J SERIES M ICROVA CJ SERIES M ICROVA C VACUVACUU M PUM PUM PUM P

TA BLE OF CON TENTSTABLE OF CON TEN TS

1.01.0 D ESCRIPTIONDESCRIPTION ______________________________________________________________________________________________________________________________________________ 11 --11

1.11.1 GGENERALENERAL (P(PRINCIPLE OFRINCIPLE OF OOPERATIONPERATION)) ____________________________________________________________________________________________________________________________ 11--11

1.21.2 GGASAS BBALLASTALLAST ________________________________________________________________________________________________________________________________________________________________ 11--22

1.31.3 WWATERATER SSYSTEMYSTEM ____________________________________________________________________________________________________________________________________________________________ 11--22

1.41.4 EELECTRICALLECTRICAL SSYSTEMYSTEM ______________________________________________________________________________________________________________________________________________________ 11--22

1.51.5 LLUBRICANTSUBRICANTS __________________________________________________________________________________________________________________________________________________________________ 11--22

1.61.6 GGUARDSUARDS ________________________________________________________________________________________________________________________________________________________________________ 11--22

1.71.7 VVACUUMACUUM BBREAK ANDREAK AND GGAGEAGE PPORTSORTS ________________________________________________________________________________________________________________________________ 11--22

2.02.0 INSTALLA TIONIN STALLA TION ____________________________________________________________________________________________________________________________________________ 22 --11

2.12.1 LLOCATING ANDOCATING AND MM OUNTINGOUNTING ____________________________________________________________________________________________________________________________________________ 22--11

