBR57 END VALVE 2

Page 7

BN Products-USA, LLC.

3450 Sabin Brown Road • Wickenburg, AZ 85390

(800) 992-3833 • (928) 684-2813 • mail@bnproducts.com

NO Part No. Part Name Qty

36 1DBR511WH CYLINDER 1

37 1DBR63 TUBE 4X2.5 1

38 3P1044 MAGNET FILTER 3

39 1C1971 RAM 3

40 1C1972 RAM RETURN SPRING 3

41 1C1973 DELIVERY VALVE 3

42 1C1331 DELIVERY VALVE SPRING 3

43 1C13352 SPRING GUIDE 3

44 1C13292 PUMP HEAD SEAL 3

45 7698 BALL BEARING 698 1

46 1C1325 BEARING GUIDE 2

47 712NQ2410A NEEDLE BEARING (1C13401) 1

48 7SRH027 SNAP RING H27 1

49 1DBR751 VALVE CASE (1DBR75) 1

50 3DS2360 CONNECTOR 1

51 1DBR62 OIL PIPE 1

52 1DBR77 GUIDE BOLT 1

53 7WF06 SEAL WASHER (3DS2026) 2

54 7CB06006 CAP BOLT M6X6 1

55 7SB3/16 STEEL BALL 3/16 1

56 3DA102K STOPPER SPRING 1

57 7CB06040 CAP BOLT M6X40 4

58 7SW006 SPRING WASHER M6

(7SW0006)

4

59 3DS23322 ROTARY VALVE 1

60 7ORP18 O RING P18 2

61 1DBR531 VALVE LEVER 1

62 7SP420 SPRING PIN Ø4X20 1

63 7SB5/32 STEEL BALL 5/32 1

64 1DBR821 VAVLE SET 1

65 7BSH4 DISK SPRING 24

66 1DBR84 GUIDE BOLT 1

67 7SS12012 SET SCREW M12X12 1

68 1C1951B PUMP CASE PACKING 1

69 3DS1939B PUMP CASE 1

70 7B10015 OIL PLUG M10X15 1

71 7WF10 SEAL WASHER WF10 1

NO Part No. Part Name Qty

72 1DBR420610 SEAL COVER 1

73 7TCV19358 OIL SEAL TCV-19-35-8 1

74 76004VV BALL BEARING 6004VV 1

75 7AR308740 ARMATURE WITH CAM (100v) 1

75 7HTK360788CB ARMATURE WITH CAM (115v) 1

75 7HTK360788EB ARMATURE WITH CAM (230v) 1

76 7HTK310546B DUST SEAL 1

77 760002RU BALL BEARING 60002RU 1

78 7HTK340318B STATOR COIL (100v) 1

78 7HTK340319CB STATOR COIL (115v) 1

78 7HTK340319EB STATOR COIL (230v) 1

79 7P205055 PAN HEAD BOLT M5X55 2

80 7HTK971050B MOTOR HOUSING (1C1961K) 1

81 7HTK971055B SIDE COVER (7971055) 1

82 7P204008 PAN HEAD BOLT M4X8 2

83 7HTK971091B TAIL COVER (1C1961S) 1

84 7P205010 PAN HEAD BOLT M5X10 2

85 7SS05008 SET SCREW M5X8 2

86 7HTK971001B BRUSH HOLDER (1C1961J) 2

87 7HTK999043B CARBON BRUSH SET

(1C1961A)

1

88 7HTK935829B BRUSH CAP (1C1961H) 2

89 7CB06090 CAP BOLT M6X90 4

90 1C2618 MAIN HANDLE 1

91 1C1946 SWITCH COVER 1

92 7HTK971390B SWITCH (100 - 230v) 1

93 7HTK308283B CONDENSER (100 - 230v) 1

94 7CB06018 CAP BOLT M6X18 4

95 7HTK958049B CORD ARMER (1BR5012G) 1

96 7P204015 PAN HEAD BOLT M4X15

(7PB04015)

2

97 7P204008 PAN HEAD BOLT M4X8

(7PB04008)

2

98 7COD-

1253C050J

CORD SET (100v) 1

98 7HTK500399ZB CORD SET (115v) 1

98 7HTK311433B CORD SET (230v) 1

99 1DBR2945 O RING P7 4

100 7PT1/8 PLUG PT1/8 2

101 1DBR419520 ARMATURE BUSH (with No.75) 1

Page 8

BN Products-USA, LLC.

