BOC Edwards EXT555H User manual

Other BOC Edwards Water Pump manuals

BOC Edwards

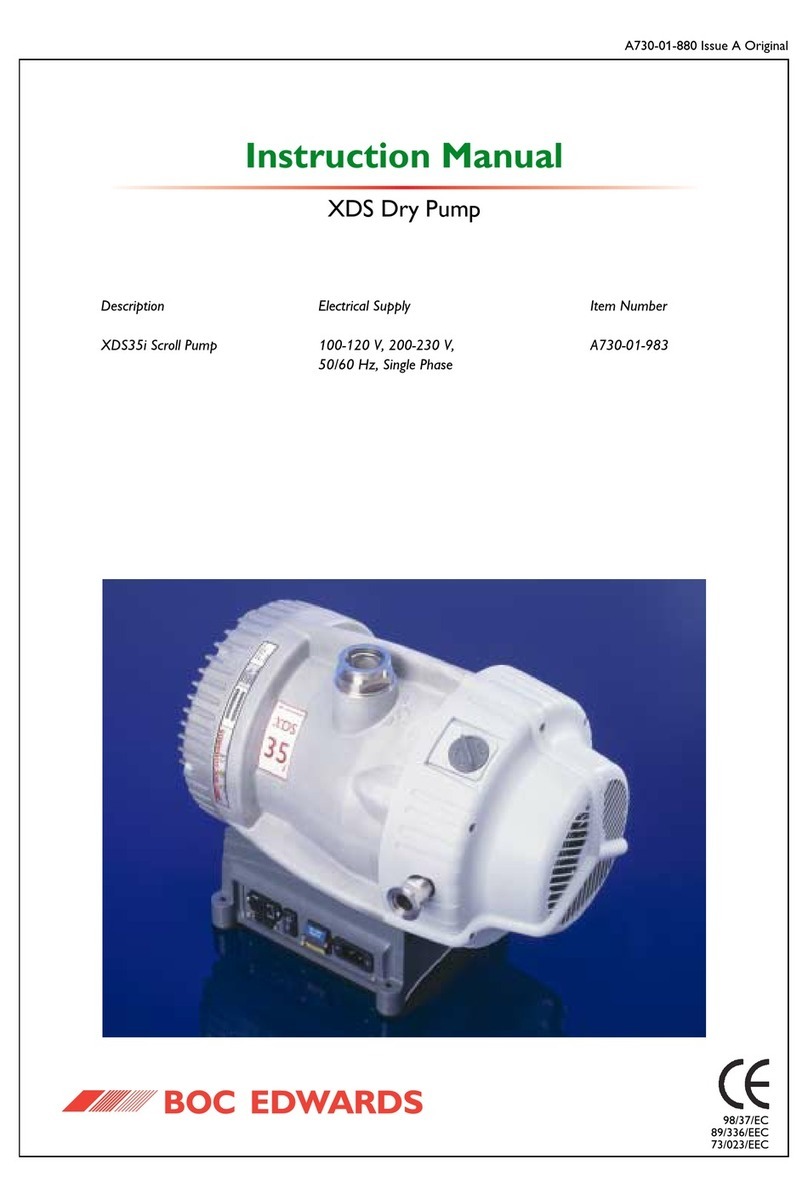

BOC Edwards XDS35i User manual

BOC Edwards

BOC Edwards EO2K User manual

BOC Edwards

BOC Edwards A343-15-904 User manual

BOC Edwards

BOC Edwards iH Series User manual

BOC Edwards

BOC Edwards ESDP12 User manual

BOC Edwards

BOC Edwards Seiko Seiki STP603 Series User manual

BOC Edwards

BOC Edwards Seiko Seiki STP A803 User manual

BOC Edwards

BOC Edwards E1M18 User manual

BOC Edwards

BOC Edwards XDS Series User manual

BOC Edwards

BOC Edwards 18B4B User manual

BOC Edwards

BOC Edwards E2M28 User manual

BOC Edwards

BOC Edwards E1M175S User manual

BOC Edwards

BOC Edwards E1M275S User manual