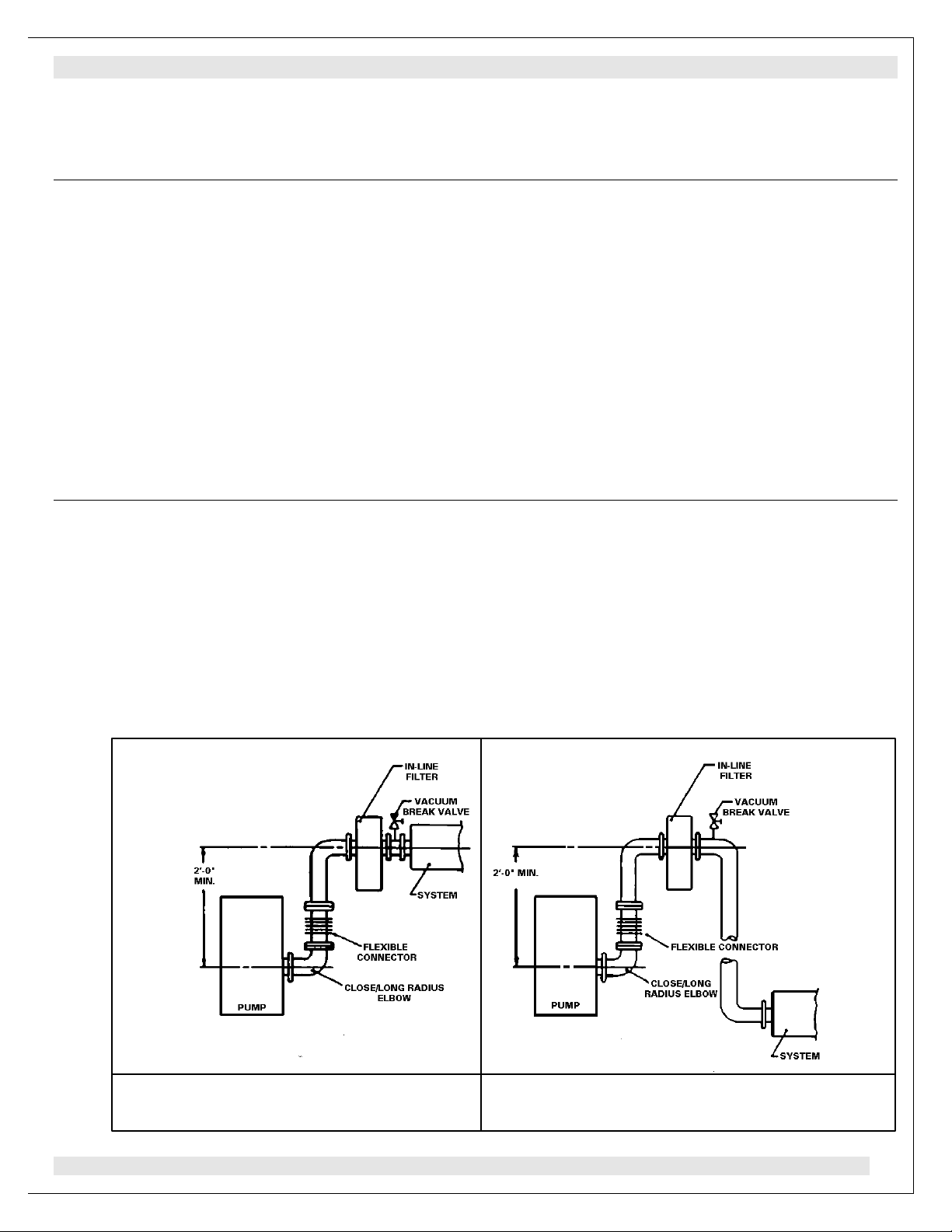

2.22.2 VVACUUMACUUM PPIPINGIPING ____________________________________________________________________________________________________________________________________________________________ 22--11

2.2.1 Types of Piping Joints________________________________________________________________________ 2-2

2.2.2 Location of Gage Port ________________________________________________________________________ 2-2

2.32.3 EEXHAUSTXHAUST PPIPINGIPING ____________________________________________________________________________________________________________________________________________________________ 22--22