3450 Sabin Brown Road • Wickenburg, AZ 85390

(800) 992-3833 • (928) 684-2813 • mail@bnproducts.com

BD25WH Bending Die Set

#15 Bend Die #20 Bend Die 1DBR80A Bend Hook (Standard)

M16 x D7 Female Threads on one end M16 x D7 Female Threads on one end M16 x D7 Female Threads on both ends

Marked: 1/2” & 15 Marked with: 3/4” & 20 3 inches wide

With this bending die push/bend

forward only

With this bending die push/bend

forward only

With this bending hook push/bend forward

& pull/bend backwards or straighten rebar

4.5” Bend Radius 6” Bend Radius 3.75” Bend Radius

ACI Approved Bend for #6 Rebar (19mm) ACI Approved Bend for #8 Rebar (25 mm) ACI Approved Bend for #5 Rebar (16 mm)

DBR-25WH Dies and Hook Bending Radiuses

Standard with DBR-25WH Bender/Straightener

Special order 1DBR80 bend die available upon

request. It measure 1 3/4” wide

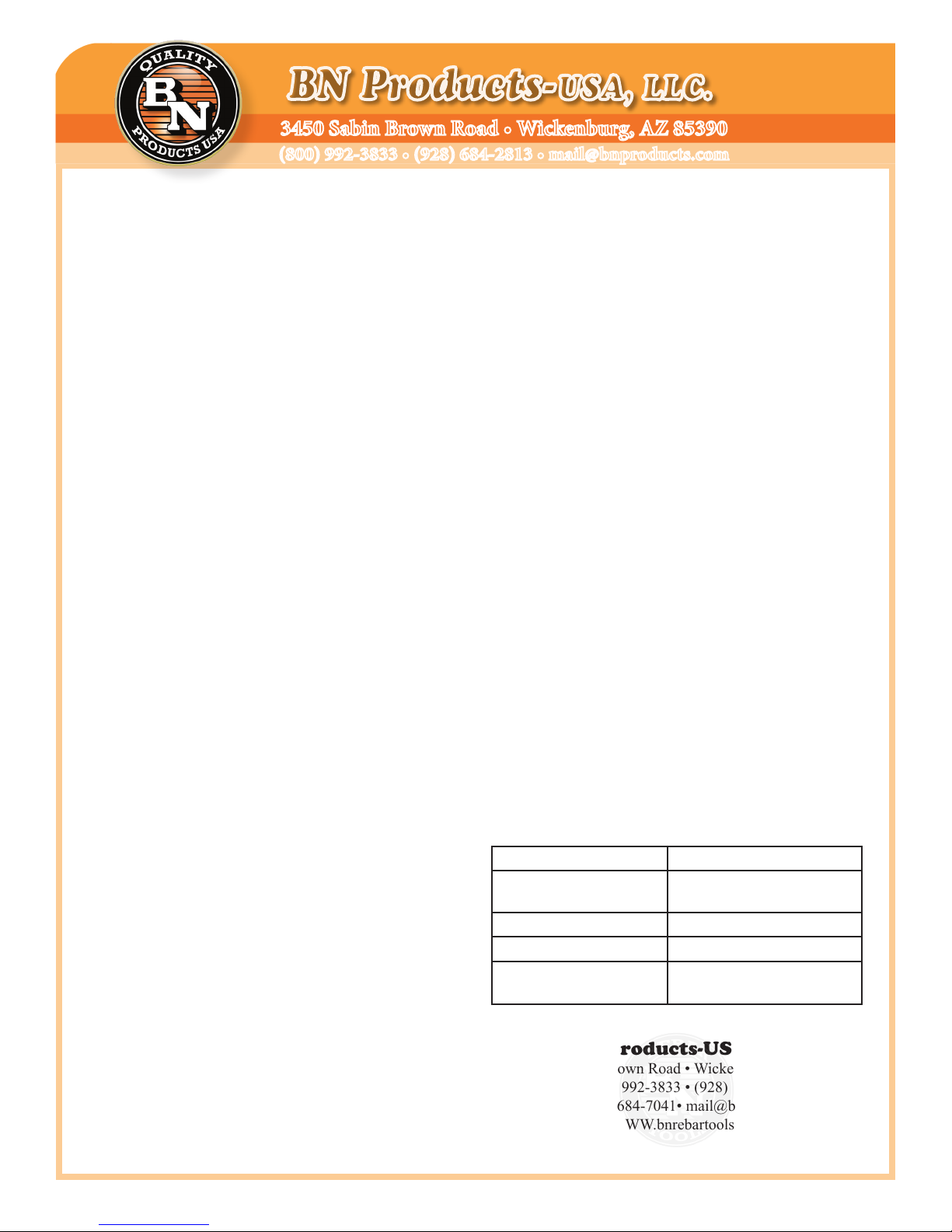

Notes: For In-place bending applications the bend-

ing head pictured to the left needs to be raised at

least 1.5” o the surface of the concrete in order

to make a complete 90 degree bend. The minimum

height above the concrete surface in which a bend

can be made is 6” or 152.5 mm.

Table of contents

Other BN Products Power Tools manuals