BOC Edwards

BOC Edwards iL70 User manual

BOC Edwards

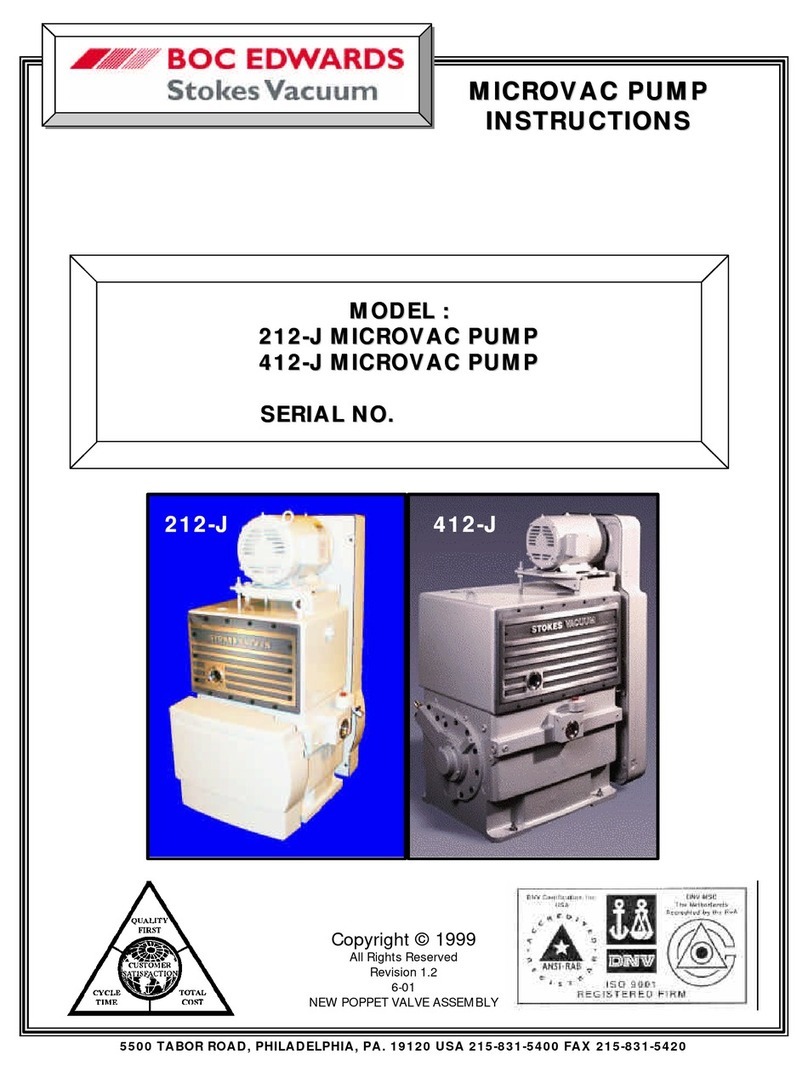

BOC Edwards 412-J User manual

BOC Edwards

BOC Edwards Seiko Seiki STPH803C User manual

BOC Edwards

BOC Edwards EXT250M/ISO100 User manual

BOC Edwards

BOC Edwards STP-A2203 Series User manual

BOC Edwards

BOC Edwards EXT200/200/30 User manual

Popular Water Pump manuals by other brands

DUROMAX

DUROMAX XP WX Series user manual

BRINKMANN PUMPS

BRINKMANN PUMPS SBF550 operating instructions

Franklin Electric

Franklin Electric IPS Installation & operation manual

Xylem

Xylem e-1532 Series instruction manual

Milton Roy

Milton Roy PRIMEROYAL instruction manual

STA-RITE

STA-RITE ST33APP owner's manual