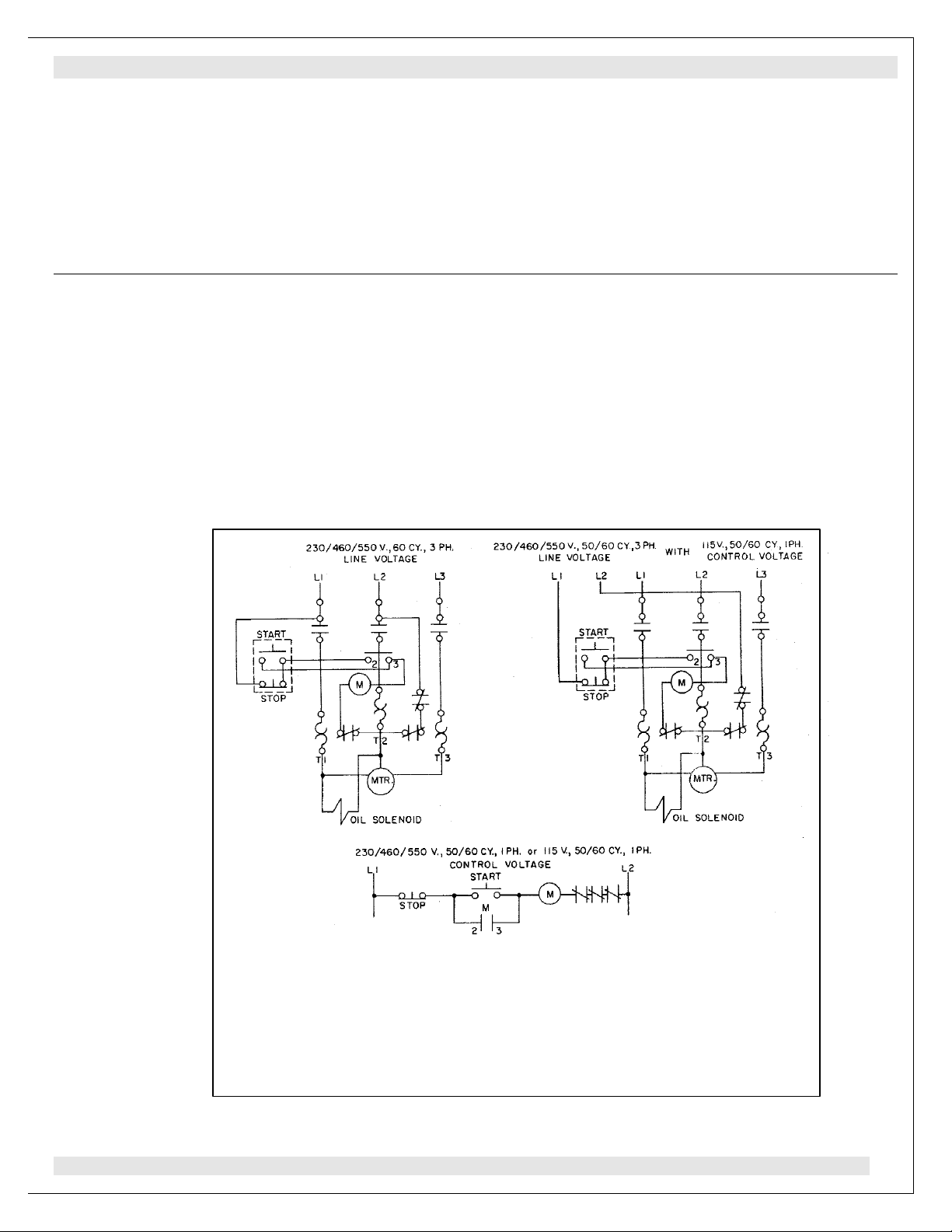

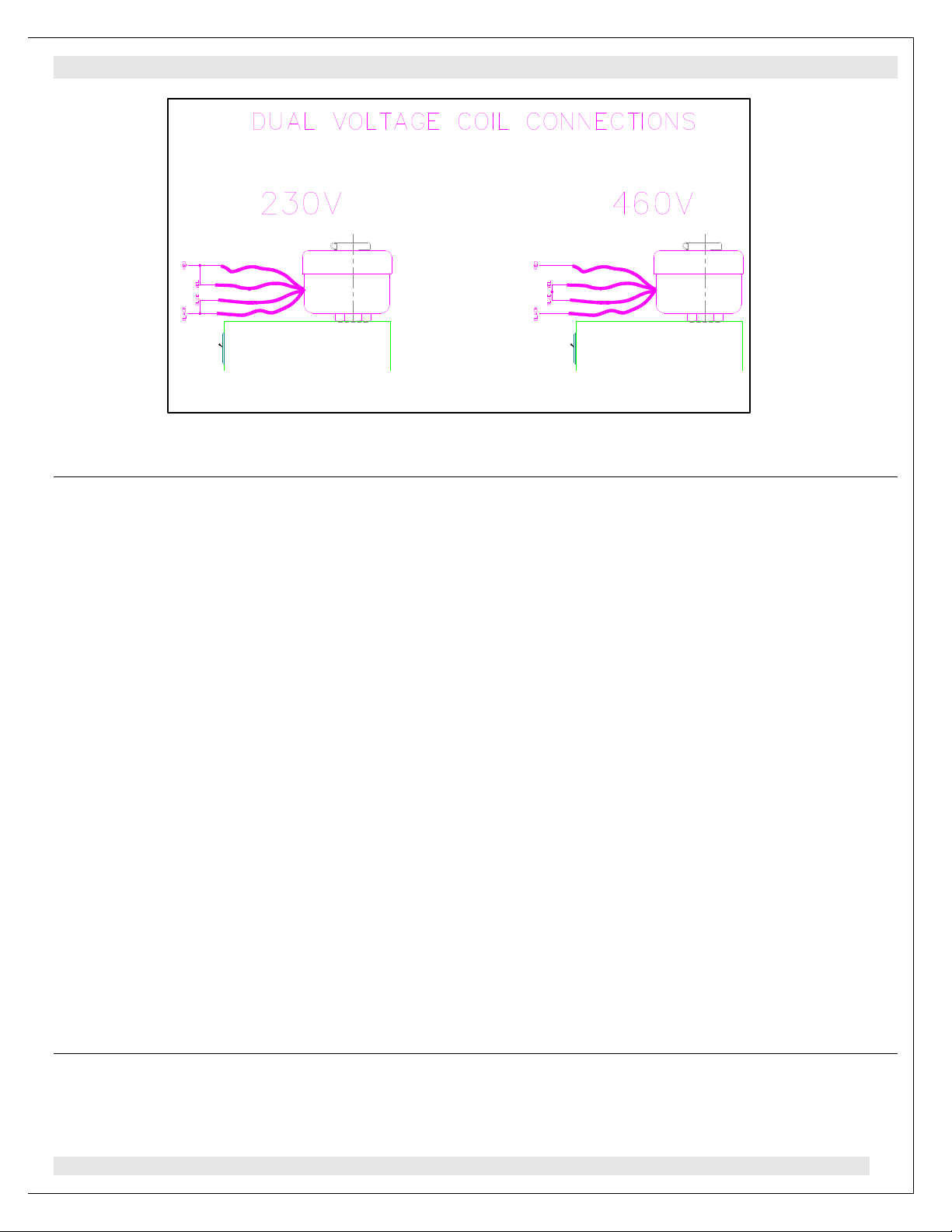

2.42.4 EELECTRICALLECTRICAL CCONNECTIONSONNECTIONS (S(SEEEE FFIGUREIGURE 5 & 5A)5 & 5A) __________________________________________________________________________________________________________ 22--33

2.52.5 CCOOLINGOOLING ______________________________________________________________________________________________________________________________________________________________________ 22--44

2.62.6 LLUBRICATION OFUBRICATION OF PPUM PUM P __________________________________________________________________________________________________________________________________________________ 22--44

3.03.0 OPERATIONOPERATION __________________________________________________________________________________________________________________________________________________ 33 --11

3.13.1 PPRERE--STARTSTART CCHECKHECK__________________________________________________________________________________________________________________________________________________________ 33--11

3.23.2 PPUM PUM P SSTARTTART__________________________________________________________________________________________________________________________________________________________________ 33--11

3.33.3 CHECKING OIL LEVELCHECKING OIL LEVEL ______________________________________________________________________________________________________________________________________________ 33--22

3.43.4 OPERATION OF GAS BOPERATION OF GAS BALLASTALLAST________________________________________________________________________________________________________________________________ 33--22

3.53.5 PUM P STOPPUM P STOP________________________________________________________________________________________________________________________________________________________________ 33--33

3.63.6 OPERATING NOTESOPERATING NOTES __________________________________________________________________________________________________________________________________________________ 33--33

4.04.0 CHECKINGCHECKIN G______________________________________________________________________________________________________________________________________________________ 44 --11

4.14.1 PPOOROOR VVACUUMACUUM ______________________________________________________________________________________________________________________________________________________________ 44--11

4.24.2 LLOCALIZINGOCALIZING LLEAKAGEEAKAGE ____________________________________________________________________________________________________________________________________________________ 44--11

4.34.3 RREPAIRINGEPAIRING SSM ALLM ALL LLEAKSEAKS ______________________________________________________________________________________________________________________________________________ 44--11

4.44.4 PPUM PUM P AACTIVITYCTIVITY RRECORDECORD ______________________________________________________________________________________________________________________________________________ 44--11

5.05.0 TROUBLESHOOTING GU ITROUBLESHOOTING GUIDED E __________________________________________________________________________________________________________________ 55 --11

6.06.0 SPECIFICATIONS A N DSPECIFICATIONS AND PA RTS LIPA RTS LISTST ____________________________________________________________________________________________________ 66 --11

6.16.1 212212--J PJ PERFORM ANCEERFORM ANCE CCURVEURVE ________________________________________________________________________________________________________________________________________ 66--11

6.26.2 MM ICROVACICROVAC MM ODELODEL 212212--J SJ SPECIFICATIONSPECIFICATIONS ____________________________________________________________________________________________________________________ 66--11

6.36.3 412412--J PJ PERFORM ANCEERFORM ANCE CCURVEURVE ________________________________________________________________________________________________________________________________________ 66--33

6.46.4 MM ICROVACICROVAC MM ODELODEL 414122--J SJ SPECIFICATIONSPECIFICATIONS ____________________________________________________________________________________________________________________ 66--33

7.07.0 M A INTEN A N CEM AIN TENANCE ________________________________________________________________________________________________________________________________________ 77 --11